BLEMO ER51 Owner's manual

ER51

Variable speed drives for synchronous and

asynchronous motors

Programming Manual

02/2016

BLEMO

Frequenzumrichter

Siemensstraße 4

D-63110 Rodgau – Dudenhofen

Tel.: +49 / 6106 / 82 95-0

Fax: +49 / 6106 / 82 95-20

Web: www.blemo.com

2

S1A28692 03/2010

The information provided in this documentation contains general descriptions and/or technical characteristics of the performance

of the products contained herein. This documentation is not intended as a substitute for and is not to be used for determining

suitability or reliability of these products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the relevant specific application or

use thereof. Neither BLEMO

®

nor any of its affiliates or subsidiaries shall be responsible or liable for misuse of the information

contained herein. If you have any suggestions for improvements or amendments or have found errors in this publication, please

notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical, including photocopying,

without express written permission of BLEMO

®

.

All pertinent state, regional, and local safety regulations must be observed when installing and using this product. For reasons of

safety and to help ensure compliance with documented system data, only the manufacturer should perform repairs to

components.

When devices are used for applications with technical safety requirements, the relevant instructions must be followed.

Failure to use BLEMO

®

software or approved software with our hardware products may result in injury, harm, or improper

operating results.

Failure to observe this information can result in injury or equipment damage.

© 2016 BLEMO

®

Frequenzumrichter. All rights reserved.

