Bircher EsGate 3 User manual

1

22.5

85

92

EsGate 3

Safety switching device for sensors with 8,2 kOhm

Original instructions

General

1Safety Instructions

2Common Applications

ENGLISH

260316L

06/19

• Read these operating instructions thoroughly before putting the device

into operation and keep them for future reference.

• The assembly, commissioning, modications and extensions may only

be completed by an experienced electrician!

• Before commencing work, remove the power supply from the device/

installations!

• During the operation of electrical components

– e. g. in the case of a short circuit hot and ionised gases can be

– emitted

– protection covers must not to be removed!

• Pay attention to all local relevant electrical safety regulations!

• Disregard of the safety regulations can cause death, severe injuries or

extensive damage!

• It is the responsibility of the equipment manufacturer to carry out a

risk assessment and to install both the detector and the equipment in

compliance with applicable national and international regulations and

safety standards, as well as the Machinery Directive 2006/42/EC,

should this apply.

Before commencing the installation or assembly complete the following

safety precautions:

• Check the voltage data on the label of the switching device.

• Ensure that the device/installations can not be switched on!

• Determine that the power supply is disconnected!

• Protect the device with a housing against contamination or aggressive

environments!

• Connect all operating and switching voltages to the same fuse.

• Connect the operating voltage to the same circuit as the industrial

door controller.

• Disconnect device from mains in the event of a fault.

• Protection max. 10 A

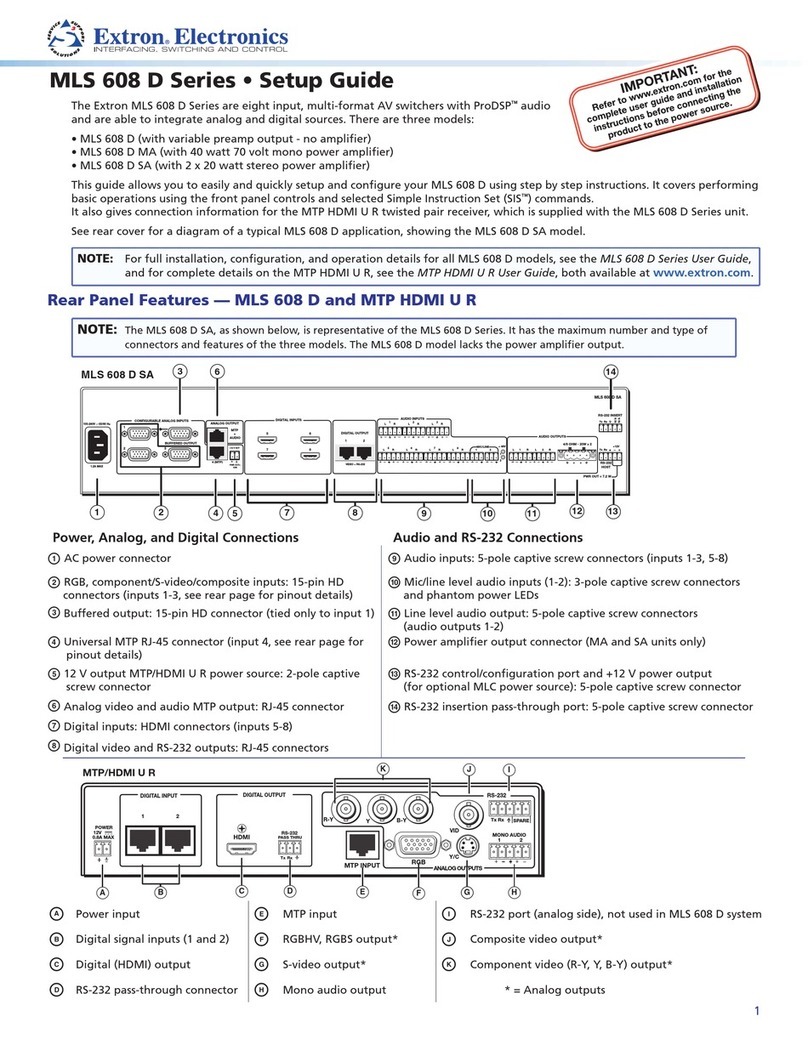

Limited protection against accidental contact!

