biossun BIO K User manual

Assembly instructions

Folding arm awning

BIO K

BIOSSUN SAS

24 rue de la Sure

38360 SASSENAGE (FR)

Téléphone : +33 (0)4.80.42.08.10

E-mail : [email protected]

Site web : www.biossun.com

02.09.2021Folding arm awning BIO K2

nFailure to follow these instructions

nWork and repairs carried out by unqualified

persons

nMechnical modifications

Address Biossun

24 Rue de la Sûre

38360 Sassenage

Téléphone 04 80 42 08 10

Fax

e-mail [email protected]

nMotor manual

nIf included: Radio remote control instruction manual

nIf included in the scope of supply: Automatic control

instruction manual

About the instructions

Limitation of liability

Support

Other applicable documents

Additional instructions

02.09.2021 Folding arm awning BIO K 3

These instructions contain important information on the correct

and safe assembly of the blind. Please read them in their entirety

before installing the blind. Failure to do so may result in injury or

damage to the blind. If you pass on the blind to a third party,

please ensure that these instructions are also included.

The illustrations in these instructions are intended to convey a

general understanding and may differ from the actual design.

The manufacturer declines all responsibility in the following cases:

Table of contents

1Folding arm awning BIO K........................................................ 5

2Safety....................................................................................... 6

3Prepare the assembly............................................................. 10

4Mount the blind....................................................................... 14

5Adjust the blind........................................................................ 17

6Problem solving....................................................................... 21