S1A28692 03/2010 3

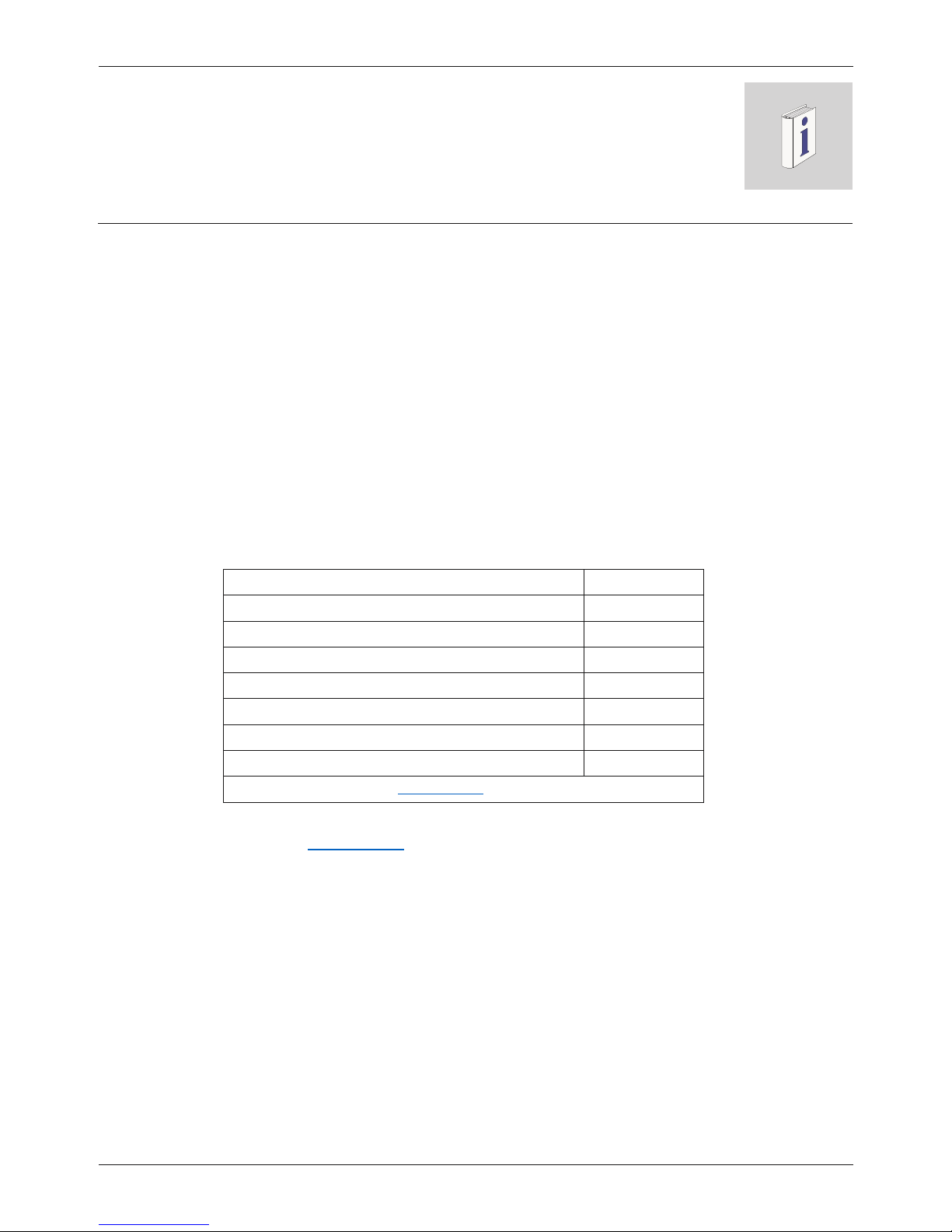

Table of Contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Book. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Steps for setting-up the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Preliminary recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Factory configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Application functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Basic functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Graphic display terminal option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Powering up the drive for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Remote display terminal option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Structure of the parameter tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Finding a parameter in this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Description of the HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Structure of the menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Chapter 3 Reference Mode (rEF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Organization tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Chapter 4 Monitoring Mode (MOn) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Organization tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

[MONIT. MOTOR] ................................................................................................... 44

[I/O MAP] ............................................................................................................... 45

[MONIT. SAFETY] ................................................................................................... 48

[MONIT. FUN. BLOCKS] ......................................................................................... 49

[COMMUNICATION MAP] ....................................................................................... 50

[MONIT. PI] ............................................................................................................ 56

[MONIT. POWER TIME] .......................................................................................... 56

[ALARMS] .............................................................................................................. 57

[OTHER STATE] ..................................................................................................... 58

[DIAGNOSTICS] ..................................................................................................... 58

[PASSWORD] ......................................................................................................... 63

Chapter 5 Configuration Mode (ConF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Organization tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

My Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table of Contents

Table of Contents

4 S1A28692 03/2010

Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Macro Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Full . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

[SIMPLY START] .................................................................................................... 73

[SETTINGS] ........................................................................................................... 77

[MOTOR CONTROL] ............................................................................................... 92

[INPUTS / OUTPUTS CFG] ................................................................................... 112

[COMMAND] ........................................................................................................ 139

[FUNCTION BLOCKS] ........................................................................................... 143

[APPLICATION FUNCT.] (FUn-) ............................................................................. 147

REFERENCE SWITCHING .............................................................................. 152

REFERENCE OPERATIONS............................................................................ 153

RAMP.......................................................................................................... 155

STOP CONFIGURATION................................................................................. 158

AUTO DC INJECTION..................................................................................... 161

JOG ............................................................................................................ 163

PRESET SPEEDS.......................................................................................... 165

+/- SPEED.................................................................................................... 169

+/- SPEED AROUND A REFERENCE ................................................................ 171

REFERENCE MEMORIZING ............................................................................ 173

FLUXING BY LOGIC INPUT ............................................................................. 174

BRAKE LOGIC CONTROL ............................................................................... 176

EXTERNAL WEIGHT MEASUREMENT .............................................................. 184

HIGH SPEED HOISTING ................................................................................. 186

PID REGULATOR .......................................................................................... 192

PID PRESET REFERENCES............................................................................ 200

TORQUE LIMITATION .................................................................................... 201

2ND CURRENT LIMITATION............................................................................ 204

LINE CONTACTOR COMMAND........................................................................ 205

OUTPUT CONTACTOR COMMAND .................................................................. 207

POSITIONING BY SENSORS........................................................................... 209

PARAMETER SET SWITCHING........................................................................ 214

MULTIMOTORS / MULTICONFIGURATIONS ...................................................... 217

AUTO TUNING BY LOGIC INPUT ..................................................................... 221

TRAVERSE CONTROL ................................................................................... 222

[COMMUNICATION] ............................................................................................. 256

Access Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Chapter 6 Interface (ItF). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Access Level (LAC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Language (LnG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Monitoring Configuration (MCF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Display configuration (dCF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Chapter 7 Open / Save as (trA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Chapter 8 Password (COd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Chapter 9 Multipoint Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Maintenance and Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Chapter 10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Chapter 11 Diagnostics and Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Error code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Clearing the detected fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Fault detection codes which require a power reset after the detected fault is cleared 291