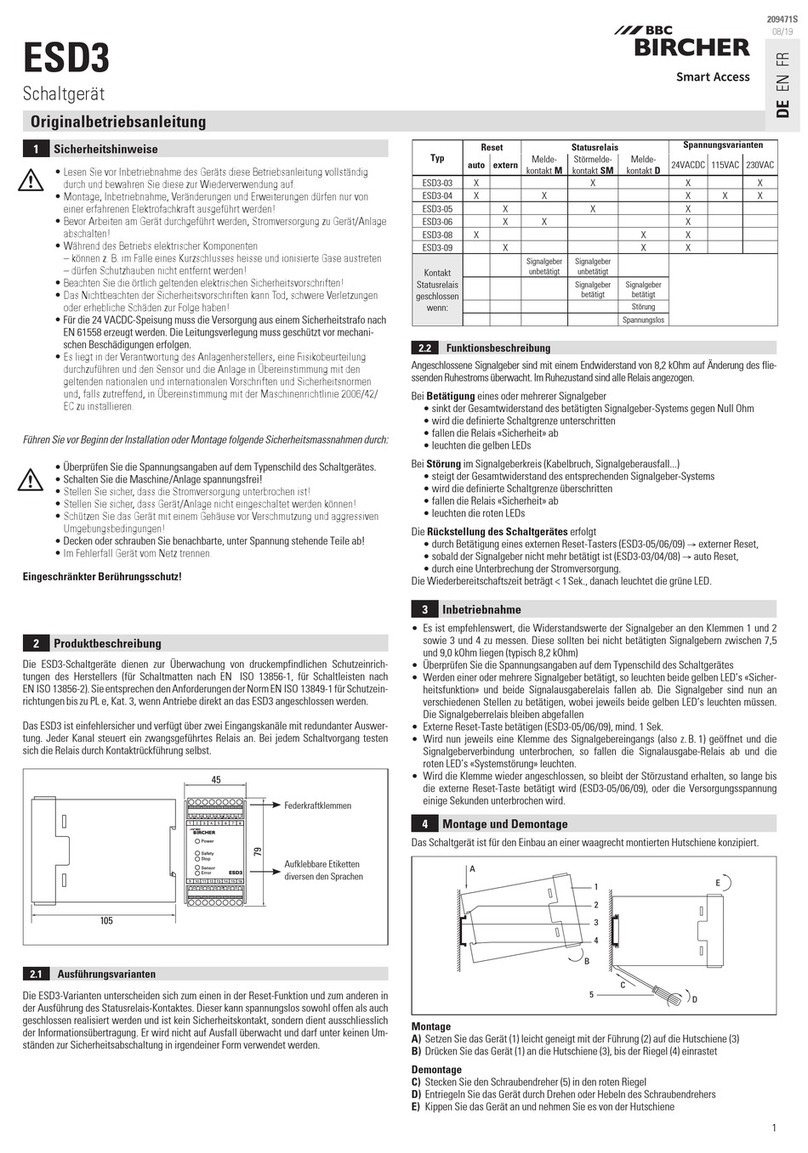

LED

LCD display

“Mode” button

“Data” button

Terminals

Label (with terminal

description)

2

A1

A2

3

4

1

2

24

21

14

11

5

6

A

A

10 A

24 V AC/DC, 100-240 V AC, 50/60 Hz

A1 / A2: ▲ Supply voltage (24 V DC or 24 V AC) / LVAC: 100 … 240 V AC

1 / 2: Sensor 1

3 / 4: Sensor 2

11 / 14: ▲ Safety output 1

21 / 24: ▲ Safety output 2

5 / 6: Status output

i

No function test possible without connected outputs (Display E 007 or E 008)

▲Wiring mandatory

Connected sensors with a terminating resistor of 8.2 kOhm are monito-

red for a change in current.

