TA04745 A Page 6 of 8

4.0 IMPORTANT OPERATING PRECAUTIONS

WARRANTY: Thomas & Betts sells this product with the understanding that the user will perform all necessary tests to determine

the suitability of this product for the user's intended application. Thomas & Betts warrants that this product will be free from

defects in materials and workmanship for the period stated on the enclosed warranty card. Upon prompt notication of any

warranted defect, Thomas & Betts will, at its option, repair or replace the defective product. Misuse, misapplication or

modication of Thomas & Betts products immediately voids all warranties.

Limitations and Exclusions: THE ABOVE WARRANTY IS THE SOLE WARRANTY CONCERNING THIS PRODUCT, AND IS IN

LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE SPECIFICALLY

DISCLAIMED. LIABILITY FOR BREACH OF THE ABOVE WARRANTY IS LIMITED TO COST OF REPAIR OR

REPLACEMENT OF THE PRODUCT, AND UNDER NO CIRCUMSTANCES WILL THOMAS & BETTS BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES.

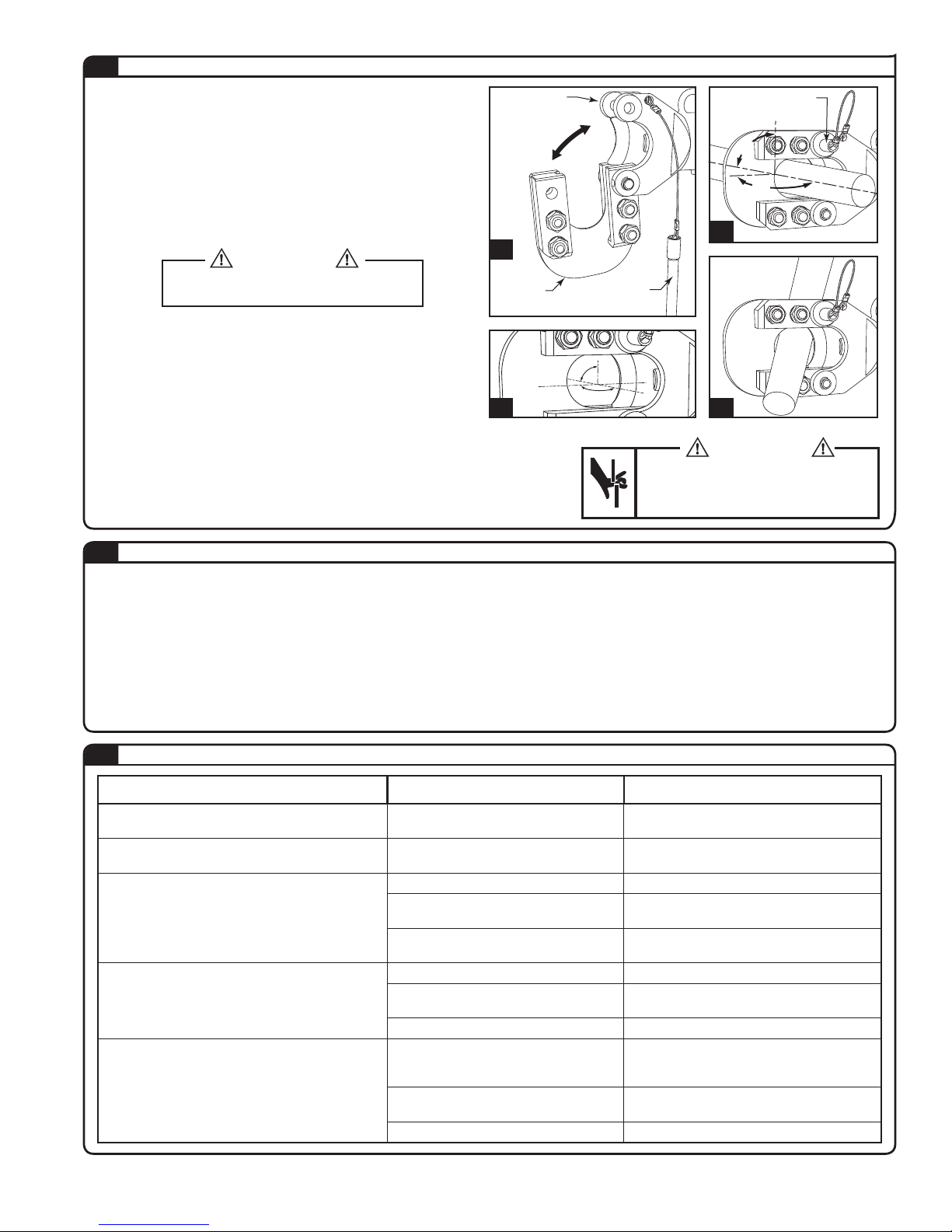

4.1 PRECAUTIONS FOR CUTTING TOOL

1. Select the appropriate materials to be cut.

WARNING

Cutting materials other than those specied will result

in severe tool damage and may cause personal injury.

2. Always cut the material at 90° to the blade. Trying to cut

at any other angle will cause the blades to spread apart

and possibly break.

3. Always point the tool away from other people.

4. If the tool is stored for an extended period at a

temperature of less than 25º F (-5º C), the tool should be

allowed to return to room temperature to ensure smooth

operation. Use the tool only after it has been at room

temperature for 1 hour.

