Tip: We do recommend that you periodically rake the top 1/3 of the mash during lauter about every 15 min to maintain a

smooth efficient lauter process. Raking the top of the mash will not disturb the lower part of the grain bed and the wort

will remain clear throughout the lauter.

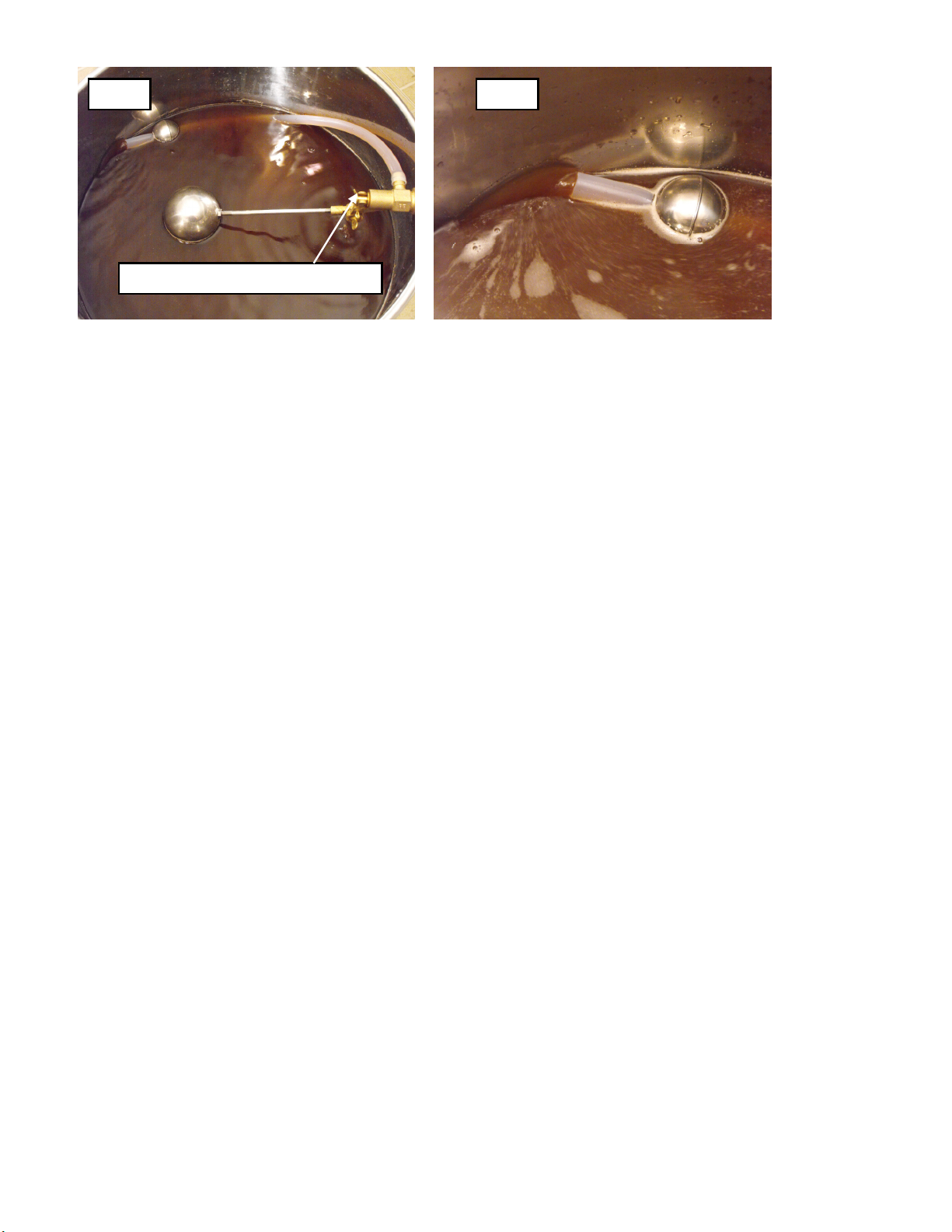

When you have finished your mash, simply turn on the hot liquor tank valve and/or pump to the full open position. Then

open the mash/lauter tun valve to the desired wort drain rate. That’s it! The AutoSparge

tm

will automatically let more hot

liquor into the tun to compensate for the rate at which you’re draining wort into your brew pot. Note that hot liquor may

flow quickly at first until you reach the level control point and then the valve will slow the flow to match the drain rate. As

you change the rate you’re draining, the AutoSparge

tm

will automatically match it, maintaining a constant liquid level over

your grain bed.

Caution: The AutoSparge

tm

is NOT intended for unattended operation or for use as an automated pot filler. City/well water

pressure will NOT be shut off by the AutoSparge!! A max pressure if 10 PSI is allowed. This is plenty for most gravity and

small magnetic drive pump installations.

