Bionova IC10/20FR User manual

Rev.26 | November 2018

IC10/20FR

Innovation in technologies for Infection Control

IC10/20FR Page 3

Bionova® IC10/20FR Auto-reader has been designed for

the incubation of the following Self-Contained Biologi-

cal Indicators (IBs):

• Rapid Readout Self-Contained Biological Indicators:

BT110 for Ethylene Oxide sterilization control, BT220

and BT221 for Steam sterilization control, BT102 for

Formaldehyde sterilization control and BT95 for Plasma

or Vaporized Hydrogen Peroxide sterilization control.

• Super Rapid Readout Self-Contained Biological Indi-

cators: BT222 and BT223 for Steam sterilization control

and BT96 for the control of Plasma or Vaporized Hydro-

gen Peroxide sterilization control.

• Ultra Rapid Readout Self-Contained Biological Indica-

tors: BT224 for Steam sterilization control.

Microorganisms contained within the Biological Indi-

cators vary depending on the sterilization process for

which they have been designed, therefore, incubation

temperatures dier depending on the indicator. Indica-

tors for Ethylene Oxide (EO) sterilization control, should

be incubated at 37ºC, while those involved in the mo-

nitoring of the rest of the sterilization processes should

be incubated at 60ºC.

Simultaneous incubation of Bls for EO proces-

ses control within Bls monitoring the other pro-

cesses, is not possible.

Bionova® IC10/20FR Auto-reader allows easy and rapid

Description of use

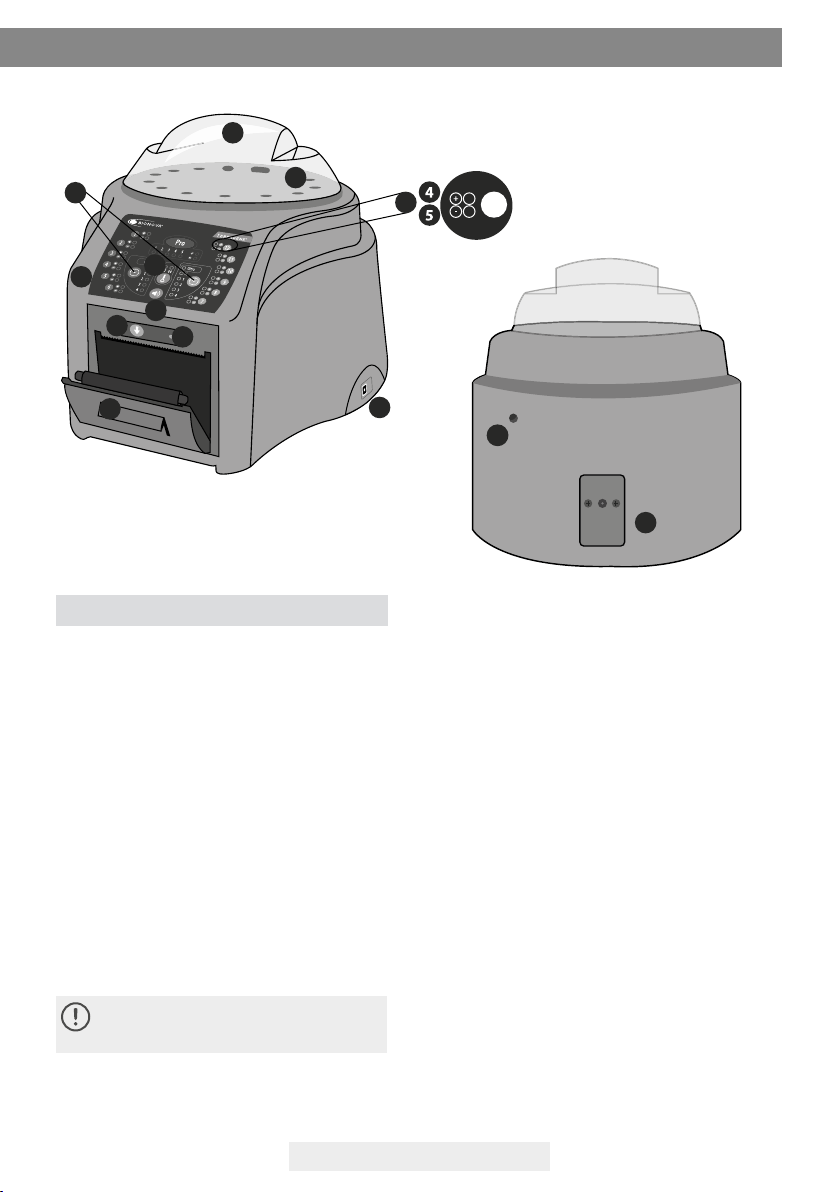

Constituent parts

15

16

detection of positive and negative Biological Indica-

tors. Six incubation programs are available: 4 hours at

37ºC, 3 hours at 60 ºC, 2 hours at 60 ºC, 1 hour at 60 ºC,

30 minutes at 60 ºC and Instant/Ultra (20 min.) at 60 °C.

A positive result can also be evidenced by culture me-

dium color change to yellow, read the instructions for

use of each indicator for more information. The choice

to perform or not the extended incubation to conrm

by color change depends on the internal protocols of

each laboratory or hospital.The auto-reader allows se-

lection of incubation time programs for two zones in an

independent way. Zone 1 includes positions 1 to 6, and

zone 2 comprises positions 7 to 12.

The Bionova® IC10/20FR Auto-reader contains a special

cavity to run quantitative readings of the Chemdye®

PRO1 System, destined to surface cleaning and conta-

mination control.

Bionova® IC10/20FR auto-reader not only allows the

detection of results, but also provides a printed ticket

to record them. In addition, the auto-reader can be

connected to computers by USB. This allows linking the

results with the Bionova® Traceability Software for Auto-

matic Reading and Traceability of Rapid, Super Rapid

and Ultra Rapid Biological Indicators and Hygiene Mo-

nitoring System. To download the latest version of the

software, go to: http://www.terragene.com.ar/produc-

tos/infection-control/incubators/software-downloads/

?lang=en, from there you can also download the user

manual.

1

1

2

3

10

11

9

12

14

13

8

6

712

IC10/20FR Page 4

Safety information

To avoid risks and damaging the equipment

-Do not place the auto-reader in an environ-

ment exposed to direct sunlight or high inten-

sity light lamps.

-Do not place the auto-reader near devices that

emit electromagnetic elds.

-Do not use the equipment on vibrating surfa-

ces.

-Do not pour any liquid inside.

-Do not immerse into any liquid.

-Use indoors only.

-Disconnect the power cord before cleaning.

-Do not use abrasive, corrosive cleaners or di-

sinfectans.

-In case of technical fault, contact the manufac-

turer for support. Please, do not try to open or

repair the auto-reader on your own, since this

will imply the loss of product warranty and

could lead to a major and irreversible damage.

-Make sure that the auto-reader is connected

to a properly rate power cord.

To reduce the risk of using incompletely ste-

rilized loads:

-Make sure to use each BI with its incubation

and reading program:

BT110 (green top) with 4 hs. (37 ºC) program.

BT220 (brown top) with 3hs. (60 ºC) program.

BT221 (blue top) with 1 h. (60 ºC) program.

BT222 (violet top) with 1 h. (60 ºC) program.

BT223 (light blue top) with 30 min. (60 ºC) program.

BT224 (aquamarine top) with 20 min at 60 ºC

Instant/Ultra program.

BT102 (red top) with 2 hs. (60 °C) program.

BT95 (white top) with 2 hs. (60 °C) program.

BT96 (grey top) with 30 min at 60ºC program.

-Check that culture medium completely wets

the spore carrier.

-Do not remove the BI until the equipment re-

ports the nal readout result, check the impre-

sion of the ticket.

To avoid the risk of injury, because of glass

fragments generated after the glass ampou-

le inside the BI tube is crushed:

-Cool the BI during the indicated time before

crushing the ampoule.

-Do not handle the BI excessively since this mi-

ght cause the glass ampoule to burst.

-Wear safety glasses and gloves when remo-

ving the BI from the sterilizer.

-Wear safety protective glasses and gloves to

crush the ampoule and to press the cap of BI.