7 Index....................................................................................... 22

Table of contents

02.09.2021Folding arm awning BIO K4

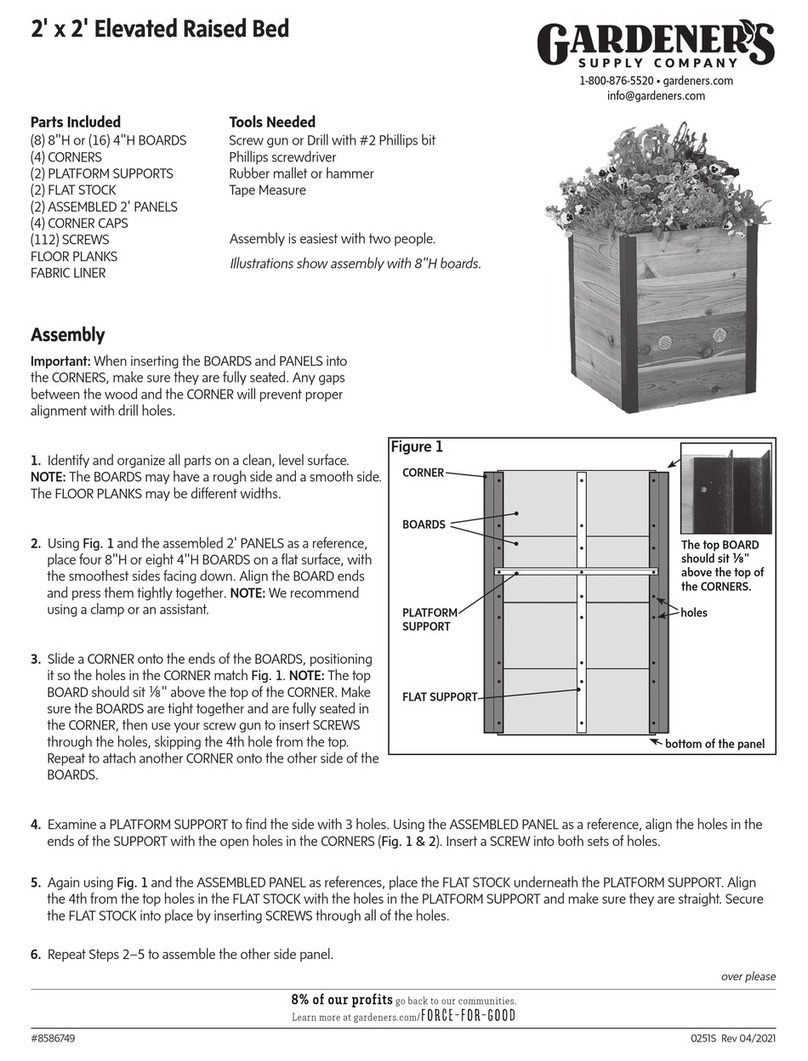

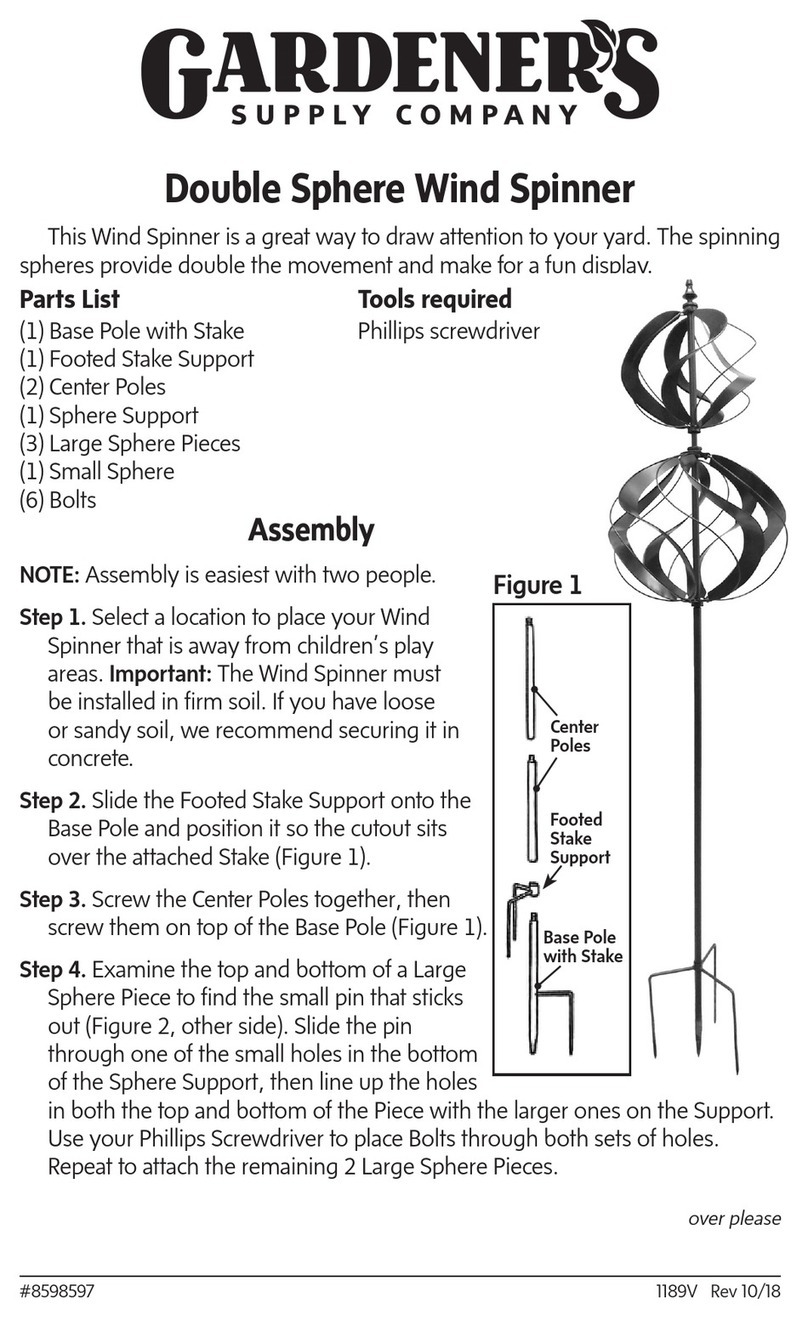

1 Folding arm awning BIO K

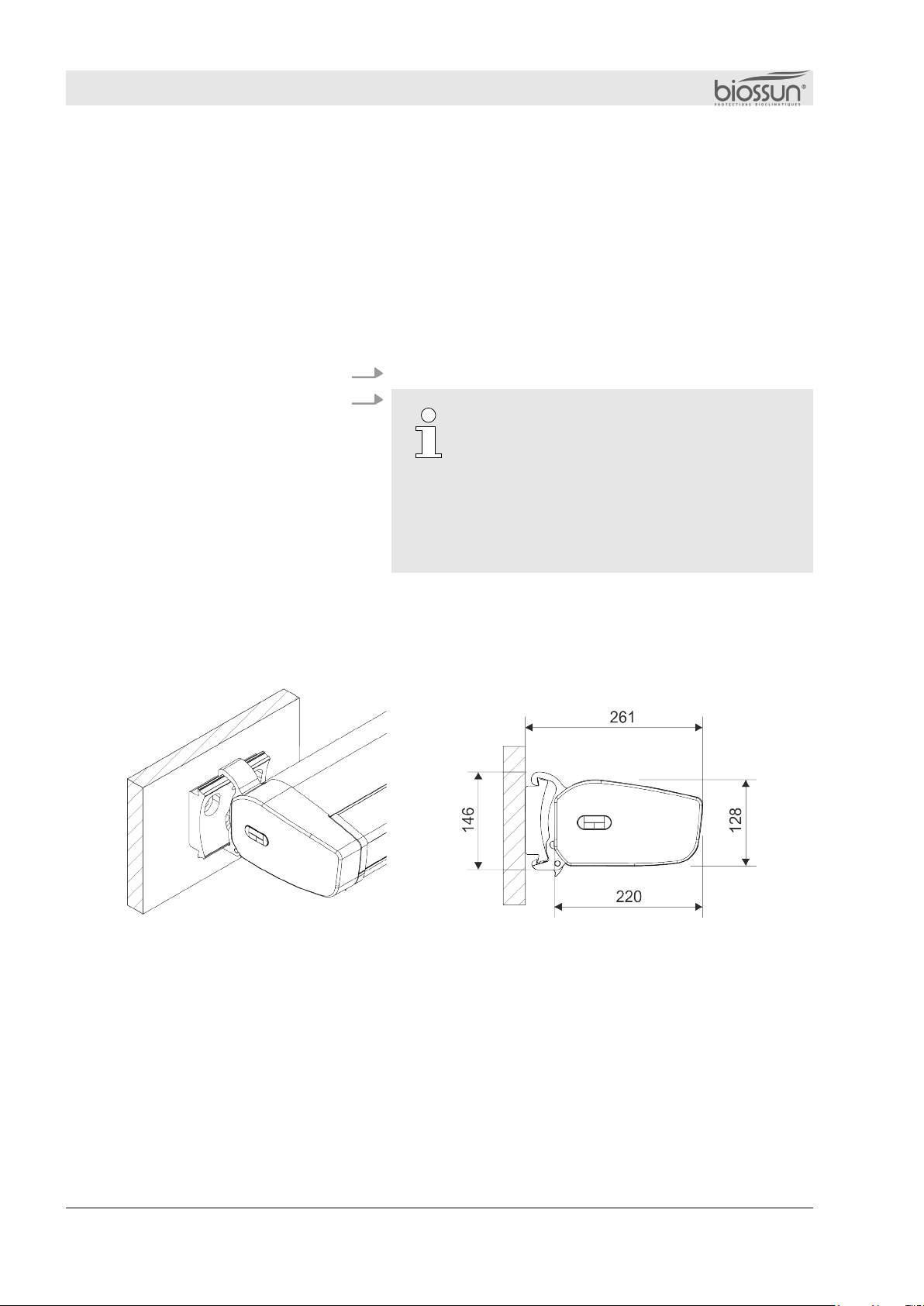

Fig. 1: Awning K

1 Cassette

2Awning

3Drop bar

4 Consoles

5Handwheel (control option)

Motor (ordering option)

The cassette (Fig. 1/1) is attached to the support surface by the

brackets (Fig. 1/4). The drop bar (Fig. 1/3) is connected to the

articulated arms (under the awning) and to the awning (Fig. 1/2).

The electric drive can be operated either by permanent wiring with

directional buttons, by a control knob, by radio remote control or by

automatic control.

Manual operation is by crank.

Folding arm awning BIO K

02.09.2021 Folding arm awning BIO K 5

Safety instructions in these instructions are indicated by symbols.

Safety instructions begin with signal words indicating the extent of

the hazard.

WARNING!

This combination of symbol and signal word

indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING!

This combination of symbol and signal word

indicates a potentially hazardous situation which,

if not avoided, could result in death or serious

injury.

WARNING!

Risk of injury from electric current!

Improper work on the awning's electrical

components can result in serious injury or death.

–Work on electrical components may only be

carried out by qualified electricians.

–The blind may only be connected if the

specifications on the nameplate match the supply

voltage.

–Follow the supplied motor operating instructions.

WARNING!

Risk of crushing from moving parts!

Moving awning parts present a crushing hazard.

- Secure support arms and end rail during assembly

2 Security

Safety notes

Electric current

(with electric drive)

Moving parts

Security

02.09.2021Folding arm awning BIO K6

WARNING !

Risk of injury from falling from height!

Working at height and using climbing equipment

present a risk of injury from falls.

–Use appropriate safety equipment.

–Never fix or support climbing aids on the

awning.

–Climbing aids must be sturdy and offer

sufficient handholds.

–Never hang on to the awning.

WARNING !

Danger when lifting the awning with ropes!

If the awning has to be lifted using ropes, there is a risk

of fatal injury due to crushing.

–Secure the ropes to the awning.

–Make sure that the awning cannot come loose from

