Blendtec BDI-501 User manual

MANUAL

BDI

Table of Contents

Section Page

1 Important Safeguards ..................................................................5

2 Introduction ........................................................................................7

3 Installation ...........................................................................................8

3.1 Counter Placement

3.2 Electrical Connections

3.3 Water Connection

3.4 Drain Connection

3.5 Product Lines and Connections

4 Basic Operations ...........................................................................9

4.1 Loading Ice

4.2 Dispense Product Only

4.3 Making Drinks

4.4 Dispense Ice Only

4.5 Dispense Water Only

4.6 Run Blender Motor Only

5 Cleaning and Sanitizing .............................................................10

5.1 After Each Use

5.2 Jar Care

5.3 Unit Care

6 Basic Programming .......................................................................13

6.1 Program Mode

6.2 Adjusting Product

6.3 Adjusting Water

6.4 Adjusting Ice

6.5 Adjusting Blend Times

6.6 Adjusting Blend Cycles

6.7 Adjusting Pause

6.8 Changing the Drink Size Ratio

7 Advanced Programming .............................................................17

7.1 Calibration

7.2 Water Flow Rate

7.3 Ice Dispense Rate

7.4 Ice Level Sensor

7.5 Ice Buster

7.6 Small Drink Defaults

7.7 Restore Defaults

7.8 Locking the Machine

7.9 Drink Counts

8 Troubleshooting ...............................................................................22

8.1 Machine won’t run

8.2 Blender stopped working

8.3 Ice stopped working

8.4 Ice dispenses when not in use

8.5 Drinks too runny

8.6 Drinks too thick or cavitation in blender

8.7 Little or no flavor in drinks

8.8 Too much flavor in drinks

8.9 Ice chunks in drinks

8.10 Water won’t dispense

8.11 Product bag is leaking

8.12 Lid light is on

8.13 Low ice Indicator

9 Warranty Information including Service .........................25

10 Blank Drink Template ................................................................26

11 Pre-Installation Check List ....................................................27

5

Section 1: Important Safeguards

READ ALL INSTRUCTIONS CAREFULLY BEFORE USING YOUR BDI

1.1 Safety Certification

BDI models 501and 503 are certified by ETL to comply with UL/ANSI standard

763-2000, 3rd Edition, November 30, 2000 and to comply with CSA standard

C22.2 No. 195-M1987.

BDI models 502 and 504 are 240VAC versions are certified to CE

standards.

1.2 Health Certification

All BDI models are certified by NSF International to comply with Standard 8.

1.3 Precautions:

• Avoid contact with moving parts.

• Keep fingers, hair, hands, and clothing away from all moving parts.

• Keep utensils away from drive socket, ice augers, and blender blades during

operation. Metal utensils will damage blades and augers.

• NEVER place a jar into the drive socket if the blender motor is operating.

• DO NOT rock the blender jar while it is operating. Keep the blender jar

straight up until the operation is complete.

These precautions will prevent personal injury and/or damage to the blender

dispenser.

1.4 Power Cord Precautions

• DO NOT operate with a damaged power cord or outlet.

• If the power cord or outlet is damaged they must be replaced by the manu-

facturer or its authorized service agent in order to prevent any hazard.

• DO NOT let the power cord hang over the edge of the work surface.

• NEVER use an extension cord with the unit.

• Unplug the unit when changing location, servicing, or cleaning.

1.5 DO NOT attempt to perform repairs. NEVER remove the covers or panels

on the unit. The unit does not contain adjustable or customer serviceable parts.

The manufacturer or their authorized agent must perform all interior service

and adjustments. Removing covers or panels, or attempting to effect repairs,

will void the warranty. Please call Blendtec Technical Support at 800 748-5400

ext. 494 or 248 for guidance on warranty and service options.

1.6 ALWAYS turn the unit off when not in use.

1.7 NEVER operate the unit if it appears to be damaged. If the unit malfunc-

tions, call the manufacturer first. If it is dropped or damaged in any way, call

Blendtec Technical Support for service to evaluate the extent of damage and

the possibility of either repair or replacement.

R

6

1.8 NEVER operate in liquid. DO NOT allow the unit to sit in a pool of liquid or

use the unit outdoors where it will be subject to precipitation. This will void the

warranty.

1.9 NEVER put items such as metal, rocks, or other hard materials into the

blender jar or the ice hopper. Metal utensils and other hard objects can dam-

age the blender jar or ice hopper and will void the warranty.

1.10 NEVER operate the unit with attachments not sold or authorized by

Blendtec. The use of unauthorized attachments may cause fire, electric shock,

unit malfunction or injury. Damage incurred by the use of such attachments

will not be covered by warranty.

1.11 ALWAYS operate the blender with the clear door closed.

1.12 ALWAYS secure the blender jar lid before starting the machine.

Even with the blending chamber it is important to put a lid on the blender jar

before initiating a blend cycle.

1.13 The blender jar blades are sharp – handle carefully.

1.14 Power Requirements

Model BDI-501, BDI-503 POWER CORD

120V, 1800W, 15A, 50-60 Hz. It is recom-

mended that a dedicated 20A receptical be

used.

NEMA 5-15P

Model BDI-502, BDI-504 POWER CORD

240V, 1800W, 7.5A, 50-60 Hz. It is recom-

mended that a dedicated 10A receptical be

used.

Varies by Country

1.15 DO NOT use any other electrical equipment on the same circuit as the

unit or you risk overloading the circuit and either burning the fuse or possibly

the electronics inside the unit. This will void the warranty. ALWAYS use a surge

protector device.