-Do not use your nger for crushing BI.

To avoid a potencially hazardous situation:

avoid contact with the hot surface of the metal

auto-reader block.

Symbols

References

Operating relative humidity.

Operating environmental temperature.

Caution, warning.

Caution: Risk of electric shock.

Caution: Hot surface.

Important, attention.

Manufacturer.

Serial number.

Direct current.

Product denomination.

80 %

30 %

10 ºC

30 ºC

REF

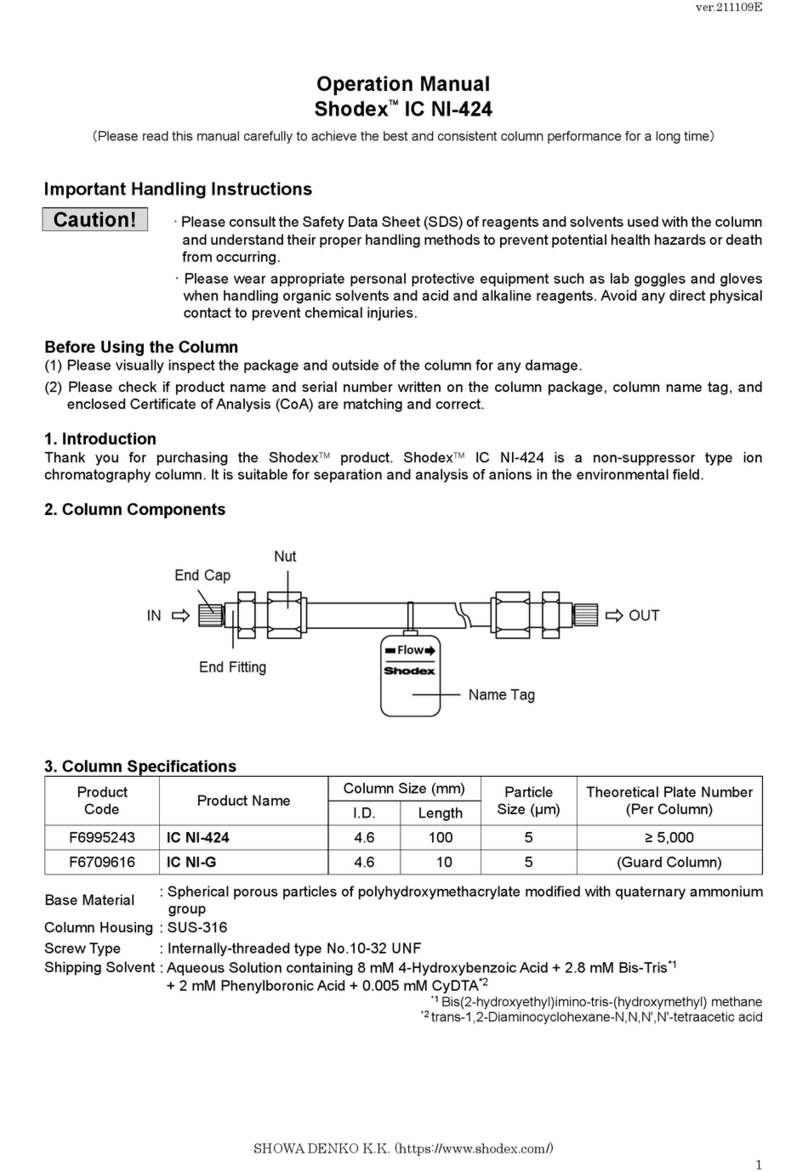

Protective cover.

Red light/Positive indicator/Position Light.

Green Light/Negative indicator/Position Light.

Reading position number.

Program selector.

Temperature Selector.

Alarm Cancellation Button.

Thermal printer.

Printer’s light.

Paper’s traction button.

Cavity for paper.

USB port.

Input for power source plug (12V DC).

Control Panel.

Incubation area for 12 BIs. Protein pen detec-

tion. BIs Ampoule crusher.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16 Hole for external temperature control.

IC10/20FR Page 5

Power supply specications

Environment operating conditions

Terragene® recommends using a UPS instead of stabi-

lizers, since the former has two functions: it stabilizes

and provides a continual power source during energy

cuto.

Serial/Batch Number

For easy identication, each IC10/20FR Auto-reader

has a unique serial number and a batch number prin-

ted on a label found at the bottom of the auto-rea-

der and on its packaging. Please, register your serial

number and batch number in this manual for future

reference:

Safety information

Record Table

Use the following table to record rmware updates.

NOTE: manufactury rmware is printed on a label found

on the bottom of the auto-reader and on its packaging.

To avoid BIs from absorbing uorescent re-

sidues: avoid BIs direct contact with chemical

indicators or tapes.

Do not use this product in a manner not speci-

ed by Terragene® S.A., otherwise the protec-

tion provided by the product might be aec-

ted.

Do not replace the power supply cord for other

not provided within the product.

Only personnel authorized by Terragene® S.A

can access the inside of the auto-reader and

its components. Parts or components inside

the machine should not be manipulated by the

user.

Input parameters

Voltage range

Frequency

Current

Output parameters

Voltage

Current

Operating

Condittion

(100-240)

50/60

0,2

Values

12

4

Units

Volts

Hertz

Ampers

Units

DC Volts

Ampers

Environmental conds.

Altitude

Operation temperature

Relative humidity

Installation/overvoltage

Degree of contamination

Storage temperature

Voltage

Functional conds.

3500 (máx.)

10-30

30-80

category II

2

0 - 50

12

Units.

Meters

ºC

%

°C

DC volts

Serial Number:

Batch Number:

Date Version Operator

Please, register your manufactory rmware in this ma-

nual for future reference:

Manufactury Firmware:

IC10/20FR Page 6

Instructions for use

Start-up to be incubated in each zone.

To change the time program, press the button o f

the correspondent zone as many times as needed to

choose the right setting.

5- Wait for temperature of the machine to be stable.

Once is stable, the indicator of the desired temperatu-

re will remain steady.

Do not put any biological indicator in the rea-

ding positions until the auto-reader does not

conrm temperature stability.

The auto-reader will keep the selected incubation pro-

gram during the reading process. The system does not

allow to modify the incubation program once the rea-

ding process has begun, unless the reading is nished.

6-Start readings once the blue temperature selec-

tion’s light remains stable, this indicates that incu-

bation temperature was reached. Once the selected

temperature has been reached and remains stable,

after turning on the equipment, a one-time automa-

tic check of the Biological Indicators and Protein Pen

incubation positions will be carried out. Indicating

lights of each well will turn on bringing the result, a

green light will show a satisfactory result while

a red light will indicate error.

When the equipment detects an error in any position,

a ticket indicating the day, time and position involved

will be printed. To guarantee the reliability of the re-

sults, these positions will be deactivated, thus preven-

ting their use. To evidence this, the red light of

that position will remain blinking indenitely, in order

to indicate that the position has been disabled.

For a correct automatic check, the protective

cover of the auto-reader should be in its place.

Read BIs instructions for use. Before placing

the vials in the auto-reader, press the top to

seal the tube. Crush the ampoule (using the

ampoule crusher within the box of BIs or the

one located within the incubation area of the

auto-reader) and make sure that the liquid has

completely wet the spore carrier placed at the

bottom of the biological indicator plastic tube.

Do not remove or change placement of BI once

the reading process has begun. If this occurs,

results may be invalidated.

Use a non-sterilized biological indicator as a

positive control every time a processed indica-

tor is incubated. For more information refer to

the Positive Control section of this user guide.

7-Place the rapid BI in a reading position and wait for

the result. Reading will start automatically. Immediate-

ly after placing the BI in a position, an alarm will sound

indicating that reading has successfully began and the

position LED will blink until the result is informed.

NOTE: If the auto-reader does not run automatically, it

might indicate that the auto-reader temperature is not

steady yet (check the temperature indicating light to

1-Place the auto-reader on a rm surface, free from

vibrations, away from sunlight, currents of hot or cold

air, chemicals and corrosive or ammable substances.

Do not place the equipment in a way that disconnec-

tion of the plug from the power supply could be di-

cult. Leave a gap of at least 10 cm from the wall. Do

not move the auto-reader periodically or during its

use. Connect the auto-reader to a secure and stable

electrical power source.

