Blohm + Voss Oil Tools VES-HCL 350 User manual

1

Blohm+Voss Pipe Handling Equipment

VES-HCL 350 Elevator Hydraulically Operated

Part no. 613000-Y-H-F (with closing signal)

Technical Documentation

Original Instructions

Manual PN 613000-Y-H-F-D Rev 005 valid from SN 84007 , April 2012

Blohm + Voss Oil Tools

2

Improper / Unsafe Use

The tool must only be used

for the designated purpose.

When using the tool, the

rated load must never be

exceeded.

Intended use of this

manual

This manual is intended

for use by field service,

engineering, installation,

operation, and repair

personnel. Every effort has

been made to ensure the

accuracy of the information

contained herein. Blohm

+ Voss Oil Tools, will not

be held liable for errors

in this material, or for

consequences arising from

misuse of this material.

Anyone using service

procedures or tools, whether

or not recommended by

Blohm + Voss Oil Tools, must

be thoroughly satisfied that

neither personal safety nor

equipment safety will be

jeopardized.

Intellectual property

All rights retained. No part

of this document may be

reproduced in any form

(print, photocopy, microfilm

or any other procedure)

or be processed using an

electronic system without

written approval of Blohm +

Voss Oil Tools.

All information contained

in this manual is based

upon the latest product

information available at any

time of printing.

Dependent on ongoing

technical improvements

(ISO 9001) “Blohm + Voss

Oil Tools” reserves the

right to change the design

and specifications without

announcement.

The values specified in

this manual represent the

nominal values of a unit

produced in series. Slight

deviations in the case of

the individual devices are

possible.

NOTE: In the event of

problems that cannot be

solved with the aid of this

manual, please contact

one of the addresses listed

below.

Warnings and Note

WARNING: A “WARNING”

INdIcAtes AdefINIte RIsk of

equIpmeNt dAmAGe oR dANGeR to

peRsoNNel. fAIluRe to obseRve

ANd folloW pRopeR pRoceduRes

could Result IN seRIous oR fAtAl

INjuRy to peRsoNNel, sIGNIfIcANt

pRopeRty loss, oR sIGNIfIcANt

equIpmeNt dAmAGe.

NOTE: A “note” indicates

that additional information is

provided about the current

topics.

WARNING: thIs techNIcAl

documeNtAtIoN coNtAINs

INstRuctIoNs oN sAfety,

INstAllAtIoN, opeRAtIoN ANd

mAINteNANce foR the blohm +

voss oIl tools tool . Itmust

be studIed befoRe WoRkING WIth

the tool.

CE Marking

The tool complies with the

Machinery Directive

98/37/EC and 2006/42/EC

For machines containing

any hydraulic or pneumatic

powered parts, the Directive

94/9/EC “Equipment

and protective systems

in potentially explosive

atmospheres” applies.

The marking is as follows:

CE Ex II 2G T5 (hydraulic

tools) or CE Ex II 2G T6

(pneumatic tools).

Manufacturer & Agents World wide

Limited Warranty

The warranty provided will

be void if the tool is either:

1. Repaired or serviced by

a service facility which

was not authorised by

Blohm + Voss Oil Tools.

2. Replacement parts not

manufactured by Blohm

+ Voss Oil Tools are

used.

3. Modifications were made

to the tool which were

not approved by Blohm

+ Voss Oil Tools.

Blohm + Voss Oil Tools

Hermann-Blohm-Straße 2

20457 Hamburg

Germany

Phone: +49 40/3119-1826/1162

Fax: +49 40/3119-8194

oiltools@blohmvoss.com

www.blohmvoss-oiltools.com

Premier Sea & Land Pte. Ltd.

1, Scotts Road

#19-12 Shaw Centre

Singapore 228208

Republic of Singapore

Phone: +65-6734-7177

Fax: +65-6734-9115

enquiries@mtqpremier.com.sg

Blohm + Voss Oil Tools, LLC

7670 Woodway, Suite 266

Houston,

Texas 77063

United States of America

Phone: +1-713-952 0266

Fax: +1-713-952 2807

www.blohmvoss-oiltools.com

GENERAL INFORMATION

3

Warning sign PN 671638

General warning

Warning sign PN 671642

Pay attention: Apply grease at least

once a day.

Warning sign PN 611524

Danger: Do not touch.

Warning sign PN 671640-1

Pay attention: Do not place your

hands between moving parts.

Warning sign PN 671641

Pay attention: Risk of crushing.

General safety issues

WARNING: oNe should AvoId

cReAtING IGNItIoN souRces, lIke

heAt, As AResult of the use of

the tool WIth otheR tools oR

equIpmeNt.