Maintenance

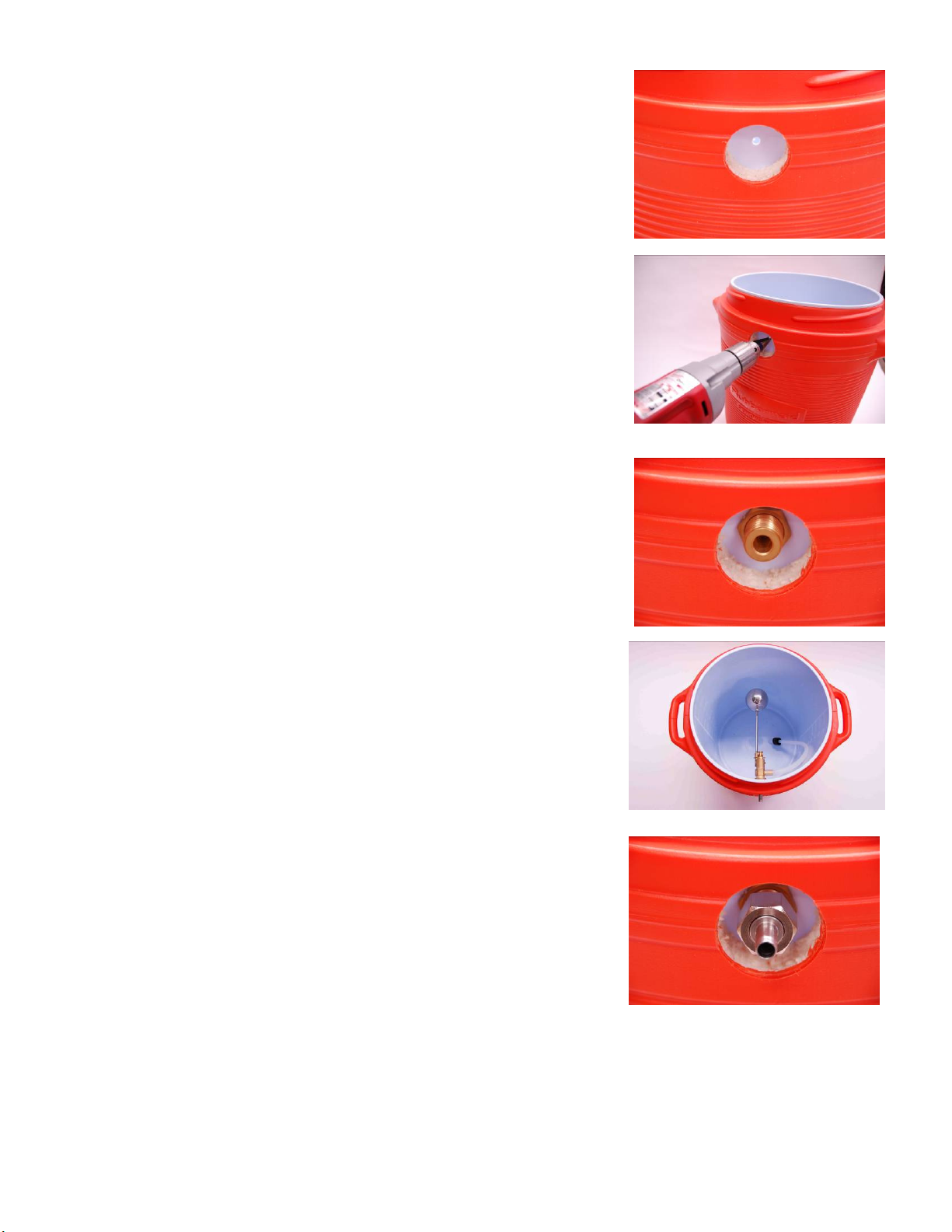

Clean the AutoSparge

tm

with any brass/stainless compatible cleaner and allow to dry thoroughly. It is not necessary to

remove the AutoSparge

tm

from the pot for cleaning, although removing the ball/arm assembly (remove the thumb screw)

will make cleaning the inside of your mash/lauter tun easier.

