KB-206-12

Table of contents

1 Introduction............................................................................................................................................................3

1.1 Also observe the following technical documents ...........................................................................................3

2 Safety ....................................................................................................................................................................3

2.1 Authorized staff..............................................................................................................................................3

2.2 Residual risks ................................................................................................................................................3

2.3 Safety references...........................................................................................................................................3

2.3.1 General safety references.................................................................................................................. 4

3 Classification of the condensing units and of its components according to the EU directives ..............................5

4 State of delivery and schematic design of the ECOLITE condensing units...........................................................7

5 Application ranges.................................................................................................................................................8

5.1 Maximum allowable pressure ........................................................................................................................8

6 Mounting................................................................................................................................................................9

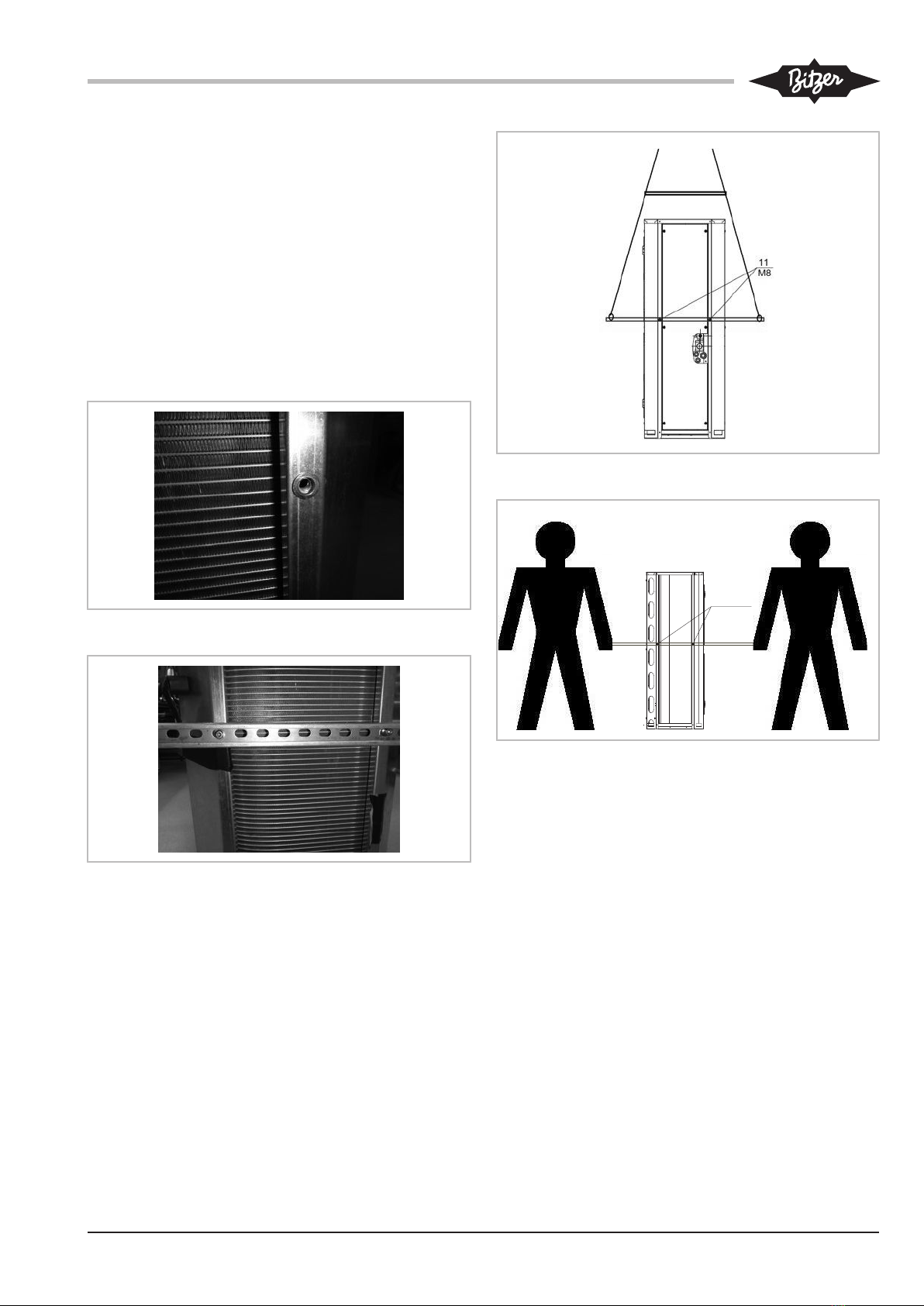

6.1 Transporting the condensing unit ..................................................................................................................9

6.1.1 Transport locks for condensing units ................................................................................................. 9

