10

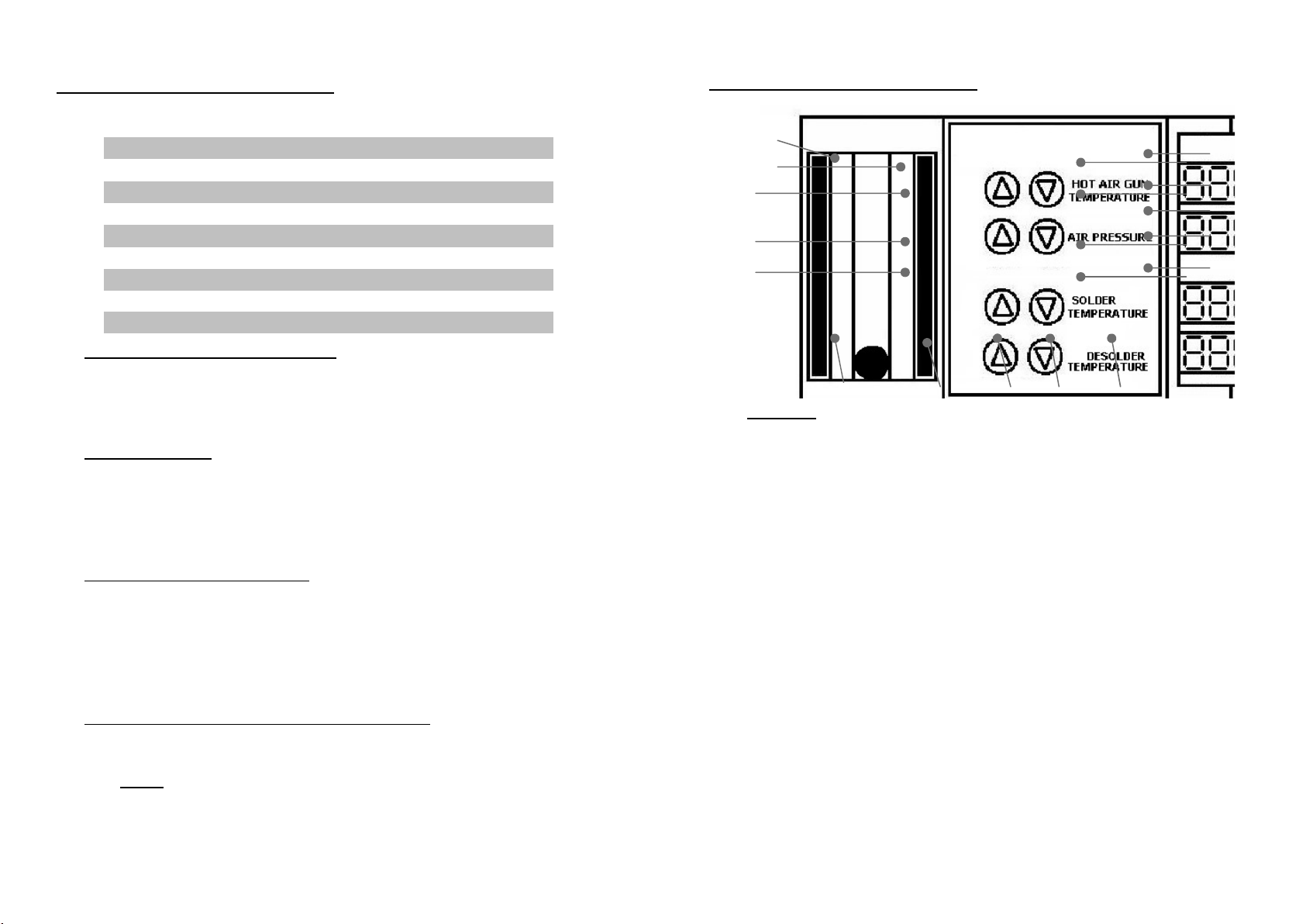

C. AUTOMATE FUNCTION

The system is equipped with a 5 stage automated hot air rework

profiling system. To access and change the time and temperature

settings of the profile follow the guide below:

1. Ensure that the hot air gun function switch is deactivated.

2. The Hot Air Gun Automate Function Selector (“17” from the control

panel) allows us to scroll thru the different stages of the profile.

The stages use the symbols A, b, c, d and E, to indicate stages 1 to

5 respectively. The Automate Display (“18” form the control panel)

shows the desired temperature for each stage and the Automate

Display (“16” form the control panel) shows the duration at which

the set temperature is to be maintained.

3. Now press the Hot Air Gun Automate Function Selector , the display

will change to “###A,” and “###t”. The suffix A indicates that we

are now adjusting the desired temperature for stage 1. The suffix

“t” indicates the time in seconds the desired temperature is to be

maintained.

4. Use the Hot Air Gun Temperature Adjustment Buttons to select the

desired temperature for this stage. Use the Hot Air Gun Airflow

Adjustment Buttons to select the desired duration. Adjust the

temperature/ duration of the other stages. Simply press the Hot Air

Gun Automate Function Selector to scroll to the next stage. Then

use the respective keys to adjust temperature and duration.

5. To save the newly inputted profile into memory, repeatedly press

the Hot Air Gun Automate Function Selector until the display shows

“SAUE”. Press the up button of the Hot Air Gun Temperature

Adjustment Button to confirm saving of the profile.

OPERATING GUIDELINES

19

J. Utilizing the Solder Iron Digital Temperature Calibration

By default, the system is properly calibrated but for some cases

when a little adjustment of the soldering iron temperature is required

the following procedure can be done.

1. Turn on the soldering iron function switch.

2. Set to appropriate temperature you want to calibrate. Place the tip

of the soldering iron on an external temperature meter.

3. The readings on the external temperature sensor should be more

or less equal to the displayed temperature.

4. If there are large discrepancy in the temperature reading we can

re-calibrate the temperature setting. First write down the set

temperature of the soldering iron and the actual temperature

reading from the external temperature meter. For example:

set temperature =350

external temperature = 300

5. Turn off the Soldering Iron Function switch (“14” from the control

panel) .Ensure that the Desoldering Gun Function switch is in the

off position(“12” from the control panel) .

6. Press and hold the UP button of the Desoldering Gun

Temperature Adjustment button (“5” from the control panel) .

7. The Soldering Iron Temperature Display (“11” from the control

panel) . Will switch to four zeros “000” indicating it is now in the

soldering iron calibration mode. Release the UP button of the

Desoldering Gun Temperature Adjustment button

8. Use the Soldering Iron Temperature Adjustment buttons (“4” from

the control panel) to increase or decrease the calibration values.

In our example the set temperature is 350 but the actual

temperature is 300, There is a difference of 50 degrees. Press the

up button until we reach “050 ”.

9. Confirm the change by pressing and holding the “UP” button of

the Desoldering Gun Temperature Adjustment button (“5” from

the control panel).

OPERATING GUIDELINES