In the idle mode

• all safety outputs are conductive

• the LED lights up green

• both dots on the display ash

When one or more sensors are actuated

• the total resistance of the sensor system drops towards zero ohm

• the dened switching threshold is not reached anymore

• the corresponding Safety output opens

• the LED lights up orange, P appears on the display

In the event of a fault in the sensor circuit (for example cable breakage)

• the total resistance of the sensor system increases

• the dened switching threshold is exceeded

• both Safety outputs open

• the LED lights up red, E appears on the display

1 2

1

4Conguration and set-up

3Function

4.1 Terminals

4.2 Switch on supply voltage

Wiring the device

If necessary, congure the device

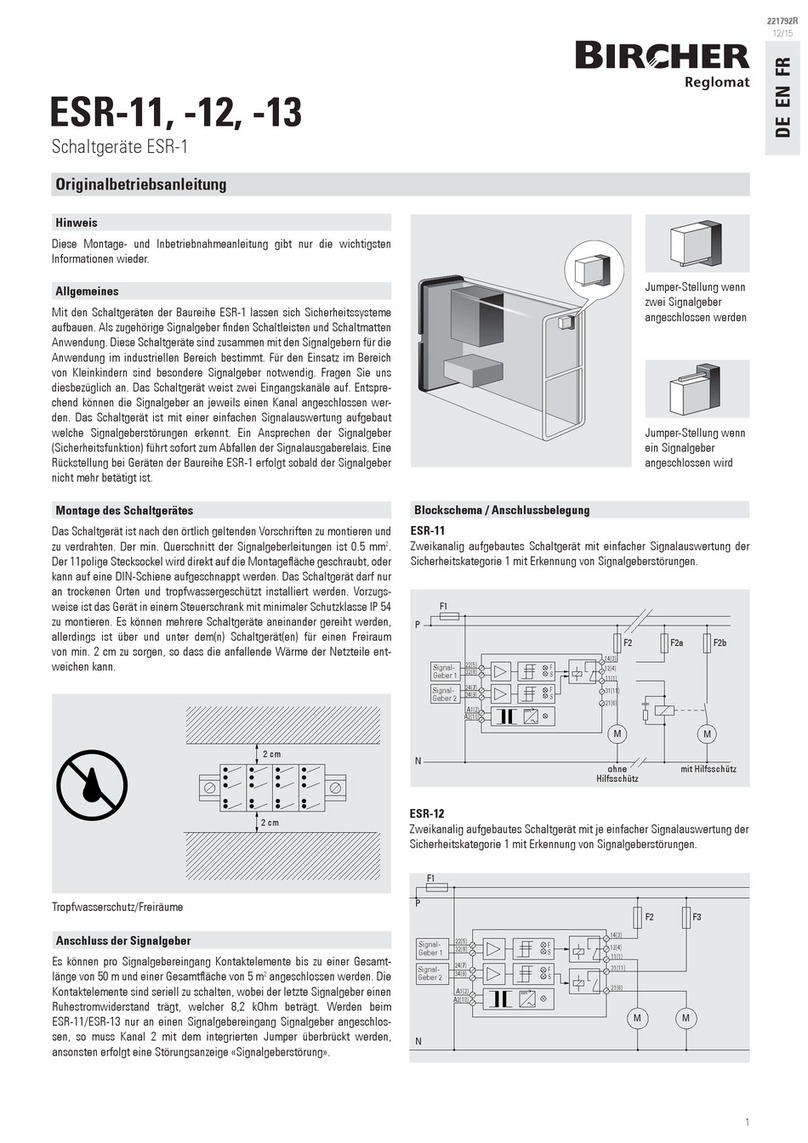

Block diagram

Function and

safety check

Function and

safety check

Safety

Output 1

Safety

Output 2

Status

Output

Power supply

Function test • Press sensor 1, check LED (orange), display (P , 1). Check if output 1 is open.

• Release sensor

• If present, press sensor 2, check LED, display (P , 2). Check if output 2 is open.

• Release sensor

After successful testing, the system is ready for operation.

