3

General description

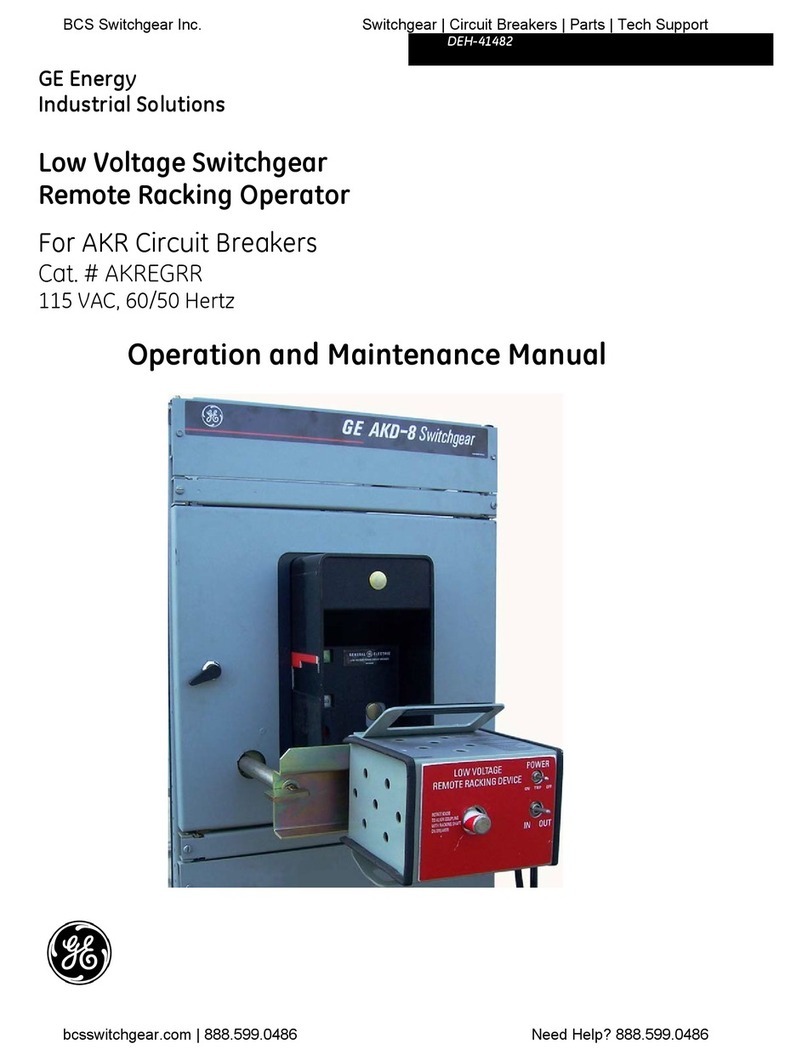

AKD-10 Switchgear is industrial-duty equipment built to

ANSI standards and uses 100% rated WavePro™Low

Voltage Power Circuit Breakers. It is designed to have more

margin within its ratings to provide maximum continuity of

service for those applications subject to severe duty, such as

repetitive switching encountered with motor starting, power

factor correction, demand control, load shedding, etc.

Amajor factor contributing to this extended continuity of

service is the availability of renewal parts complete with

detailed maintenance instructions and original equipment

documentation. From a coordination standpoint, WavePro

circuit breakers provide full selectivity with each other and

with other protective devices. The bus sizing is based on

temperature rise rather than on current density (as with

switchboard construction).

AKD-10 switchgear is available with the following maximum

nominal ratings:

• 600 Vac

• 5000 Amps ac

• 50/60 Hz

• 2200 Vac RMS dielectric

• 200 kA symmetrical short circuit

AKD-10 switchgear sections are provided in either 22", 30" or

38" widths. It is designed to be operated in an ambient tem-

peraturebetween -30°C and 40°C (-22°F and 104°F).

WavePro low voltage power circuit breakers are available for

AKD-10 switchgear in six frame sizes:

• 800A WPS/WPH/WPX/WPF-08

• 1600A WPS/WPH/WPF-16

• 2000A WPS-20

• 3200A WPS/WPH/WPX-32

• 4000A WPS/WPX-40

• 5000A WPS/WPX-50

All breakers can be equipped with current limiting fuses.

WPF-08 and WPF-16 are provided with integrally mounted

fuses, while a separate fuse carriage is required for WPS-20,

WPS-32, WPS-40, and WPS-50 type breakers.

Low voltage circuit breakers rated 800/1600/2000 amps can

bestacked in four-high combinations resulting in reduced

floor space requirements. The 11-gauge, bolted modular-

designed steel frame permits flexibility in arrangements of

breakers and associated components.

AKD-10 switchgear houses low voltage power circuit breakers,

instrumentation, and other auxiliary circuit protective devices

in single or multiple source configurations. AKD-10 switchgear

can be applied either as a power distribution unit or as part

of a unit substation in indoor or outdoor construction.

AKD-10 switchgear is manufactured in GE’s ISO 9002 certified

facility in Burlington, Iowa. It complies with ANSI standards

C37.20.1 and NEMA SG-5, and it is UL listed to standard

1558, file no. E76012. The switchgear has been conformance

tested according to ANSI C37.51. AKD-10 switchgear can

also be labeled per CSAstandard C22.2.

ANSI standards requirethat switchgear operates at the rat-

ings of devices installed. Switchgear short circuit ratings are

based on two30-cycle withstand tests with 15-second interval,

performed at 15% power factor and 635 Vac maximum. For

switchboards, a single 3-cycle withstand test at 20% power

factor and 600 Vac maximum is performed.

General Electric’s AKD-10 Low voltage switchgear can help

you meet today’s challenges for greater productivity,

increased operator safety and improved equipment reliability

and maintainability.