Biosan PST-60HL User manual

DOMINIQUE DUTSCHER SAS

2

DOMINIQUE DUTSCHER SAS

3

Contents

1. Safety Precautions ....................................................................................... 4

2. General information ...................................................................................... 6

3. Getting started .............................................................................................. 7

4. Operation ...................................................................................................... 8

5. Calibration .................................................................................................. 10

6. Specifications ............................................................................................. 12

7. Maintenance ............................................................................................... 13

8. Warranty and Claims .................................................................................. 14

9. Declaration of Conformity ........................................................................... 15

DOMINIQUE DUTSCHER SAS

4

1. Safety Precautions

The following symbols mean:

Caution! Make sure you have fully read and understood the present

Manual before using the equipment. Please pay special

attention to sections marked by this symbol.

Caution! Surfaces can become hot during use.

GENERAL SAFETY

Use only as specified in the Operating Manual provided.

Save the unit from shocks or falling.

Store and transport the unit in a horizontal position (see package label).

After transportation or storage and before connecting to electric circuit, keep

the unit under room temperature for 2-3 hrs.

Before using any cleaning or decontamination methods except those

recommended by the manufacturer, check with the manufacturer that the

proposed method will not damage the equipment.

Do not make modifications to the design of the unit.

ELECTRICAL SAFETY

Connect only to the external power supply unit with voltage corresponding to

that on the serial number label.

Use only the external power supply unit provided with this product.

Ensure that the switch and external power supply are easily accessible during

use.

Do not plug the unit into an ungrounded power socket, and do not use an

ungrounded extension lead.

Disconnect the unit from electric circuit before moving. Switch the unit off and

disconnect the power cord plug from power socket to disconnect the unit from

electric circuit.

hazardous material is spilt on or penetrates into the equipment. If liquid

penetrates into the unit, disconnect it from electric circuit and have it checked

by a repair and maintenance technician.

Do not operate the unit in premises where condensation can form. Operating

conditions of the unit are defined in the Specifications section.

DOMINIQUE DUTSCHER SAS

5

DURING OPERATION

Do not leave the operating unit unattended.

Do not impede the platform motion.

Do not operate the unit in environments with aggressive or explosive chemical

mixtures. Please contact manufacturer for possible operation of the unit in

specific atmospheres.

Do not operate the unit if it is faulty or has been installed incorrectly.

Do not fill in the microplates after they have been inserted in the unit.

Do not use outside laboratory rooms.

Do not check the temperature by touch. Use a thermometer.

BIOLOGICAL SAFETY

hazardous material is spilled on or penetrates into the equipment.

DOMINIQUE DUTSCHER SAS

6

2. General information

PST-60HL / PST-60HL-4 Plate Shaker-Thermostat is designed for shaking 1

to 4 standard 96-well plates in the thermal regulation mode.

Plate Shaker-Thermostat was designed using the multi-system principle,

which allows using it as three independent devices:

1) incubator for lasting incubation of micro quantities (insect, plant cell cultures,

etc.) in plates;

2) plate shaker for operation in the cold room or other conditions, which do not

require temperature stabilization;

3) microplate thermo-Shaker for immunochemistry and molecular diagnostics,

where the requirements to the result reproducibility and thus to the precise

method regulation are particularly high.

A distinctive feature of Biosan plate thermoshakers is the patented two-side

plate heating that allows to achieve full correspondence of the set and actual

temperature in the plate wells.

PST-60HL/PST-60HL-4 Plate Shaker-Thermostat provides:

soft or intensive sample shaking;

rotation speed regulation, stabilization and indication;

even shaking amplitude throughout Shaker-Thermostat platform;

required operation time setting and indication;

automatic stopping of the platform movement after the set time expires;

current operation time indication;

setting and indication of the required temperature;

fault automatic diagnostics (temperature sensor, platform heating, lid heating

and other errors).

The device can be used in:

cytochemistry

for in situ reactions;

immunochemistry

for immunofermentative reactions;

biochemistry

for enzyme and protein analysis;

molecular biology

for matrix analysis, DNA and RNA analyses.

The maximum guaranteed number of diagnostic cycles in the Plate Shaker-

Thermostat mode, which require 15-30 min work in one cycle, is 7000-14000 times.

External 12V power supply unit is used to power the device. It makes it safe

to work in the cold room, where condensation may cause leakage current from

electric circuit.