Display: A and two ashing dots

4.3 Function test

Sensor 1

8k2

Sensor 2

8k2

Outputs

Contacts Unpowered Sensor 1

idle

Sensor 1

actuated

Sensor 2

idle

Sensor 2

actuated

Sensor 1 + 2

idle

Fault

Safety output 1 OPEN closed OPEN closed OPEN

Safety output 2 OPEN closed OPEN closed OPEN

Status output OPEN OPEN OPEN closed OPEN

3

Congu-

ration

Holding

time

001*

Sensor 1 + 2

001

none

End

002

Sensor 1

002

100 ms

003

Sensor 2

003*

200 ms

004

500 ms

005

1 s

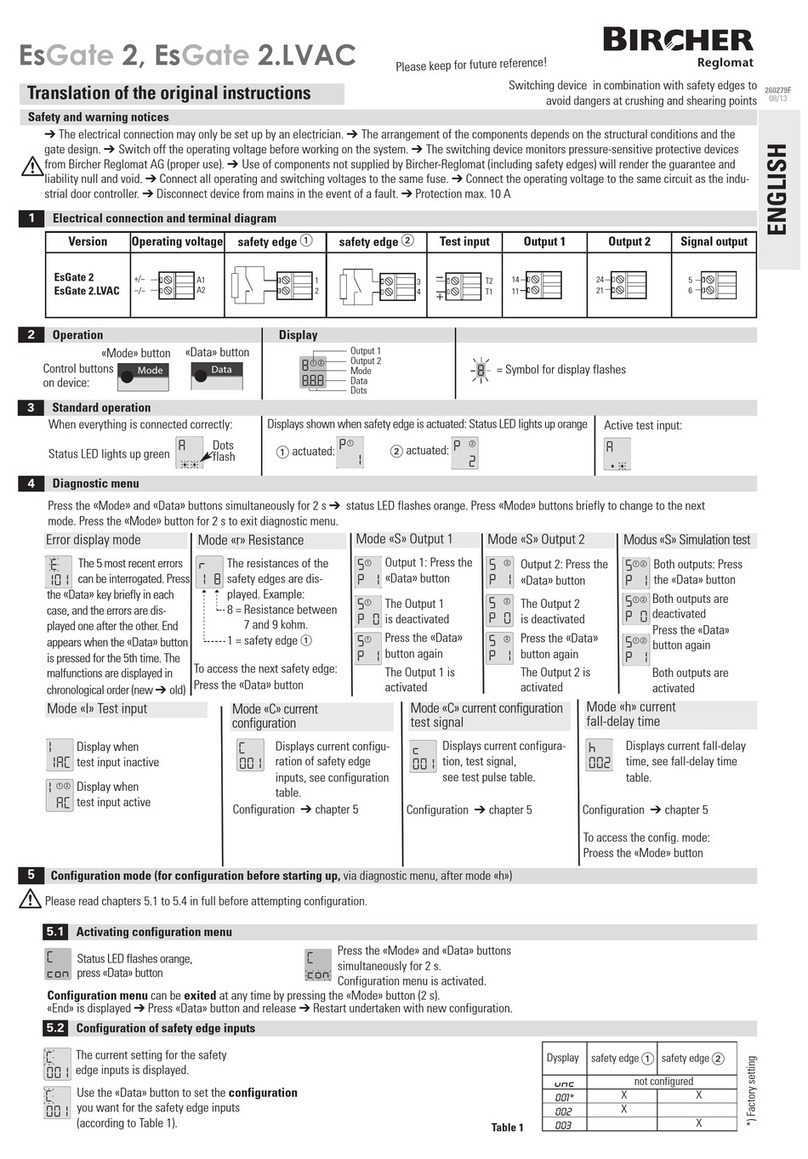

E last 5 error messages (displayed by pressing “Data”)

r current resistances of the sensors (displayed in kOhm: 1, 2, 4, 6, 8, 10, 12 or 14)