Do not wet or heat the auto-reader. If liquid is

spilled on the auto-reader, disconnect it and

dry it immediately. Before turning on, verify

that all reading positions are empty.

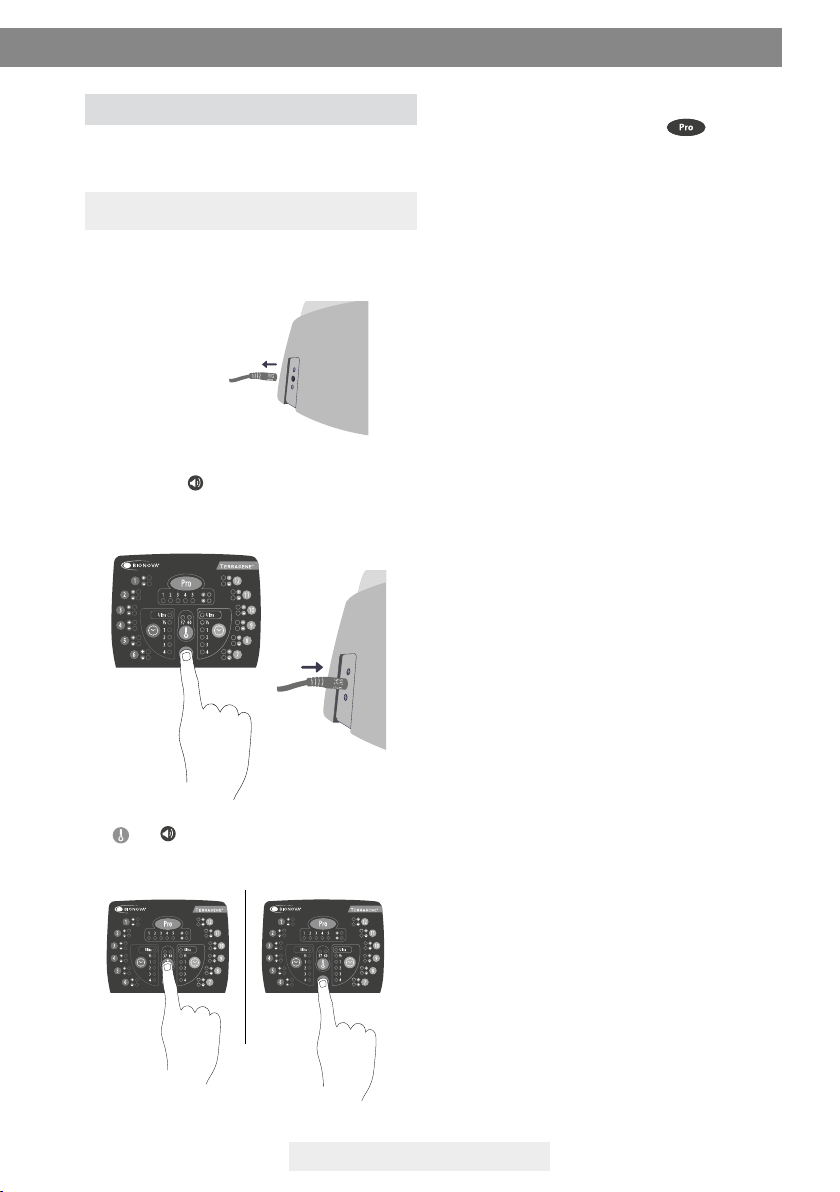

2-Turn on the machine by connecting the end of the

AC power supply to the mains and then connect the

other end of the source (plug) on the rear of the IC10/

20FR unit. The printer’s paper indicator light will turn

on, if this light becomes intermittent, this means that

the thermal paper must be loaded, or that the printer

cover is not tightly closed. Otherwise, the light will

remain stationary.

The machine will start running the last time and tem-

perature set-up.

If the auto-reader has an out-of-date Firmware

version, the settings might not be saved.

3-Synchronize IC10/20FR with local time using Biono-

va® software available at http://www.terragene.com.ar/

productos/infection-control/incubators/software-down-

loads/ ?lang=en. For this, connect a PC to the USB plug

of the auto-reader and start the program. The Bionova®

IC10/20FR will be synchronized with the time and time

zone in the PC. Synchronization can be done as long as

there is not an ongoing reading. See other congura-

tion methods in the Time setting mode section.

All equipment is manufactured with the fo-

llowing settings:

- Time zone: UTC +0:00

- Printing language: English

For changing time zone, refer to Time zone change

mode section. For changing printing language, refer

to Printing language section.

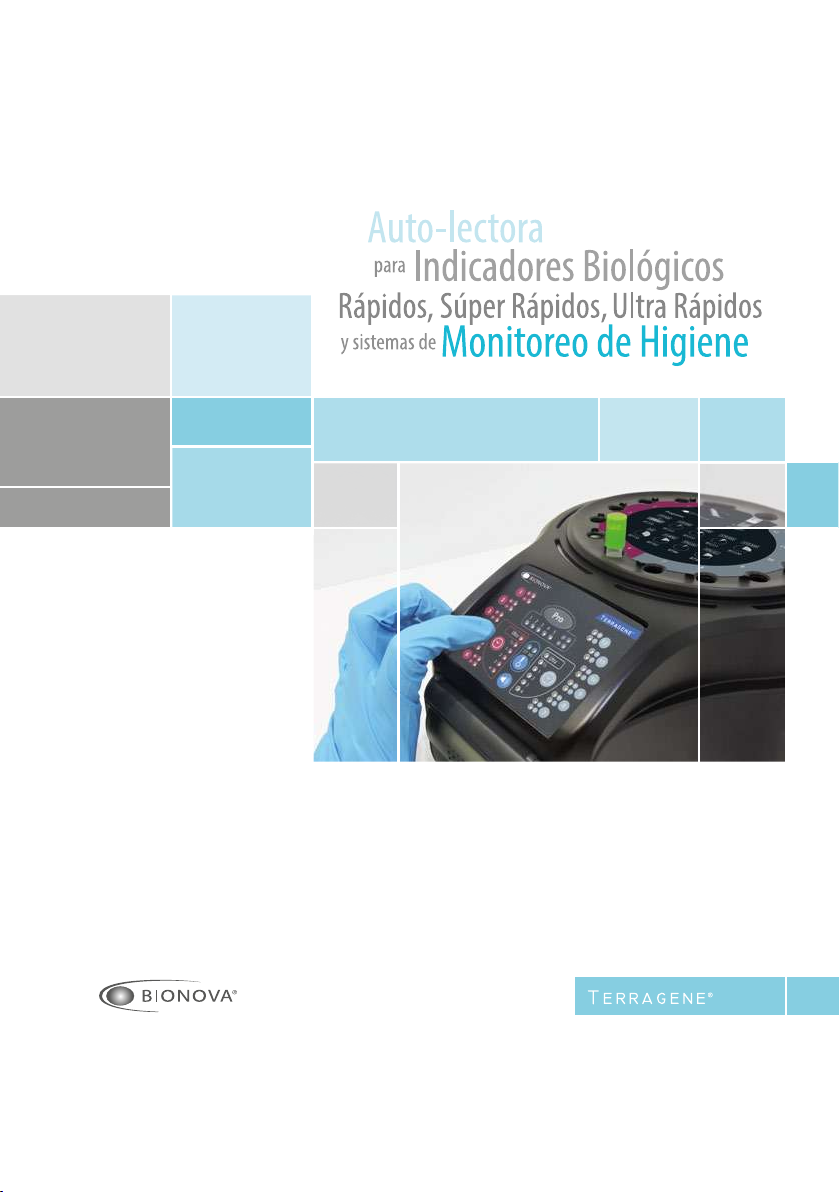

4- Check that the incubation temperature is correct.

To change it, press the button for 3 seconds.

Lights corresponding to 37 °C and 60 °C will start blin-

king, indicating that a temperature program must be

selected. For temperature selection, press the button

to select 37 ºC or 60 ºC. After 4 seconds the tempe-

rature modication will be accepted.

For 37 ºC, the IC10/20FR auto-reader will automati-

cally select the 4 hrs. nal reading program in both

halves of the incubation area (1-6 and 7-12).