Fault detection codes that can be cleared with the automatic restart function after the

cause has disappeared . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Fault detection codes that are cleared as soon as their cause disappears . . . . . . . . 295

Table of Contents

S1A28692 03/2010 5

Option card changed or removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Control block changed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Fault detection codes displayed on the remote display terminal . . . . . . . . . . . . . . . . 296

Annex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Chapter 12 Index of Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Chapter 13 Index of Parameter Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Table of Contents

6 S1A28692 03/2010

S1A28692 03/2010

7

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before trying

to install, operate, or maintain it. The following special messages may appear throughout this documentation

or on the equipment to warn of potential hazards or to call attention to information that clarifies or simplifies

a procedure.

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard

exists, which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER

indicates an imminently hazardous situation, which, if not avoided,

will result

in death or serious

injury.

WARNING

WARNING

indicates a potentially hazardous situation, which, if not avoided,

can result

in death, serious

injury, or equipment damage.

CAUTION

CAUTION

indicates a potentially hazardous situation, which, if not avoided,

can result

in injury or

equipment damage.

CAUTION

CAUTION,

used without the safety alert symbol, indicates a potentially hazardous situation which, if not

avoided, can result in equipment damage.

PLEASE NOTE

The word "drive" as used in this manual refers to the controller portion of the adjustable speed drive as

defined by NEC.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel. No

responsibility is assumed by BLEMO

®

for any consequences arising out of the use of this product.

© 2016 BLEMO

®

Frequenzumrichter. All Rights Reserved.

§

Safety Information

Important Information

Safety Information

8

About the Book

Document scope

The purpose of this document is to:

•

help you to set-up the drive,

•

show you how to program the drive,

•

show you the different menus, modes and parameters,

•

help you in maintenance and diagnostics.

Validity note

This documentation is valid for the ER51 drive.

Related documents

Title of

Documentation

Reference Number

ER51 Quick Start

S1A41715

ER51 Installation manual

S1A28686

ER51 Modbus manual

S1A28698

ER51 CANopen manual

S1A28699

ER51 Communication Parameters

S1A44568

ER51 Atex manual

S1A45605

ER51 Safety manual

S1A45606

ER51 other option manuals: see www.blemo.com

You can download the latest versions of these technical publications and other technical information from

our website at www.blemo.com.

About the Book

At a Glance

About the Book

S1A28692 03/2010 9

Product related information

(1) For additional information, refer to NEMA ICS 1.1 (latest edition), #Safety Guidelines for the Application, Installation, and

Maintenance of Solid State Control$ and to NEMA ICS 7.1 (latest edition), #Safety Standards for Construction and Guide

for Selection, Installation and Operation of Adjustable-Speed Drive Systems.$

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

!Read and understand this manual before installing or operating the Altivar 32 drive. Installation,

adjustment, repair, and maintenance must be performed by qualified personnel.

!The user is responsible for compliance with all international and national electrical code requirements with

respect to grounding of all equipment.

!Many parts of this drive, including the printed circuit boards, operate at the line voltage. DO NOT TOUCH.

Use only electrically insulated tools.

!DO NOT touch unshielded components or terminal strip screw connections with voltage present.

!DO NOT short across terminals PA/+ and PC/% or across the DC bus capacitors.

!Before servicing the drive:

- Disconnect all power, including external control power that may be present.

- Place a #DO NOT TURN ON$ label on all power disconnects.

- Lock all power disconnects in the open position.

- WAIT 15 MINUTES to allow the DC bus capacitors to discharge.

- Measure the voltage of the DC bus between the PA/+ and PC/% terminals to ensure that the voltage is

less than 42 Vdc.

- If the DC bus capacitors do not discharge completely, contact your local Schneider Electric

representative. Do not repair or operate the drive.

!Install and close all covers before applying power or starting and stopping the drive.

Failure to follow these instructions will result in death or serious injury.

DANGER

UNINTENDED EQUIPMENT OPERATION

!Read and understand this manual before installing or operating the Altivar 32 drive.

!Any changes made to the parameter settings must be performed by qualified personnel.

Failure to follow these instructions will result in death or serious injury.