5. Do not drop the tool. Dropping the tool may damage the

hydraulic circuit and cause malfunctions.

6. Keep the head and ram clean and free of debris. Solvents

can be used to clean the head but should not be used on

the plastic body. Use soap & water to clean the body.

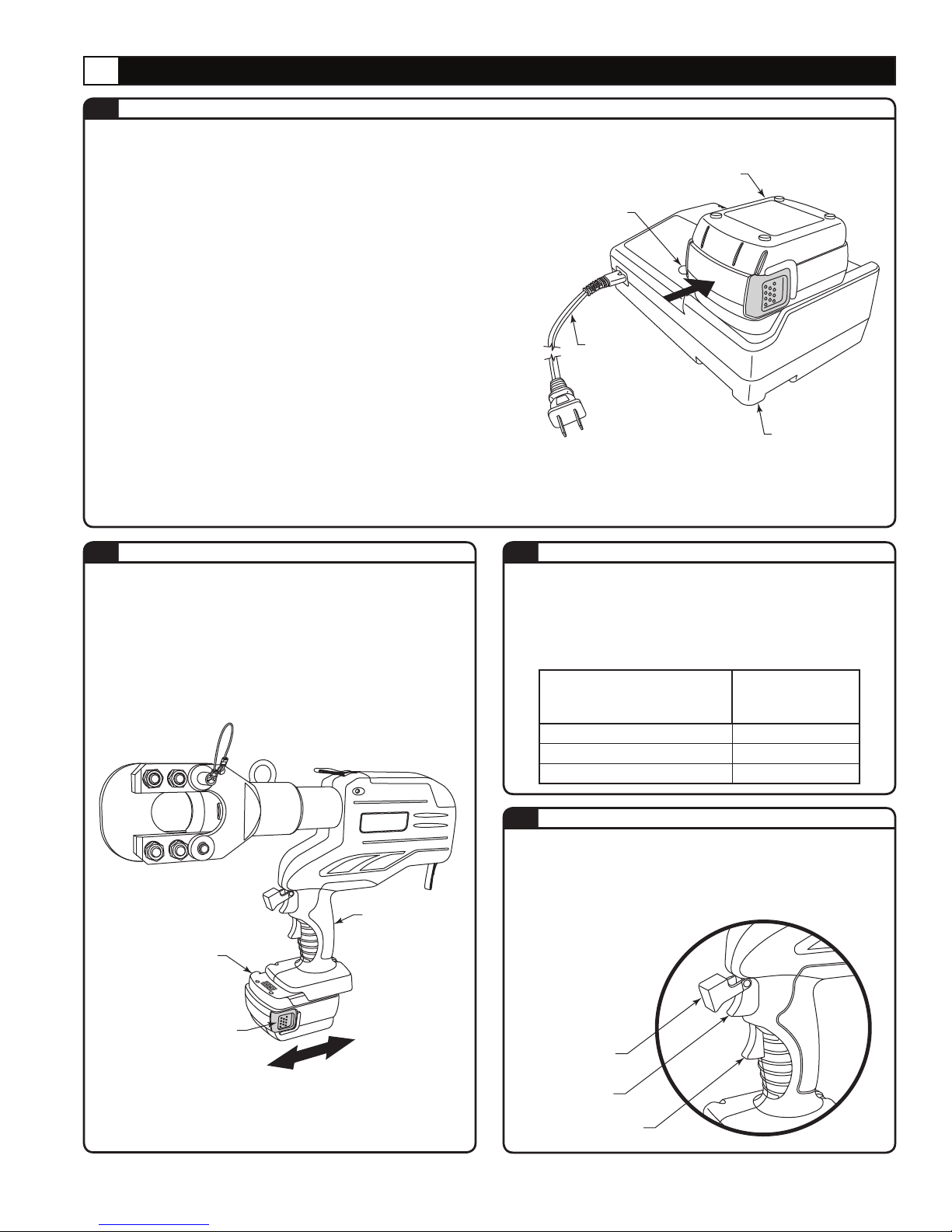

PRECAUTIONS FOR THE BATTERY PACK

4.2

1. Do not short circuit the contacts or expose the battery to

water, oil or solvents.

2. Do not disassemble or attempt to repair the battery or

dispose of in a re.

3. Do not drop or otherwise abuse the battery.

4. Do not leave the battery in locations where it will be

exposed to a temperature greater than 104 degrees F (40

degrees C) for an extended period.

5. The battery has a limited life. When the capacity

becomes about 1/2 that of the original capacity, the

battery should be replaced.

6. If the battery is stored without being charged, natural

drainage will cause the power to be reduced. The battery

should be charged every 3 months if not in use regularly.

PRECAUTIONS FOR THE CHARGER

4.3

1. The LED lamp lights up green and remains lit when the

unit starts charging a battery. The indicator turns orange

when charging is completed.

2. This unit is for charging battery 144-BAT-LI only. Do not

use the charger for any other devices.

3. Allow battery cartridges to cool before charging. Allow at

least 15 minutes between charges when charging several

batteries in succession.

4. Charge batteries at an ambient temperature of 50-95

degrees F (10-35 degrees C). Charging time is

approximately 25 minutes for 80% capacity and 45

minutes for 100% capacity.

5. Never short circuit the output contacts.

6. Do not expose the charger to water, oil or solvents.

7. Do not disassemble, modify, drop or otherwise abuse

the charger.