For 60 ºC, Instant/Ultra (20 min.), 30 min., 1, 2 or 3 hrs.

program can be selected. It’s possible to select die-

rent programs for each half or the same for both, de-

pending on the indicator´s nal reading characteristics.

Check that the time setting is appropriate for the BIs

IC10/20FR Page 7

Rapid Readout

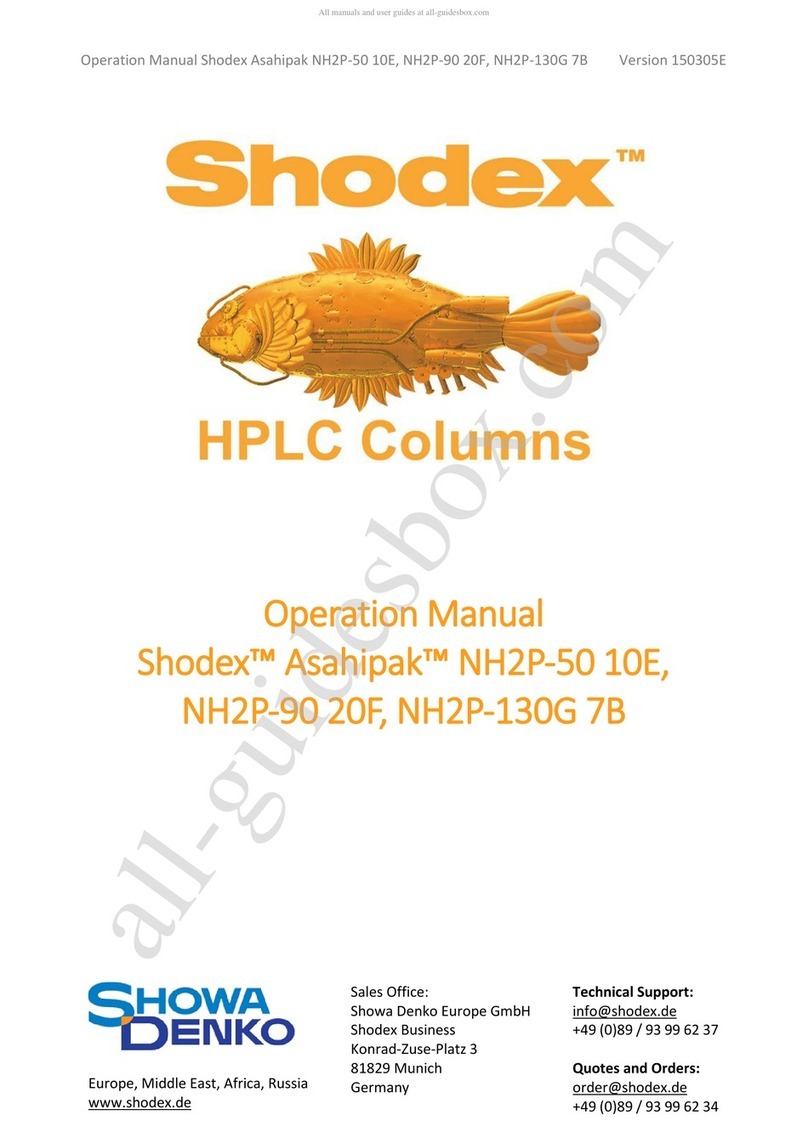

The indicator used as positive control should show

a positive result (red light ). The processed BI

results are not valid until the biological indicator used

as positive control shows a positive result . A

processed BI with a positive result, indicates a failure

in the sterilization process. A negative result, (green

light ) after 20 min. (60 °C), 30 min. (60 ºC), 1 h.

(60 ºC), 2 hs. (60 °C), 3 hs. (60ºC) 4 hs. (37 ºC) according

to the used program, indicates that the sterilization

process was eective.

Take action on any positive result inmediately. A posi-

tive result indicates a sterilization process failure may

have ocurred. Determine the cause of the positive

BI following current facility policies and procedures.

Always retest the sterilizer and do not use the sterili-

zer for processing loads until 3 consecutive BI results

are negative.

Visual Readout

The Rapid readout system allows the conrmation of

results by color change after 48 hours or 7 days incu-

bation analysis (if 7-day readout is made, an humidi-

ed auto-reader will be required to avoid media dry

out). If the sterilization process was not successful, the

growth media contained in the indicator will turn to

yellow. If the sterilization process was successful, the

media will remain unchanged.

The color of the growth media in the BI used as

positive control must turn to yellow during the

process of incubation for the results to be valid.

Record the positive ones and discard them im-

mediately as shown in the biological indicators

instructions for use.

Instructions for use

remain steady) or that the incubation position is disa-

bled due to an error in the initial autotest.

8-If the incubator detects a positive result, the red light

and the audible alarm will turn on. This will indicate

that the sterilization process to which the BI was sub-

ject, has failed. 30 seconds after removing the IB from

the incubation position, the alarm and the red light will

turn o automatically and the position will be available

to start a new reading.

The negative BIs will be informed with a green light in

the corresponding position. This will indicate that the

sterilization process to which it was subject has been

successful. The green light will remain on for up to 30

seconds after the BI is withdrawn from the reading po-

sition.

The incubator will inform results within 20 min (60 °C),

30 min. (60 ºC),1 h. (60 ºC), 2 hs. (60 °C), 3 hs. (60 ºC) or

4 hs. (37 ºC), according to the program selected. These

periods of incubation are the time-limits used by the

equipment to inform the uorescence nal readout.

9-Every time a positive result is detected, it will be

informed through the printing of the corresponding

ticket and with an audible alarm. The alarm can be can-

celled by pressing the button .

10-To register the tickets, press paper’s traction button,

take the paper and press up for the paper to be cut

with the serrated edge of the printer.

NOTE: If the paper runs out, printer’s blue light will

start blinking (see Replacement of the paper roll in the

printer). The incubator will save the last 12 results, for

re-printing, follow the Reprinting of the last results ins-

tructions.

POSITIVE CANCELEDNEGATIVE

Positive control

The positive control should belong to the same

batch of the processed BI.

Use a non-sterilized biological indicator as a

positive control every time a processed indica-

tor is incubated.

Incubate the processed biological indicator

and the indicator used as positive control as

long as specied in the instructions.

Press the cap to seal the tube and crush the ampoule,

make sure the media completely wets the carrier. Wri-

te a C(for control) and the date on the label. The posi-

tive control can be placed in any well of the Bionova®

IC10/20FR Auto-reader.

It is a good practice to use a positive control, this

helps ensuring:

- Correct temperature is reached

-Viability of spores has not been altered due to im-

proper storage temperature, humidity, or proximity

to chemicals.

-Capability of the media to promote rapid growth.

-Proper functioning of Bionova® IC10/20FR Auto-reader.

Interpretation of results

Disposal

Dispose Bls after use, according to your healthcare

and safety regulations (see BIs instructions for use).

Chemdye® PRO1MICRO reading system

Chemdye® PRO1MICRO reading system consists of

an incubation position that allows the quantitative

analysis of the products destinated to evaluate clea-

ning and contamination control.

Hygiene monitoring systems

IC10/20FR Page 8

Instructions for use

Approximate amounts of

BSA expressed in µg

1 µg 2 µg

3 µg

4 µg

5 µg

12345

IC10/20FR can run a quantitative analysis of PRO1MI-

CRO Hygiene monitoring system, adjusted by a BSA

(Bovine Seric Albumin) calibration curve. This analysis

ensures the traceability of the control of surface cle-

aning.

The method has a detection limit of 1 µg and a sensi-

tivity of 0.3 μg.The result is indicated with a resolution

of 0.1μg, and its accuracy is ± 0.5μg (IC95%), in the

range of 0 to 5μg, and ±0.7μg (IC95%), in the range of

5 to 10 μg with a range of 10 μg.

Readings will be able to initiate once the incuba-

tion temperature has been selected and is stable.

The lights corresponding to the selected tempe-

rature (37 ºC or 60 ºC) will blink until the tempe-

rature is reached, and then stay stable. PRO1MI-

CRO readings must be performed at 60 ºC.

