BLASTONE 4000-01 User manual

CLIMATE CONTROL DEVICE 4000-01

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

2

RESPIRATOR COMPONENTS

TC No. Protection

1

M

O

D

E

L

Alternate

Helmets

Alternate

Flow

Regulator

and Belt

Alternate

Capes

Alternate Quick

Disconect

Alternate

Hoses

Breat-

hing

Air

Tube

Alternate

Visor Alternate Lenses Cautions and

Limitations 2

NV2001

02-803

NV2016

4000-01

NV2015

4000-20

NV2002

NV2002L

NV2002XL

02-813

NV2025

NV2024

NV2032

NV2034

NV2035

NV2028

NV2029

NV2035

NV2036

NV2021

NV2004

02-804

NV2018

NV2031

NV2017

02-810

02-811

19C-363 SA/CF/SB NOVA

2000 X X X X X X X X X X X X X X X X X ABCDEJMNOS

19C-417 SA/CF/SB ASTRO X X X X X X X X X X X X ABCDEJMNOS

19C-422 SA/CF/SB NOVA

2000 X X X X X X X X X X X X X X ABCDEJMNOS

19C-423 SA/CF/SB ASTRO X X X X X X X X X X X ABCDEJMNOS

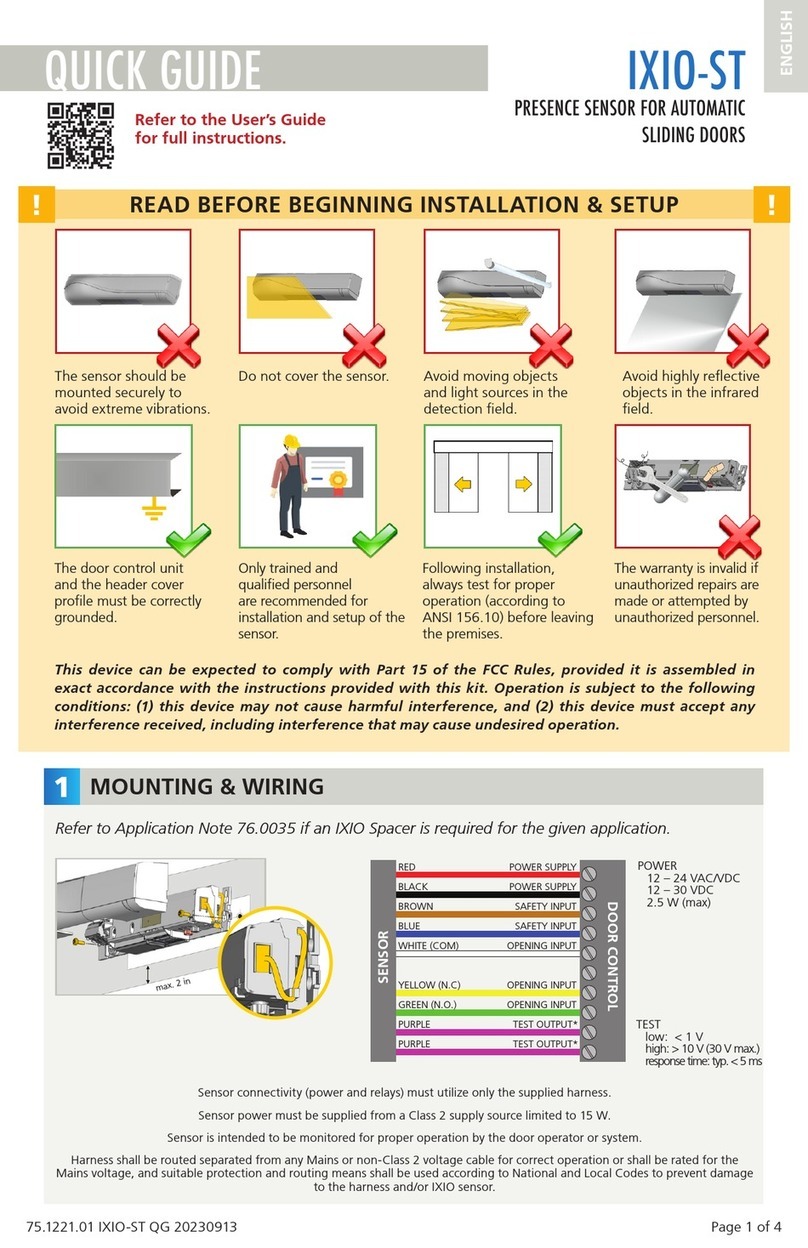

TYPE CE, CONTINUOUS FLOW, SUPPLIED-AIR RESPIRATOR

THESE RESPIRATORS ARE APPROVED ONLY IN THE FOLLOWING CONFIGURATIONS

1. PROTECTION

CF- Continous ow SA- Supplied Air SB- Supplied - Air Abrasive Blast

2. CAUTIONS AND LIMITATIONS

A- Not for use in atmospheres containing less than 19.5 percent oxygen.

B- Not for use in atmospheres immediately dangerous to life and health.

C- Do not exceed maximum use concentrations established by regulatory standards.

D- Air-line repirators can be used only when the repirators are supplied with respirable air meeting the

requirements of CGA G-7.1 Grade D or Higher Quality.

E- Use only the pressure ranges and hose lenghts specied in the User's instructions.

J- Failure to properly use and maintain this products could result in injury or death.

M- All approved respirators shall be selected, tted, used and maintained in accordance with MSHA, OSHA, and

other applicable regulations.

N- Never substitute, modify, add, or omit parts. Use only exact replacement parts in the conguration as

specied by the manufacturer.

O- Refer to User's instructions, and/or maintenance manuals for information on use and maintenance of these

repirators.

S- Special or critical User's instrucions and/or specic Limitations apply. Refer to User's instrucions.

3

INTRODUCTION

The 4000-01 Cold Air Tube is NIOSH approved to supply a continuous ow of cool compressed

air to the Supplied Air Respirator. All Genuine Parts must be present and correctly assembled to

constitute a NIOSH approved respirator.

AIR QUALITY

The respirator must be supplied at all times with clean breathable air Grade D or better. Always

use an inlet lter on your compressor - locate your compressor in a clean environment. The AIR

QUALITY must be constantly monitored to ensure Grade D air is supplied at all times. A carbon

monoxide alarm must always be used.

