7

6) Bottom Plate Reassembly:

a. Visually inspect the cavity, the pump cylinder, and the new components to

be assembled. Ensure all parts are free of damage, contamination, and

mechanical malfunction. Depress the check valve to ensure proper

functionality and smooth motion. Clean Parts if necessary.

b. Coat the outer body of the Check Valve with Pam Cooking Spray © or Olive

Oil. It is very important that the Check Valve is inserted into the bottom of

the cavity with the correct orientation. The “Bullet” end should be inserted

first into the cavity.

c. Use a flat head screwdriver to depress all 4 plastic

tabs on the Check Valve center rim as shown in Figure

6. Press the Check Valve into the cavity of the Piston,

“Bullet” end first (Figure 6), until the Check Valve is

seated and clears the Snap Ring Groove. If any part of the Groove is covered by the

Check Valve, it is not properly seated and requires more force to properly seat it, see

Figure 7.

d. Use Snap Ring Pliers, .070” tip, to insert the Snap Ring into the Groove.

e. Ensure proper functionality and full range of motion in the Check Valve and

proper seating of the Snap Ring.

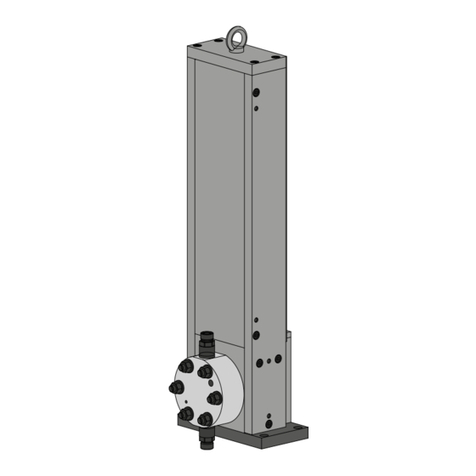

7) Pump Body Installation:

a. Visually inspect the threaded connection areas of the Pump Body and the Water

Source Line for damage and cleanliness. Clean parts if necessary.

b. Wrap fresh Teflon tape around the threads of the Water Source Line. Set the

Pump Body over the Water Source Line, aligning the mating connection. Thread the

Pump Body onto the Water Source by turning it Clockwise. Tighten the connection with a Pipe Wrench

in the Clockwise Direction.

c. Align the Pump Body so that the 4 attachment bolts in the Base Plate align with their original mount

holes.

d. Install the 4 Carriage Bolts through the base plate and mounting surface. Use a 9/16” wrench or socket

to install 4 Flat Washers and 4 Nuts onto the Carriage Bolts. Thread the nuts in a clockwise direction

until they are tight.

8) Rod/Piston Assembly:

a. Visually inspect the Piston, Rod and components for damage and cleanliness. Clean parts if necessary.

b. Install new Piston Cup Seal onto the Piston Cup using your hands to work the Seal over the cups radial

surface. Make sure the “Cup” Side of Cup Seal (as shown in Figure 8) is facing towards the Piston Lift Rod

and/or the top of the Pump Body.