Bism Neleus RX Series User manual

RX (NELEUS)

RK (re//brass)

RB (Beans)

RS (SUMERGE)

Regulators

OPERATING MANUAL

Introduction

Thank you for purchase of our product.

This manual is the guidebook to provide instructions

on how to use your single hose type regulator

(hereinafter just called regulator) of open circuit

scuba for recreational diving.

We believe this manual is useful in mastering

technology of a regulator for people who have learned

the right usage of a regulator and obtained a C-card

through proper training at a diving instruction

organization as well as people who use it at C-card

training. Please carefully read and digest the

contents of this manual before use. We also suggest

that you take this manual with you to refer to before

diving.

Keep this manual in a safe place. If you lose it,

contact your original dealer or authorized

distributor of our company. A replacement manual will

be reissued later.

The main contents consist of the check before use,

usage, care after use, storage, and a periodic

inspection.

This product is diving gear to use in combination

with gauges, octopus and B.C., etc. for recreational

diving. Therefore, the knowledge of the right

handling of combination equipment is also necessary.

Please use the operating manual of the combination

equipment which you use as well as this manual.

In addition, depending on the model of gauges,

octopus, low pressure hose for B.C. and dry suit to

be attached to the first stage, it is considered not

being suitable for the use by the combination with

this product. We recommend you use by the combination

with the equipment made by Bism.

We are constantly researching and improving our

Regulators, and so the product you purchased may

differ in certain details from the one described in

this manual. If you have any queries regarding your

regulator or the information contained in this

manual, please feel free to contact our company at

the address lower right.

CONTENTS

Introduction ・・・・・・・・・・・・・・・・1

Important Infomation

・・・・・・・・・・・ 2

Special Features ・・・・・・・・・・・・・・2

Precaution is

・・・・・・・・・・・・・・・ 3

Names of Parts & Specifications ・・・・・4~8

Installation of Various Hoses ・・・・・・・・9

Check before Use & Setting ・・・・・・・・10

Basic Usage ・・・・・・・・・・・・・・・・11

Care after Use & Storage ・・・・・・・・・・12

Periodic Inspection & Service after the Sales・13

Troubleshooting ・・・・・・・・・・・・・・14

Key to Symbols Used in this Manual

Danger

Warning

Caution

【Note】 Useful Information to know.

Bism CORPORATION

5F, NF Bldg., Higashinihonba shi, Chuo—ku, Tokyo Japan 103-0004

Phone: +81-3-5640-8126 Fax: +81-3-5640-8131

E-mail: info@bism.co.jp URL: http://www.bism.co.jp

Danger indicate a great risk of death or

serious injury from improper use.

Warning indicate a risk of death or serious

injury from improper use..

Caution indicate a risk of minor injury or

damage to property from improper use.

Before Use

It is vital to safety that you use and maintain your regulator correctly and have it inspected periodically. Carefully

read and understand the advice on safety given in the manuals of this product and also the combination equipment which

you use before diving.

Warning

● Do not use this product for any purpose other

than recreational diving.

■ Use only for recreational diving.

Warning

● Use this product after having obtained a C-card

and completing a proper training program at a

recognized diving school, and be familiar with

the product, or under the instruction of the

diving school. Otherwise it may cause an accident

resulting in injury or death.

■ Obtain C-card before use.

Warning

● When you use this product, please follow all the

instructions about the safety directed in this

operating manual.

■ Please follow instructions about safety.

Warning

● Do not use this product if it is not functioning

normally.

● If your regulator starts to function abnormally,

contact your original dealer or authorized

distributor of our company. Using a faulty

regulator may cause an accident resulting in

injury or death.

■ Do not use if functioning abnormally.

IMPORTANT INFORMATION

Purpose of Use

This product is diving gear for recreational diving use.

The connection with the cylinder for scuba (hereinafter called“tank”) allows the use and is a breathing apparatus

supplying of air in the tank at the time of recreational diving.

The Features of this Product

SPECIAL FEATURES

Since the second stage and a low-pressure hose are connected by the double swivel mechanism, the 360-degree rotation to back and forth and

around is possible for the second stage. As it follows a motion of a diver's face naturally, you can use it comfortably.

The balance twin piston designed to supply stable air depending on depth is adopted to the first stage.

Adding the Primary Low-Pressure Port only for the main second stage, natural inhalation feeling with large flow and low resistance is realized.

The lightweight exclusive plastic hose is adopted as a low-pressure hose. Since it is no odor nature (Food Sanitation Act conformity hose), the

air to supply is also clean. In addition, its excellent flexibility also reduces the stress of your month.