Blichmann Engineering Product Warranty

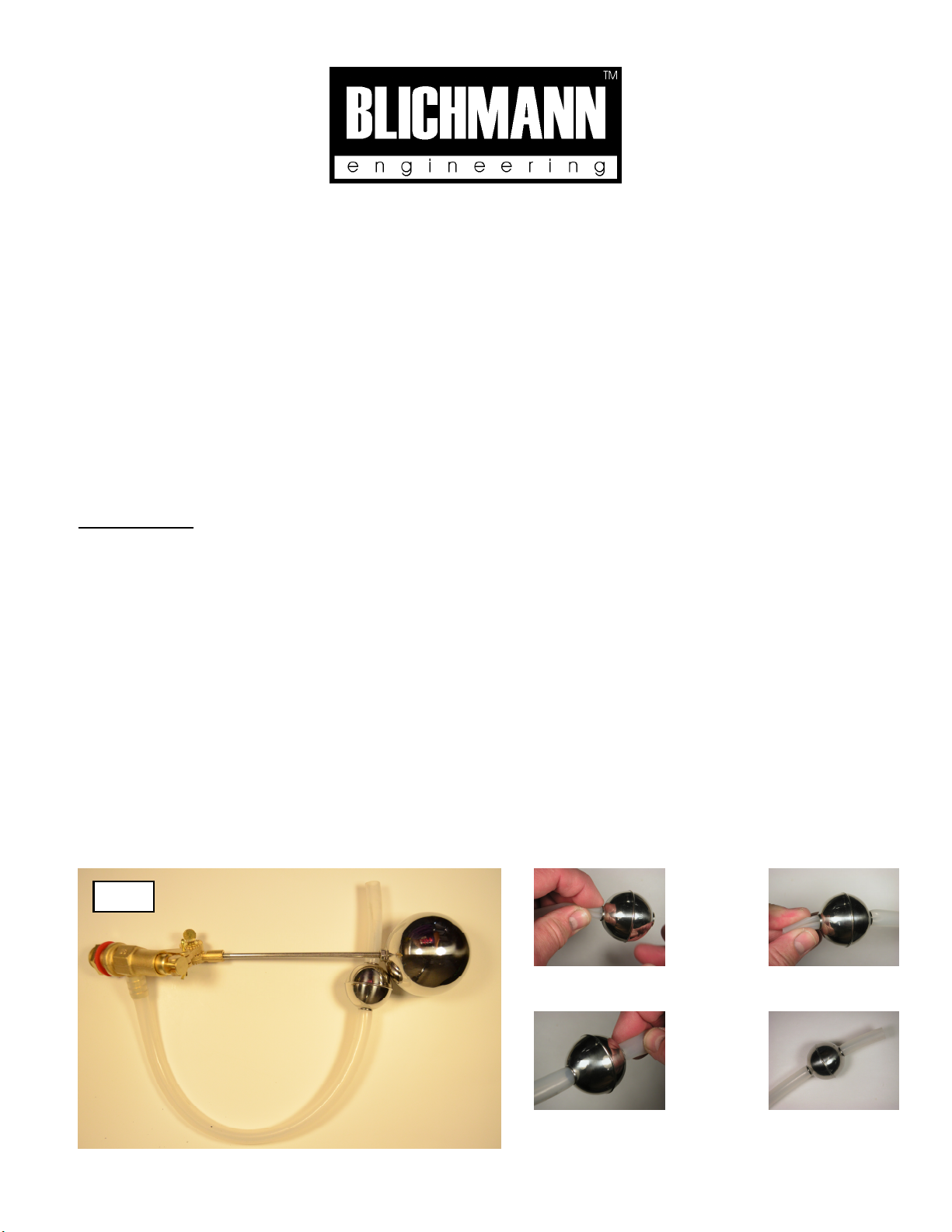

Float adjustment thumb screw

A. Limited Warranty

1. Blichmann Engineering warrants to the original purchaser that this product will be free from manufacturing defects in material and workmanship for a period of one (1) year from the

date of purchase by the customer. Proof of purchase is required. Blichmann Engineering’s obligation to repair or replace defective materials or workmanship is the sole obligation of

Blichmann Engineering under this limited warranty.

2. The limited warranty covers only those defects that arise as a result of normal use of the product and does not cover any other problems, including, but not limited to, those that arise

as a result of:

a. Improper maintenance or modification;

b. Damage due to incorrect voltage or improper wiring by customer;

c. Operation outside of the product’s specifications;

d. Carelessness or neglect to operate the product in accordance with instructions provided with the product;

e. Damaging the tamper label on the product;

f. Damage by over-tightening the fasteners;

g. Failure to follow cleaning and / or maintenance procedures; or

h. Exceeding published operational temperatures.

3. Blichmann Engineering reserves the right to request delivery of the defective component for inspection before processing the warranty claim. If Blichmann Engineering receives,

during the applicable warranty period, notice of a defect in any component that is covered by the warranty, Blichmann Engineering shall either repair or replace the defective

component with a new or rebuilt component at Blichmann Engineering’s option.

4. Blichmann Engineering must be notified within seven (7) days of the delivery date of any shipping damage. Customer is responsible for shipping damage outside of this time period.

Approval for return must be provided by Blichmann Engineering prior to any return. Customer is responsible for keeping all original packaging material for warranty returns.

Blichmann Engineering is not responsible for damage from improperly packaged warranty returns, and these repair costs will be the sole responsibility of the customer. Shipping

costs for warranty returns are covered only for the contiguous United States.

5. Blichmann Engineering’s limited warranty is valid in any country where the product is distributed.