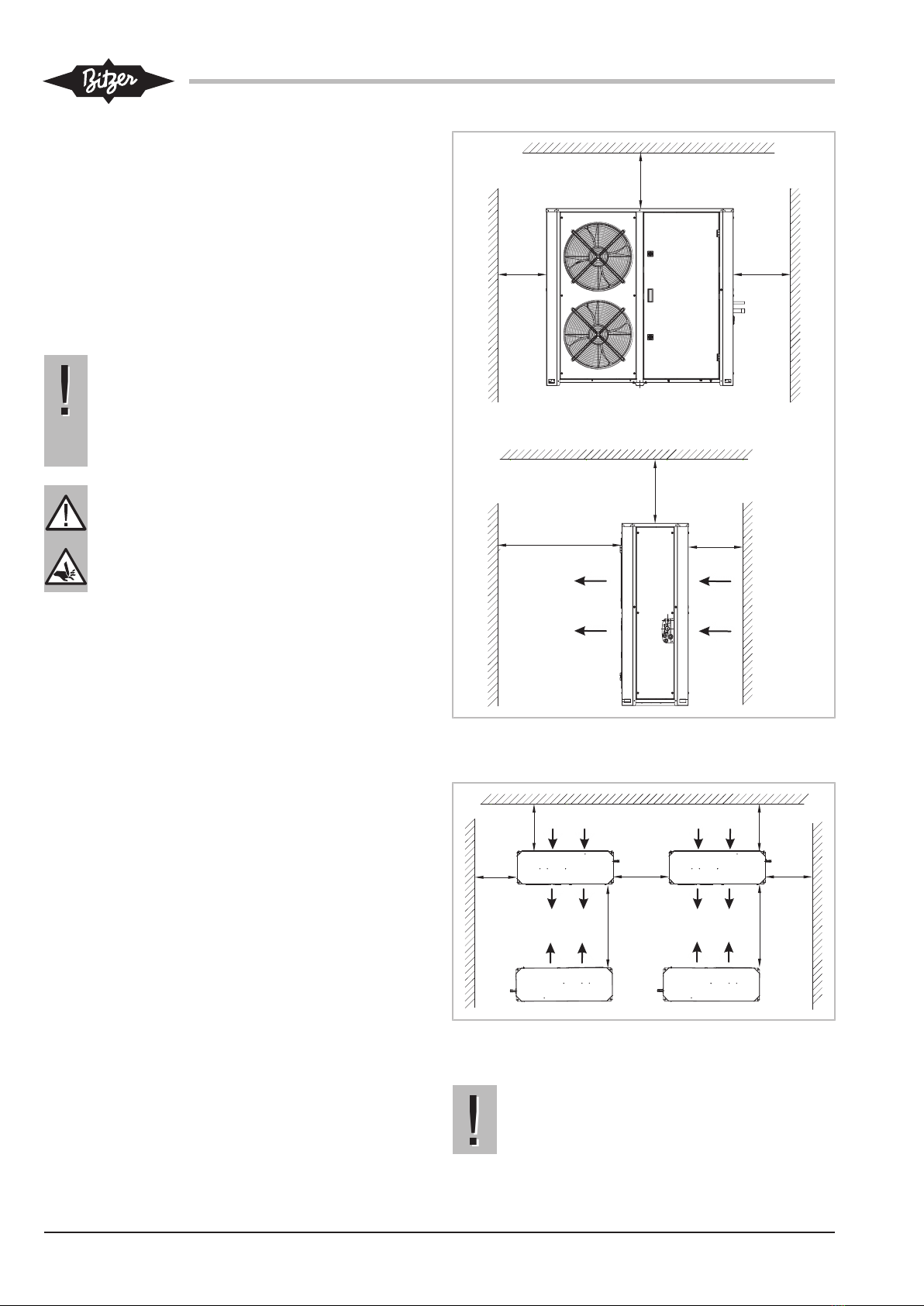

6.2 Installing the condensing unit ........................................................................................................................9

6.3 Pipelines ......................................................................................................................................................11

6.4 Incorporation of the condensing unit into the refrigeration system ..............................................................11

6.5 Connections and dimensional drawing........................................................................................................12

7 Electrical connection............................................................................................................................................13

7.1 Schematic wiring diagram for ECOLITE condensing units..........................................................................13

8 Commissioning ....................................................................................................................................................15

8.1 Setting the controller....................................................................................................................................15

8.1.1 Function keys................................................................................................................................... 16

8.1.2 Display ............................................................................................................................................. 16

8.1.3 First switching on of the power supply ............................................................................................. 17

8.1.4 Status menu..................................................................................................................................... 17

8.1.5 Programming menu ......................................................................................................................... 22

8.1.6 BIOS menu ...................................................................................................................................... 29

8.1.7 Alarm messages .............................................................................................................................. 30

8.1.8 Communication ................................................................................................................................ 31

9 Operation.............................................................................................................................................................31

9.1 Regular tests................................................................................................................................................31

10 Decommissioning ................................................................................................................................................32

10.1 Standstill ......................................................................................................................................................32

10.2 Disassembly of the condensing unit or of components ...............................................................................32

10.3 Drain oil........................................................................................................................................................32

10.4 Remove or dispose of the compressor and other components ...................................................................32