The flow of the second stage can be arbitrarily adjusted with the FCV mechanism installed in the double swivel portion according to a diver's

vital capacity, a breathing pattern, and dive depth.

2

■ Adoption of Balance Twin Piston

■ Adoption of Primary Low-Pressure Port (PLP)

■ Adoption of Double Swivel

■ Adoption of an exclusive plastic hose

■ Adoption of Flow Control Valve (F.C.V.) (Except RB3010・3011, RS3000)

A feeling of inhalation improves by adoption of the Turbo Lever.

■ Adoption of Spiral Flow EX (RX・RK・RB3400.3401)

End configuration of couplings for regulator hose is changed into the full conformity form of ANSI.Z86.7.2 of the U.S. diving industry standard

from the JIS threads.

■ Global standard correspondence of couplings for regulator hose.

The first stage of RX series corresponds to the low water temperature.

■ First stage (RX) corresponding to the low water temperature (4℃ )

The Spiral Flow designed to supply light and stable air even in the great depth is adopted to the second stage.

■ Adoption of Spiral Flow (Except RB3010, RS3000)

Warning

● Please do not fold or pull a hose. It

not only breaks, but it may cause an

accident resulting in injury or death.

□ Do not fold or pull a hose.

□ Avoid contact with chemicals.

If mercury and chemicals (thinner, gasoline

and various solvents or those cleaner,

adhesives, paint, medicine and cosmetics

which are containing them) adhere,

discoloration and breakage may be occurred on

the main body and hoses.

□ Please use designated grease.

Please apply the designated grease to the

designated portion only. Breakage may be

caused, if greases other than designated are

used or you apply to the portion out of the

designation. (Please refer to “Installation

of Various Hoses”in the page 9)

Warning

● This product is designed to attach to

the tank which can fill up 250bar or

less with the air in the atmosphere.

Therefore, the tank with pure oxygen or

high fraction of oxygen cannot be used.

● Please do not use the tank with the

fraction of oxygen of greater than 40%

for the regulator made out of titanium.

Ignition and combustion is generated,

and it may cause an accident resulting

in injury or death.

□ Check the tank to use.

□ Follow the safety rules.

Only use under the direction of a recognized diving school or

after obtaining a C-card having completing a proper training

program at a recognized diving school and thoroughly

familiarizing yourself with the correct use of a regulator.

Have your buddy double check everything.

Avoid diving deeper than 30m/98ft. (This is the maximum safe

depth for normal recreational diving.)

□ Please use the Bism made hose guard.

Please do not attach hose guards and hose protectors other than

our products to a low-pressure hose. It may cause hose breakage.

□ Avoid shocks.

Though the product can withstand the shock in

the usual use, drops and hard knocks may

damage it.

Warning

● It is a regulator for recreational diving to use in

the normal water area (the ocean, a lake, fresh water

and seawater swimming pool). You cannot use it in

special environment containing a medicine, a solvent,

oil, etc.

□ Do not use it in special environment.

PRECAUTIONS

□ Do not modify the product.

Since it may become a safety problem, please

do not modify the product. Responsibility

cannot be taken about the trouble after

modification.

Warning

● A regulator does not operate

normally when the water pressure

sensor hole of the first stage and

the second stage of the regulator is

blocked up. Please do not block up

the water pressure sensor hole.

□ Do not block up the water pressure sensor hole.