1.16 NEVER use a water jet to clean the unit. Use of a water jet to clean the

unit can result in the malfunction or damage to the unit. This type of damage/

malfunction will not be covered under warranty.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

IMPORTANT

We took care to ensure your machine was clean when it was shipped from

the factory, but since we do not have any control over shipping conditions we

strongly recommend that you sanitize the machine before you prepare any

drinks. (see Section 5.4).

7

Section 2: Introduction to the Blender with Ice Dispenser

WELCOME TO AN EXCITING NEW WAY OF BLENDING

Blendtec® Blender Dispenser with Ice!

(BDI)

The Blendtec Blender Dispenser with Ice (BDI) combines some of the best

ideas in blending into one easy-to-operate machine. The result is a machine

that provides:

• Fast delivery to large crowds.

• Controlled labor and finished product costs.

• Portability and easy set-up.

• Maximum revenue generated per square foot.

• Multiple drink combinations from one machine.

The Blender Dispenser with Ice is a microprocessor-controlled machine

designed to quickly make precise blended drinks from concentrates or other

liquids including alcohol, ice, and water. It has three main sections, the blend

station, the ice hopper, and the control board. The following pages will intro-

duce you to one of the most advanced blending systems available today.

2.1 Blend Station:

This contains a powerful blender motor that is controlled by the microproces-

sor on the control board. You can select the speed and duration of each blend

cycle for each drink size.

2.2 Ice Hopper:

This is a double auger system for consistent ice delivery to ensure that your

drinks are the same every time. The ice hopper holds six gallons (22.71 liters)

of ice. The hopper is insulated to minimize temperature loss. The hopper also

integrates an interlock safety feature to prevent personal injury – the removal

of the lid will stop the movement of the augers.

2.3 Control Board:

This is the microprocessor that controls all of the functions of the unit. The

control board is utilized to make and program drinks.

2.4 Water Input Line:

Allows cold water to be added to drinks to help reconstitute concentrated

purees or to help increase volume.

2.5 Drain Line:

Provides for the removal of ice melt water as well as minor spillage in the blend

station. The drain line is located on the back of the unit.

8

2.6 BDI models

Voltage:

Models BDI-501, BDI-503

120VAC

Models BDI-502, BDI-504

240VAC

Size:

Narrow Versions Models BDI-503, BDI-504

Height: 32” Width: 12.75” Length (depth): 21”

Wide Versions Models BDI-501, BDI-502

Height: 32” Width: 19.25” Length (depth): 14.5”

Limitations:

Volume Limited - Models BDI-501 Through BDI-504

Products other than those dispensed by the unit (concentrates, ice cream,

yogurt, etc.) are added to the blending jar before dispensing. The total blend-

ing capacity is limited to 32 ounces.

Section 3: Installation

Read all instructions, cautions, notes, and warnings before attempting to set up

and operate this machine. WARRANTIES WILL BE VOIDED if this machine is

improperly installed. (See Pre-Installation sheet at the end of this manual.)

3.1 Counter Placement:

Ensure there are at least 4 inches on each side and at least 6 inches in back

(room for plumbing – product lines and drain). Be sure there is sufficient room

above the BDI to remove the ice hopper lid and put ice into the ice hopper dur-

ing regular use. Counter location should be near water, ice, and product bags.

3.2 Electrical Connections:

See power requirements in section 1.14.

3.3 Water Connection:

A ⅜” compression fitting is located behind the lower panel in the upper right-

hand corner (from the rear of the machine). You must use a reinforced water

line with this unit. Incoming water must have a pressure rating of at least 30PSI

(2.1097 kg/cm) and be no greater than 120PSI (8.4388 kg/cm) to operate cor-

rectly. You must add an inline water filter with a flow rate of at least 1 gallon

(3.78 liters) per minute. Adequate backflow protection might be needed to

comply with applicable federal, state, or local codes.

9

3.4 Drain Connection:

A ¾” hose bib fitting is located on the lower left-hand corner (from the rear of

the machine). It is recommended that you use Teflon tape on the threads to

help prevent leaks. Only a rigid reinforced hose with at least a ¾” ID can be

used to prevent kinking and backflow into the blender chamber. Adequate

backflow protection might be needed to comply with applicable federal, state,

or local codes.

3.5 Product Lines and Connections:

The inlets for the product lines are located on the back of the unit. There are

labels next to each inlet with numbers that correspond to the pump numbers

in programming. These fittings are ⅜” outer diameter and are barbed to help

retain the hose. Use a hose clamp to retain the hose on the inlet fitting.

Section 4: Basic Operations

4.1 Loading Ice:

Remove the black ice hopper lid from atop the unit (removing the lid will dis-

able the functions of the unit). Carefully pour up to 6 gallons (22.71 liters) of

ice into the ice hopper. Ensure that the ice covers both augers to provide for

the most consistent ice dispense. Place the lid back on the top of the unit to

re-enable the unit to function. If you are filling an empty ice hopper you should

prime the system by putting a blender jar in the blend station and press the ICE

button on the control panel (see 4.4).

4.2 Making Drinks:

Place an empty blender jar in the blend station with the blender lid in place.

After programming drinks into the microprocessor (see section 6.0), you simply

press the drink number (1-64), select the size (S, M, or L), and then press GO.

The unit will automatically dispense ice, product, and water, and then blend. All

parameters for drink production can be manipulated to suit your needs (see

Section 6.0).

4.3 Dispense Product Only:

You can dispense only product by pressing the number of the pump (1-8) and

then pressing and holding the JUICE button. The unit will dispense the product

selected until you release the JUICE button. The maximum time that the JUICE

button will dispense is 25 seconds. This feature allows you to prime your prod-

uct lines easily with little waste.