DOMINIQUE DUTSCHER SAS

7

3. Getting started

3.1. Unpacking.

Remove packing materials carefully and retain for them future shipment or

storage of the unit.

Examine the unit carefully for any damage incurred during transit. The

warranty does not cover in-transit damage.

Warranty covers only the units transported in the original package.

3.2. Complete set. Package contents:

- PST-60HL / PST-60HL-4 Plate Shaker-Thermostat .............................. 1 pce

- spare rubber belt ...................................................................................2 pcs

- external power supply ............................................................................ 1 pce

- power cord ............................................................................................. 1 pce

- Operating manual, Certificate ..............................................................1 copy

3.3. Set up:

- place the unit upon even horizontal non-flammable surface away from any

flammable materials (not less than 30 cm);

- remove protective film from the display;

- plug the external power supply unit into the socket at the rear side of the unit

and position the unit so that there is easy access to the power switch and

the external power supply unit.

DOMINIQUE DUTSCHER SAS

8

4. Operation

Recommendations during operation

For proper mixing, it is not recommended to fill microplates for more than 75%

of their nominal volume.

Seal the microplates with an appropriate adhesive film to avoid spilling the

sample.

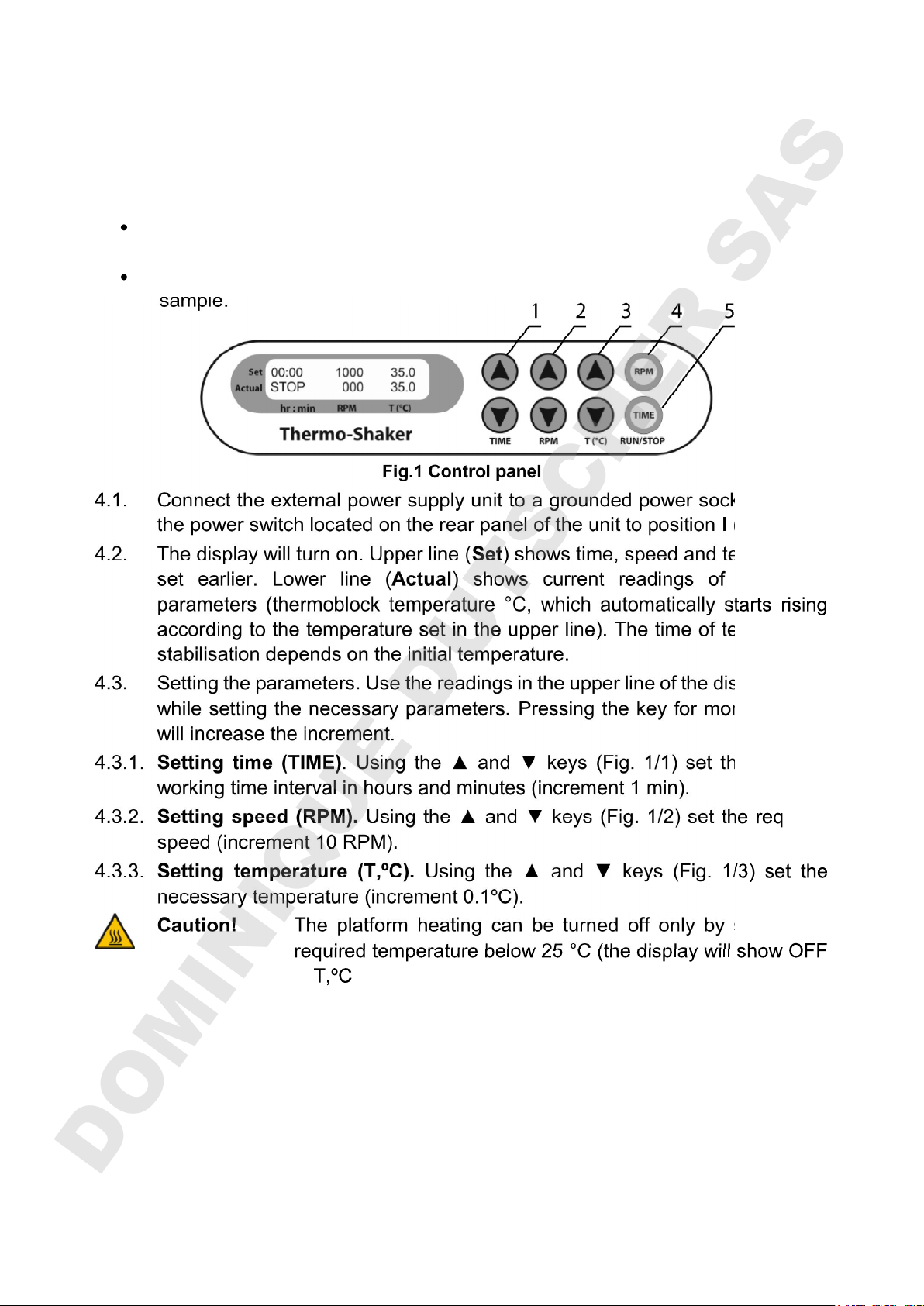

Fig.1 Control panel

4.1. Connect the external power supply unit to a grounded power socket and set

the power switch located on the rear panel of the unit to position I (ON).

4.2. The display will turn on. Upper line (Set) shows time, speed and temperature

set earlier. Lower line (Actual) shows current readings of the same

according to the temperature set in the upper line). The time of temperature

stabilisation depends on the initial temperature.

4.3. Setting the parameters. Use the readings in the upper line of the display (Set),

while setting the necessary parameters. Pressing the key for more than 3 s

will increase the increment.

4.3.1. Setting time (TIME) he required

working time interval in hours and minutes (increment 1 min).

4.3.2. Setting speed (RPM). uired

speed (increment 10 RPM).

4.3.3.

Caution! The platform heating can be turned off only by setting the

- - set point).It can be used in cold rooms as a mixing

device without thermal regulation in this mode.

4.4. Program execution. After the thermal stabilisation of the unit (when the set

and current temperature readings become the same):

4.4.1. Microplate fixation:

PST-60HL: Place microplates on the platform and fix it with the special

push-down clip by pressing it against the plate covers.

PST-60HL-4: Unscrew the fixation screws. Place microplates on the

platform and fix them by tightening the fixation screws.