3

Oxygen

Grease

Gasoline

4

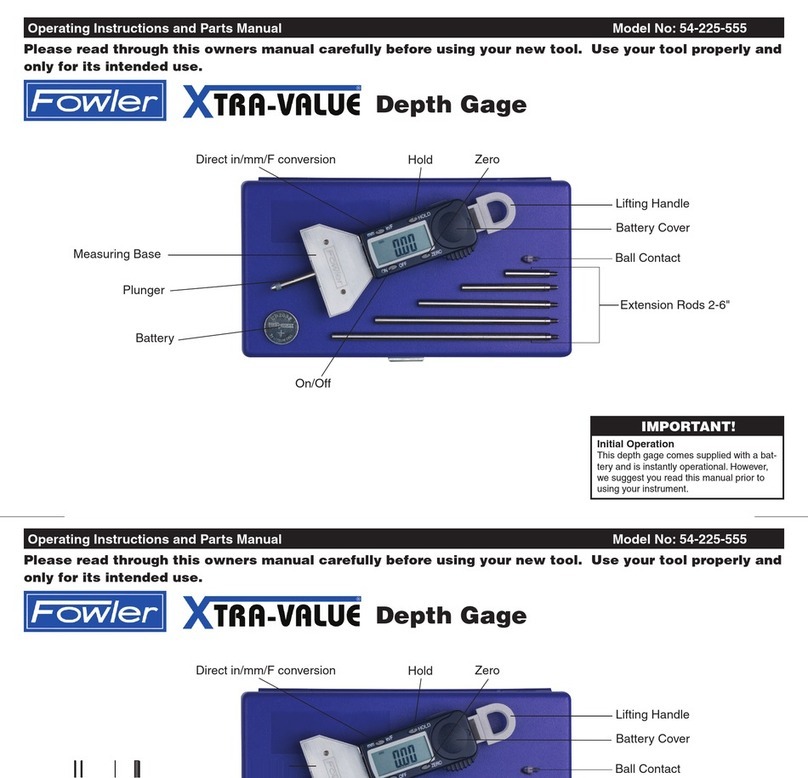

NAMES OF PARTS & SPECIFICATIONS

Names of Parts Names of Parts

Specifications Specifications

Weight …………………………… 460 g

Height …………………………… 60 mm

Working Pressure…………………… 250 bar

Intermediate Pressure (L.P. /P.L.P.) Port…4 ports (3/8-24UNF)

High Pressure (H.P.) Port ………… 2 ports (7/16-20UNF)

Temperature Range ………………… + 4 ~+ 50℃

Decompression Method ……………………… Balance Twin Piston

Material ………………………… Titanium

Surface Treatment DLC Coating (RX3400PT)

Weight …………………………… 460 g

Height …………………………… 60 mm

Working Pressure…………………… 250 bar

Intermediate Pressure (L.P. /P.L.P.) Port…4 ports (3/8-24UNF)

High Pressure (H.P.) Port ………… 2 ports (7/16-20UNF)

Temperature Range ………………… + 4 ~+ 50℃

Decompression Method ……………………… Balance Twin Piston

Material ………………………… Titanium

Weight (Including Hose)… 360 g

Width of Exhaust Tee………… 90 mm

Operation Method……………… Combined Use of Diaphragm and Downstream

Temperature Range………… + 4 ~+ 50℃

Material Body Case: POM Plastic

Face Cover: Titanium

Mouth Piece: Silicone Rubber

Valve: Titanium, POM Plastic

Surface Treatment PTIP Treatment (RX3400PT)

Weight (Including Hose)… 365 g

Width of Exhaust Tee………… 90 mm

Operation Method……………… Combined Use of Diaphragm and Downstream

Temperature Range………… + 4 ~+ 50℃

Material Body Case: POM Plastic

Face Cover: Aluminum Alloy

Mouth Piece: Silicone Rubber

Valve: Titanium, POM Plasti

Surface Treatment Hard Anodizing Coating

RX3400/3410 RX3411

First Sta First Stage

Second Stage Second Stage

HP

PLP

PLP

Mouth Piece

Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

Dust Cap

HP

PLP

PLP

Mouth Piece

Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

Mouth Piece

Purge Button

Water Pressure

Senser Hole

Face Cover

Dust Cap

Dust Cap

NAMES OF PARTS & SPECIFICATIONS

Names of Parts Names of Parts

Specifications Specifications

Weight …………………………… 460 g

Height …………………………… 60 mm

Working Pressure…………………… 250 bar

Intermediate Pressure (L.P. /P.L.P.) Port…4 ports (3/8-24UNF)

High Pressure (H.P.) Port ………… 2 ports (7/16-20UNF)

Temperature Range ………………… + 4 ~+ 50℃

Decompression Method ……………………… Balance Twin Piston

Material ………………………… Titanium

Weight …………………………… 460 g

Height …………………………… 60 mm

Working Pressure…………………… 250 bar

Intermediate Pressure (L.P. /P.L.P.) Port…4 ports (3/8-24UNF)

High Pressure (H.P.) Port ………… 2 ports (7/16-20UNF)

Temperature Range ………………… + 4 ~+ 50℃

Decompression Method ……………………… Balance Twin Piston

Material ………………………… Titanium

Weight (Including Hose)… 340 g

Width of Exhaust Tee………… 90 mm

Operation Method……………… Combined Use of Diaphragm and Downstream

Temperature Range………… + 4 ~+ 50℃

Material Body Case: POM Plastic

Face Cover: ABS Plastic

Mouth Piece: Silicone Rubber

Valve: Titanium, POM Plastic

Weight (Including Hose)… 365 g

Width of Exhaust Tee………… 90 mm

Operation Method……………… Combined Use of Diaphragm and Downstream

Temperature Range………… + 4 ~+ 50℃

Material Body Case: POM Plastic

Face Cover: ABS Plastic

Mouth Piece: Silicone Rubber

Valve: Titanium, POM Plastic

RX3430K RX3430W

First Stage First Stage

Second Stage Second Stage

5

HP

PLP

PLP

Mouth Piece

Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

Mouth Piece Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

Dust Cap

HP

PLP

PLP

Mouth Piece

Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

Mouth Piece Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

Dust Cap

6

NAMES OF PARTS & SPECIFICATIONS

Names of Parts Names of Parts

Specifications Specifications

Weight …………………………… 45560 g

Height …………………………… 63 mm

Working Pressure…………………… 250 bar

Intermediate Pressure (L.P. /P.L.P.) Port…4 ports (3/8-24UNF)