the ropes.

–Keep the awning horizontal when lifting.

–Do not enter the danger zone beneath the load.

Working at height

Lifting with ropes

Security

02.09.2021 Folding arm awning BIO K 7

WARNING!

Risk of injury from incorrect disassembly/

reassembly!

Incorrect disassembly/reassembly increases

the risk of injury from moving parts or working

at height.

–Disassembly/reassembly should only be carried out

by a qualified installer.

–If you plan to reassemble the blind, make sure you

have all the documentation.

–Ask Biossun for any missing documents.

–Make sure you have enough space before you start

work.

–Handle exposed and sharp components with care.

–Keep your workspace tidy and clean! Stacked or

scattered components and tools present an accident

hazard.

–Dismantle the components as required. Note that

some of the components are heavy. If necessary,

use a lifting device.

–Secure components to prevent them from falling or

tipping over.

–In doubt, consult Biossun

WARNING

Risk of material damage when folding out

the awning!!

Extending the awning can cause it to fall or be

damaged.

–Do not test in freezing or snowy conditions.

–Remove dead leaves and other foreign

objects from the awning.

–Remove any obstacles.

Hearing protection

Hearing protection is used to protect hearing from noise

damage.

Dismantling old systems

Awning extension

Personal protective equipment

Security

02.09.2021Folding arm awning BIO K8

Safety helmet

Safety helmets protect the head from falling objects, swinging

loads and impacts with fixed objects..

Safety goggles

Goggles are used to protect eyes from flying debris and liquid

splashes.

Safety shoes

Safety shoes protect feet from falling parts, and prevent crushed

feet or slipping on slippery floors.

Qualified installer

A qualified installer has the technical skills, experience and

knowledge of applicable standards and regulations required to

carry out work on awnings and to recognize and avoid potential

hazards. A qualified fitter has training and experience in the

following areas:

nOccupational health and safety, industrial safety and accident

prevention regulations

nHandling ladders and scaffolding

nHandling and transport of long, heavy components

nTool and machine handling

nFastener installation

nBuilding structure assessment

nCommissioning and use of the product

Permanent electrical wiring may only be installed by an officially qualified

electrician.