4.4 Dispense Ice Only:

This feature will allow you to dispense ice only. Place an empty jar in the blend

station and press and hold the ICE button to dispense the desired amount of

ice. The ice will dispense as long as the ICE button is held down or up to 25

seconds. Use this feature when you’re filling an empty ice hopper to prime the

system.

10

4.5 Dispense Water Only:

By pressing and holding the WATER button you can dispense cold water only

as desired. The maximum amount of time the feature will run is 25 seconds.

4.6 Run Blender Motor Only:

This feature can be used in two ways: as a ramp pulse (gradually increasing

speed) or to run a constant speed. To use as a ramp pulse, press and hold the

BLEND button until the drink is completed, the motor will stop when the BLEND

button is released. To run at a constant speed, select the speed (1-9) and then

press and hold the BLEND button. The unit will run until the BLEND button is

released or for 25 seconds.

Section 5: Cleaning and Sanitizing

5.1 After Each Use:

After every use of the unit, the operator should ensure that the blender jar has

been rinsed, the blend station has been wiped out if there is spillage, and that

the blender door is wiped down if there is spillage. Always keep an empty jar

on the blender motor when the unit is not in use. This helps any melt water

that is not captured by the ice hopper drain from splashing onto the blender

motor itself.

5.2 Jar Care:

SHORT TERM – As needed, wash the jars with a mild detergent solution. Do not

immerse the jars for longer than necessary in any type of liquid. Wash quickly

with a smooth cloth or sponge, rinse, and sanitize with appropriate solution.

Some sanitizer manufacturers require their sanitizer to remain in contact with

the sanitized object for a specific amount of time before rinsing or removing.

Refer to your manufacturer’s instructions before rinsing. Hold the jar by the

handle and give three or more sharp downward shakes to remove all water

from around the shaft area. Then place the jar upside down on a rack to dry.

LONG TERM – As needed, fill the jar with hot water and a tablespoon of chlo-

rine bleach or other sanitizer, per manufacturer’s instructions. Stir and let stand

for 5 minutes, then empty. Hold the jar by the handle and give three or more

sharp downward shakes to remove all water from around the shaft area. Then

place the jar upside down on a rack to dry

5.3 Unit Care:

SHORT TERM – Daily or weekly, wipe down the exterior of the unit and the

interior of the blend station with a damp rag. Carefully tilt the machine either

backward or forward (two person operation) and wipe underneath the unit with

a damp rag. Disconnect the drain tube from the back of the unit and run hot

sanitizer solution through the tube to help keep the tube clear.

LONG TERM – Monthly, sanitize the ice hopper and blend station utilizing the

steps below. The best time to perform this cleaning is either before or after

11

work hours when you have plenty of time. Mix up 2-5 gallons of sanitizer solu-

tion per the manufacturer’s directions.

ICE HOPPER:

• Turn off the power. Remove all ice from the ice hopper. Using caution, manu-

ally take the ice out from around the augers. Once you have removed as

much ice as you can, replace the ice hopper lid and place an empty blender

jar in the blend station. Turn the power on. Press and hold the ICE button to

dump the remaining ice pieces. Empty the jar and replace in the blend sta-

tion.

Cleaning: Spray or wipe the interior surface of the ice hopper with a mild

soapy solution. A handheld spray bottle will work best. Allow this solution to

remain in contact with the ice hopper surfaces as required by the manufac-

turer’s specifications.

Rinsing: Spray clean, hot water over the surfaces of the ice hopper to rinse

the soapy solution away. A handheld spray bottle will work best. The rinse

water will mostly run down the drain of the unit but some will go into the

empty blender jar. Watch so that it does not overflow. Empty as needed.

Sanitizing: Spray the sanitizing solution over the surfaces of the ice hop-

per. A handheld spray bottle will work best. Remember that some sanitizer

manufacturers require their sanitizer to remain in contact with the sanitized

object for a specific amount of time before rinsing or removing. Refer to

your manufacturer’s instructions before rinsing.

BLEND STATION:

• Remove the blender jar from the blender station (empty if needed).

• Using a mild soapy solution, wipe down all surfaces of the blend station.

Excess water will drain through the drain opening located at the back of the

unit.

• Use clear, hot water to rinse the surfaces of the blend station. A handheld

spray bottle will work best. Avoid getting excess water on the motor.

• To sanitize the surfaces of the blend station either spray or wipe the surfaces

of the blend station with the sanitizing solution.

• Remove the blend station door by opening the door and gently lifting it off

the hinges (do not lose the small plastic washers). Wash the door in the sink

and allow to air dry.

• Dry any water off the blender motor area and replace the blender door.

DRAIN HOSE:

• After sanitizing the ice hopper and blend station, the internal drain tube

should be fairly well cleaned so it is not necessary to run sanitizer down the

internal tube again.

• Remove the drain hose from the back of the machine.

• Slowly pour sanitizer solution down the tube. It is not necessary to rinse the

12

drain hose.

PRODUCT TUBES:

There are two options to sanitize product lines. The first is to use the sanitizing

cycle built into the machine; the second is a simpler method using the JUICE

button. You may use either one depending on preference; the beginning steps

are the same.

• Disconnect all product bags from the product lines.

• Place an empty blender jar in the blend station.

• Empty each product line by pressing the number of the pump (1-8) and then

holding the juice button down. This will remove the bulk of the remaining

product from the machine. Be sure that the blender jar does not overflow.

• Disconnect all product bag connectors from the product lines. You

will want to have a bucket or empty blender jar to capture any

product that leaks back out of the tubes.

• Place the product bag connectors in the sink to soak in a sanitizing solution.

• Mix up a solution of hot soapy water.

• Place the ends of the product tubes into the soapy solution.