Reading Process:

1-Press and hold the button for 1 second to en-

ter the reading program. A beep will sound. Then wait

three seconds to conrm the selection. The auto-rea-

der will emit two beeps indicating that a program has

been selected.

2-Use the PRO1MICRO pen to take the sample from

the surface to be analyzed. For this, follow directions

described in Figure 1 (Also explained on PRO1MI-

CRO’s directions for use).

3-Once the solutions contained within the device

have been correctly mixed, proceed with incubation

(remember that the reading cone must not contain

the swab). For this, insert the pen on the incubation/

reading position (Figure 2). Make sure to place PRO-

1MICRO as it is indicated on the auto-reader label.

When it is inserted in the correct position, it cannot

be rotated (Figure 2).

4-Press and hold the button for 2 seconds

to iniciate the incubation and reading process (15

minutes 60 °C). The lights and will start

blinking.

Do not move or remove the pen from its position

during the reading process, this can cause erro-

neous readings or even cancellation of the same.

If the auto-reader detects that the protein pen

has not been placed properly in the reading

position, a ticket will be printed indicating:

"Pen not detected. Check result visually".

It is not possible to reuse an already incubated

protein pen.

5-Once the incubation process is complete, an audible

alarm indicates the end of the program.The sample is

read and the protein value is calculated based on a

BSA (Bovine Seric Albumin) calibration/standard cur-

ve.Then, the auto-reader will print a ticket conrming

the calculated protein concentration. If the value is

below the selected threshold, a green light will

appear, indicating a negative result, if it is by above

the selected threshold, a red light will appear,

indicating a positive result. In both cases, one of the

lights of the PRO panel will indicate the approximated

rank of concentration calculated between 1 to 5 µg; if

the value exceeds the 5 µg all the lights on the panel

they will light up. The threshold to determine a po-

sitive or negative result can be congured using the

Bionova® traceability software.The conguration pro-

cess is outlined in the Bionova® traceability software

manual. The factory-set threshold is 1µg.

NOTE: 30 seconds before the end of the program, the

auto-reader will emit an alarm that will last until the

reading is complete, notifying the operator that the

incubation time will be fullled. The color of the so-

lution can be used for a qualitative reading only if the

pen is removed once the program nalizes. If the pen

is not removed at that time, the color of the solution

will continue to evolve.

Read the directions for use of each product and

be aware of the sensibility limits.

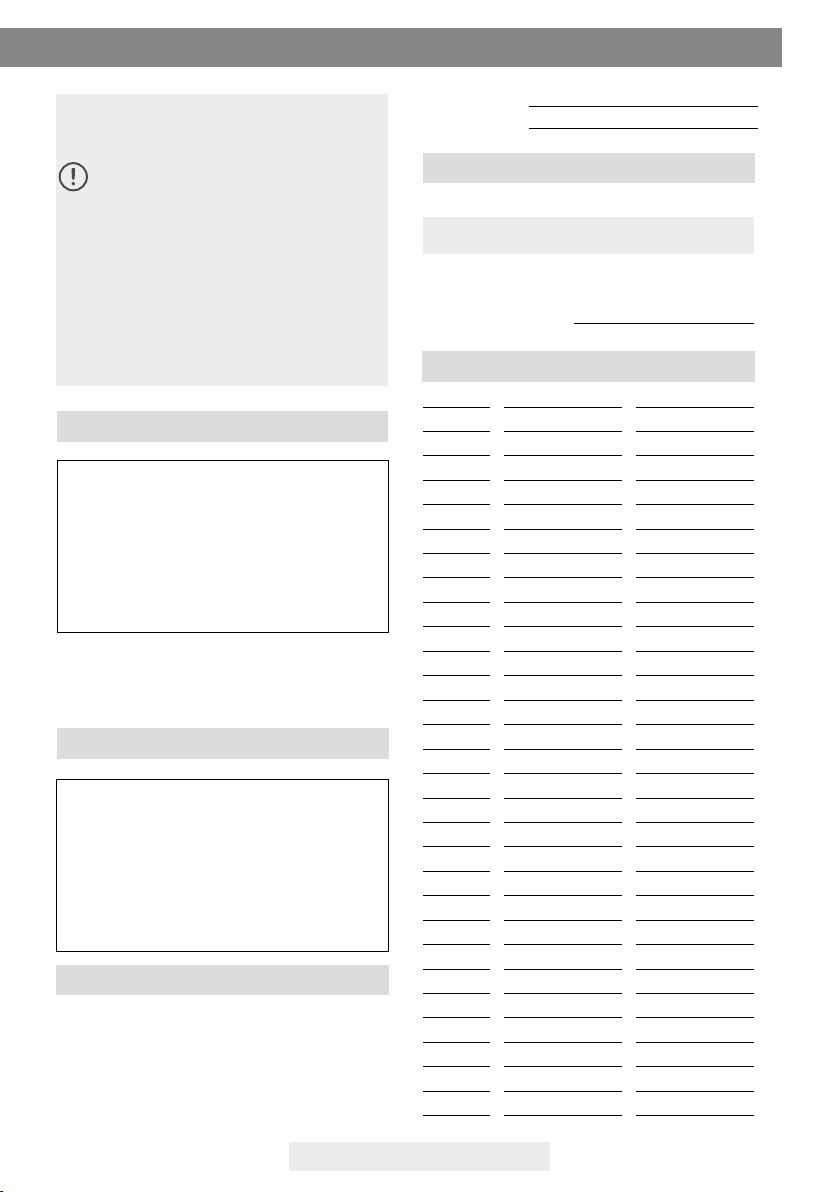

Figure 1

Remove the swab

from the device.

Carefully apply 2

drops of moisturizer

on the swab.

Swab thoroughly

the desired surface

Cuantitative Results: For IC10/20FR-2.10 (March

2017) rmware version or higher (others versions

could report dierent values).

IC10/20FR Page 9

Instructions for use

Place swab back

into the device.

Place swab

downwards rmly

to activate.

Slide swab

downwards.

Shake for

15 seconds.

Slide swab

upwards.

Slide swab

upwards.

Shake vigorously

and collect solution

in the readout cone.

Shake vigorously

and collect solution

in the readout cone.

Readout cone

without swab.