Qualified persons

Security

02.09.2021 Folding arm awning BIO K 9

3 Preparing the assembly

Assembly requires at least two people.

Protective equipment :

Staff: nQualified personnel

nHearing protection

nIndustrial helmet

nSafety shoes

nSafety goggles

1. Check load-bearing capacity of support surface 2.

Suitable fastening materials

–For outdoor installation, use stainless steel

bolts.

–In the vicinity of swimming pools, use

galvanized steel bolts to counter the risk of

corrosion due to the presence of chlorine in

the air.

–To avoid contact corrosion, do not use steel

and stainless steel parts together.

Keep appropriate fastening materials (not

included) on hand.

Fig. 2: Bracket for wall mounting

Preparing for installation

Wall mounting

Preparing the assembly

02.09.2021Folding arm awning BIO K10

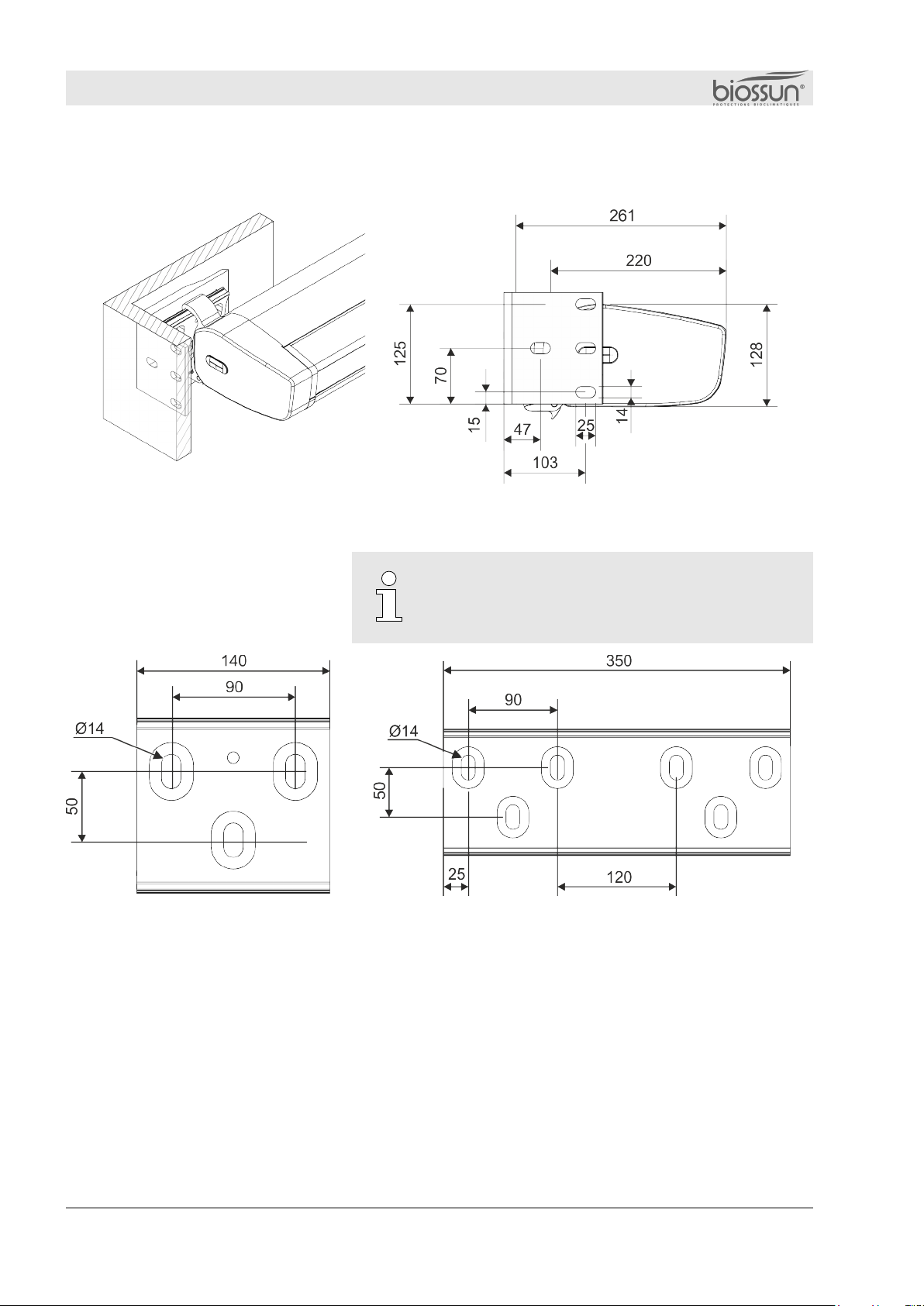

The 90° rotated wall bracket matches the ceiling

bracket

Fig. 3: Bracket for ceiling mounting

Fig. 4: Bracket for rafter mounting

Ceiling mounting

Assembly preparation

02.09.2021 Folding arm awning BIO K 11

Fig. 5: Bracket for frame mounting

The brackets for wall and ceiling mounting can

also be used as drilling templates.

