Introduction

2

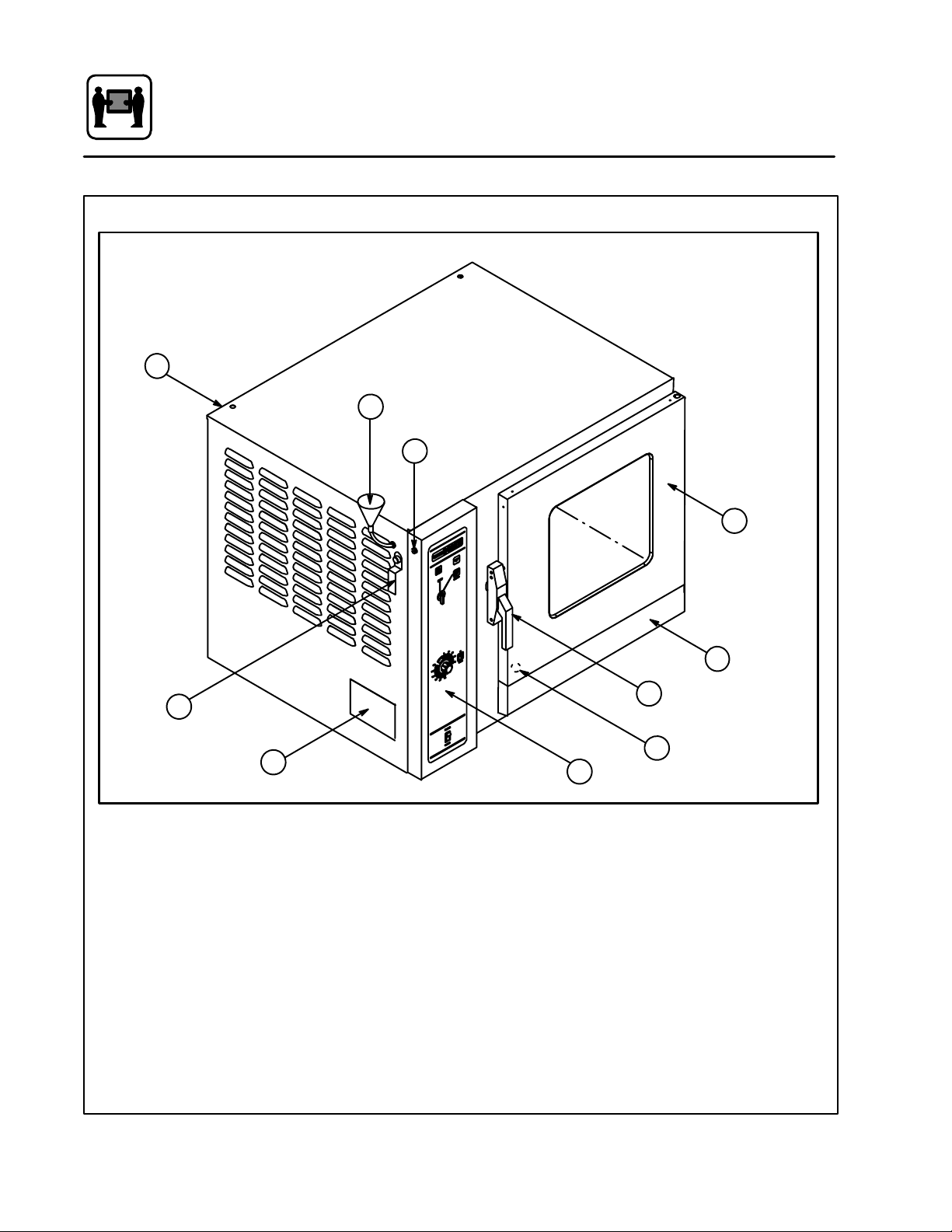

The Convection Steamer

Steaming āis āa wellĆknown cooking process freĆ

quently used in restaurant and institutional kitchĆ

ens. With the Blodgett Convection Steamer, it is

now possible to enjoy the many advantages of

steaming, some of which are:

Simplified Work Process

he work process is simplified since products are

prepared on or in steam table āpans āand trays.

Food can be cooked, stored, and transported with

āthe āsame āāpans. āSmall āamounts of product can be

processed efficiently; preĆcooked and conveĆ

nience foods can be rethermalized within minutes.

āMany frozen foods can be processed without preĆ

thawing. his flexibility in preparation reduces the

need for kettles and steam tables since there is no

need for large amounts of food to be kept warm for

long periods of time.

Hi h Quality Foods

oday the improvement of food quality is more imĆ

portant than ever. With ātheā useāāā ofā steam,ā valuable

taste and aroma are preserved since steamed

foods retain their own natural taste. During the

steaming process foods retain the nutrients and

vitamins which are lost in water during boiling.

herefore when compared, steamed foods have

much better color than foods that have been

boiled. āAlso,ā by using shallow containers the prodĆ

uct is not layered as deeply and mushing is

avoided.

Vitamin Retention

In āthe āBlodgettā Convection Steamerā vitamins are not

destroyed. his is due to the shorter cooking times,

the use of less or little water and the use of a low temĆ

perature; slightly less than 212_F (100_C).

Firmness

With the use of steam, overcooking āisā notā a probĆ

lem and firmness can be individually controlled.

Simultaneously Steamin Different Foods

here is no flavor transfer when cookingā āwithā ātheā

āConvection Steamer. For this reason, various

types of food with different cooking times can be

loaded or removed at any point during the steamĆ

ing process.

HOW STEAMING WORKS

he Blodgett Convection Steamer gently cooks

food using nonĆpressurized steam. Fresh steam is

directed into the unit from the generator. It is not

necessary to add water to foods during the steamĆ

ing process.

WHAT CAN BE STEAMED

Vegetables, side dishes, fish, meat, poultry, diet

foods, garnishes, dumplings, casseroles, meat

loaf, fruits, desserts and eggs.

In the Steam mode you can:

Dsteam

Ddefrost

Dblanch

Dpoach

Drethermalize