3|Areas of application

ATTENTION! Compressor operation is possible within the limits of application

showninthediagrams.Pleasenotethesignicanceofthe

shaded areas. The limits of application must be observed.

Thresholds should not be selected as design or continuous

operating points.

-Max.permissibledischargeendtemperature:140°C

-Max.permissibleambienttemperature:100°C

-Max.permissibleswitchingfrequency:12x/h

-Aminimumrunningtimeof2min.atequilibrium

(continuous operation) must be achieved.

Avoid continuous operation near the threshold. Should the

compressor happen to be used near the thresholds, we

recommend the use of a thermal protection thermostat

(Accessories, Chap. 7).

Foroperationwithcapacityregulator:

- Continuous operation, when the capacity regulator is activated, is

not permissible and can cause damage to the compressor.

- The suction gas superheat temperature may need to be reduced or

set individually when operating near to the threshold.

- When the capacity regulator is activated, the gas velocity in the

systemcannotundercertaincircumstancesensurethatsufci-

ent oil is transported back to the compressor.

When operating in the vacuum range, there is a danger of air

entering on the suction side. This can cause chemical reactions,

a pressure rise in the condenser and an elevated compressed-

gas temperature. Prevent the ingress of air at all costs!

Thecompressorsarefactory-lledwiththefollowingoiltype:

- for R134a, R404A/R507, R407C FUCHS Reniso Triton SE 55

- for R22 FUCHS Reniso SP 46

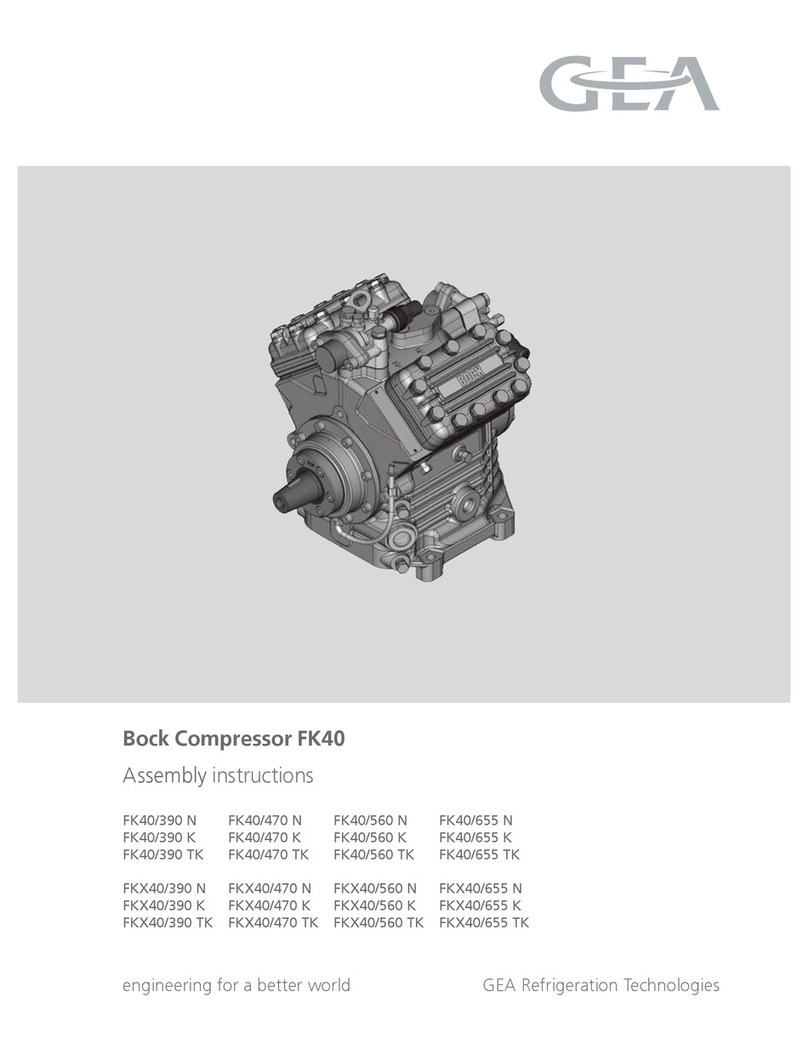

Compressorswithesteroilcharge(FUCHSRenisoTritonSE55)aremarkedwithanXinthetype

designation (e.g. FKX50/775N).

3.1 Refrigerants

• HFKW / HFC: R134a, R404A/R507, R407C

• (H)FCKW/(H)CFC: R22

3.2 Oil charge

3.3 Limits of application

INFO! Forrecharging,werecommendtheaboveoiltypes.Alternativesare:

see lubricants table, Chapter 6.5.