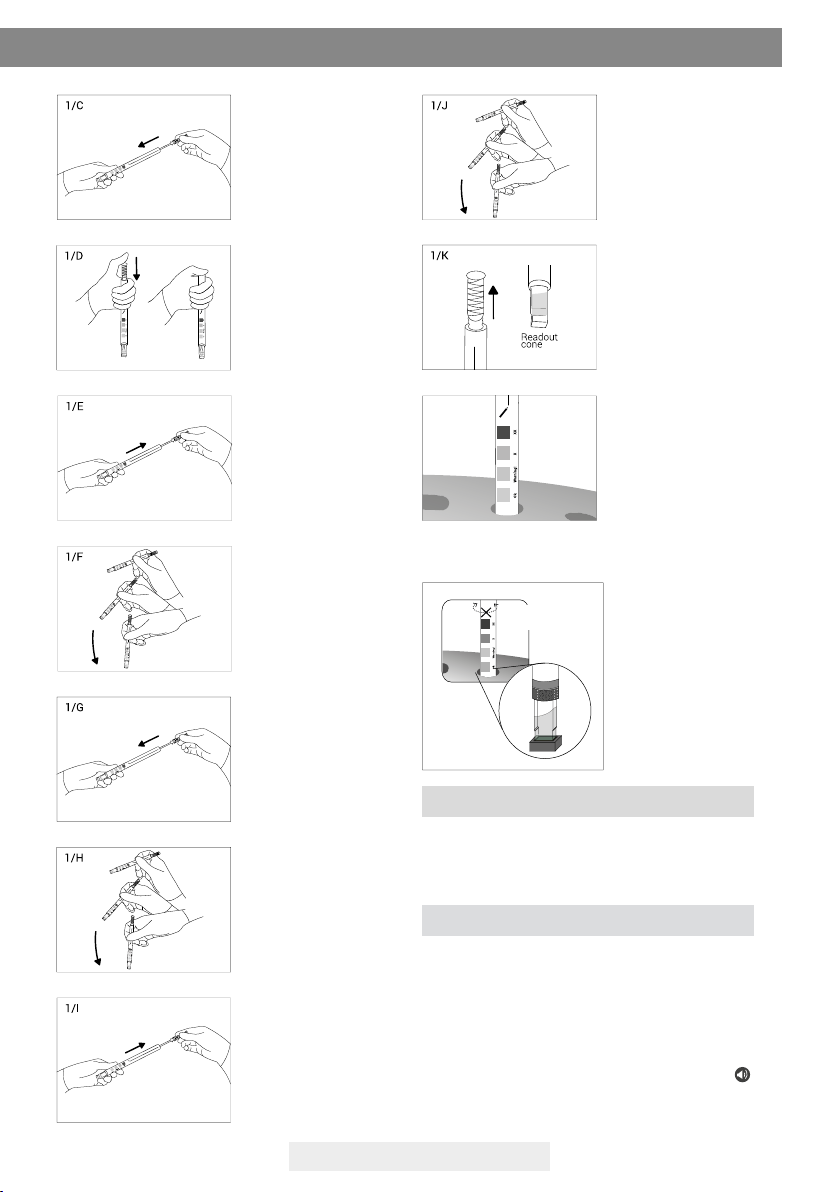

Figure 2

Insert the pen on the

incubation/reading

position.

Impossible

to rotate

Audible alarm

The auto-reader is equipped with several alarm func-

tions that indicate dierent states after the incubation.

In the case of the biological indicators, an alarm will

go o whenever the Bionova® IC10/20FR Auto-rea-

der emits a positive result. This will allow the user to

immediately detect a positive result without visually

verifying the result on the equipment.

The alarm can be cancelled by pressing the button .

The hygiene monitoring system, is equipped with

an alarm that the auto-reader will set o 30 seconds

before the program cycle ends and will last until

Incubate and read.

1/K

1/L

After reading, discard the hygiene indicators according to

the sanitary regulations of your country. The hygiene indi-

cators used cannot be reused (read the Instructions for use

of Chemdye® PRO1 MICRO Hygiene Monitoring System).

Disposal

IC10/20FR Page 10

Instructions for use

Canceling a reading

When a BI is removed from it’s position during incu-

bation process, an audible alarm will sound to indica-

te the tube should be returned to its corresponding

position.

If the indicator is not returned to the reading position

within 10 seconds from its removal, the reading will

be canceled and the auto-reader will print out a ticket

conrming the cancellation.

In the hygiene monitoring system, the user can can-

cel the reading by pressing the button of the

chosen position and the button for three seconds.

The device will cancel the reading and the auto-rea-

der will print out a ticket conrming the cancellation.

Replacement of the paper roll

The printer uses thermal paper rolls.

Thermal paper specications

Reprinting of results

The auto-reader allows reprinting of the last 12 results

by uorescence readout and the last result of hygiene

monitoring reading. For printing the results, press the

button for 5 seconds.

1. To replace the paper

roll, pull the handle of

the printer’s door.

2. Open the printer’s

cover and remove the

spent roll.

3. Place the new paper

roll with the outer side

up.

4. Close the printer co-

ver by pressing on the

sides of the lid.

Remaining incubation time

The Bionova® IC10/20FR Auto-Reader also allows veri-

fying the remaining incubation time in every reading

position. Whenever a reading process is in course,

press and hold the button for ve seconds, a

ticket will then be printed containing the following in-

formation: reading position, incubation program and

remaining incubation time.

Recommended paper: JUJO AF50KSE3 or similar (or-

der code ICTP).

Paper width : 58 mm

Maximum paper thickness: 60 g/m2

Maximum diameter size: 50 mm

NOTE: This feature is available starting from the IC10/

20FR Rev. 2.5 Firmware version.

For the detailed procedure for updating the rmware, plea-

se refer to the Firmware Update section of this user guide.

Temperature monitoring

The Bionova® IC10/20FR Auto-reader contains an in-

ternal temperature control. If the temperature falls

outside of the specied range (37±2 or 60±2 ºC), the

blue temperature led light will start to twinkle.

Temperature can be externally monitored by using

a Bionova® TB- IC1020 thermometer or other similar.

The Auto-Reader IC10/20FR has a special hole for pla-

cing the thermometer which is located at the back of

the device.

the reading is complete, notifying the operator that

the incubation time will be fullled. The color of the

solution can be used for a qualitative reading only

if the pen is removed once the program nalizes. If

the pen is not removed at that time, the color of the

solution will continue to evolve.

IC10/20FR Page 11

Instructions for use

Care and cleaning

Firmware update

The IC10/20FR Auto-reader allows updating the r-

mware periodically (program that controls the device

and denes its diferent functionalities) through the use

of the Bioupdate Software. This software veries, by

using the internet, the latest rmware version available

for IC10/20FR Auto-reader; downloads it and installs it

in a few seconds without the loss of any device data.

The Bioupdate Software must be downloaded, only

once, from the following web site: http://www.terra-

gene.com.ar/productos/infection-control/incubators/

software-downloads/ ?lang=en.

Download le:

UPDATE PROCEDURE:

Before starting the process, make sure that the Biono-

va® software is closed. Turn o the auto-reader for ve

seconds, then turn it on and follow this steps:

1- Connect the auto-reader to a PC using a USB cable

and make sure to have an internet connection.

2- Open Bioupdate program.

3- Select the device and press Start button to update.

4- Wait until the software indicates that update pro-

cess has been completed. The auto-reader will print

a ticket indicating the new version of the Firmware.

NOTE: This process must be repeated every time that

a new rmware version is available, this will be infor-

med in the website.

The equipment calibration procedure is described in

the attached software manual Bionova® Traceability

Calibration

Clean the exterior surface of the Bionova® IC10/20FR

Auto-reader with a damp cloth moistened with an

small amount of detergent. Do not clean interior com-

ponents. If additional cleaning of the wells is required,

contact your distributor or manufacturer.

Always unplug the IC10/20FR Auto-reader and

allow it to cool before cleaning. Do not immer-

se the unit in liquid.

NOTE: Bionova® IC10/20FR Auto-reader does not need

routine maintenance.

This function allows you to advance or delay the in-

ternal auto-reader clock in order to adopt a dierent

time zone.

NOTE: Remember that it is possible to synchronize

the time with the Bioupdate® software and Bionova®

traceability software.