WARNING

DAMAGE DRIVE EQUIPMENT

Do not operate or install any drive or drive accessory that appears damaged.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

LOSS OF CONTROL

!The designer of any control scheme must

- consider the potential failure modes of control paths and, for certain critical control functions,

- provide a means to achieve a safe state during and after a path failure.

Examples of critical control functions are emergency stop and overtravel stop.

!Separate or redundant control paths must be provided for critical control functions.

!System control paths may include communication links. Consideration must be given to the implications

of unanticipated transmission delays or failures of the link.(1)

Failure to follow these instructions can result in death, serious injury, or equipment damage.

10

S1A28692 03/2010

About the Book

CAUTION

INCOMPATIBLE LINE VOLTAGE

Before turning on and configuring the drive, ensure that the line voltage is compatible with the supply voltage

range shown on the drive nameplate. The drive may be damaged if the line voltage is not compatible.

Failure to follow these instructions can result in injury or equipment damage.

CAUTION

RISK OF DERATED PERFORMANCE DUE TO CAPACITOR AGING

The product capacitor performances after a long time storage above 2 years can be degraded.

In that case, before using the product, apply the following procedure:

•

Use a variable AC supply connected between L1 and L2 (even for ER51-…/4K-references).

•

Increase AC supply voltage to have: - 25% of rated voltage during 30 min

- 50% of rated voltage during 30 min

- 75% of rated voltage during 30 min

- 100% of rated voltage during 30 min

Failure to follow these instructions can result in equipment damage.

User comments

The word "drive" as used in this manual refers to the controller portion of the adjustable speed drive as defined by NEC.

S1A28692 03/2010 11

I

General Overview

What's in this Part?

This part contains the following chapters:

Chapter Chapter Name Page

1 Setup 13

2 Overview 17

12 S1A28692 03/2010

S1A28692 03/2010 13

Setup

1

Setup

What's in this Chapter?

This chapter contains the following topics:

Topic Page

Steps for setting-up the drive 14

Preliminary recommendations 15

14

S1A28692 03/2010

Setup

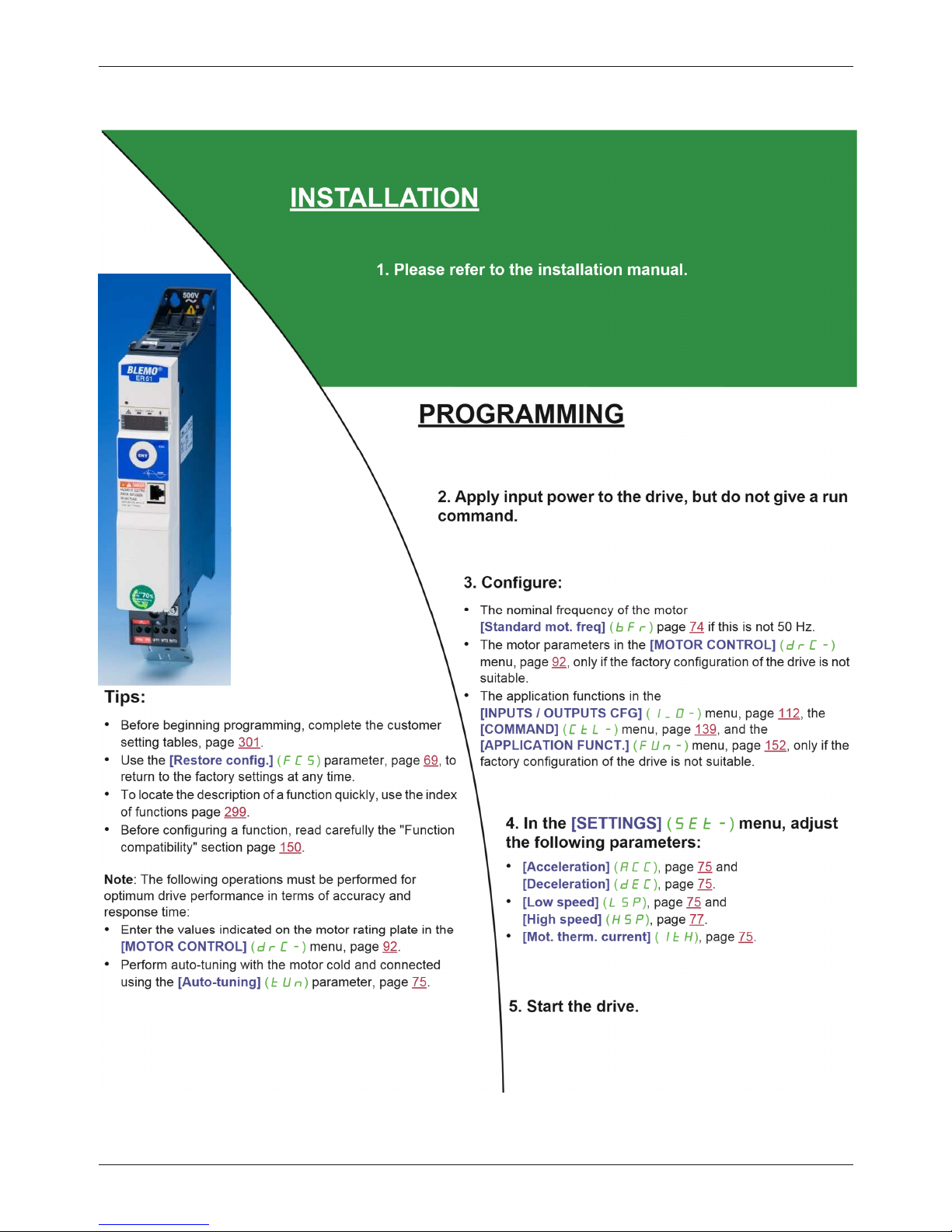

Steps for setting-up the drive

Setup

S1A28692 03/2010 15

Preliminary recommendations

Before powering up the drive

Start-up

Note: When factory settings apply and during power-up/manual reset or after a stop command, the motor can

only be powered once the "forward", "reverse" and "DC injection stop" commands have been reset. If they

have not been reset, the drive will display [Freewheel stop] (nSt)but will not start. If the automatic restart

function has been configured ([Automatic restart] (Atr)parameter in the

[FAULT MANAGEMENT] (FLt-)menu, page 232), these commands are taken into account without a

reset (to zero) being necessary.

Line contactor

Using a motor with a lower rating or dispensing with a motor altogether

With the factory settings, motor output phase loss detection is active ([Output Phase Loss] (OPL) =

[Yes] (YES), page 238). To avoid having to use a motor with the same rating as the drive when testing the

drive or during a maintenance phase, deactivate the motor output phase loss detection

([Output Phase Loss] (OPL) = [No] (nO)). This can prove particularly useful if very large drives are being

tested with a small motor.

Set [Motor control type] (Ctt), page 92, to [Standard] (Std)in [Motor control menu] (drC-).

DANGER

UNINTENDED EQUIPMENT OPERATION

Read and understand this manual before installing or operating the ATV32 drive.

Any changes made to the parameter settings must be performed by qualified personnel.

Check that all logic inputs are inactive to avoid any unintended operation.

Failure to follow these instructions will result in death or serious injury.

CAUTION

RISK OF DAMAGE TO DRIVE

Frequent use of the contactor will cause premature aging to the charge circuit of the filter capacitors.

Do not power-up the drive less than every 60 seconds.

Failure to follow these instructions can result in equipment damage.

CAUTION

RISK OF DAMAGE TO THE MOTOR

Motor thermal protection will not be provided by the drive if the motor 's nominal current is 20& lower than

that of the drive.

In this case, find an alternative source of thermal protection.

Failure to follow these instructions can result in equipment damage.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

If [Output Phase Loss] (OPL)is set to [No] (nO), Loss of cable is not detected.

Check that this action will not endanger personnel or equipment in any way.

Failure to follow these instructions will result in death or serious injury.

Setup

16 S1A28692 03/2010

S1A28692 03/2010 17

Overview

2

Overview

What's in this Chapter?

This chapter contains the following topics:

Topic Page

Factory configuration 18

Application functions 19

Basic functions 23

Graphic display terminal option 24

Graphic display terminal option 24

Powering up the drive for the first time 27

Remote display terminal option 30

Structure of the parameter tables 31

Finding a parameter in this document 32

Description of the HMI 33

Structure of the menus 34

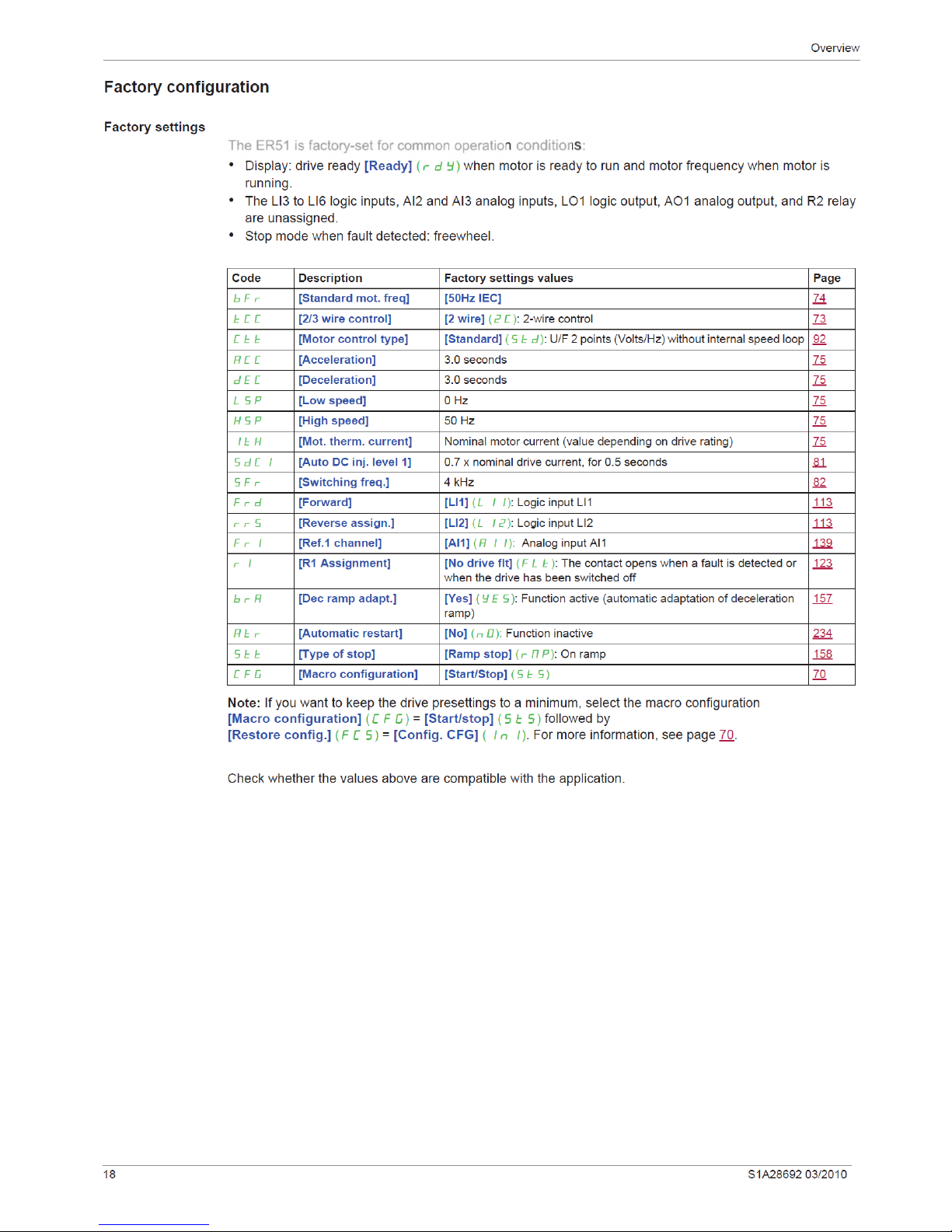

The ER51 is factory-set for common operation conditions:

Overview

S1A28692 03/2010 19

Application functions

The tables on the following pages show the combinations of functions and applications, in order to guide your

selection.

The applications in these tables relate to the following machines, in particular:

!Hoisting: cranes, overhead cranes, gantries (vertical hoisting, translation, slewing), lifting platforms

!Handling: palletizers/depalletizers, conveyors, roller tables

!Packing: carton packers, labeling machines

!Textiles: weaving looms, carding frames, washing machines, spinners, drawing frames

!Wood: automatic lathes, saws, milling

!Process

Each machine has its own special features, and the combinations listed here are neither mandatory nor

exhaustive.

Some functions are designed specifically for a particular application. In this case, the application is identified

by a tab in the margin on the relevant programming pages.