DOMINIQUE DUTSCHER SAS

9

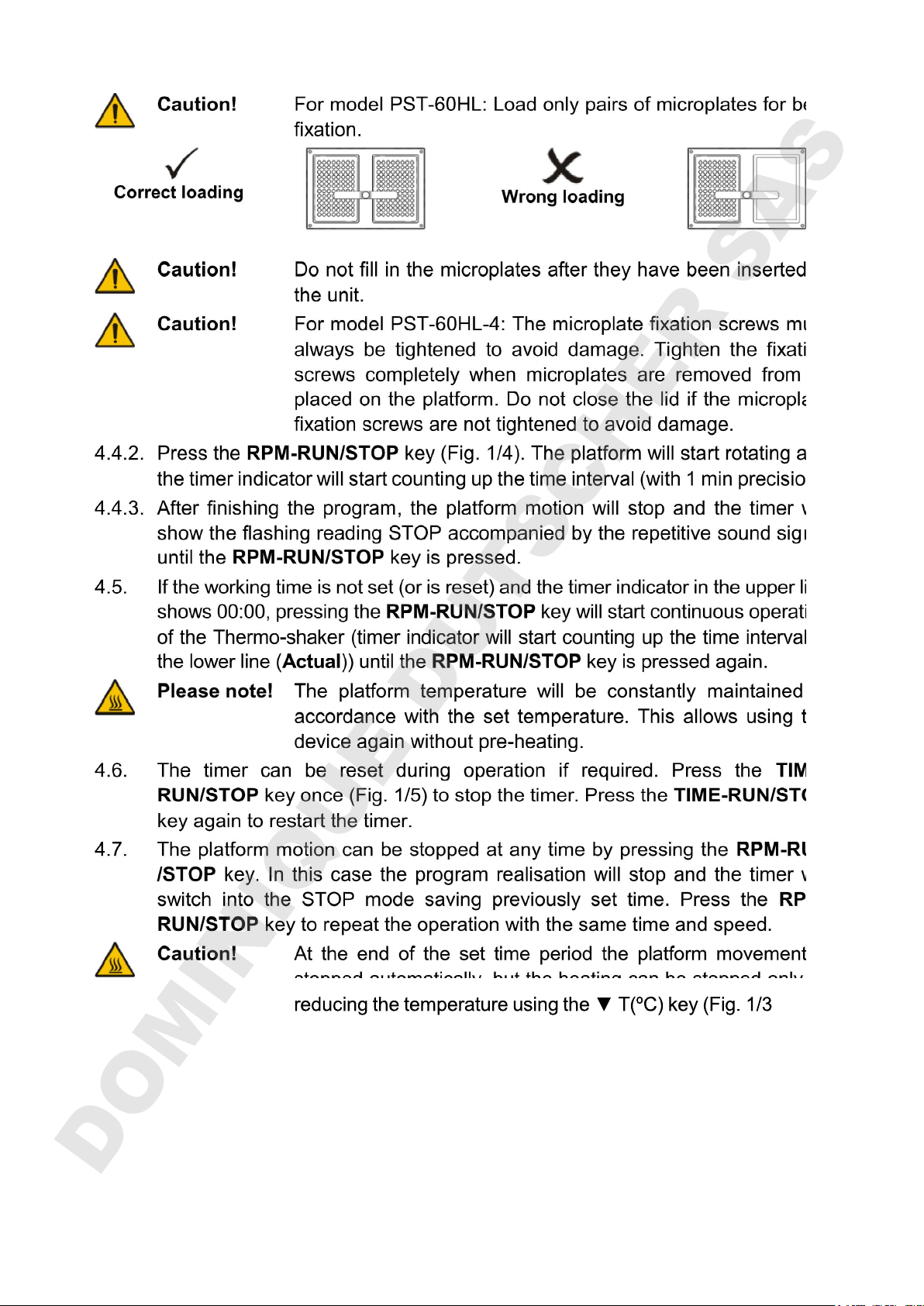

Caution! For model PST-60HL: Load only pairs of microplates for best

fixation.

Correct loading

Wrong loading

Caution! Do not fill in the microplates after they have been inserted in

the unit.

Caution! For model PST-60HL-4: The microplate fixation screws must

always be tightened to avoid damage. Tighten the fixation

screws completely when microplates are removed from or

placed on the platform. Do not close the lid if the microplate

fixation screws are not tightened to avoid damage.

4.4.2. Press the RPM-RUN/STOP key (Fig. 1/4). The platform will start rotating and

the timer indicator will start counting up the time interval (with 1 min precision).

4.4.3. After finishing the program, the platform motion will stop and the timer will

show the flashing reading STOP accompanied by the repetitive sound signal

until the RPM-RUN/STOP key is pressed.

4.5. If the working time is not set (or is reset) and the timer indicator in the upper line

shows 00:00, pressing the RPM-RUN/STOP key will start continuous operation

of the Thermo-shaker (timer indicator will start counting up the time interval in

the lower line (Actual)) until the RPM-RUN/STOP key is pressed again.

Please note! The platform temperature will be constantly maintained in

accordance with the set temperature. This allows using the

device again without pre-heating.

4.6. The timer can be reset during operation if required. Press the TIME-

RUN/STOP key once (Fig. 1/5) to stop the timer. Press the TIME-RUN/STOP

key again to restart the timer.

4.7. The platform motion can be stopped at any time by pressing the RPM-RUN

/STOP key. In this case the program realisation will stop and the timer will

switch into the STOP mode saving previously set time. Press the RPM-

RUN/STOP key to repeat the operation with the same time and speed.

Caution! At the end of the set time period the platform movement is

stopped automatically, but the heating can be stopped only by

, lower

button) till the OFF sign appears in the upper part of the display.

4.8. After finishing the operation set the power switch, located on the rear panel of

the unit, in position O (Off) and disconnect the external power supply from

electric circuit.