High Pressure (H.P.) Port ………… 2 ports (7/16-20UNF)

Temperature Range ………………… + 4 ~+ 50℃

Decompression Method ……………………… Balance Twin Piston

Material ………………………… Titanium

Weight …………………………… 790 g

Height …………………………… 60 mm

Working Pressure…………………… 250 bar

Intermediate Pressure (L.P. /P.L.P.) Port…4 ports (3/8-24UNF)

High Pressure (H.P.) Port ………… 2 ports (7/16-20UNF)

Temperature Range ………………… + 5 ~+ 50℃

Decompression Method ……………………… Balance Twin Piston

Material ………………………… Cupper Alloy

Weight (Including Hose)… 385 g

Width of Exhaust Tee………… 90 mm

Operation Method……………… Combined Use of Diaphragm and Downstream

Temperature Range………… + 4 ~+ 50℃

Material Body Case: POM Plastic

Face Cover: ABS Plastic

Mouth Piece: Silicone Rubber

Valve: Copper Alloy, POM Plastic

Weight (Including Hose)… 440 g

Width of Exhaust Tee………… 90 mm

Operation Method……………… Combined Use of Diaphragm and Downstream

Temperature Range………… +5~+ 50℃

Material Body Case: POM Plastic

Face Cover: Copper Alloy

Mouth Piece: Silicone Rubber

Valve: Copper Alloy, POM Plastic

RX3440K RK3400

First Stage First Stage

Second Stage Second Stage

HP

PLP

PLP

Mouth Piece Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

Dust Cap

HP

PLP

PLP

Mouth Piece

Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

Dust Cap

7

Names of Parts Names of Parts

Specifications Specifications

Weight …………………………… 790 g

Height …………………………… 60 mm

Working Pressure…………………… 250 bar

Intermediate Pressure (L.P. /P.L.P.) Port…4 ports (3/8-24UNF)

High Pressure (H.P.) Port ………… 2 ports (7/16-20UNF)

Temperature Range ………………… + 5 ~+ 50℃

Decompression Method ……………………… Balance Twin Piston

Material ………………………… Cupper Alloy

Weight …………………………… 790 g

Height …………………………… 60 mm

Working Pressure…………………… 250 bar

Intermediate Pressure (L.P. /P.L.P.) Port…4 ports (3/8-24UNF)

High Pressure (H.P.) Port ………… 2 ports (7/16-20UNF)

Temperature Range ………………… + 5 ~+ 50℃

Decompression Method ……………………… Balance Twin Piston

Material ………………………… Cupper Alloy

Weight (Including Hose)… 380 g

Width of Exhaust Tee………… 90 mm

Operation Method……………… Combined Use of Diaphragm and Downstream

Temperature Range………… + 5 ~+ 50℃

Material Body Case: POM Plastic

Face Cover: ABS Plastic

Mouth Piece: Silicone Rubber

Valve: Copper Alloy, POM Plastic

Weight (Including Hose)… 370 g

Width of Exhaust Tee………… 90 mm

Operation Method……………… Combined Use of Diaphragm and Downstream

Temperature Range………… +5~+ 50℃

Material Body Case: POM Plastic

Face Cover: ABS Plastic

Mouth Piece: Silicone Rubber

Valve: Copper Alloy, POM Plastic

RB3400/3401 RB3010/3011

First Stage First Stage

Second Stage Second Stage

HP

PLP

PLP

Mouth Piece

Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

Mouth Piece

Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

Dust Cap

Dust Cap

HP

PLP

PLP

Dust Cap

Mouth Piece

Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

Dust Cap

Mouth Piece Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

FCV Knob

Yoke Screw Yoke H.P. Port

P.L.P. port

NAMES OF PARTS & SPECIFICATIONS

8

Nominal Size of Coupling Threads………………… 3/8-24UNF

Hose Working Pressure…………… 15 bar

Minimum Bending Radius (Inside of Hose)… 15 m m

Hose Guard

……………………… Regular Equipment

Material: Elastomer Plastic

Hose Length……………………… RX,RK,RS : 750 mm

RB3400・3401,RB3010・3011 : 700 mm

Outer Diameter……………………………… 13 mm

Material of Inner Tube and Outer Cover…………Vinyl Chloride

ChlorideMaterial of Couplings…………………… Copper Alloy

NAMES OF PARTS & SPECIFICATIONS

Names of Parts

Specifications

Specifications

Weight …………………………… 790 g

Height …………………………… 60 mm

Working Pressure…………………… 250 bar

Intermediate Pressure (L.P. /P.L.P.) Port…4 ports (3/8-24UNF)