Method 1 Sanitizing Cycle:

• To clean the tubes, run the soapy solution by pressing 9-8-0-GO. This

cycle will clean two product tubes at a time. The beginning screen will read

“CLEAN 1 2 READY”. Press GO to activate the cycle. Pumps 1 and 2 will

run approximately 12 seconds, each dispensing the soapy water into the

empty blender jar. Ensure that the jar does not overfill!

• Once the wash cycle is done, the screen will read “CLEAN 3 4 READY”. Make

sure the blender jar is empty and press GO. Pumps 3 and 4 will run. Repeat

for all 8 product tubes.

• Retrieve a container (bucket) of clear rinse water.

• Place all eight ends of the product tubes into the bucket of water.

• To run the cycle to rinse, press 9-8-0-GO. This cycle will rinse two product

tubes at a time. The beginning screen will read “CLEAN 1 2 READY”. Press

GO to activate the cycle. Pumps 1 and 2 will run approximately 12 seconds,

each dispensing the rinse water into the empty blender jar. Ensure that the

jar does not overfill!

• Once the rinse cycle is done, the screen will read “CLEAN 3 4 READY”. Make

sure the blender jar is empty and press GO. Pumps 3 and 4 will run.

• Repeat to rinse the remaining product tubes.

• Mix up a solution of sanitizer per manufacturer’s instructions.

• Place all eight tubes, with connectors attached, into the sanitizer solution.

• To run the sanitizing cycle – press 9-8-0-GO. This cycle will sanitize two

product tubes at a time. The beginning screen will read “CLEAN 1 2

READY”. Press GO to activate the cycle. Pumps 1 and 2 will run approxi-

mately 12 seconds, each dispensing the sanitizer into the empty blender jar.

Ensure that the jar does not overfill!

• Once the sanitizing cycle is done, the screen will read “CLEAN 3 4 READY”.

Make sure the blender jar is empty and press GO. Pumps 3 and 4 will run.

• Repeat to sanitize the remaining lines.

• Remove the hose and connectors from the container of sanitizer.

• Run each pump individually to clear the remaining sanitizing solution from

13

the product tubes.

• Reconnect the product tubes to the product bags, prime each line.

Method 2 Sanitizing Cycle:

• Using the JUICE button, follow the steps above EXCEPT do not use 9-8-0-

GO; instead, press the button of the product pump (1-8) and then press and

hold the JUICE button.

• Once the product has stopped dispensing from the unit, release the JUICE

button.

• Repeat for all eight pumps.

• Follow the instructions for wash, rinse, and sanitize above.

• Regardless of the method used, refill the product lines by pressing the pump

number (1-8) and the JUICE button until the product dispenses, then release

the JUICE button.

Section 6: Blending 101 & Basic Programming

Blending 101:

Making the ideal smoothie with the BDI is just a matter of simple physics. The

input variables include the temperature and thickness of the ingredients, the

output variable is the desired texture achieved at 29°F (-1.667°C). A smoothie

much warmer than this (above 32°F, 0°C) will be runny, a smoothie much colder

(below 25°F, -3.889°C ) will cavitate (develop an air pocket above the blade)

and not blend. So let’s make a perfect smoothie, simply.

1. Determine the concentration ratio of your flavor ingredients to ice and water.

In other words, what’s your ideal recipe? What does your product supplier

recommend will be the proper amount of juice concentrate or puree, and how

much will be ice and water for a given drink size? For example, in a 12 ounce

drink, some recipes call for 5, others 4, 3, or even just 2 ounces of flavored

product. These concentration values would be 1.4, 2, 3, and 5 to 1, respectively,

where the 1 is the product, and the 5, 3, 2 and 1.4 values represent the relative

amounts of ice/water needed to make the desired 12 ounce drink. So if the

recipe called for 2 ounces of product, you need to put in 10 ounces of ice/wa-

ter (5 to 1 ratio). If the recipe called for 3 ounces of product, you would need to

put in 9 ounces of ice/water (3 to 1 ratio) to make a 12 ounce drink.

2. Determine the water to ice ratio necessary to bring the final drink to 29°F

(-1.667°C). If I have a 3 to 1 flavor concentrate, then I will need to put in 9

ounces of some combination of ice and water into my 12 ounce drink. If I put

in all ice I run the risk of freezing the drink and failing to blend (aka cavitation).

If I put in all water, I am guaranteed to lose a customer. So the ice/water ratio

is like a teeter-totter. I have to put in 9 ounces total, the only question is how

much of this will be ice, and how much will be water? It is recommended that

you begin with approximately a 4 to 1 ratio of ice to water. In the present case,

try 7 ounces of ice to 2 ounces of water. If the drink is a little too runny, go to 8

ounces ice and 1 ounce water. If it is initially too thick, go to 6 ounces ice and 3

ounces water. You get the idea. The two values have to add up to 9 ounces, so

adjust according to preference. And with the BDI, you do not need to experi-

ment with only whole numbers of ounces as the computer allows dispensing in

14

tenths of seconds!

3. Determine the desired texture of the finished drink. The same ingredients

(raspberry concentrate, water, and ice) can be blended slowly to achieve a

nice, crunchy Italian ice, while a more aggressive blend will turn them into a

velvet smooth granita. It’s your choice.

4. Now for a little fine print.

First, different ingredients have inherent thickness differences within and

between flavors. For instance, think of the difference in thickness there is

between strawberry juice, strawberry concentrate, and a strawberry puree with

lots of pulp and seeds. The first two will be on the thinner side, the puree on

the thicker side. Now play the same game with fruits having more fiber such as

pineapple or mango. You can see that different types of products (juice, syrup,

puree) and different flavors (e.g., apple, mango) have different levels of thick-

ness and fiber. The thicker the ingredients, the tougher the blend.