DOMINIQUE DUTSCHER SAS

10

5. Calibration

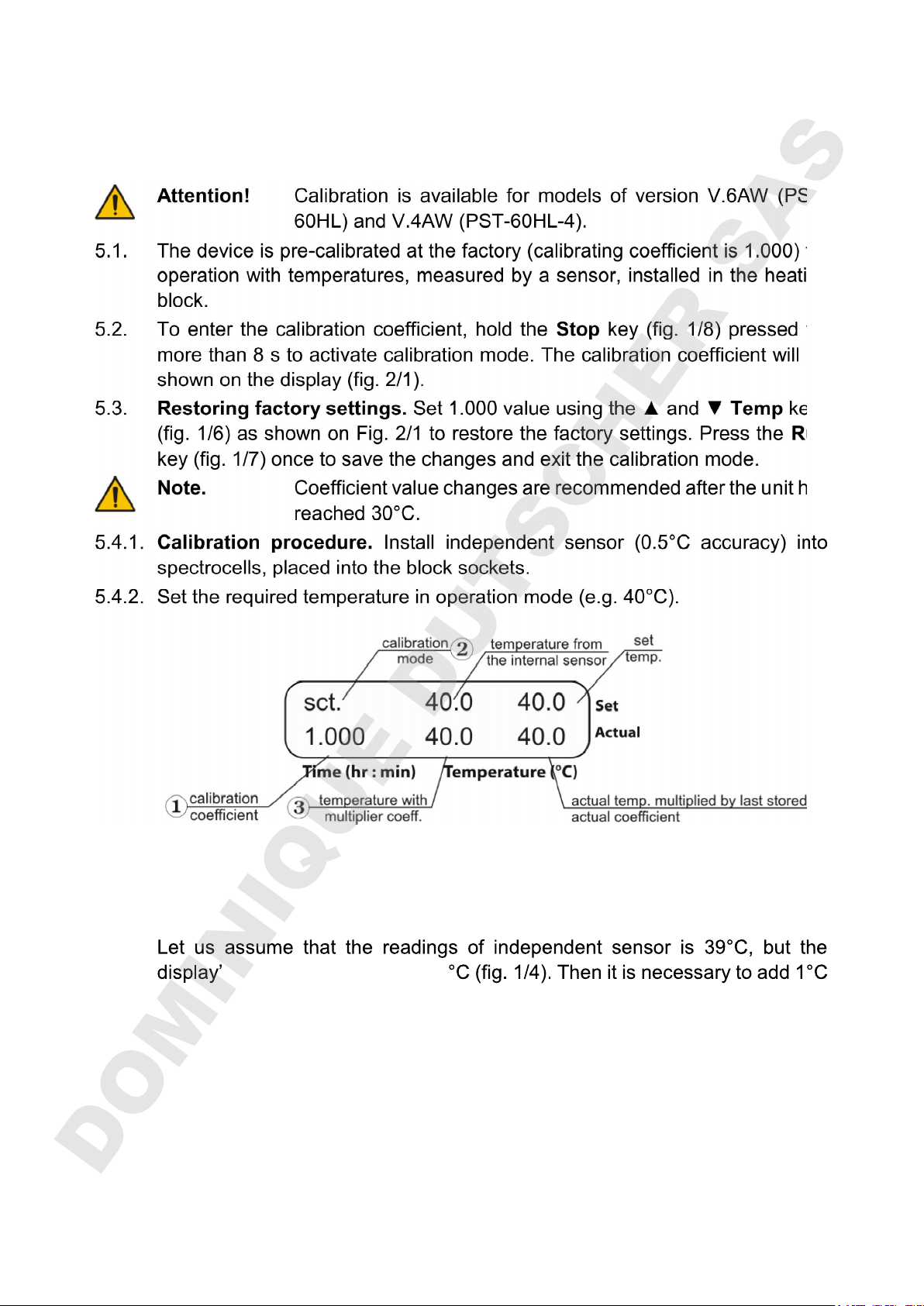

Attention! Calibration is available for models of version V.6AW (PST-

60HL) and V.4AW (PST-60HL-4).

5.1. The device is pre-calibrated at the factory (calibrating coefficient is 1.000) for

operation with temperatures, measured by a sensor, installed in the heating

block.

5.2. To enter the calibration coefficient, hold the Stop key (fig. 1/8) pressed for

more than 8 s to activate calibration mode. The calibration coefficient will be

shown on the display (fig. 2/1).

5.3. Restoring factory settings. Temp keys

(fig. 1/6) as shown on Fig. 2/1 to restore the factory settings. Press the Run

key (fig. 1/7) once to save the changes and exit the calibration mode.

Note. Coefficient value changes are recommended after the unit has

5.4.1. Calibration procedure.

spectrocells, placed into the block sockets.

5.4.2.

Fig.2 Control panel in calibration mode

5.4.3. After the unit reaches the set temperature (when the set and current

temperature readings equal) leave the unit for 30 minutes for thermal

stabilization.

5.4.4.

s actual temperature is 40

correction.

5.4.5. Hold Stop key (fig. 1/8) pressed for more than 8 s to activate calibration mode.

The following parameters will be shown on the display (fig. 2).

DOMINIQUE DUTSCHER SAS

11

5.4.6. Temp keys (fig. 1/6), change the calibration coefficient

(fig. 3/1) so that the new temperature value (fig. 3/2) corresponds to the

independent sensor temperature. In our example, the calibration coefficient

will be 0.974.