High Pressure (H.P.) Port ………… 2 ports (7/16-20UNF)

Temperature Range ………………… + 5 ~+ 50℃

Decompression Method ……………………… Balance Twin Piston

Material ………………………… Cupper Alloy

Weight (Including Hose)… 375 g

Width of Exhaust Tee………… 90 mm

Operation Method……………… Combined Use of Diaphragm and Downstream

Temperature Range………… +5~+ 50℃

Material Body Case: POM Plastic

Face Cover: ABS Plastic

Mouth Piece: Silicone Rubber

Valve: Copper Alloy, POM Plastic

RS3000 COMMON

First Stage

Hose

Second Stage

HP

PLP

PLP

Dust Cap

Mouth Piece Purge Button

Water Pressure

Senser Hole

Face Cover

Low Pressure Hose

Double Swivel

Yoke Screw Yoke H.P. Port

P.L.P. port

Installation of High Pressure Hoses

Warning

● Please install the high pressure hose to an H.P. port,

and only the thread size of 7/16-20UNF of high pressure

hose couplings should be connected. Otherwise, not only

it causes the damage of equipment, but also a hose comes

off and it may cause an accident resulting in injury or

death.

Warning

● Please install the high pressure hose to an H.P. port,

and only the thread size of 7/16-20UNF of high pressure

hose couplings should be connected. Otherwise, not only

it causes the damage of equipment, but also a hose comes

off and it may cause an accident resulting in injury or

death.

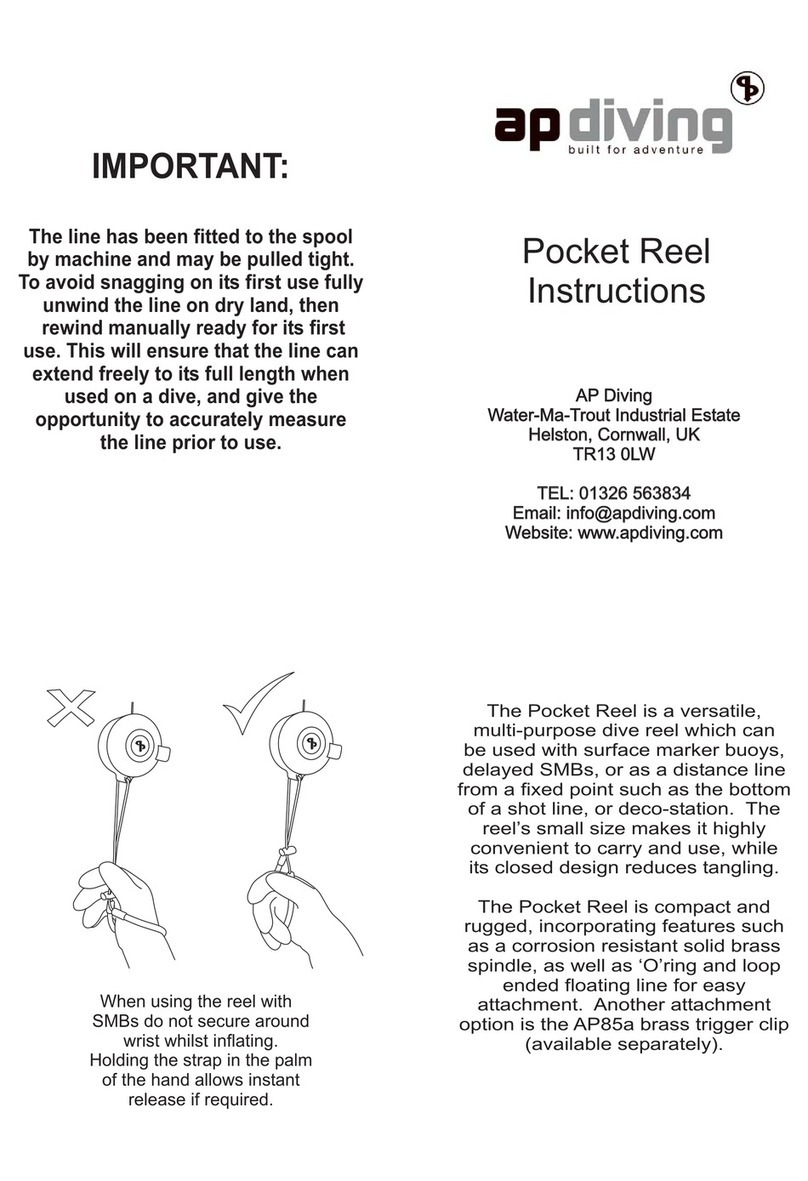

Installation of Low Pressure Hoses

* High Pressure Hose: It means the hose for pressure gauge here. * Low Pressure Hose: The hose for safety second.