Second, be aware of the brix factor. Sweeter liquids have higher dissolved

sugar ratios (solids in water). A 100 gram liquid with a brix level of 10 degrees

has 10 grams of sugar combined with 90 grams of water. A 100 gram liquid

with a brix level of 25 degrees has 25 grams of sugar combined with 75 grams

of water. The higher the solids to water ratio, the more difficult to blend.

Third, what is the temperature of your ingredients, all of them? The warmer

the flavor product, water, or ice, the thinner the resulting drink. Conversely, the

colder the ingredients, any of them, the thicker the drink.

Fourth, what is an alternative spelling for alcohol? Antifreeze. If you are adding

alcohol to a drink, its effect on drink consistency is greater than water, so plan

accordingly. In terms of the ice/water in #2 above, more ice is needed relative

to the amount of alcohol added to maintain the same consistency between

virgin (non-alcoholic) and alcoholic beverages.

Finally, all ice values above are by weight. If you do not have a scale and are

instead measuring ice by volume, the melt ratio of ice to water is 2 to 1. That is,

two cups of ice by volume melt to one cup of water by weight and 16 ounces

of ice by volume melt to 8 ounces of water by weight (the same ratios apply to

any metric measurements). If your drink calls for 10 ounces of ice by weight, be

sure that you are putting 20 ounces of ice by volume into your blending jar!

The rest of this section will help you with the basics of programming and allows

for the programming of drinks to your requirements. This feature will give you

the opportunity to view, and if necessary, change your data set parameters

(see Figure 1 for the data set sequence).

Pmp1 Pmp2 Pmp3 Pmp4 Pmp5 Pmp6 Pmp7 Pmp8 Pmp9 Watr Ice Stime Scycl Mtime Ltime Lcycl Pause

Drink 1

Drink 2

Drink 64

Figure 1

15

6.1 Program Mode:

This is the mode that you will utilize to change settings for pumps, water, ice,

blend cycles, blend times, and pause. To enter this mode you press 7-8-9-GO

in sequence. The display will change from “Enter Drink #” to “Drink 1 Pmp 1

00”.

• Navigating in the program is done with the S, M, L, and GO buttons on the

control panel.

• The S and M buttons move you up and down in drinks: 1-64 on M and 64-1

on S.

• The L and GO button will move you up and down in the data sets; GO moves

forward (pump 1-8) and L moves backward (pump 8-1).

• You must enter the programming mode before any changes can be made.

• To exit the programming mode at any time, press the STOP button twice.

• It is possible to access a specific drink number in the Drink Settings Menu

(7-8-9-GO) by pressing 1, then the drink number (1 to 64), and then GO.

6.2 Adjusting Product:

• Product values can be added, removed, or adjusted as you see fit; however,

when you find a drink setting that works for you it is recommended that you

do not change it unless absolutely necessary.

• To adjust product settings, scroll to the drink number (S or M buttons) you

wish to change.

• Now use the GO button to move to the pump number that needs to be

changed.

• Pump values are recorded in tenths of a second. In other words, 22 on the

display represents 2.2 seconds of dispense time.

• The dispense rate will vary slightly depending on the type of product you are

using. A 4 to 1 concentrate will be thicker and will therefore need more time

to dispense. (See Section 7.1 for calibration help.)

• Enter the value you want by pressing the correct numbers on the control

panel and then the GO button.

• The value will be stored and then move onto the next pump or data set.

• To zero out a value, scroll to the appropriate pump, enter 0 on the keypad

and press GO.

6.3 Adjusting Water:

• Scroll to the Water data set by pressing either the L or GO buttons.

• Water is also entered in tenths of a second. The water dispense rate should

not vary unless your water pressure coming into the unit is less than 30PSI

(2.1097 kg/cm).

• Enter the value required by pressing the numbers on the control pad and

then pressing the GO button.

• To zero out the water value, enter 0 on the keypad and press GO.

6.4 Adjusting Ice:

• Scroll to the Ice data set by pressing either the L or GO buttons.

• Ice is also entered in tenths of a second.

• Enter the value required by pressing the numbers on the control pad and

then pressing the GO button.

16

• To zero out the ice value, enter 0 on the keypad and press GO.

• Ice dispense rate may vary depending on the type and shape of ice cube that

you utilize. (See Section 7.1 for calibration instructions.)

6.5 Adjusting Blend Times:

• Scroll to the first blend time data set (Small) by pressing either the L or GO

buttons.

• Blend times are in whole seconds. 21 in the blend cycle set represents 21 sec-

onds of blend time. The blender motor will run for the programmed time and

then stop.

• The blender motor will run in the pattern as described by the Cycle in the next

data set.

• To zero out the blend time value, enter 0 on the keypad and press GO.

• To move to the next blend time for Medium or Large press the GO button to

reach them. (Cycle settings are between each.)

6.6 Adjusting Blend Cycles:

• Scroll to the first blend cycle data set (Small) by pressing either the L or GO

buttons.

• There are 6 pre-programmed cycles already stored in the unit. See Figure 2

• Select the cycle you want by pressing the appropriate number (1-6) and press

GO.