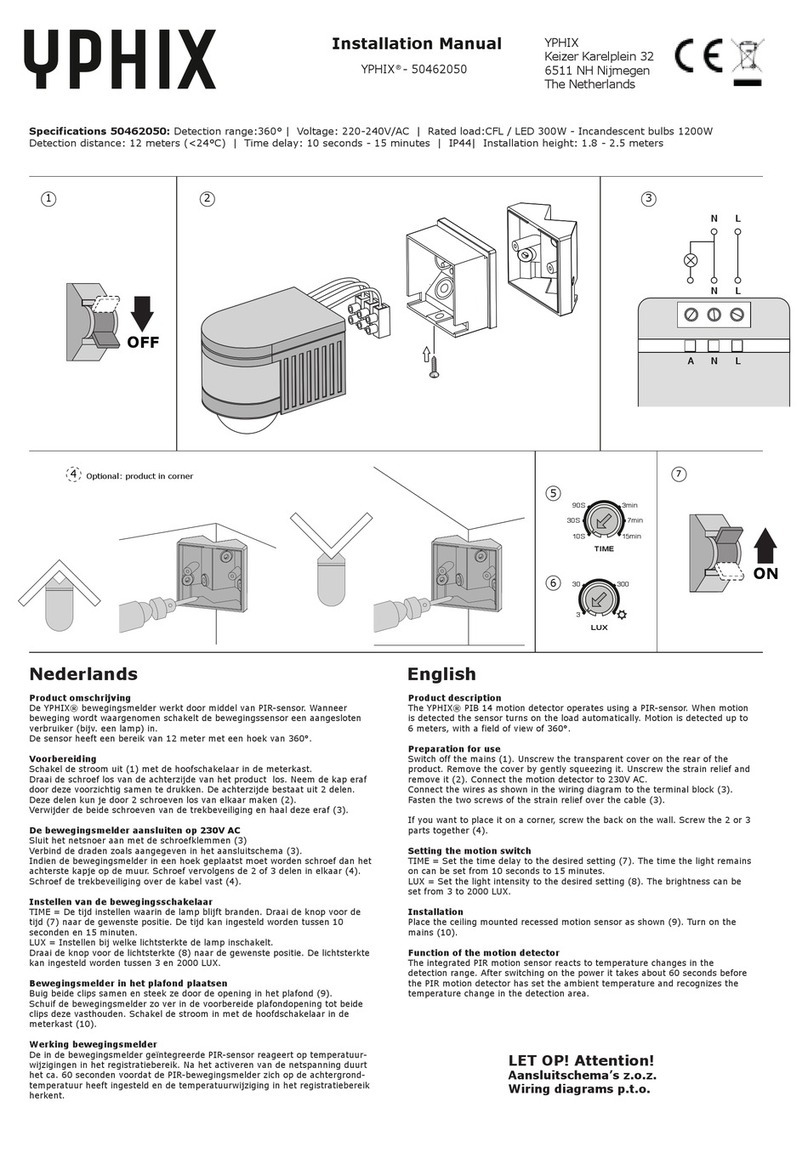

AIR PRESSURE

The air pressure supplied to the respirator must be continuously monitored to ensure it keeps

within the specied range as detailed on the breathing air pressure tables.

Do not connect the air supply hose to nitrogen, toxic gases, inert gases

or any other non Grade D air source.

WARNING

Make sure the correct table is used. When using 4000-01 use (Fig 3)

Breathing Air Pressure Table.

WARNING

• DO NOT use the 4000-01 until you have been trained in its use, maintenance and

limitations by a qualied individual (appointed by your employer) who has extensive