Fig. 7: Drilling template for wall bracket extension

Frame assembly

Drilling jigs

Fig. 6: Drilling template for

wall/ceiling bracket

Assembly preparation

02.09.2021Folding arm awning BIO K12

Fig. 8:Console extension for wall or ceiling mounting

Fig. 9: Rafter extension

Console extension for wall or

ceiling mounting

Rafter extension

Assembly preparation

02.09.2021 Folding arm awning BIO K 13

Staff:

Protective equipment:

nQualified installer

nHearing protection

nSafety helmet

nSafety shoes

nSafety goggles

1. Determine console mounting height

Positioning

The projection area of the awning must be

free of any rigid or mobile obstacle. The

minimum distance (Fig. 10/X) between the

end rail and a rigid or mobile object must be

at least 40 cm. The minimum height (Fig.

10/Y) between the end rail and the ground

must be at least 180 cm. If these

specifications cannot be met, appropriate

safety measures must be applied to the

building (e.g. fencing).

2. Align brackets horizontally.

Use a spirit level or string to align the

mounting holes horizontally.

3. Transfer the drilling diagram (Fig. 12).

4 Mounting the awning

Mounting the brackets

Fig. 10: Blind deployment zone

Fig. 11: Aligning brackets

Fig. 12: Console markings

Mounting the awning

02.09.2021Folding arm awning BIO K14

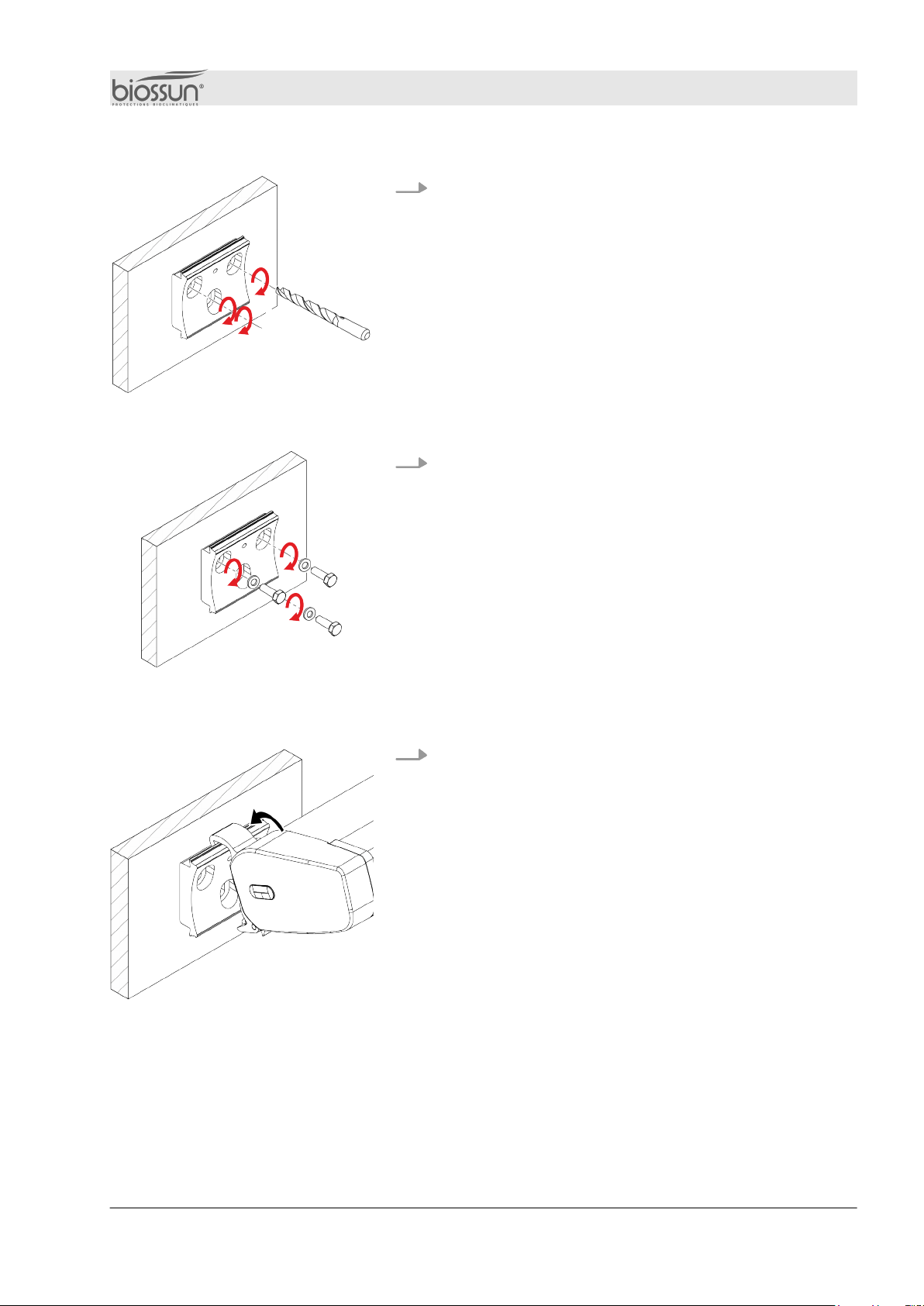

4. Drill the console mounting holes and insert wall plugs if necessary.

(Fig. 13).