S shows the state of output 1:

output activated, 1 = current flow =ˆ okay, E = no current flow =ˆ error

(press “Data”) output deactivated, 0 = no current flow =ˆ okay, E = current flow =ˆ error

S shows the state of output 2:

output activated, 1 current flow =ˆ okay, E = no current flow =ˆ error

(press “Data”) output deactivated, 0 = no current flow =ˆ okay, E = current flow =ˆ error

S shows the state of both outputs:

outputs activated, 1 = current flow =ˆ okay, E = no current flow =ˆ error

(press “Data”) outputs deactivated, 0 = no current flow =ˆ okay, E = current flow =ˆ error

C shows the current conguration (active inputs):

001 = both inputs 1 and 2, 002 = only input 1, 003 only input 2

h The holding time (extension of the output signal):

001 = none, 002 =100 ms, 003 = 200 ms, 004 = 500 ms, 005 = 1000 ms

C conguration: entering into the conguration mode by pressing “data”→chap. 4.5

Enter Diagnostic menu:

Press “Mode” and “Data” buttons simultaneously for

2 seconds → Status LED ashes orange

To see the next parameter, press “Mode”, Data query

(Mode E and r): press “Data”

Exit Diagnostic menu:

Press “Mode” button for 2 seconds

Errors ash

r

Resistors

S

Output 1

S

Output 2

S

both

outputs

C

Congu-

ration

h

Fall-delay

time

C

Congu-

ration

Error 5

latest

1

value

1

1or E

1

1 or E

11

11 or E

C

001

h

002

con

Error 4 2

value

0

0 or E

0

0 or E

00

00 or E

con

(ashing)

Error 3

Error 2

Error 1

End

›

›

›

›

››

› › › ›

›

›

›

2 sec

* Factory setting

4.5 Conguration mode (edit mode)

4.4 Diagnostic menu (read only)

Data Back to

start

Mode

›

›

›

›

Back

to top

›

›

›

› › › › › › ›

2 sec

Access Conguration

(see chapter 4.5)

On initial commissioning, the device must be adapted (congured)

to the application.

Conguration

• Press the “Mode” button to select the requested parameter.

• Press the “Data” button to set the value.

Exit Conguration menu:

Press “Mode” until “h End”, than press “Data”.

Adjustable parameters:

C active inputs: 001 = both inputs 1 and 2, 002 = only input 1,

003 only input 2

h The holding time (extension of the output signal):

001 = none, 002 =100 ms, 003 = 200 ms, 004 = 500 ms, 005 = 1000 ms

›

›

›

›

›

›

›

›

›

›

› › ››

Exit

Conguration

menu

›

{

{

›

To enter Conguration menu (see also chapter 4.4):

• Enter diagnostic menu: Press “Mode” and “Data” buttons simultaneously for 2 seconds → Status LED ashes orange.

• Press “Mode” repeatedly until “C” and “con” are displayed.

• Press “Data” button, “con” starts ashing.

• Press “Mode” and “Data” buttons simultaneously until “con” stops ashing.

• Release “Mode” and “Data”, “C” starts ashing, both safety outputs open.

E

C

h

h

4

Designed in Switzerland / Made in EU

BBC Bircher Smart Access, BBC Bircher AG, Wiesengasse 20, CH-8222 Beringen, www.bircher.com

4.6 Service mode

4.7 Error displays

5Technical Data

Supply voltage EsGate 3: 24 V AC/DC, ±15%

EsGate 3.LVAC: 100 – 240 V AC, 50/60 Hz

Power consumption max. 3 VA

Inputs sensors for sensors with 8,2 kOhm termination

Safety outputs

Solid state relays, 24 V DC,

min. 0.5 mA, max. 50 mA

internally protected by a fuse

RDS (on) ca. 60 Ω

Status output Solid state relays, 24 V AC/DC,

max. 50 mA, RDS (on) ca. 30 Ω

Reaction time

(at activation)

< 20 ms

Start-up time < 500 ms

Housing Polyamide grey / red

Dimensions 22,5 x 94 x 88 mm (W x H x D)