knowledge of the 4000-01

• DO NOT ingest the ice that may form around the cold air outlet as it could contain oils or

toxic element that could cause illness or death.

• USE ONLY NIOSH approved NOVA 2000 air supply hose.

• DO NOT modify or alter parts of the respirator. The use of non approved parts voids the

entire approval of the Respirator.

WARNINGS

4

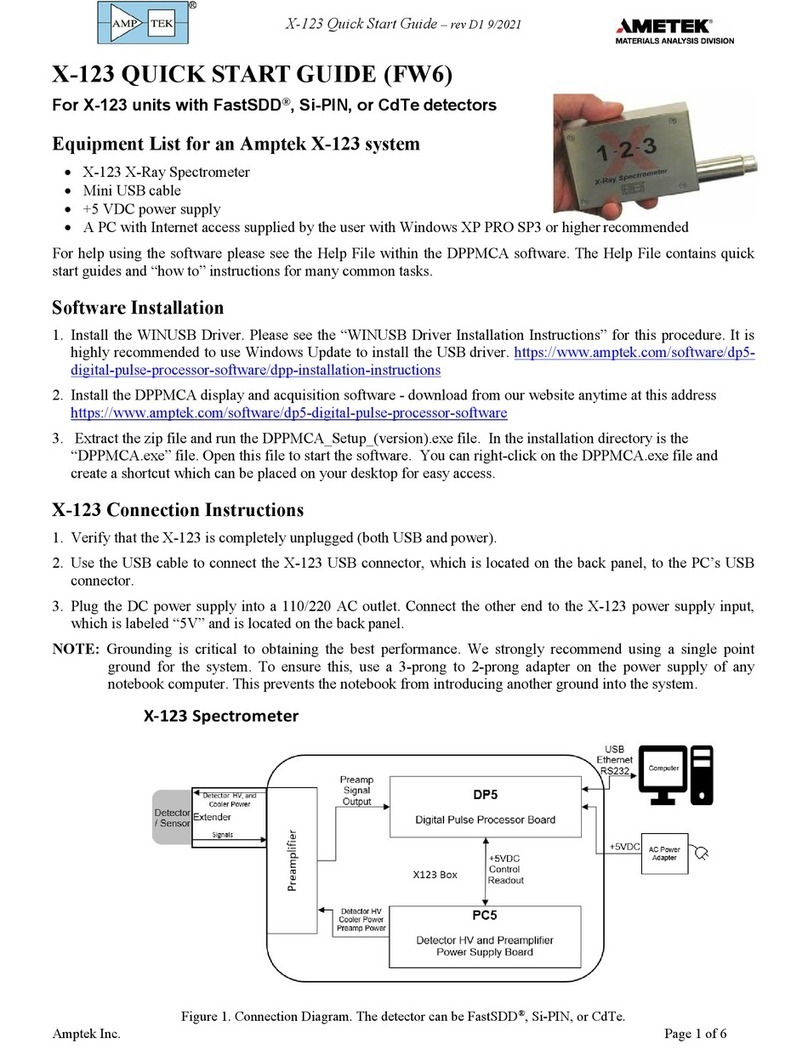

SET UP AND USE

1. To supply cold air to the respirator connect the

outlet to the NV2021 breathing tube and tighten by

hand. (Fig 1).