Note. Calibration coefficient can be changed in range from 0.968 up

to 1.031 with increment 0.001. This calibrating coefficient will

correct temperature through all the operation range.

Note. Coefficient value changes are recommended after the unit has

5.4.7. After finishing the calibration press the Run key (fig. 1/7) once to save the

changes and exit the calibration mode.

5.4.8. The display will show calibrated temperature as shown on fig. 4/1 and the unit

will continue thermal stabilization according to the previously set temperature.

Fig. 3 Control panel in calibration and

operation mode

Fig. 4 Control panel in operation mode

after calibration

DOMINIQUE DUTSCHER SAS

12

6. Specifications

The unit is designed for operation in cold rooms, incubators and closed

-condensing

decreasing linearly to 50% relat

6.1. Temperature specifications

Setting range ........................................................................

Control range ......................................................

Setting resolution ..................................................................................

Stability ................................................................................................

Accuracy ..............................................................................................

...........................................................................

....................................... 12 min

Temperature calibration option*

Calibration coefficient range* ......................................

6.2. General specifications

Speed setting range .............................................................. 250 - 1200 rpm

Speed setting resolution ..................................................................... 10 rpm

Orbit ....................................................................................................... 2 mm

Display .................................................................................. 16x2 signs, LCD

Digital time setting range ........................................ 1 min 96 hrs / non-stop

Max. continuous operation time ....................................................... 96 hours

(recommended interval between operation sessions not less than 8 hours)

Time setting resolution .......................................................................... 1 min

Max. height of microtest plate ............................................................. 18 mm

External power supply .......... input AC 100-240 V 50/60 Hz, output DC 12 V

PST

-

60HL

PST

-

60HL

-

4

Current/power consumption

12 V DC, 3.3 A / 40 W

12 V DC, 4.15 A / 50 W

Number of microplates

2

4

Platform dimensions

250 x 150 mm

210 x 290 mm

Dimensions

270x260x125 mm

380x390x140 mm

Weight

**

6.1 kg

8.8 kg

Replacement parts

Description

Catalogue number

Rubber belt

122x0.6x6 mm

BS

-

000000

-

S18

Biosan is committed to a continuous program of improvement and reserves

the right to alter design and specifications of the equipment without additional notice.

* Only for models of version V.6AW (PST-60HL) and V.4AW (PST-60HL-4).

**

DOMINIQUE DUTSCHER SAS

13

7. Maintenance

7.1. If the unit requires maintenance, disconnect the unit from the mains and

contact Biosan or your local Biosan representative.

7.2. All maintenance and repair operations must be performed only by qualified

and specially trained personnel.

7.3. Standard ethanol (75%) or other cleaning agents recommended for cleaning

of laboratory equipment can be used for cleaning and decontamination of the

unit.

7.4. Rubber belt replacement.

For maintenance of reliable operation of the device, the producer recom-

mends to replace rubber belts after 1.5 years or 2000 hours of operation time.

To replace the belt:

- Disconnect the external power supply unit

from the device.

- Remove 4 fixation screws on the underside

and remove the bottom plate.

- Replace the rubber belt (fig. 5).

- Reassemble the device.

Fig. 5. Rubber belt

replacement

7.5. Error codes in case of a defect.

Following error codes are shown in the lower right corner of the display (fig. 1),

accompanied by a sound signal every 8 s. Press RPM RUN/STOP key to turn

off the signal. Disconnect the unit from the electric circuit and contact Biosan

or your local Biosan representative.

Error code

Description

ERR 1

Lower

plate heat sensor error

ERR 2

Upper lid heat sensor error

ERR 3

PCB plate error

ERR 4

PCB plate error

ERR 5

Upper lid heating error

ERR 6

Upper lid overheating

DOMINIQUE DUTSCHER SAS

14

8. Warranty and Claims

8.1. The Manufacturer guarantees the compliance of unit with the requirements of

Specifications, provided the Customer follows the operation, storage and

transportation instructions.

8.2. The warranted service life of unit from date of delivery to the Customer is 24

months (excluding consumables such as rubber belts). Contact your local

distributor to check availability of extended warranty.

8.3. Warranty covers only the units transported in the original package.

8.4. If any manufacturing defects are discovered by the Customer, an

unsatisfactory equipment claim shall be compiled, certified and sent to the

local distributor address. Please visit www.biosan.lv, Technical support

section to obtain the claim form.