WARNING: doNot use the

tool foR ANy otheR puRpose thAN

GIveN IN thIs documeNt WIthIN Its

specIfIcAtIoN.

WARNING: fAIluRe to coNduct

RoutINe mAINteNANce could Result

IN equIpmeNt dAmAGe oR INjuRy to

peRsoNNel.

WARNING: WeAR peRsoNAl

pRotectIoN equIpmeNt WhIle

WoRkING WIth the equIpmeNt.

WARNING: IfANy sAfety

elemeNts (lIke sAfety Ropes,

sAfety sheets, plAtes oR

WAsheRs) WeRe dIsAssembled due

to mAINteNANce WoRk, do Not

Re-use them. AlWAys ReplAce

them WIth NeW sAfety elemeNts.

WARNING: All WARNING plAtes,

sIGNs ANd lAbels AttAched to

the equIpmeNt must be obseRved.

the WARNING plAtes, sIGNs ANd

lAbels must be pReseNt oN the

tool. doNot Remove the lAbels.

Ifthey ARe mIssING, ReplAcING Is

mANdAtoRy.

WARNING: ANy modIfIcAtIoN to

the tool cARRIed out WIthout the

AppRovAl of blohm + voss oIl

tools WIll voId ANy WARRANty.

WARNING: usING the tool WIth

dAmAGed oR WoRN pARts cAN

cReAte seRIous INcIdeNts.

WARNING: ItIs Not AlloWed to

use ANy compoNeNts WhIch ARe

of "NoN-b+v" oRIGINe, oR use

"NoN-oem" pARts WhIch ARe Not

AppRoved by b+v. ItWIll voId

ANy WARRANty ANd mAy effect the

coRRect fuNctIoNING of the tool

ANd It'ssAfety feAtuRes.

WARNING: the compANy

opeRAtING the tool Is RespoNsIble

foR evAluAtING sAfe ANd pRopeR

use of the tool IN AhAzARd

ANAlysIs.

WARNING: the opeRAtING

compANy Is oblIGAted to Issue

WoRkING INstRuctIoNs foR sAfe

use ANd supeRvIse obseRvANce of

these WoRkING INstRuctIoNs.

WARNING: eveRy employee,

WhIch opeRAtes, seRvIces,

INspects oR otheRWIse INvolved

WIth the use of the tool IN otheR

AReA`shAs to eNsuRe, thAt these

ActIoNs ARe doNe by tRAINed ANd

by AN blohm + voss oIl tools

AuthoRIzed peRsoNNel,

ANd should complete ReGulAR

couRses of tRAINING, to eNsuRe

pRopeR use As Well As sAfe

opeRAtIoN, coRRect mAINtAINANce

ANd INspectIoN.

WARNING: IfNecessARy,

AReAsoNAble, AddItIoNAl

supeRvIsoR should be AppoINted

duRING opeRAtIoN.

WARNING: stAy AWAy fRom the

tool duRING opeRAtIoN. INcAse

It Is Remote opeRAted It mAy mAke

movemeNts WIthout WARNING.

Safety issues elevator

WARNING: doNeveR uNlAtch/

opeN the tool WhIle ApIpe Is

suspeNded IN the tool; the pIpe

WIll be lost!

WARNING: WhIle usING the

elevAtoR, AlWAys mAke suRe

the dooR Is completely closed

WIth the lAtch/lAtch lock

fully eNGAGed ANd If ApplIcAble

the veRIfIcAtIoN pIN pRopeRly

INstAlled.

WARNING: pAy specIAl

AtteNtIoN to the veRIfIcAtIoN pIN

(If ApplIcAble), lAtch ANd lAtch

lock foR ANy sIGNs of WeAR,

beNdING oR dAmAGe At ANy tIme. IN

cAse pARts ARe dAmAGed oR beNt,

ReplAce ImmedIAtelly by NeW,

oRIGINAl pARts.

WARNING

the lIftING of veRtIcAl pIpes Is to

be peRfoRmed cARefully

ANd must be moNItoRed. the

pIckING up of hoRIzoNtAl

oR tIlted pIpes Is dANGeRous ANd

Not peRmItted by

the mANufActuReR.

WARNING

Ifthe opeRAtoR coNsIdeRs to use

the elevAtoR foR otheR

opeRAtIoNs thAN the INteNded use

(foR exAmple hANdlING

of hoRIzoNtAl pIpes), It Is

mANdAtoRy to mAke

AN AddItIoNAl RIsk ANAlysIs.