5. Screw the brackets to the support surface (Fig. 14).

1. Connect awning to brackets (Fig.15)

Fig. 13: Console drilling

Fig. 14: Screwing the console

Awning connection

Fig. 15: Awning connection

Mounting the awning

02.09.2021 Folding arm awning BIO K 15

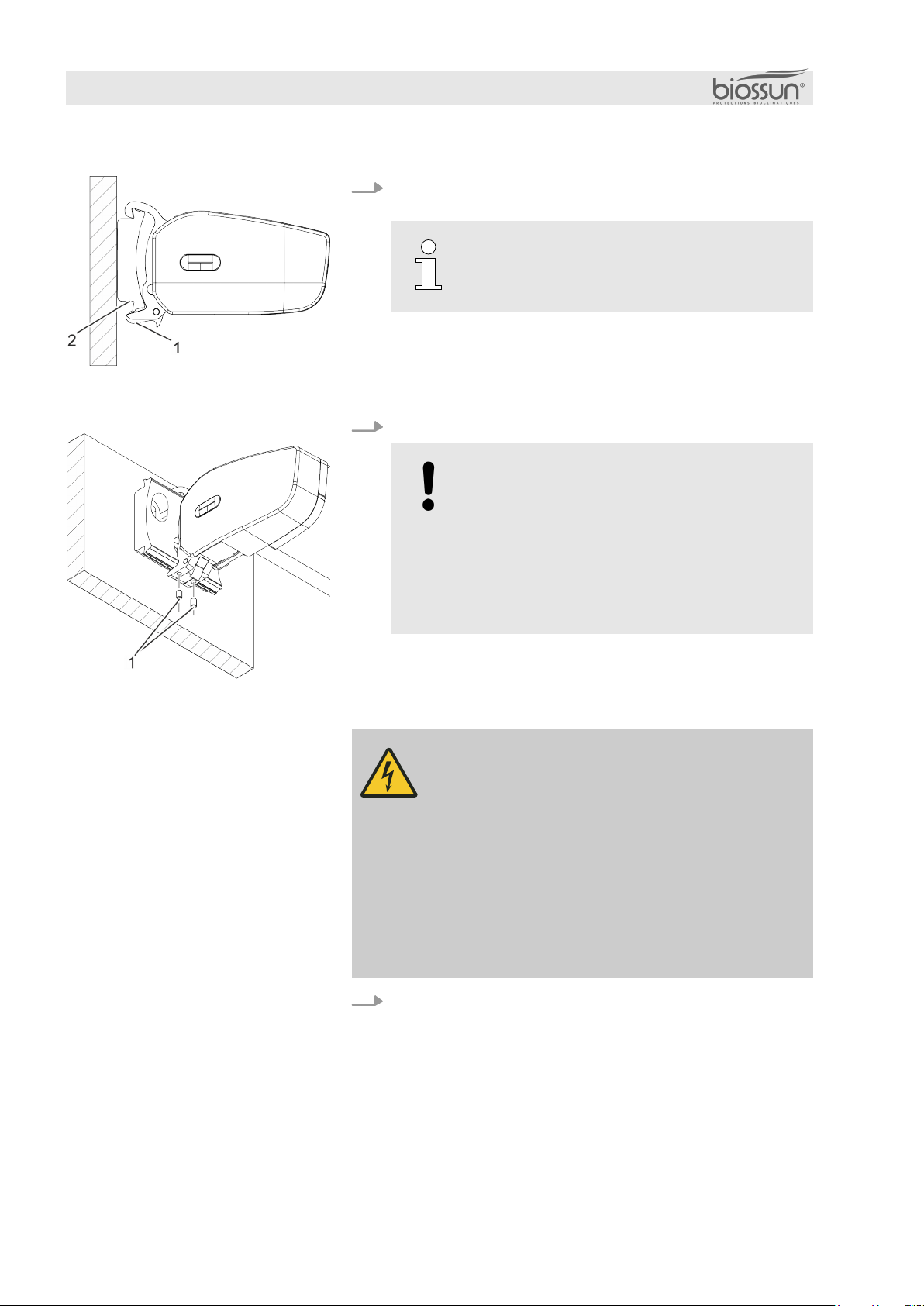

2. Use the ratchet levers (Fig. 16/1) to lock the awning securely in the locking lugs

Fig. 16/2).

The ratchet lever is permanently tensioned

by a spring. When it engages the locking

lugs, a click is heard.

3. Secure the awning with the clamping screws (Fig. 17/1).

WARNING!

Material damage and injury if awning is

not secured!

Si l'auvent glisse hors des consoles, cela

peut entraîner des dégâts matériels

importants et des blessures.

– Always secure the awning with the

clamping bolt

WARNING!

Risk of injury from electric current!

Improper work on the awning's electrical

components can result in serious injury or death.

–Work on electrical components may only be

carried out by qualified electricians.

–The blind may only be connected if the

specifications on the nameplate match the supply

voltage.

–Follow the supplied motor operating instructions.

Connect the drive to the power supply as described in

the enclosed motor manual.