Time zone change mode

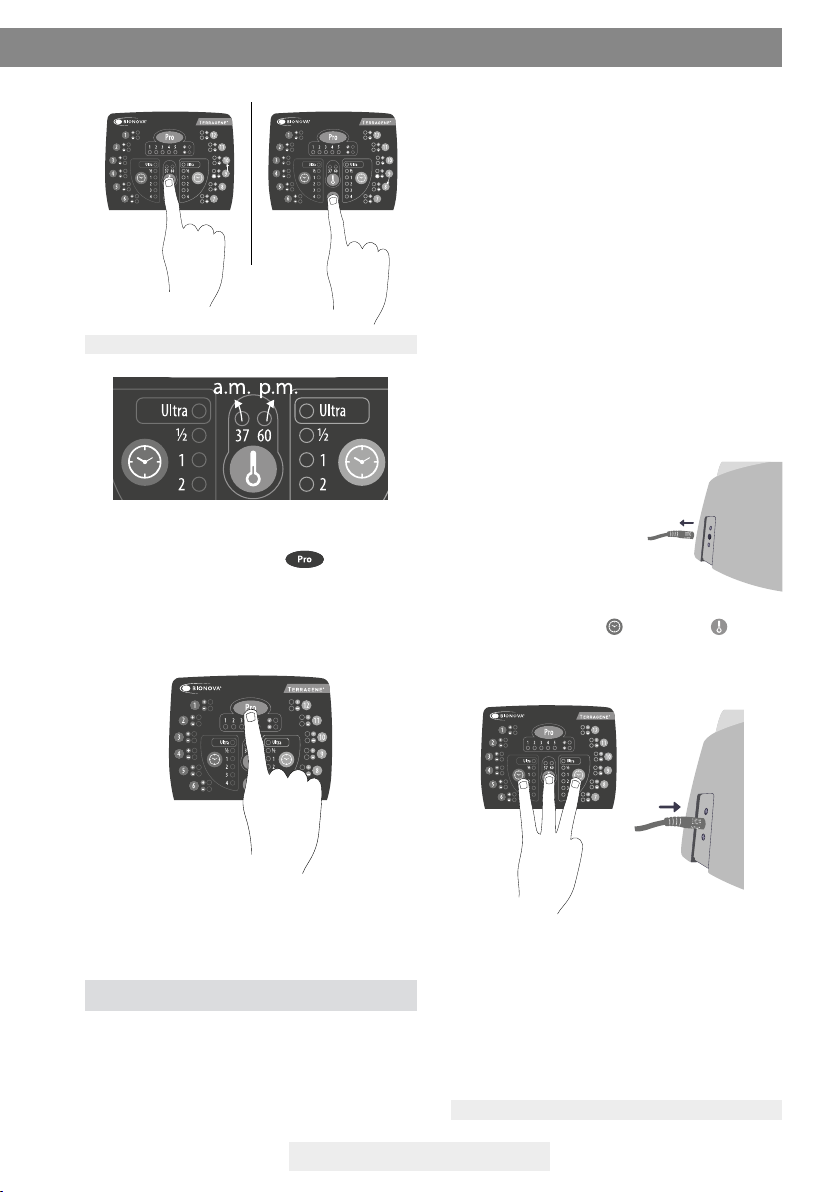

Enter Time zone change mode

De-energize the auto-reader.

Press and hold both buttons simultaneously and

energize the equipment. A beep will be emitted to

indicate access to Time zone change.

NOTE: when entering Time zone change mode a

green light will turn on in one of the incubation/

reading position. This number corresponds to the cu-

rrent auto-reader time.

Time zone change

To advance time, press button as many times as

hours you need to advance. To delay time press but-

ton as many times as hours you need to delay.

Software for Automatic Reading and Traceability of

Rapid

, Super Rapid and Ultra Rapid Biological Indicators

and Hygiene Monitoring System. You can also download

it from http://www.terragene.com.ar/productos/infec-

tion-control/incubators/software-downloads/ ?lang=en.

IC10/20FR Page 12

Cancel time zone change

To cancel time zone change process without saving

the changes, disconnect power source.

Enter Time setting mode

De-energize the auto-reader.

Time setting functionality allows you establish a spe-

cic time regardless of auto-reader current time.

Press and hold both buttons and button

simultaneously and energize the equipment. A beep

will be emitted to indicate access to Time setting

mode.

NOTE: 37 °C light indicates a.m. 60 °C light indicates p.m.

Complete time zone change

To save changes press and hold button (Figure

4) for three seconds. A beep will sound indicating that

process has been completed successfully. A ticket

with the new set time will be printed.

Figure 4

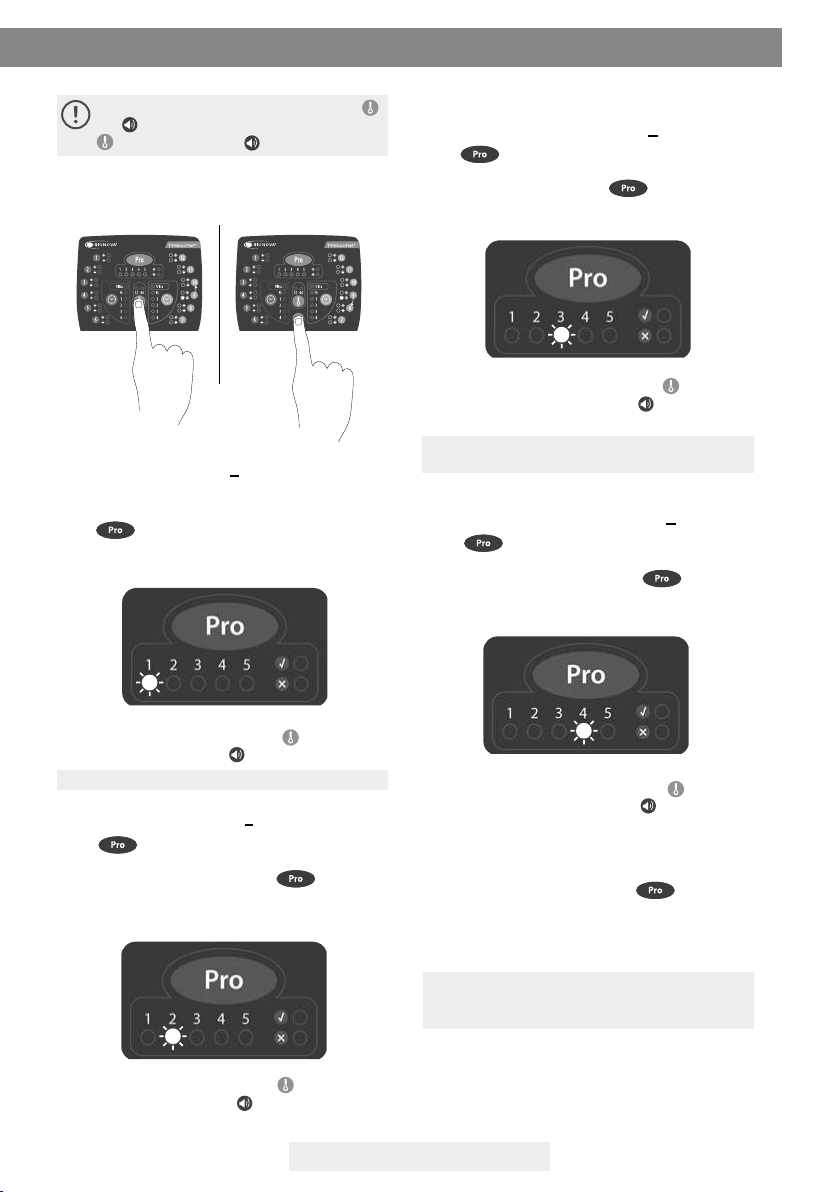

Time setting mode

Instructions for use

Advance Delay

Hours setting

Lights corresponding to 1 to 10 incubation/reading

positions indicate the digit value which is set. Lights

from 1 to 9 indicate digit value from 1 to 9. Light 10

indicates 0 value.

In time setting mode, light 1 from PRO sector will turn

on to indicate ten hour modication and incubation

light corresponding to the 10th position will turn on to

indicate setting started.

NOTE: 24-hour format.

Modication of the time using the Bioupdate®

Software

Connect the auto-reader via the USB port to a PC and

start-up the program. Select the Bionova® IC10/20FR

Auto-reader and press the Clock Sync button, the

auto-reader will be synchronized with the PC's clock.

Synchronization can only be done as long as there is

not an ongoing reading.

Change the time using the Bionova® Traceability

Software

Connect the auto-reader via the USB port to a PC

and start-up the program. The Bionova® IC10/20FR

Auto-reader will be synchronized with the PC's clock.

Synchronization can only be done as long as there is not

an ongoing reading.

Change the time using the panel

IC10/20FR Page 13

- Hours setting: Ten hours (Hh:mm)

The blue light number 1 corresponding to PRO sector

should be on. If any other light from PRO sector is on,

press button as many times as necessary to

turn on the blue light number 1. This indicates ten

hour setting.

To increase ten hours value, press button. To re-

duce ten hours value, press button. (See Figure 5).

NOTE: the possible values for ten hour are 0, 1 and 2.

- Hours setting: Unit hours (hH:mm)

Press button to turn on the blue light num-

ber 2. This indicates unit hours setting. If any other li-

ght from PRO sector is on, press button as

many times as necessary to turn on the blue light

number 2.

To increase unit hours value, press button. To de-

crease unit hours value, press button. (See Figure 5).

To increase ten minutes value, press button. To

decrease ten minutes value, press button. (See Fi-

gure 5).

NOTE: possible values for ten minutes are 0, 1, 2, 3,

4 y 5.

Minutes setting

- Minutes setting: Ten minutes (hh:Mm)

Press button to turn on the blue light number

3. This indicates ten minutes setting. If any other light

from PRO sector is on, press button as many

times as necessary to turn on the blue light number 3.

Figure 5

To change hours and minutes digits, use

and buttons. To increase digit value press

; to decrease press (see Figure 5).