Mounting Direct DIN-rail mounting

Terminals Pluggable screw terminals

Protection class IP30

Operating temperature –20°C to +60°C

Storage temperature –40°C to +70°C

Humidity < 95% non-condensing

8Contact

Data Back to

start

Mode

›

›

Back

to top

Enter Service mode: Press “Data” for 10 seconds

→ Green status LED ashes

To show the next parameter, press “Mode”

Data query in each mode: press “Data” button

Exit Service mode: Press “Mode” button for 2 seconds

In the service mode, further information can be displayed:

H Hardware Version

S Software Version

t Type (Cat. acc. to EN ISO 13849-1)

U Internal supply voltage

o Current chip temperature

E The last ve error messages (displayed by pressing “Data”)

E rES: press and hold “Data” button until --- is displayed to reset

the error messages

Should other fault messages appear, please contact your supplier.

12If an error is detected both safety outputs are deactivated and symbols & and an error code are displayed.

The status LED lights up red.

Display E001 E002 E006 E007 E008 E101 E102

Error Sensor 1

wiring defective

Sensor 2 wiring

defective

Conguration mode

incorrectly set

Undervoltage Overvoltage

Outputs not OK

Remedy Check sensor 1 Check sensor 2 Check congura-

tion

Check output wiring Check supply

H

Hardware

version

S

Software

version

t

Type

U

Supply

voltage

o

Internal

temperature

E

Errors

ash

E

Errors

ash

005 5.12 3 value value Error 5

latest rES

Error 4 ---

Error 3

Error 2

Error 1

End

›

›

›

› › › › ›

› › › ›› ›

›

10 sec

2 sec

6EU Declaration of Conformity 7WEEE

See attachment Devices with this symbol must be treated separately during disposal.

This must be done in accordance with the laws of the respective coun-

tries for environmentally sound disposal, processing and recycling of

electrical and electronic equipment.