Fig. 16: Fixing the awning

Fig. 17: Mounting the awning

Device connection

Mounting the awning

02.09.2021Folding arm awning BIO K16

WARNING!

Risk of damage to the fall bar and

malfunction of the awning!

–Make sure the drop bar is horizontal.

–The angle of inclination of the individual

folding arms must not differ by more than

10°.

Tilt angle can be set from 0 to 40°.

To change the shaded area and orient the awning, adjust

the angle of inclination.

1. Extend the awning by 50 to 80 cm.

2. Take the strain off the blind by gently lifting it while

adjusting the angle of inclination.

Fig. 19: Angle adjustment

3. Adjust the angle of inclination of all folding arms using the

adjusting screw with hexagon socket SW10 (Fig. 19/1).

Counter-clockwise : The angle of inclination increases - the

folding arm lowers.

nClockwise : The angle of inclination is reduced - the

folding arm is raised.

4. Check that the blind is horizontal.

5 Awning adjustment

Tilt angle adjustment

Fig. 18: Tilt angle adjustment

Awning adjustment

02.09.2021 Folding arm awning BIO K 17

Fig. 20: Arm level adjustment

To ensure that the folding arms move freely and avoid contact with the

canopy, the level of the arms must be adjusted.

1. Extend the awning by 50 to 80 cm.

2. Ease the awning by gently lifting it while adjusting the

arm level.

Fig. 21: Arm level adjustment components

3. Loosen the M6x10 hex head clamping screw

(Fig. 21/1) on the upper arm fork (Fig. 21/3).

4. Bring the folding arms into a horizontal position using a 5

mm wrench on the folding arm eccentric bearing screw (Fig.

21/4) (Fig. 21/2).

Arm level adjustment

Blind adjustment

02.09.2021Folding arm awning BIO K18

5. Tighten the M6x10 hex head clamping bolt

(Fig. 21/1).

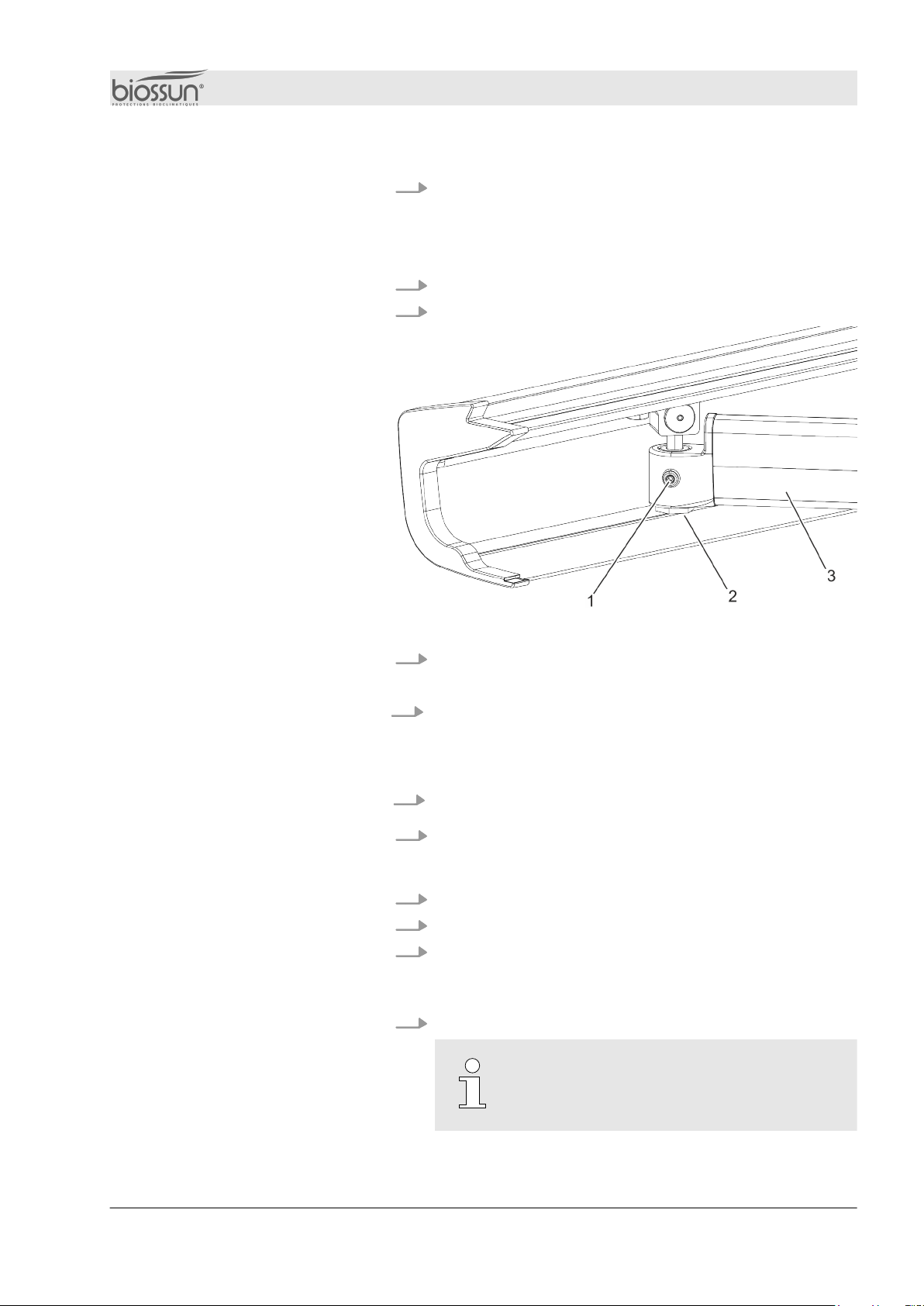

1. Unfold the blind by approx. 70 cm.

2.

