7102619 03/13

Operating Instruction

Operation

4 Operation

4.1 Safetyinstructions

• Neverpointcompressedairatpersons.

• Donotusecompressedairforbreathing

withoutcorrespondingtreatment.

• Usemountingpartsanddevices

downstreamfromthecompressorwhich

havebeendesignedforthemaximumope-

ratingpressureofthecompressor.

• Donotreachintotherotatingwheelswhen

thecompressorisoperational.

• Touchthecompressorsystemattheon

andoffswitchonlyduringandshortlyafter

operation.Hotsurfacecancausesevere

injuries.

• Switchthecompressoroffimmediatelyin

caseoffaults.

• Keepcombustiblematerialsawayfromthe

compressorsystem.

• Operatethecompressoronlywithsuction

lterandclosedfancowland/orbeltguard.

• Operatethecompressoronlyattheper-

missibleoperatingpressureofthepressure

reservoir.

• Tightenthescrewconnectionsofthepres-

sure pipes.

• Weartight-ttingworkclothswhenhandling

the compressor.

• Weargogglesandearmuffswhenworking

withcompressedair.

• Wearahairnettoprotectlonghairand

removeanylosejewellery.

• Checkthecablesfordamageinregular

intervals.

• Keepdomesticanimalsandchildrenaway

fromthecompressorsystem.

• Switchthecompressoroffwhennotnee-

ded.

• Whenoperatingthecompressorwithan

engine,pleaseobservetheadditionalsafe-

tyinstructionsintheoperatinginstructions

enclosed.

4.2 Switching the unit on

Checktheoillevelthroughtheoillevel

inspectionglassandtopuptheoil,ifand

whennecessary(cf.chapter5.2“Checking

andtoppinguptheoillevel”).

Setthepowerswitchtoonorpluginthe

powerplug.

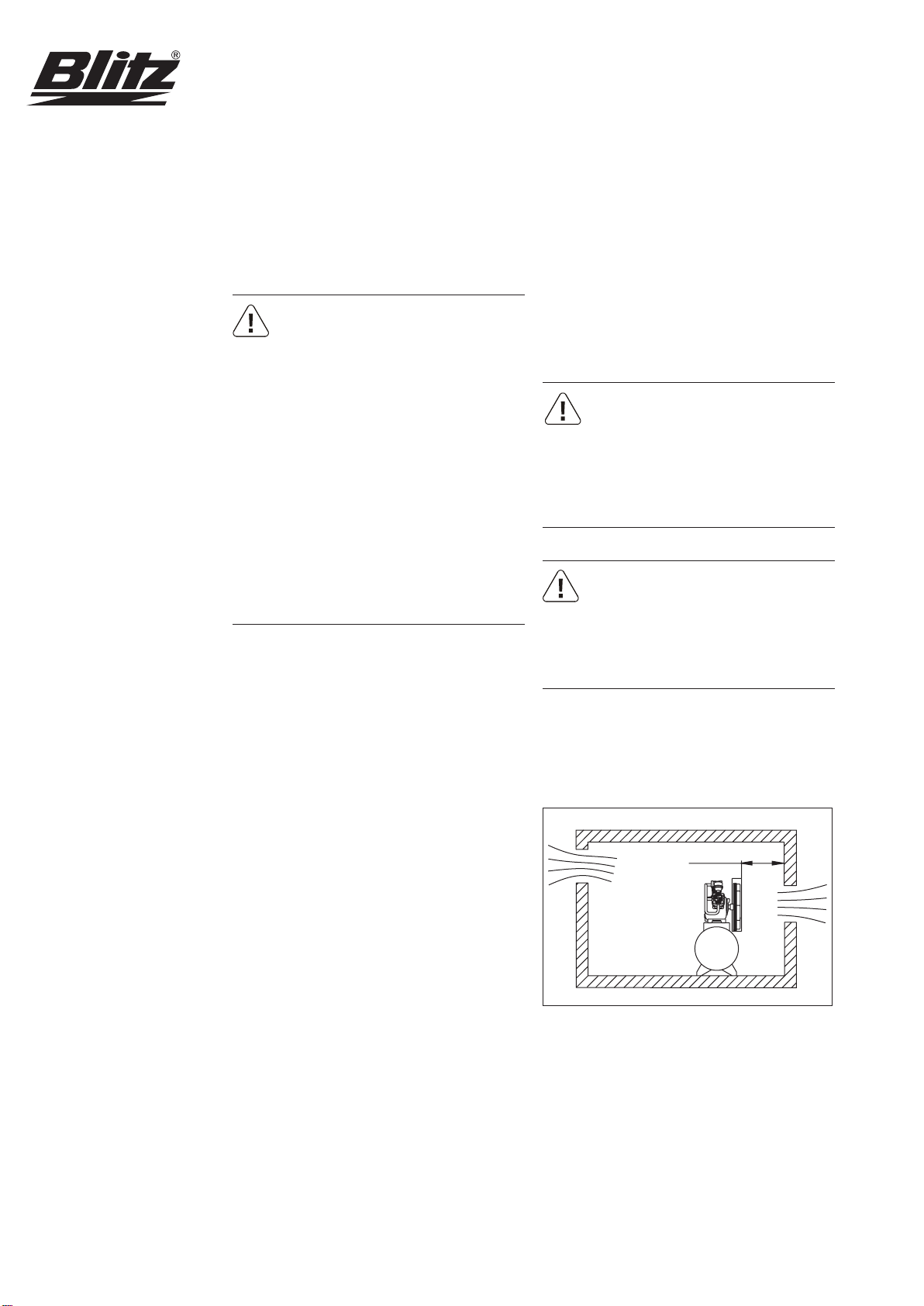

Settheoperatingswitchtoposition1(cf.

Fig.1:Componentoverview).

Thecompressorwillstartupautomatically

whenthepressureinthenetworkislowerthan

thecut-inpressureset.Theunitwillstopauto-

maticallywhentheoperatingpressureismade

inthenetwork.

Incaseoffaults,pleaserefertochapter7titled

“Troubleshooting”formorehelp.

4.3 Dailycheck-ups

• Drainthecondensationwateratthecom-

pressed-airreservoir(cf.chapter5.4“Drai-

ningthecondensationwater”).

• Checktheoillevelofthecompressor(cf.

chapter5.2“Checkingandtoppingupthe

oillevel”).

4.4 Switchingtheunitoff

Settheoperatingswitchtoposition0(cf.

Fig.1:Componentoverview).

Setthepowerswitchtoofforremovethe

powerplug.

4.5 OriginalBLITZaccessories

BLITZoffersyouthefollowingaccessories:For

moreinformation,pleaserefertotheBLITZ

pricelistordirectlytoBlitzRotary.

Compressed-airlter

Tocleanthecompressedairforspecialappli-

cations.

Coldorabsorptiondrier

Topreventfaultsofthecompressedairduct-

worksystem,compressed-airtools,instru-

mentsandcontrolscausedbyhumidair.

Automaticcondensationwaterdrain

Tospareyouthedailydrainingofcondensation

water.