SpeedA TimeA SpeedB TimeB SpeedC TimeC SpeedD TimeD SpeedE TimeE SpeedF TimeF SpeedG TimeG SpeedH TimeH

Cycle 1 5 15

Cycle 2 6 15

Cycle 3 7 15

Cycle 4 3 1 4 1 1 2 3 1 4 2 5 2 6 2 7 3

Cycle 5 3 1 5 1 1 2 3 2 5 2 3 3 6 6 8 6

Cycle 6 3 2 1 3 3 3 5 3 6 4 7 15 8 6

Figure 2. Standard Blend Cycle Profiles

• Regardless of the time listed above (Figure 2), the blender motor will run for the

amount of time that you have programmed into the Cycle time data set. How-

ever, the cycle will start over at the beginning of its programmed time. In other

words, looking at Cycle 5 above, you can see that it is set for a total time of 24

seconds. If your cycle time is greater than 24 seconds, the cycle will start over

at the lower speed and repeat until the time is up.

• You must have a cycle programmed into the data set even if you have no cycle

time.

• Press the GO button to move to the Mcycl and Lcycl data sets and change or

set as needed.

6.7 Adjusting Pause:

• Scroll to the pause data set (Small) by pressing either the L or GO buttons.

• Pause is the amount of time the blender motor will wait until it begins to blend.

• The use of Pause is to allow your ingredients to dispense into the blender jar

without being thrown back out.

• Pause is again, in whole seconds. Enter the value with the number keys on the

control panel and press GO.

17

6.8 Changing the Drink Size Ratio:

• You can set the drink sizes for the S, M, and L buttons on the keypad.

• To access the menu press 7-8-8-GO on the control pad (from the Enter Drink

# screen).

• The display will now read “Size Small XX”. Enter the size, in ounces, of the

small drink you want to make and press GO.

• The data set will automatically move to the Size Medium data set; enter the

ounces size of your medium drink and press GO.

• The data set will automatically move to the Size Large data set; enter the

ounces size of your large drink and press GO.

• It is not necessary to have all three sizes, but you must have a “small” drink.

The “small” drink size correlates directly with the data set programmed into

the 7-8-9-GO menu. This is very important! If you set your 7-8-9-GO menu,

ice and water values to make a 12 ounce drink and your small size to 14

you will only make 12 ounce drinks and the M and L drinks will not turn out

correct. The microprocessor uses the small drink size and the settings in the

7-8-9-GO menu to automatically generate your M and L drinks. Ensure that

the size of drink and the programmed data sets match directly.

• Press the STOP button twice to exit the drink size menu.

Section 7: Advanced Programming

This section is intended for anyone who needs more detail in order to be able

to do more than just the basic programming operations. There is additional

information about controls and reports the unit can supply. Pressing 7-8-9-GO

on the control panel, unless otherwise noted, accesses all functions.

7.1 Calibration:

There are two ways to optimize the drinks made in the BDI. You can use the

trial and error method, which involves making small changes to a drink and

testing each change as you go until you get it the way you want it. Or, you can

calibrate the BDI and make drinks according to a formula. Because fittings,

tubing, temperature, and product can all cause the pumps to dispense at differ-

ent rates, each drink you wish to make from a formula will require a calibrated

pump. This section will tell you how to isolate and calibrate each dispensing

function.

• Press 7-8-9-GO to access the program mode. (If you have not read Section

6, do so now.)

• Press 0 then GO. This will zero out the pump run time for Pmp 1 in Drink 1.

The display will now read “Drink 1 Pmp 0.”

• Press 0 and GO until all eight pumps are at 0. Continue to zero out water,

ice, and the blend times (you cannot zero out the cycles).

• Select the concentration ratio for the product you use in pump 1 from the

table below. We are assuming that the pumps deliver about 1 oz. per sec-

ond. Divide your recipe’s product amount (our 12 oz. drink) by 1.0 to get the

suggested pump time. For example, If you use 2 to 1 product, divide 4 oz.

by 1.0 oz per second. 4/1 = 4.0 seconds. With the display showing “Drink

1 Pmp 1 0” enter the suggested run time, remembering that what you enter

is in tenths of a second. In this example, enter “40” to get 4.0 seconds, then

18

press GO. This is a starting point only. The viscosity of the liquid you are

pumping will require you to do some experimentation and adjust accordingly.

For example, if you have a product which is thicker and only pumps at ½ oz

per second, to get 4 oz of product you would need to pump for 8 seconds.

Suggested Drink Formulae – Figure 3

Concentration

Ratio

Small

12 oz. Drink

Medium

18 oz. Drink1

Large

24 oz. Drink2

1.4 to 1

Pmp 5 oz.

Water 0 oz.

Ice* 14 oz.

Pmp 7.5 oz.

Water 0 oz.

Ice* 21 oz.

Pmp 10 oz.

Water 0 oz.

Ice* 28 oz.

2 to 1

Pmp 4 oz.

Water 2 oz.

Ice* 12 oz.

Pmp 6 oz.

Water 3 oz.

Ice* 18 oz.

Pmp 8 oz.

Water 4 oz.

Ice* 24 oz.

3 to 1

Pmp 3 oz.

Water 3 oz.

Ice* 12 oz.

Pmp 4.5 oz.

Water 4.5 oz.

Ice* 18 oz.

Pmp 6 oz.

Water 6 oz.

Ice* 24 oz.

4 to 1

Pmp 2 oz.

Water 4 oz.

Ice* 12 oz.

Pmp 3 oz.

Water 6 oz.

Ice* 18 oz.

Pmp 4 oz.

Water 8 oz.

Ice* 24 oz.

*The amount of ice shown is volume, not weight. When blended, the weight is only ½ of what is shown.

1) The product coming from the pump and the water for these drinks are automatically propor-

tioned to 1.5 times the “S” drinks unless the proportions have been changed as in Section 8.1.

2) The product coming from the pump and the water for these drinks are automatically propor-

tioned to 2 times the “S” drinks unless the proportions have been changed as in Section 8.1.

• Place a jar in the blend station, press STOP twice to exit the program mode,

then press S to select a small drink. Press 1 to activate Drink (pump) 1 then

press GO.