2. Connect the NIOSH approved air supply hose to a

breathing air source, supplying Grade D orbetter

quality air. Connect the air supply hoseto the 4000-

01 quick disconnect tail. (Fig 2).

3. With air owing through the respirator, adjust

the air pressure at the point of attachment. (Fig

2) to the recommended air pressure specied in

the BREATHING AIR PRESSURE TABLE (Fig 3).

4. To obtain cooler air turn the regulator control knob anti cockwise, this will increase the airow

out of the exhaust port (Fig 4). Turn the knob clockwise to obtain air closer to ambient temperature.

5. With the compressed air owing into the respirator

at the correct pressure range for the correct supply

hose length you are now ready to enter the work

area. Do no remove your respirator until you are

outside the blasting area.

Make sure you understand the breathing air pressure table

before using the respirator. Make sure you set the correct

air pressure for the correct FIG 2 supply hose length.

WARNING

Fig 1

Fig 2

BREATHING AIR PRESSURE TABLE

AIR

SOURCE

BREATHING TUBE

ASSEMBLY AIR SUPPLY HOSE AIR SUPPLY HOSE

LENGTH

MAX NUMBER OF

SECTIONS

PRESSURE RANGE

(PSIG Air)

Portable or Stationary

Compressor

4000-01

Cold Air Tube

NV2028/

NV2029

25

50

100

150

200

250

300

1

1

2

3

4

5

6

55 - 56

55 - 57

60 - 62

65 - 67

70 - 72

77 - 78

80 - 82

Fig 3

Leave work area immediately if you are unwell, airow

stops or slows down, breathing becomes difcult, you

become dizzy, too cold or if any respirator part is damaged.

WARNING

DO NOT USE THE 4000-01 when ambient temperature

is below 68¡ (20¡C) as ice could form in the cold

air outlet and reduce airow.