B.C. hose.

Air supply hose for dry suit.

Please remove the plug from the H.P. port of the first stage of

a regulator.

1 1

Please

screw in the coupling of a high pressure hose to H.P. port and turn it clockwise

with a spanner to tighten it. Tightening torque is 9.8 N・m (100 kgf・m).

2 2

Please remove the plug from the L.P. port of the first stage of

a regulator.

Please screw in the coupling of a low pressure hose to L.P. port and turn it

clockwise with a spanner to tighten it. Tightening torque is 9.8 N・m (100 kgf・m).

9

INSTALLATION OF VARIOUS HOSES

Caution

● Please ask the authorized distributor of our company for installation of high and low pressure hoses and

plugs.

● When you tighten hose couplings with a spanner, please keep the tightening torque (1/36 turns from a

tightening start) of 9.8N・m (100kgf・cm). Otherwise it may cause to damage the threads portion. In the

case of the value of tightening torque listed in the operating manual of a tightened side (gauge, safety

second, etc.) is smaller than 9.8N, m, please follow the value.

Warning

● Please attach a hose in the state that the first stage of a regulator is not connected

to a tank. If the first stage is pressurized during work, a plug in the port flies and

it is dangerous.

● Please confirm that O-rings are set at the threads portion of each hose. When there are

no O-rings, it causes the air leakage.

Check of the hoses.

Check of the air leakage.

Check of the air intake and exhaust.

Check if there is any air leakage on the first and second stage of

regulator, connecting portion of hose and hose itself.

Please hold a mouthpiece in your mouth, breathe with a mouth 4 ~ 5

times, and check that air flows normally.

Check that the O-ring is attached to the tank valve.

(1)

Turn a yoke screw to the right, and tighten it until the end

connection stops shaking.

(3)

Making the direction of the second stage of a regulator so as it

comes out of a right shoulder, and put a yoke so that the end

connection of the first stage of a regulator may suit the groove

of the O-ring of the tank valve.

(2)

Open the tank valve slowly and once it gets to full open, return

by half-rotation.

(5)

【Note】

○ A tank valve also has a kind. The question about a tank valve

should read the operating manual of the tank valve.

Bite the projection portion of a mouthpiece lightly with your teeth,

and hold it in your mouth so that the whole may be covered with lips.

Cover with your lips.

How to Hold a Mouthpiece in Your Mouth.

Caution

● Please do not bite the projection portion of a

mouthpiece strongly. You may cut it off, if you

bite strongly.

Warning

● If there is an abnormality in your regulator by following various checks, you must not use it.

● When there is an abnormality, contact your original dealer or authorized distributor of our company. Use

of the regulator which is not normal may cause an accident resulting in injury or death.

Before setting your regulator to a tank valve, please check whether

the hose is damaged and has not broken.

All the hoses, such as a hose of the safety second connected to the

first stage and a high pressure hose, are to be checked.

Setting the regulator to a tank.

Warning

● After setting, when air does not come out from the

second stage of the regulator normally, please do

not use it.

● When the inhaled air has a smell, please stop to

use the tank and change for other tanks. When the

air still has a smell even if you change a tank,

please stop to use the regulator.

Caution

● Please do not tighten a yoke screw too much

strongly. It may be unable to take off after use.

10

Check of the second stage.

Check if there is any crack in each part of the second stage by

visual.

Warning

● Please check whether the face cover is

tightened enough.

If not, please retighten it.

Before opening the tank valve, please hold a mouthpiece in your

mouth and inhale air to check if the air does not leak and does

not come in to your mouth.

(4)

Warning

● Please open a tank valve after

checking that the regulator is set to

a tank in the right direction, and

that the yoke screw is tightened

firmly.

● Please open the tank valve slowly.

CHECK BEFORE USE & SETTING

1

2

4

5

3

Bite with your teeth.

Warning

● Please be sure to breathe, after draining by performing

regulator clearing before inhaling air.

It may cause drowning by drinking water accidentally.

● If it carries out in the state that regulator clear is

not mastered, it may cause drowning by drinking water.

Please perform practice of regulator clear under

instruction of a diving school.