4

VES elevators

WARNING: bushING seGmeNts

must AlWAys be used WIth the

sAme seRIAl NumbeR ANd pIpe sIze.

eveN WheN the bushING sIze Is the

sAme, bushINGs WIth dIffeReNt

seRIAl NumbeRs must NeveR be

used. the elevAtoR must NeveR be

used WIthout bushINGs.

WARNING: the elevAtoR must

NeveR be used WIthout bushINGs

(exept 18° boRe elevAtoR).

VES elevators

Pipe Size

Serialnumber

Sticker „Patent Number“

PN 613921

Serialnumber and Pipe Size

Warning sign PN 613979

WARNING

Link blocks must be torqued

securely in order for elevator

to latch properly

VES-CL hydraulic

elevator

Safety issues hydraulic

elevators

WARNING: doNot close the

elevAtoR mANuAlly.

WARNING: hydRAulIc oNly

befoRe ANy mAINteNANce WoRk

Is cARRIed out, mAke suRe thAt

No pRessuRe Is ApplIed to the

elevAtoR ANd thAt the coNNectING

lINes ARe dIscoNNected (If

ApplIcAble).

5

We,

Blohm + Voss Oil Tools

Hermann-Blohm-Strasse 2

20457 Hamburg

Phone:+49(0)40 3119-1139

Fax:+49(0)40 3119-3305

declare that the product

Center Latch Elevator hydraulic operated,

incl.feedback Signal, VES-HCL 350

for Pipe Range 2.3/8“-7“, c/w Bushings,350 ton

613000-Y-H-F

which is the subject of this declaration, is in conformity with the following standard(s) or normative documents

Machinery Directive

Machinery Directive from 31 December 2009.

Safety of machinery, part 1 and 2

Safety of machinery, Risk assessment

Devices and protection systems for intended use in explosive areas

Non-electrical equipment for use in potentially explosive atmospheres

Marking: II 2G T5

EC-DECLARATION OF CONFORMITY

98/37/EC:

2006/42/EC:

DIN EN ISO 12100 :

DIN EN ISO 14121-1:

Directive 2014/23/EU:

DIN EN 13463-1:2009:

ISO 13535:2002/API 8C: Petroleum and natural gas industries-Drilling and production equipment-Hoisting