• When the pump has stopped delivering product to the blender jar, you may

measure the product and get an actual dispense rate of the product from

pump number 1. For instance, if the volume of product in the jar is 4.4

ounces, 4.4 oz. / 4 seconds = 1.1 oz per second. Calculate the actual pump

time by dividing the required ounces by the actual pump rate. E.g. 4.0 /1.1

= 3.6 seconds. Record this number; it will be entered later. Re-enter the

programming mode (7-8-9-GO) and zero out Drink 1 Pmp 1.

• Repeat the earlier steps for each pump port. You may use a different con-

centration ratio in each pump and your formula may call for different quanti-

ties of product than the suggested formula. Keep a record of the measured

pump flow rates in the chart below or one similar.

19

Pump Number Flow Rate

Pump Port 1 Flavor oz /sec

Pump Port 2 Flavor oz/sec

Pump Port 3 Flavor oz/sec

Pump Port 4 Flavor oz/sec

Pump Port 5 Flavor oz/sec

Pump Port 6 Flavor oz/sec

Pump Port 7 Flavor oz/sec

Pump Port 8 Flavor oz/sec

7.2 Water Flow Rate:

Calibrate water flow (it is done much the same way as calibrating pumps):

• Press 7-8-9-GO to enter the drink program mode

• With all data sets of Drink 1 at “0”, press the GO or L pad until the display

reads: “Drink 1 Watr 0”

• Press 5-0-GO to enter and store 5 seconds of water dispense time for drink 1

• Press STOP twice to exit the program mode

• Make sure a jar is in the blend station and press S-1-GO to start dispensing

water into the jar. Water will dispense for 5 seconds.

• Measure the water in the jar and divide by 5 to calculate the water flow

rate. For example, with 2.5 oz. of water in the jar, 2.5/5 = 0.5 oz per second.

Record this number. Because the water comes from the same valve for all

drinks, the water flow rate will be the same for every drink.

7.3 Ice Dispense Rate:

Calculating the ice dispense rate is done in a similar fashion as the water flow

rate.

• Press 7-8-9-GO to enter the drink program mode

• With all of the data sets of Drink 1 at “0”, press the GO or L pad until the

display reads: “Drink 1 Ice 0”

• Press 5-0-GO to enter and store 5 seconds of ice dispense time

• Press STOP twice to exit the program mode

• Using any water source fill a jar with 10 ounces of water and place the jar in

the blend station

• Press S-1-GO to start dispensing ice into the jar. Ice will dispense for 5 sec-

onds

• Measure the ice in the jar by reading the water level and subtracting 10 from

the result. This will give you the volume of ice that was dispensed. Divide the

new result by 5 to calculate the ice dispense rate. Record this number.

• Example: After the ice dispense is complete the volume of water/ice is 16

oz. Calculate the ice dispense rate by subtracting out the water portion: 16

– 10 = 6; then divide by 5 to obtain the dispense rate: 6/5 = 1.2 ounces per

second.

20

7.4 Ice Level Sensor:

• The Ice Level Sensor notifies the user when the ice hopper is close to being

empty.

• The sensor can be disabled or enabled by pressing 3-5-8-GO. The display

will either read, “Ice Sensor On” or “Ice Sensor Off”. Pressing S or M will

make a selection. Once the mode of operation is selected press STOP twice

to exit the menu.

7.5 Ice Buster:

The ice buster’s purpose is to run the ice auger for a period of time every so

often to keep the ice ready to be dispensed. This feature allows the Ice buster

to be enabled or disabled. The duration of the ice buster and the interval be-

tween ice busting can also be set from this menu.

• Access this menu by pressing 3-5-7-GO.

• The screen will read, “Ice Buster On” or “Ice Buster Off”. Make a selection

by pressing the S or M button.

• Press the GO button to advance the menu to the Interval between bust

cycles. The screen should read, “Interval (min)___”. Enter the desired inter-

val in minutes and press GO to store the value and also to advance to the

duration of the bust cycle.

• The screen will now read, “Duration (sec)___”. Enter the desired duration in

seconds and press GO to store the value.

• Press STOP to exit the menu.

7.6 Small Drink Default:

Use this feature to select the mode for the default drink size. There are 3 op-

tions. The first is for the SMALL to be the default drink size. The second is that

the drink size will remain the same after a drink has been made. The third op-

tion is that no drink size will be selected after a drink is made. This requires that

the user select a drink size each time a drink is made.

• To make a selection for the mode of operation press 3-5-6-GO.

• The screen will show one of the three following options: “Revert To Small”,

“Revert To Same”, and “Revert To None”.

• Press the S or M button to scroll through the three options.

• Once you have selected the option you want, press GO. The setting you

selected will be stored. Press STOP twice to exit the menu.

7.7 Restore Defaults:

There are three types of restore defaults: Drink Settings, Blend Cycles, and

Misc Settings. These three will revert key settings back to the factory default.

If you do not have a profile that is installed at the factory then the default set-

tings will revert to “0”.

• Restore Drink Settings: This feature will restore the Drink Settings to their

factory defaults. Press 4-4-4-GO and the screen reads, “Reset Drinks?”.