Warning

● Please do not bite the projection

portion of a mouthpiece strongly.

Otherwise, as you may cut it off,

and there is a possibility of

becoming easy to separate from a

mouth which leads to be drowned,

thus it may cause an accident

resulting in injury or death.

● Please hold the second stage in your

mouth so that a hose installed

portion comes to a lower position.

Breathing

After holding a mouthpiece in your mouth and performing regulator

clear, breathe with your mouth deeply and slowly.

How to Hold a Mouthpiece

Please hold it in your mouth so that a

mouthpiece comes to an upper position and a

hose comes to a lower position.

Regulator Clearing

Before inhaling air, perform discharge operation of water which

entered in the second stage of a regulator. (Regulator Clear)

【Note】

○ Water can be effectively discharged by taking an upward slanting

posture.

If a Free Flow is Carried Out・・・

▼ Please plug up the hole of a

mouthpiece with a palm or a finger.

Caution

● Although a free flow may be carried out from the

second stage of a regulator immediately after an

entry, if you cannot stop it by the method

explained below, please stop use.

■ Regulator Clearing with the Purge Button.

In the state of holding a mouthpiece in

your mouth, depress the purge button

while exhaling.

Since water may remain, inhale air

slowly so that you may not drink water,

and if the water still remains carry out

the same once again.

■ Regulator Clearing by Exhaling.

In the state of holding a mouthpiece in

your mouth, exhale air strongly to blow

off the water in the second stage.

Since water may remain, inhale air

slowly so that you may not drink water,

and if the water still remains carry out

the same once again.

【Note】

○ While breathing, if a face cover side of a

regulator is turned to the surface, breathing

resistance will increase.

Exhale air strongly.

▼ Turn mouthpiece downward

underwater.

By the direction of second stage, such as immediately after an entry,

air may blow off from a mouthpiece portion. It is not failure when it

stops by the following method.

Operation Method of FCV (Flow Control Valve).

The flow (feeling of an inhalation) of a second stage can be adjusted

at the discretion of a diver. An adjustable range is about 4 rotations

of knob.

■ FCV knob is turned to the (-) side.

→ The flow of air decreases.

■ FCV knob is turned to the (+) side.

→ The flow of air increases.

In the case free flows generates on land and

in the water of shallow depth before or after

diving, turn the FCV knob to the (-) side to

decrease the flow of air.

Warning

● If you feel the shortage of air flow during

diving, please turn a FCV knob to the (+) side

immediately to adjust the air flow. If diving is

continued in the state of insufficient air flow,

condition, such as headache, dizziness and

nausea, is occurred and it may cause accident

resulting in injury or death.

Caution

● A free flow may be generated, if a FCV knob is

adjusted to the (+) side when on land and in the

water of shallow depth.

● When you adjust a FCV knob to the (+) or (-)

side, please do not turn a FCV knob by force from

an adjustment limit position (position at which

the knob stopped). Parts may be damaged.

11

BASIC USAGE

Removal from a Tank.

Close a tank valve.

1

1

Push a purge button to release the air inside a regulator

completely.

2

2

Caution

● Please be sure to release the compressed air in a

regulator, before working to remove the first

stage of a regulator from a tank valve. If it is

not released, it may lead an explosion and cause

an accident resulting in injury or death.

Wash.

Soak the whole equipment to

fresh water for about 15

minutes in the state of

being set with the

regulator. Then, rinse the

whole in water to wash the

salt away.

Caution

● Equipment may be damaged if soaked in hot water

of 50℃ or more.

● Please do not push purge button of the second

stage of a regulator by any means during washing.

Water comes in and may cause the trouble.

● Please be sure to put the dust cap of the first

stage of a regulator firmly. Otherwise water

comes in the gauge and hose, and it causes

failure.

Loosen yoke screw and remove a regulator.

3

Pour water on the groove

portions of mouthpiece and

face of second stage, and

rinse them.

After removing the water of the dust cap enough with an air blow

or a towel, turn a yoke screw and fix to the connecting portion

of the first stage of a regulator firmly.

4

【Note】

○ When you push the purge button of the second stage of a regulator

by accident during washing, connect the first stage to a tank again

and push the purge button to blow off internal water. Then, contact

your original dealer or authorized distributor of our company.

■ Wash and dry a regulator fully.

■ Avoid direct rays, and store a regulator after making it fully dry

in the shade with the dry, cool and sufficient ventilation.

Drying-Out and Storage

Caution

● Please keep the hose in a natural form. Forced

bending causes kinking of a hose and shorten a

hose life remarkably.

● If you leave a regulator in

the state of high

temperature, such as in a car

or on a beach, it may

interfere with a function.