Instructions for use

- Minutes setting: Unit minutes (hh:mM)

Press button to turn on the blue light num-

ber 4. This indicates unit minutes setting. If any other

light from Pro sector is on, press button as

many times as necessary to turn on the blue light

number 4.

To increase unit minutes value, press button. To

decrease unit minutes value, press button. (See Fi-

gure 5).

Finish hours setting

To save changes press and hold button (see

Figure 4) for three seconds. A beep will sound, PRO

green light will turn on and a ticket with the new set

time will be printed to indicate the procedure has

been completed successfully.

NOTE: If the modication has not been done correct-

ly, the auto-reader will emit 3 beeps and the red light

from PRO sector will turn on. Repeat the procedure.

Cancel hours setting

To cancel hours setting procedure without saving the

changes, disconnect power source.

Increase Decrease

IC10/20FR Page 14

Finish printing language change

To save changes press and hold button for

three seconds. A sound will be emitted indicating

that process has been completed successfully. A tic-

ket with the new language will be printed.

Press and hold button and energize the equip-

ment. A sound will be emitted to indicate Access to

Printing language change mode.

Use and buttons to select the position number

corresponding to language code.

Instructions for use

Enter to Printing language change mode

De-energize the auto-reader.

This function allows you to change the auto-reader

printing language.

Printing language change mode

NOTE: each language has a code number assigned:

1: English | 2: Spanish | 3: Portuguese | 4: Turkish

IC10/20FR Page 15

Troubleshooting chart

Fault Possible cause Action

The auto-reader does not start

The auto-reader gives an error

in one position during “Auto-

test”.

The auto-reader gives an error

in the “Autotest”.

The auto-reader does not run a

BI reading.

The red light of that position is

blinking.

The auto-reader does not run a

BI readout in any position.

The auto-reader does not run

Chemdye® PRO1 MICRO readings.

The red light of that position is

blinking.

When initiating the PRO incu-

bation program the machine

makes a sound but it does not

initiate.

The auto-reader does not allow to

change the incubation program.

The printer does not print and

the printer indicating light blinks.

The printer releases unprinted

paper.

The Bionova® traceability sof-

tware does not detect the au-

to-reader.

The update of the auto-reader

fails.

Power source is not connected.

A BI is placed in the position at

the moment of starting the au-

to-reader.

Soil particles might be obstruc-

ting the light path between the

sensors.

The autotest gives an error in

that position, which becomes

disabled.

The incubation temperature is

not stable.

The autotest gives an error in

the PRO position, which beco-

mes disabled.

The incubation temperature is

not stable.

Ongoing reading.

The printer cover is not tightly

locked.

Printer without paper.

Paper roll is placed in the wrong

direction.

The auto-reader is turned o or

the USB cable is disconnected.

The auto-reader is connected to

the Bionova® traceability software.

Check that the power source is con-

nected to the power supply and

that the plug is connected to the au-

to-reader.

Check that every position is empty at

the moment of starting the auto-rea-

der.

Ensure cleanliness of the incubation

position. Use of air is recommended.

Do not use solid objects that could

damage internal components. Res-

tart the auto-reader.

Make sure that the position is empty

when starting the auto-reader. Res-

tart the auto-reader.

Wait for temperature to be stable.

Make sure that the PRO position is

empty when starting the auto-reader.

Restart the auto-reader.

Wait for temperature to be stable.

Wait for the readings to nish.

Check that the cover is tightly closed.

Place a new paper roll in the right di-

rection.

Check the paper roll direction.

Check that the auto-reader is turned

on, the USB cable is connected and

the COM port is correctly installed and

accepted by the operative system.

Close the program, restart the au-

to-reader and try again.

IC10/20FR Page 16

Warranty

Terragene® S.A. guarantees both the quality of the

product material components and the quality of its

manufacturing process. Should any material or ma-

nufacturing faults be detected within the warranty

period (1 year from the time of purchase), the only

obligation of Terragene® S.A. will be product repairing

or substitution.

Limitation of liability

Technical assistance

Terragene® S.A. shall not be liable for any loss or da-

mage that may result from the unsuitable use of the

equipment, negligence or user’s full responsibility.

Terragene S.A

Ruta Nacional Nº 9, Km 280 - CP 2130.

Parque Industrial Micropi- Alvear-Santa Fe-Argentina.

Rev.26 | Noviembre 2018

IC10/20FR

Innovación en tecnologías para el Control de Infecciones

IC10/20FR Pág. 20

La Auto-lectora Bionova® IC10/20FR ha sido diseñada

para la incubación de los siguientes Indicadores Bioló-

gicos (IBs) Autocontenidos:

• IBs Autocontenidos de Lectura Rápida: BT110 para el

control de esterilización por Óxido de Etileno, BT220 y

BT221 para el control de esterilización por Vapor, BT102

para el control de esterilización por Formaldehído y

BT95 para el control de esterilización por Plasma de Pe-

róxido de Hidrógeno.

• IBs Autocontenidos de Lectura Súper Rápida: BT222 y

BT223 para el control de esterilización por Vapor y BT96

para el control de esterilización por Plasma de Peróxido

de Hidrógeno.

• IBs Autocontenidos de Lectura Ultra Rápida: BT224

para el control de esterilización por Vapor.

Los microorganismos contenidos dentro de los indi-

cadores biológicos varían de acuerdo al proceso de

esterilización para el cual han sido diseñados, por ello,

las temperaturas de incubación son diferentes según el

indicador. Los indicadores para el control de esteriliza-

ción por óxido de etileno (OE), deben ser incubados a 37

°C, mientras que aquellos para el control de los restantes

procesos de esterilización deben incubarse a 60 °C.

No es posible la incubación simultánea de IBs

para el control de procesos por OE junto con IBs

para el control de los demás procesos.

La incubadora Bionova® IC10/20FR permite la detección

Descripción de uso

Composición

rápida y fácil de indicadores biológicos positivos y nega-

tivos. Dispone de 6 programas de incubación: 4 hs. a 37

°C, 3hs. a 60 °C, 2 hs. a 60°C, 1 h. a 60 °C, 30 min. a 60 °C e

Instant/Ultra (20 min.) a 60 °C. Un resultado positivo tam-

bién puede evidenciarse a través del cambio de color del

medio de cultivo al color amarillo, lea las instrucciones de

uso de cada indicador para más información. La elección

de realizar o no la incubación extendida para conrma-

ción por cambio de color depende de los protocolos in-

ternos de cada laboratorio u hospital.

La auto-lectora permite la selección de programas de

tiempo de incubación de manera independiente para

dos zonas. La zona 1 incluye las posiciones 1 a 6 y la zona

2, las posiciones de 7 a 12.

La Auto-lectora IC10/20FR Bionova® contiene una cavi-

dad especial para realizar lecturas cuantitativas del Sis-

tema Chemdye® PRO, destinado al control de limpieza y

contaminación de supercies.

La Auto-lectora IC10/20FR Bionova® no sólo permite la

detección de los resultados, también proporciona un

ticket impreso para su registro. Además, la Auto-lectora

IC10/20FR Bionova® puede conectarse a una PC por un

puerto USB. Este permite vincular los resultados con el

Software de Trazabilidad Bionova® para la Lectura Auto-

mática yTrazabilidad de Indicadores Biológicos Rápidos,

Súper Rápidos, Ultra Rápidos y Sistema de Monitoreo de

Higiene. Para descargar la última versión del software

ingrese en: http://www.terragene.com.ar/productos/

control-de-infecciones/incubadoras/descargas-de-sof-

tware/, desde allí también podrá descargar el manual

de uso del mismo.

15

16

1

1

2

3

10

11

9

12

14

13

8

6

712

Other manuals for IC10/20FR

1

Table of contents

Languages:

Other Bionova Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Fluke

Fluke ii900 user manual

Showa Denko

Showa Denko Shodex Asahipak NH2P-50 10E Operation manual

REITEL

REITEL ROTOGRIND NT operating instructions

Showa Denko

Showa Denko Shodex IC NI-424 Operation manual

Prior Scientific

Prior Scientific OptiScan II ES111 operating instructions

BioLAB

BioLAB BFSD-502 Operation manual