8.5. The following information will be required in the event that warranty or post-

warranty service comes necessary. Complete the table below and retain for

your records.

Model PST-60HL / PST-60HL-4 Plate Shaker-Thermostat

Serial number

Date of sale

DOMINIQUE DUTSCHER SAS

15

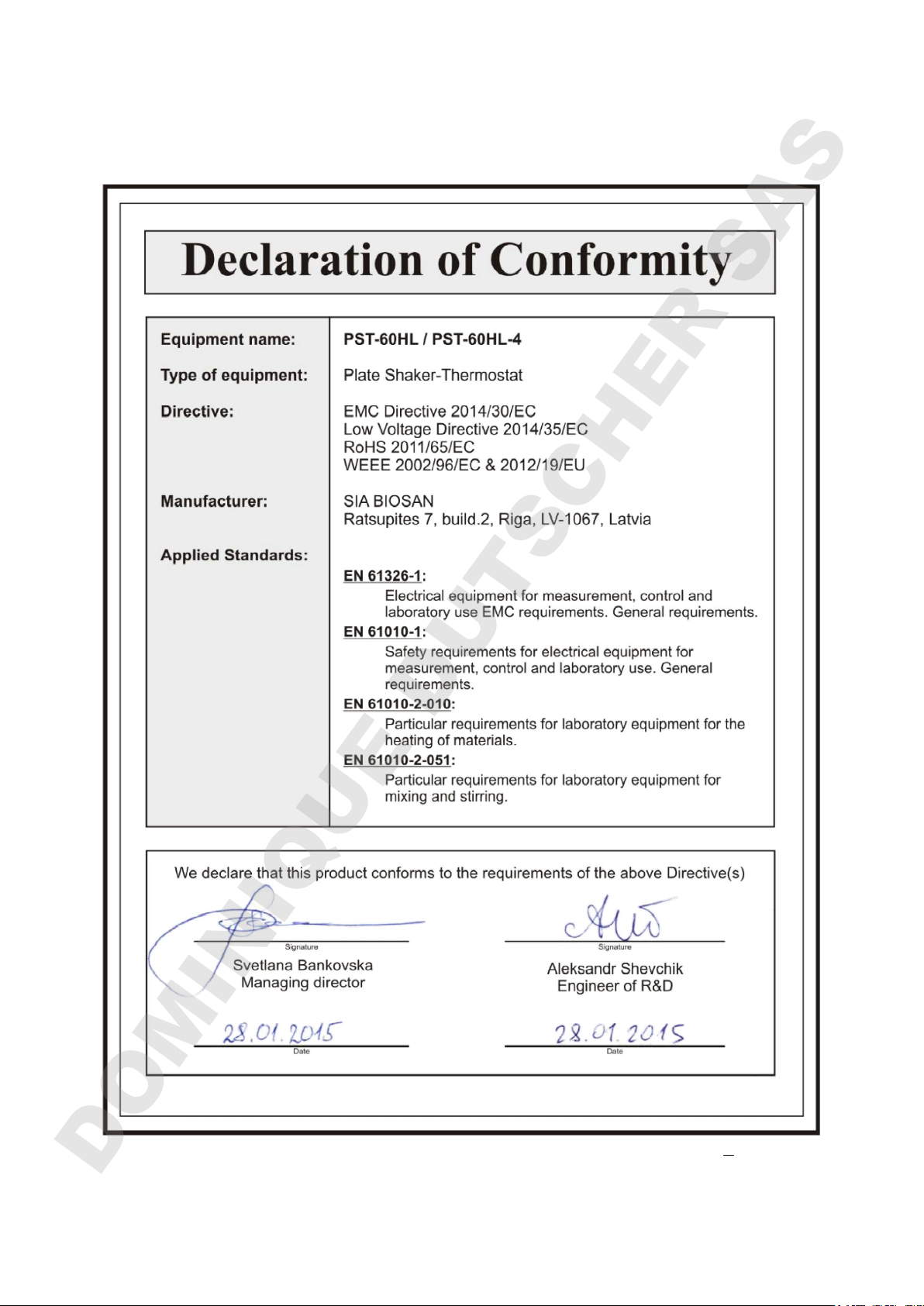

9. Declaration of Conformity

Edition 4.-6.01 April 2016

DOMINIQUE DUTSCHER SAS

DOMINIQUE DUTSCHER SAS

This manual suits for next models

1

Table of contents