Press GO again to confirm that the drink settings should be reset to the

defaults. The screen will say “Storing Drinks” and a count will show the

This manual suits for next models

3

Table of contents

Popular Dispenser manuals by other brands

METZGER

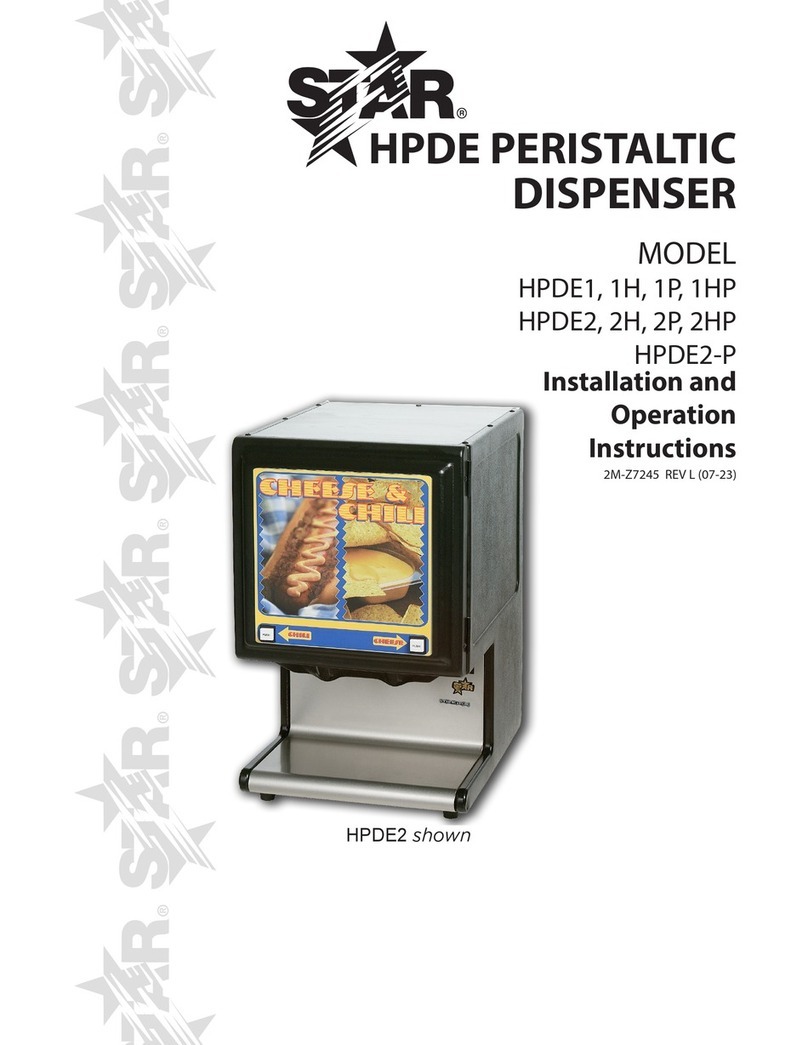

METZGER Cosmos Series user manual

Perfect Servings

Perfect Servings UV-PSPD-5-AV-BL-T Installation and operating manual

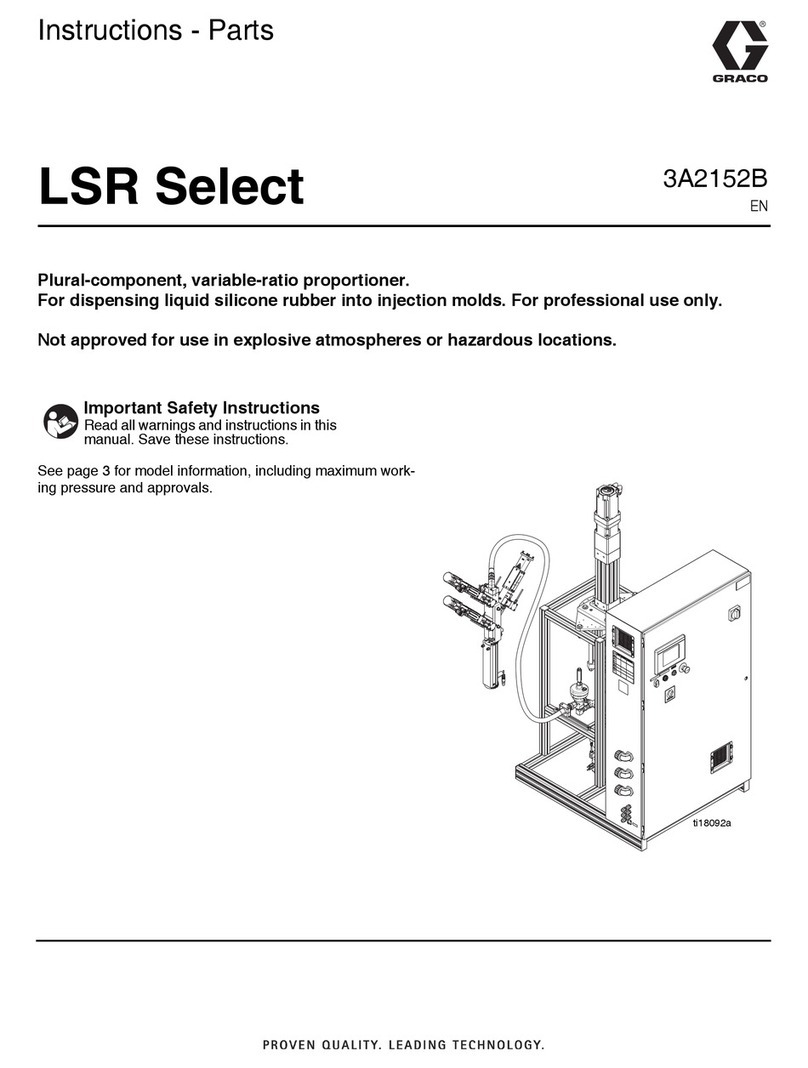

Graco

Graco LSR Select instructions

icetro

icetro ID-0300-AN Installation and service manual

SATO

SATO TURN-O-MATIC installation guide

Dolphin

Dolphin BC633FC Installation and maintenance guide