Fig. 22: End rail adjustment

3. Unscrew the M5x10 threaded pin from the clamping screw

(Fig. 22/1).

4. Use the size 22 drop bar attachment (Fig. 22/2) on the arm

profile (Fig. 22/3) to adjust the drop bar.

nCounter-clockwise : The drop bar lifts.

nClockwise : The drop bar lowers.

5. Tighten the M5x10 threaded pin of the clamping screw

(Fig. 22/1).

6. Check that the end rail is horizontal.

1. Fully extend the awning

2. Retract the blind by about 1 cm.

3. Fix the position of the bottom end of the motor as indicated

in the motor manual.

1. Retract the blind.

The motor stops in the upper end position

due to the increased torque.

Load bar adjustment

End position adjustment

(with electric drive)

Lower end position

Upper end position

Blind adjustment

02.09.2021 Folding arm awning BIO K 19

2. Check cassette alignment and closure. If the cassette

does not close properly :

n

Ä

"Arm level adjustment" on page 18

n

Ä

"Adjusting the drop bar" on page 19

1. Fully extend the awning. Make sure the engine is

switched off.

Retract blind

2. Make sure the blind rolls up evenly.

nMake sure the cassette closes properly. If the

cassette does not close properly :

n

Ä

"Arm level adjustment" on page 1

n

Ä

"Adjusting the drop bar" on page 19

Function control

Blind adjustment

02.09.2021Folding arm awning BIO K20

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

FLORABEST

FLORABEST FGS 10 A1 translation of original operation manual

Goodlife

Goodlife Guardian instruction manual

LuxenHome

LuxenHome WHPL1274 instruction manual

Tube-Line

Tube-Line BF 5000SL manual

FLORABEST

FLORABEST FLV 1200 A1 translation of original operation manual

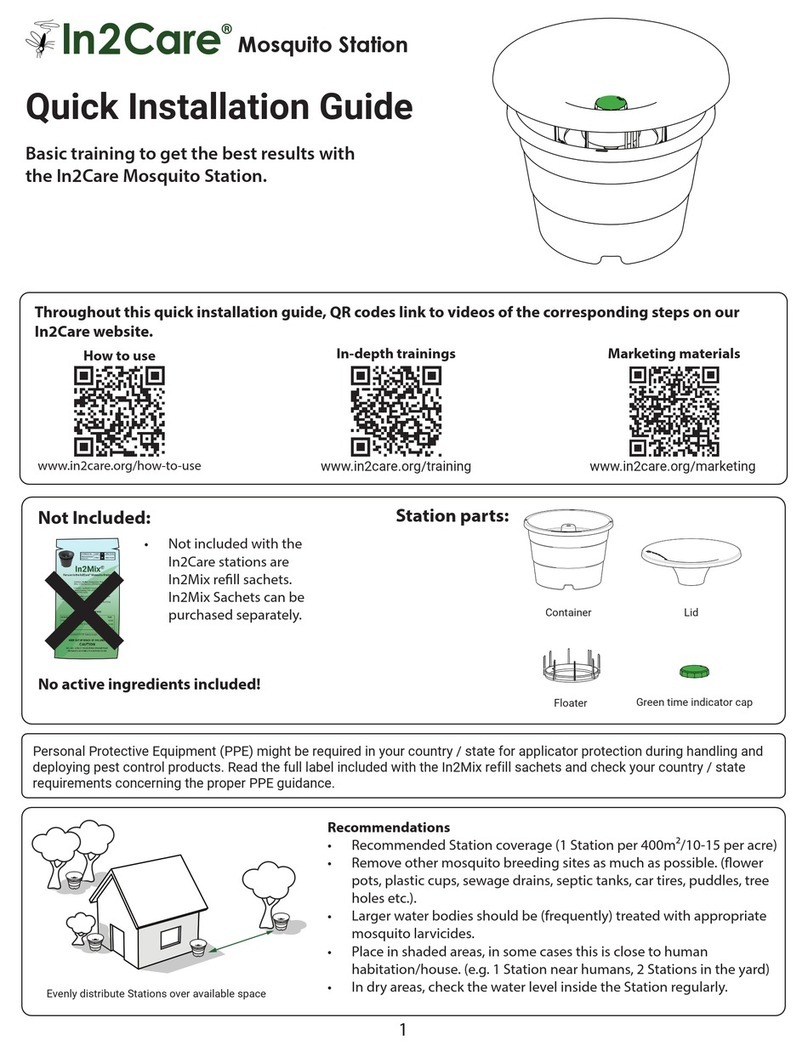

In 2 Care

In 2 Care Mosquito Station Quick installation guide