WARNING Fig 4

5

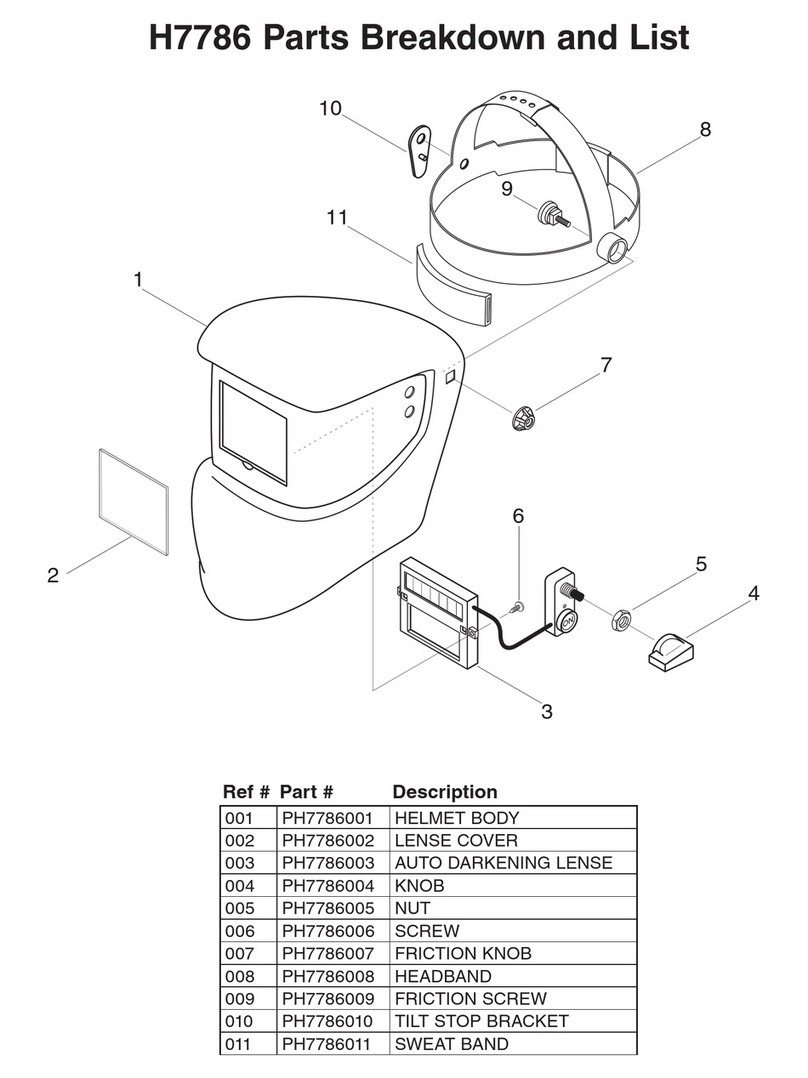

CCT 4000 PARTS LIST

Item PART No.

Top Threaded Cap 4000-03

Air Spinner 4000-04

Body 4000-05

1/4'' Quick Disconnect Tail 4000-06

Breaker 4000-07

Regulator Body 4000-08

Spindle & Knob 4000-09

Locking Screw 4000-10

Regulator Assembly 4000-11

Heat Sheild 4000-12

Belt NV2022

Due to the high noise levels created during abrasive blasting earplugs must be worn at all

time. During Abrasive Blasting operations do not use Silica Sand, the use of Silica Sand can

cause serious respiratory disease or death, refer: www.osha.gov.Silica.IT69D_1.html

WARNING

6

NOTES

7

NOTES

8

OTHER

PRODUCTS

DID YOU KNOW

We can also supply you with the following...

NOVA 2000 BLASTING HELMET

The NOVA 2000 has been designed for blasting professionals.

The NOVA 2000 is the most advanced abrasive blasting helmet

available, with fully padded pillow foam liner for extra comfort and

noise attenuation, wide angle vision, even air distribution assures

a pleasant working environment, optional climate control devices.

Things cannot get much better.

ASTRO BLASTING HELMET

ASTRO is your number one choice economic Abrasive Blasting Helmet

which meets safety standards worldwide.

This is the lightweight, robust helmet you have been waiting for. It

helps to reduce fatigue, reduce down time and increase productivity.

HEAD SOCKS & SPRAY HOODS

Stay cleaner with Head Socks and Spray Hoods. One size ts all. The

cool comfortable Spray Hood protects from over spray and sanding

dust. The Head Sock can be worn as a hygienic liner.

HEAD SOCKS & SPRAY HOODS

The RADEX Airline Filter offers you more capacity, versatility &

ltration. You can combine the versatility of either oor or wall

mounting with increased ltration capacity.

Our range of optional equipment means you can customise your

lter to meet your requirements.

ISO9001

ACCREDITED COMPANY

BLASTONE INTERNATIONAL (AUST) PTY LTD

57 Alexandra Place Murarrie

Queensland 4172 Australia

PO Box 3385 Tingalpa DC

Queensland 4172 Australia

Toll Free 1800 190 190

Tel (07) 3329 5000

Fax (07) 3329 5066

Email [email protected]om

www.BlastOne.com

AUSTRALIAN OFFICES

Adelaide |Brisbane |Darwin |Mackay |

Melbourne |Perth | Sydney

BLASTONE INTERNATIONAL

4510 Bridgeway Avenue

Columbus Ohio 43219 USA

Toll Free 800 999 1881

Tel (614) 476 3000

Fax (614) 476 3002

Email [email protected]om

www.BlastOne.com

NORTH AMERICAN OFFICES

Chicago |Columbus |Los Angeles |

Minneapolis

© BlastOne 2018

B3626-1 AU

Table of contents

Popular Security Sensor manuals by other brands

Gas Clip Technologies

Gas Clip Technologies Multi Gas Clip Simple user manual

IFM Electronic

IFM Electronic efector300 SM8001 operating instructions

Bentel Security

Bentel Security DT800 quick start guide

Eterna

Eterna MHDB installation instructions

Hytronik

Hytronik HIR27 Installation and instruction manual

HP

HP 423A Operating note