2-45D Operating Instructions

3

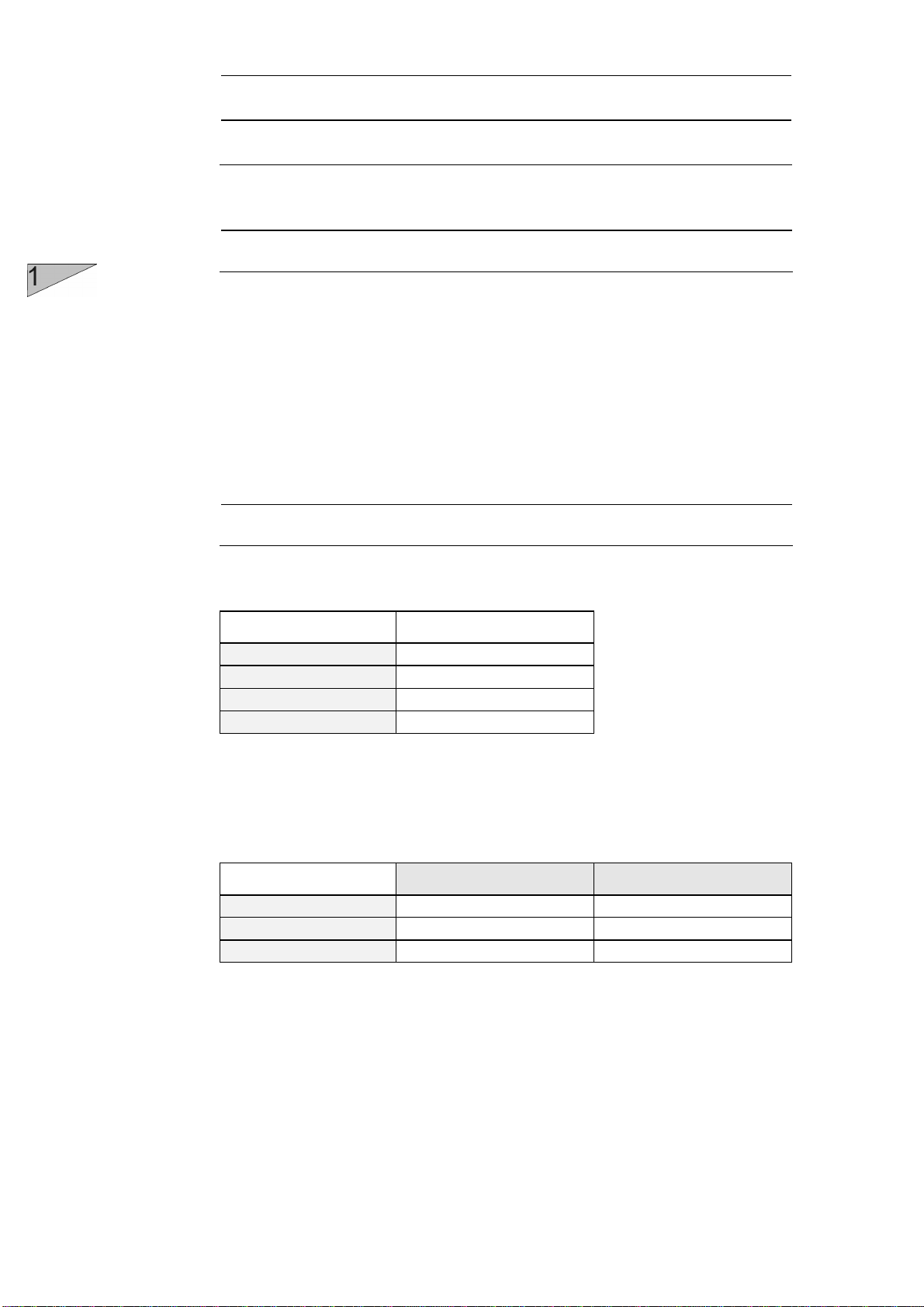

Rated speed

Blast wheel speed 4000 min-1

Magnet drum speed 160 min-1

Blast wheel size : 2 x 349 mm Ø

Working width : 1150 mm

Required drive speed : 0 - 5,0 km/h

Blast cleaning output : up to 2000 m²/h

Dust hose connection : 2 x 150 mm Ø

Recommended abrasive : Shot 460-550

Abrasive consumption : 0,1 - 0,5 kg/m²

Recommended filter unit : 2-45 TDC

1.3 Operative range and correct usage

The 2-45D is exclusively designed to clean dry, frost-

free horizontal surfaces. The machine may not be

used for other purposes. The manufacturer will not

be liable for damage resulting from such incorrect

usage. In these cases the user assumes all risks.