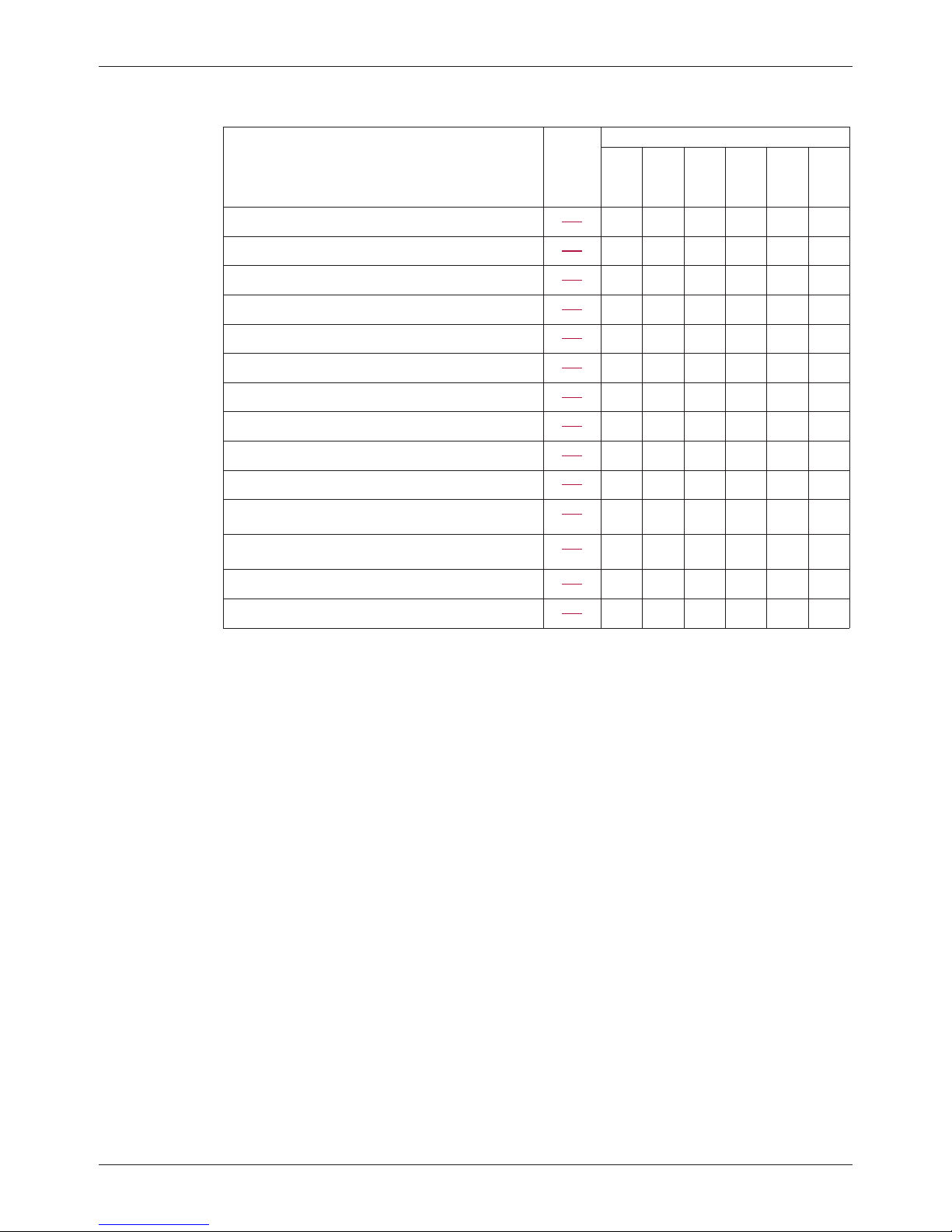

Motor control functions

Functions Page Applications

Hoisting

Handling

Packing

Textiles

Wood

Process

V/f ratio 92 b b

Sensorless flux vector control 92 b b b b b b

2-point vector control 92 b b

Open-loop synchronous motor 92 b

Output frequency up to 599 Hz 92 b b

Motor overvoltage limiting 107 b b

DC bus connection (see Installation manual) - b b

Motor fluxing using a logic input 174 bbb

Switching frequency of up to 16 kHz 82 b b

Auto-tuning 75 b b b b b b

Overview

20 S1A28692 03/2010

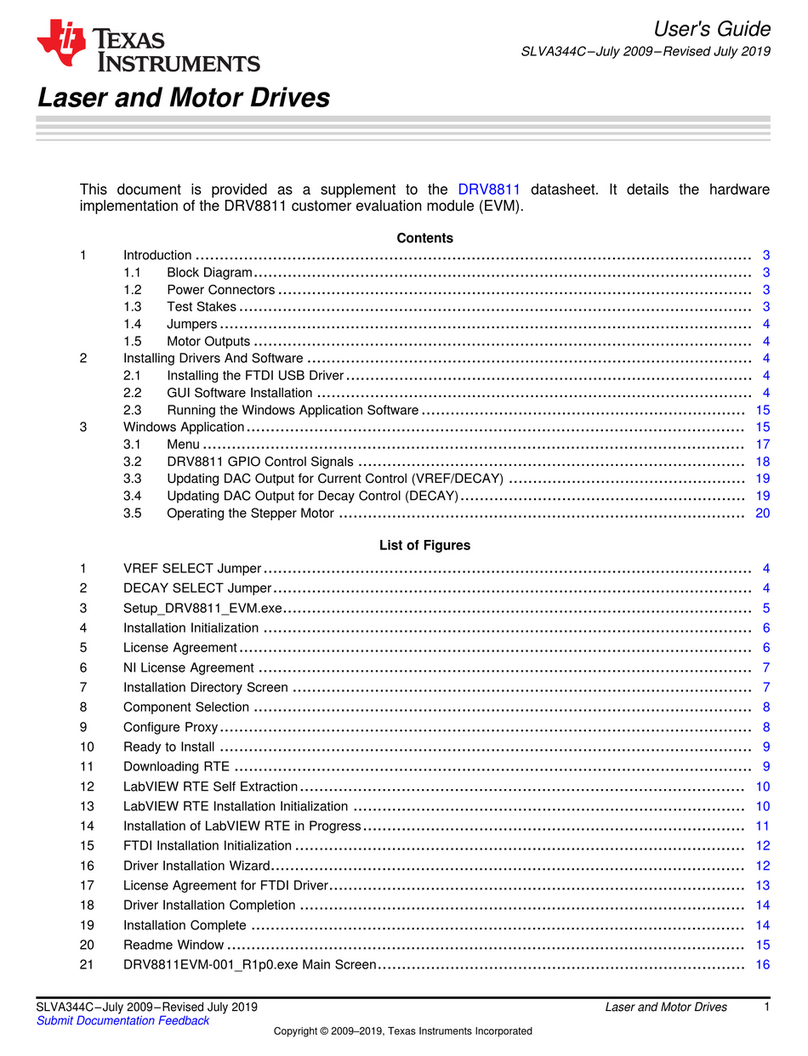

Functions on speed references

Functions Page Applications

Hoisting

Handling

Packing

Textiles

Wood

Process

Differential bipolar reference 116 bbb

Reference delinearization (magnifying glass effect) 119 b b

Frequency control input 139 b b

Reference switching 152 b

Reference summing 153 b

Reference subtraction 153 b

Reference multiplication 153 b

Adjustable profile ramp 155 b b

Jog operation 163 bbb

Preset speeds 165 bbb

+ speed / - speed using single action pushbuttons

(1 step)

169 b

+ speed / - speed using double action pushbuttons

(2 steps)

169 b

+/- speed around a reference 172 b b

Save reference 173 b

Table of contents

Other BLEMO DC Drive manuals

Popular DC Drive manuals by other brands

Texas Instruments

Texas Instruments DRV8811 user guide

ABB

ABB PSTX30 Service instruction

SOMFY

SOMFY J4 WT Short installation guide

SEW-Eurodrive

SEW-Eurodrive Movigear Performance MGF**-DFC-C Series operating instructions

GFA

GFA ELEKTROMAT SI 17.30 FU-30,00 installation instructions

Danfoss

Danfoss VLT AutomationDrive FC 360 operating guide

American Control Electronics

American Control Electronics Minarik MDVF03-D230-PCM quick start guide

Novoferm

Novoferm Helix S600 user manual

Newport

Newport New Focus 8712 user manual

SEW-Eurodrive

SEW-Eurodrive MOVI4R-U operating instructions

Seagate

Seagate EXOS ST3000NM007A product manual

Hitachi

Hitachi WJ200-001S instruction manual