Other Bircher Switch manuals

Popular Switch manuals by other brands

Festo

Festo SMTSO-1 Series manual

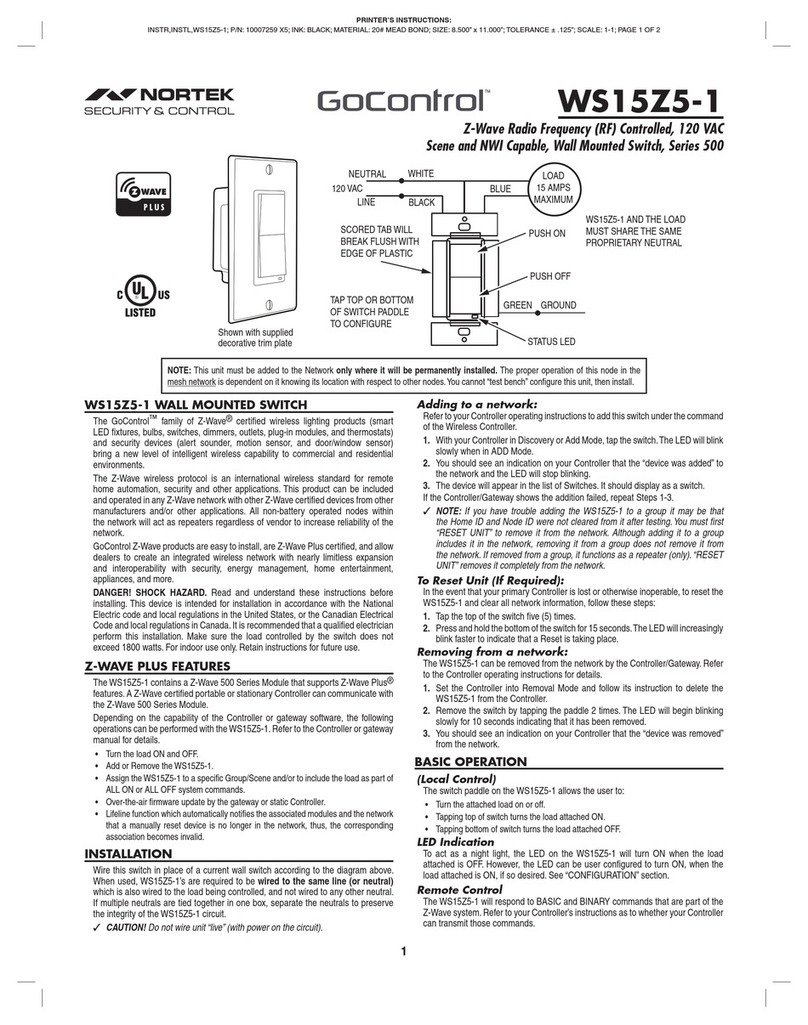

Nortek

Nortek GoControl WS15Z5-1 manual

Altronix

Altronix NetWaySP4 installation guide

H3C

H3C s5820x series ACL and QoS Command Reference

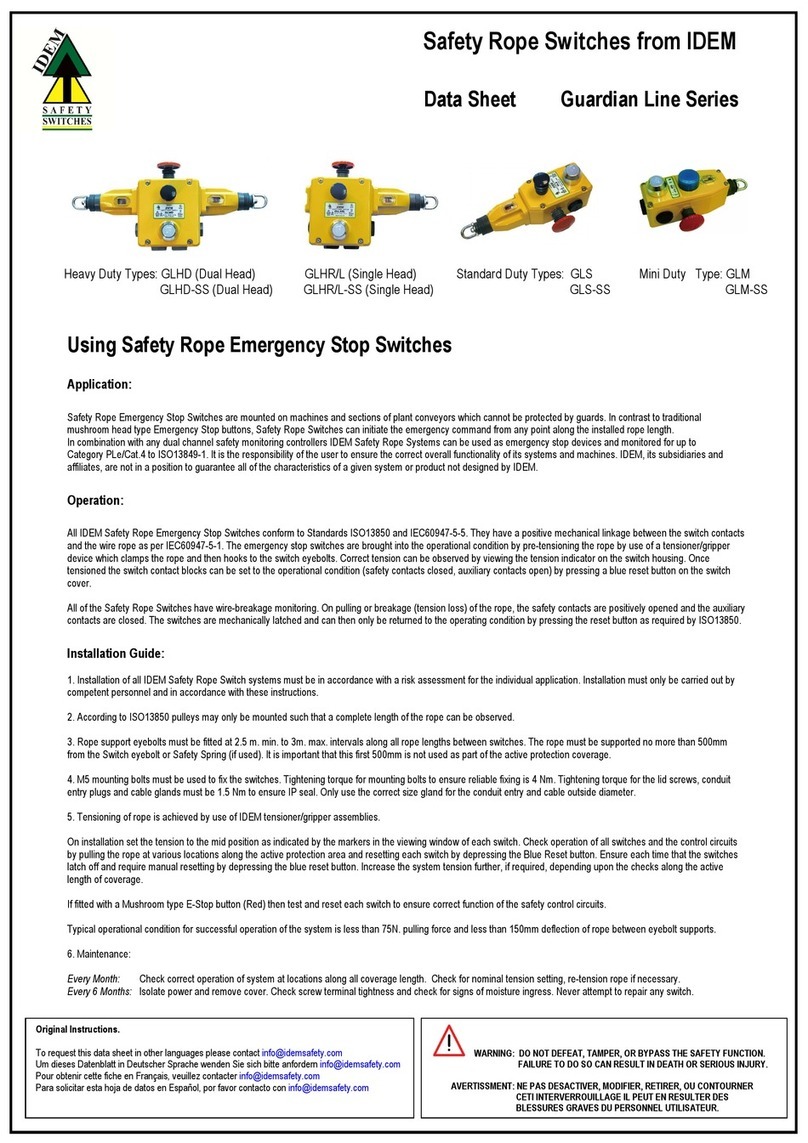

IDEM SAFETY SWITCHES

IDEM SAFETY SWITCHES Guardian Line Series datasheet

Power-Genex

Power-Genex LSB-1000 Series Instructions and operating manual