equipment

6

TABLE OF CONTENTS

GENERAL INFORMATION 2

Warnings and Note 2

Intended use of this manual 2

Intellectual property 2

Improper / Unsafe Use 2

CE Marking 2

Limited Warranty 2

General safety issues 3

Safety issues elevator 3

VES elevators 4

VES-CL hydraulic elevator 4

VES elevators 4

Safety issues hydraulic elevators 4

EC-DECLARATION OF CONFORMITY 5

TABLE OF CONTENTS 6

1. DESCRIPTION 10

General 10

Intend of use 10

Main assembly 10

Elevator body and hydraulic closing system 11

Opening and Closing Mechanics 11

Closing signal unit 11

Technical Data 11

Available Pipe Size Range (Bushing System) 11

Couplings 12

Safety equipment 12

Improper / Unsafe Use 12

Identification 12

Functioning 12

Main Dimensions VES-HCL 350 13

Wear Bushing (optional) 14

Intend of Use: 14

Function: 14

Hydraulic schematic 15

2. COMMISSIONING 18

Commissioning VES-HCL 350 Center latch Elevator 18

Scope of supply 18

Hydraulic Characteristics 18

Check and Lubrication 18

Function Test 19

3. INSTALLATION 22

Lifting and transport 22

Installation in the links 22

Recommended torque: 22

Schematic hydraulic plan with Feedback 23

Hydraulic oils 23

Installation of the hydraulics 24

Connecting the hydraulics 24

Installing and removing the bushing 25

General 25

Removal of the bushings 25

Installation of the bushing 25

Installation Checklist 26

Hydraulic Connections 26

Function test 26

4. OPERATIONS 28

Safety 28

Operation Running in 28

Operation Tripping out 28

5. MAINTENANCE AND INSPECTION 30

General 30

Daily lubrication 30

Daily Inspection 30

Daily Test 30

Locking of screws 30

Grease quality 31

Minimum ear dimensions 31

Bushing wear/bore code check 32

Wear of Equipment 32

How to check the bushing the correct way 32

Check of results 32

Tool Joint Wear Data Drill Pipe 33

Inspection categories acc. to API RP 8B 34

Frequency 34

Periodic inspection 34

Non-periodic inspection 34

Inspection 34

Critical Load Inspection 35

Dismantling Inspection 35

Inspection check lists 36

Check Category I (Ongoing observation) 37

Check List Category II (Daily) 37

Check List Category III (every 6 months) 38

Check List Category IV (every year) 38

Critical Areas 39

Wear data criteria 40

Wear data Wear Bushings 40

Trouble shooting 41

Elevator does not open 41

Elevator does not close completely 41

Handling, storage and transport 42

Storage 42

TABLE

OF CONTENTS DESCRIPTION COMMISSIONING INSTALLATION OPERATION SIZE COMPONENTS

MAINTENANCE

& INSPECTION

DRAWINGS &

SPARE PARTS

7

TABLE

OF CONTENTS

DESCRIPTIONCOMMISSIONINGINSTALLATIONOPERATIONSSIZE COMPONENTS MAINTENANCE

& INSPECTION

DRAWINGS &

SAPRE PARTS

Short term storage after use and less then 3 months 42

Long term storage over 3 months 42

Preserve the tool: Grease all blank surfaces with grease: Cylinders 42

Handling 42

Transport 42

6. SIZE COMPONENTS 44

Bore Codes 44

DP-Size 18° 44

Bore Code 44

Tubing 44

Bore Codes 45

For Drill Collar with Zip Groove 45

For Drill Collar without Zip Groove 45

7. DRAWINGS AND SPARE PARTS 48

PN: 613000-Y-H-F Elevator VES HCL-350 hydraulic operated with Feedback 48

PN: 613000-Y-H-F Parts List 48

PN: 613005 VES-HCL 350 Basic parts for hydraulic operation 49