● When a translucent mouthpiece

and white parts (hose etc.)

are left under sunlight or a

fluorescent light for a long

time, it may yellow.

Moreover, if they touch

rubber commodities, such as a fin, for a long

time, a color of the rubber may stain.

12

CARE AFTER USE & STORAGE

To the customer who equipped a humidification

device.

Warning

● According to the instruction manual of the

humidification device, please be careful so that

water and cleaning solution are not in the inside

of the first stage. When water enters, please stop

use, and contact your original dealer after

removing the internal water. Rust and corrosion

may cause failure, and the pollution of the

breathing air may cause an accident resulting in

injury or death.

【Note】

● Some parts carry out natural deterioration. Exchange of such parts

is also performed by periodic check.

Warning

● Please ask your original dealer or authorized

distributor of our company for a periodic

inspection per once in a year or once in every

100 dives.

● Regardless whether or not you use it, regulator

may not function normally when you ignore a

periodic inspection.

■ Please ask your original dealer or authorized distributor of our

company for a periodic inspection per once in a year. (Pay Service)

Service after the Sales

□ When your regulator is out of condition, check it first.

Please refer to the clause of "Troubleshooting" and check whether it is failure.

□ When it is still out of order;

Please contact your original dealer or authorized distributor of our company.

□ Reserving period of parts.

Our company reserves the performance parts (the parts required to maintain the function of the product) for

repairing a regulator for at least 8 years after the production is discontinued. Since repair may be

possible depending on a problem even after this reserving period passes, please consult with your original

dealer or authorized distributor of our company.

13

Periodic Inspection

PERIODIC INSPECTION & SERVICE AFTER THE SALES

Please check it once again before sending it to repair. When still not operating normally, please consult with your

original dealer or authorized distributor of our company for repair.

14

TROUBLESHOOTING

Trouble Major Cause Measure Page

Air does not

ow.

○ A failure to open the cock of a

tank valve.

○ A tank is empty.

○ Water pressure sensor hole of

either rst stage or second stage

is blocked.

○ Open the tank valve.

○ Change to a tank with full of air.

○ Check whether the water pressure

sensor hole is blocked.

10

10

3

Inhalation

resistance is

high.

○ There is little air in a tank.

○ Tank valve is not fully opened.

○ Operation failure of the second

stage.

○ Water pressure sensor hole of

either rst stage or second stage

is blocked.

○ Lack of air ow in the second

stage.

○ Change to a tank with full of air.

○ Make a tank valve full open.

○ Consult with your original dealer

or authorized distributor of our

company

○ Check whether the water pressure

sensor hole is blocked.

○ Adjust air ow by turning FCV knob

to (+) side.

10

10

-

3

11

Exhalation

resistance is

high.

○ Fixing of body case and exhaust

valve.

○ Dip in water and melt the crystal

of salt.

12

Free ow ○ Air is blow off by Venturi

effect.

○ Excess of air ow in the second

stage.

○ Block the hole of mouthpiece, or

face it downward.

○ Adjust air ow by turning FCV knob

to (-) side.

11

11

Water comes in to

the second stage.

○ Regulator clear is not enough.

○ A foreign substance is caught

in an exhaust valve.

○ Slack and crack of a

mouthpiece.

○ Crack of a second body case.

○ Perform the regulator clear again.

○ Check of the exhaust valve.

○ Check of a mouthpiece.

○ Consult with your original dealer

or authorized distributor of our

company

11

-

-

-

Air leakage from

the rst stage.

○ Thread portion of a hose loosen

or comes off.

○ Abrasion of O-ring of an air

leak portion, a crack and a

foreign substance.

○ Retighten the thread portion of

all hose.

○ Consult with your original dealer

or authorized distributor of our

company

9

-

15

Memo

20150605MR

Bism CORPORATION

5F, NF Bldg., Higashinihonbashi, Chuo—ku, Tokyo Japan 103-0004

Phone: +81-3-5640-8126 Fax: +81-3-5640-8131

E-mail: [email protected] URL: http://www.bism.co.jp

16

Memo

This manual suits for next models

15

Table of contents

Other Bism Diving Instrument manuals

Popular Diving Instrument manuals by other brands

Azoth Systems

Azoth Systems O'Dive Complete Instructions Manual

Carromco

Carromco 01020 instruction manual

Shearwater

Shearwater DiveCAN Petrel 1 Operation manual

Subtronic

Subtronic Pro 160 Fusion user manual

Northern Diver

Northern Diver Hotwater Evolution 8 Instruction and maintenance

Ocean Reef

Ocean Reef OCTOPUS SYSTEM owner's manual