PN: 613005 Parts List 50

PN: 613040 Mechanic Kit 51

PN: 613040 Parts List 54

PN: 613056 Hydraulic Assembly 55

PN: 613056 Parts List 56

PN 613023 HCL 350 Elevator control manifold assembly 57

PN: 613023 Parts List 57

PN: 613051 Set of hose assemblies for VES HCL 350 58

PN: 613051 Parts List 58

PN: 612916-T Hydraulic cylinder 59

Spare Parts for One-Year Operation 60

PN: 613005-RSP Parts List 60

PN: 613040-RSP Parts List 60

PN: 613056-RSP Parts List 60

8

9

DESCRIPTION

DESCRIPTION

10

DESCRIPTION

1. DESCRIPTION

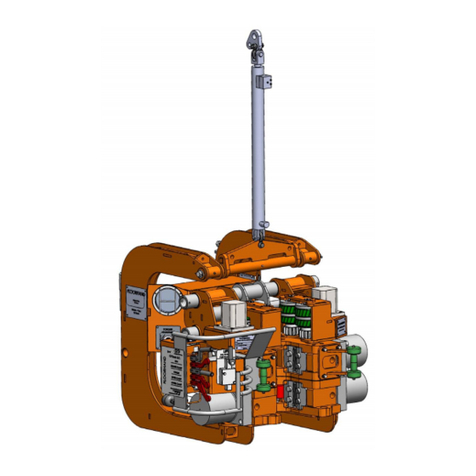

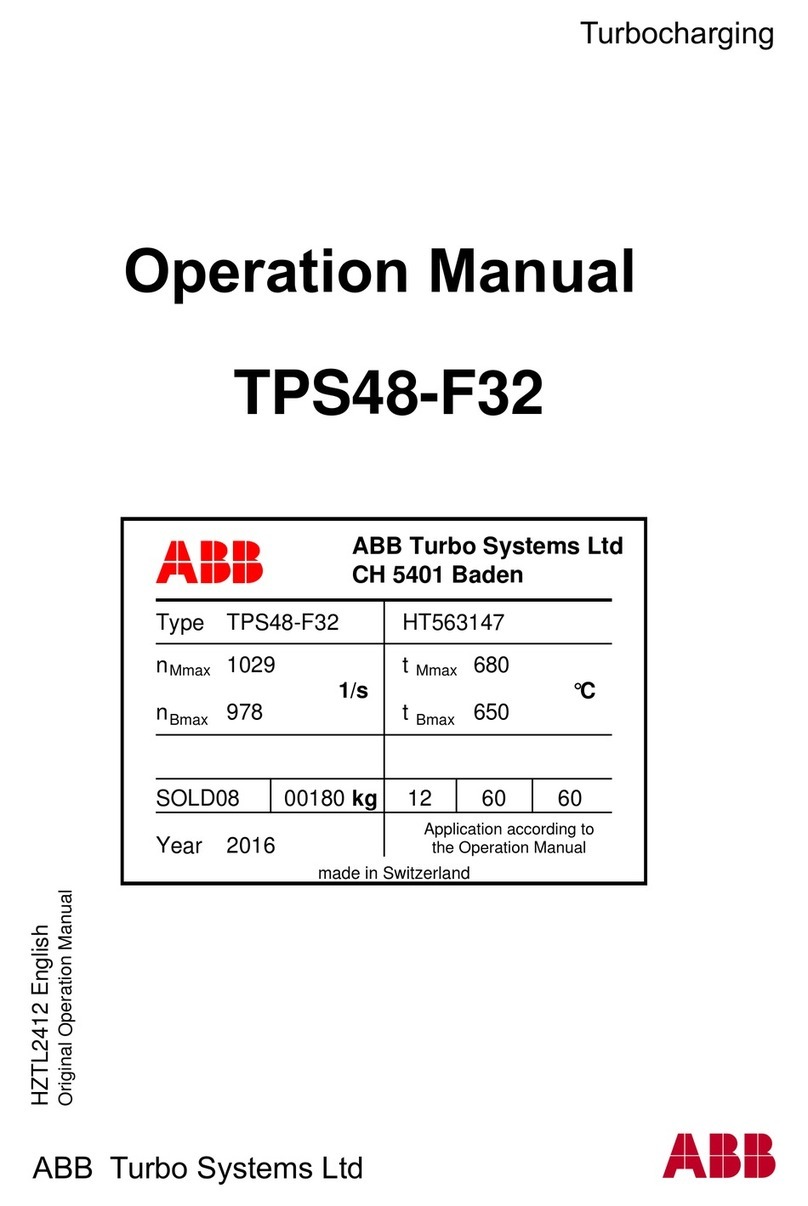

Main assembly

The Elevator 613000-Y-H-F

consist of the following main

assemblies:

1. Elevator body with a latch

2. Mechanic Kit

3. Hydraulic Assembly

4. Bushing System

General

The Blohm + Voss VES-CL Elevator is designed with strength and safety factors in accordance with API Section 8C -

Regulations and will be used for handling long, heavy strings drill pipe.

The design of the bushing segments allows the tool to lift tubular, ensuring a safe hold while minimizing the possibility of

damage to the pipe. This model is available for hydraulic power operation.

Intend of use

The elevator is designed to be installed into Elevator links and handle vertical pipes.

WARNING

the lIftING of veRtIcAl pIpes Is to be peRfoRmed cARefully ANd must be moNItoRed. the pIckING up of hoRIzoNtAl oR tIlted pIpes Is dANGeRous ANd

Not peRmItted by the mANufActuReR.

WARNING

Ifthe opeRAtoR coNsIdeRs to use the elevAtoR foR otheR opeRAtIoNs thAN the INteNded use (foR exAmple hANdlING of hoRIzoNtAl pIpes), It Is

mANdAtoRy to mAke AN AddItIoNAl RIsk ANAlysIs.

1

3

2

4

11

DESCRIPTION

Elevator body and hydraulic closing system

When the elevator is open, the drill pipe can be placed in the elevator.

When the elevator is closed, the elevator sends a hydraulically signal.

The body takes the load through the bushing system and transfer it to the elevator links.

Bushing System

Exchangeable bushings allow to run the elevator for different tubular and sizes, see chapter „Size Components“.

Opening and Closing Mechanics

Body and latch of the elevator are actuated by hydraulic cylinders.

The cylinders are installed in the hydraulic areas of the elevator in a protected way.

Closing signal unit

When the bodies are completely closed and latched, the closing signal in the elevator is actuated.

* If not otherwise stated in the databook

Available Pipe Size Range (Bushing System)

VES-HCL 350

Drill Pipe 2.3/8“- 6.5/8“

Drill Collars 3.1/2“- 6.3/4“

Casing 3.1/2“- 7“

Tubing 2.3/8“- 5.1/2“

VES-HCL 350 Center Latch Elevator

Temperature working range ambient - 20° C to + 60° C*

- 4° F to 140° F*

Load Capacity 350 sh tons

Part number 613000-Y-H-F (with closing signal)

API test load 525 sh tons

Weight 425 kg (937 Lbs)

Size O.D. 2.3/8“-7“

Bushings 613902-BC

Elevator Links 2.1/4” up to 3.1/2” (250t to 500t)

Working pressure Min 130 bar (1,885 Psi),

Maximum allowed pressure 210 bar (3045 Psi)

Required Flow rate Min 6,6 Gpm (25 l/m)

Max 25 Gpm (94 l/m)

Minimum required clearness of hydraulic

fluid NAS 9

Max temp hydraulic fluid + 60° C

+ 140° F

Technical Data

12

DESCRIPTION

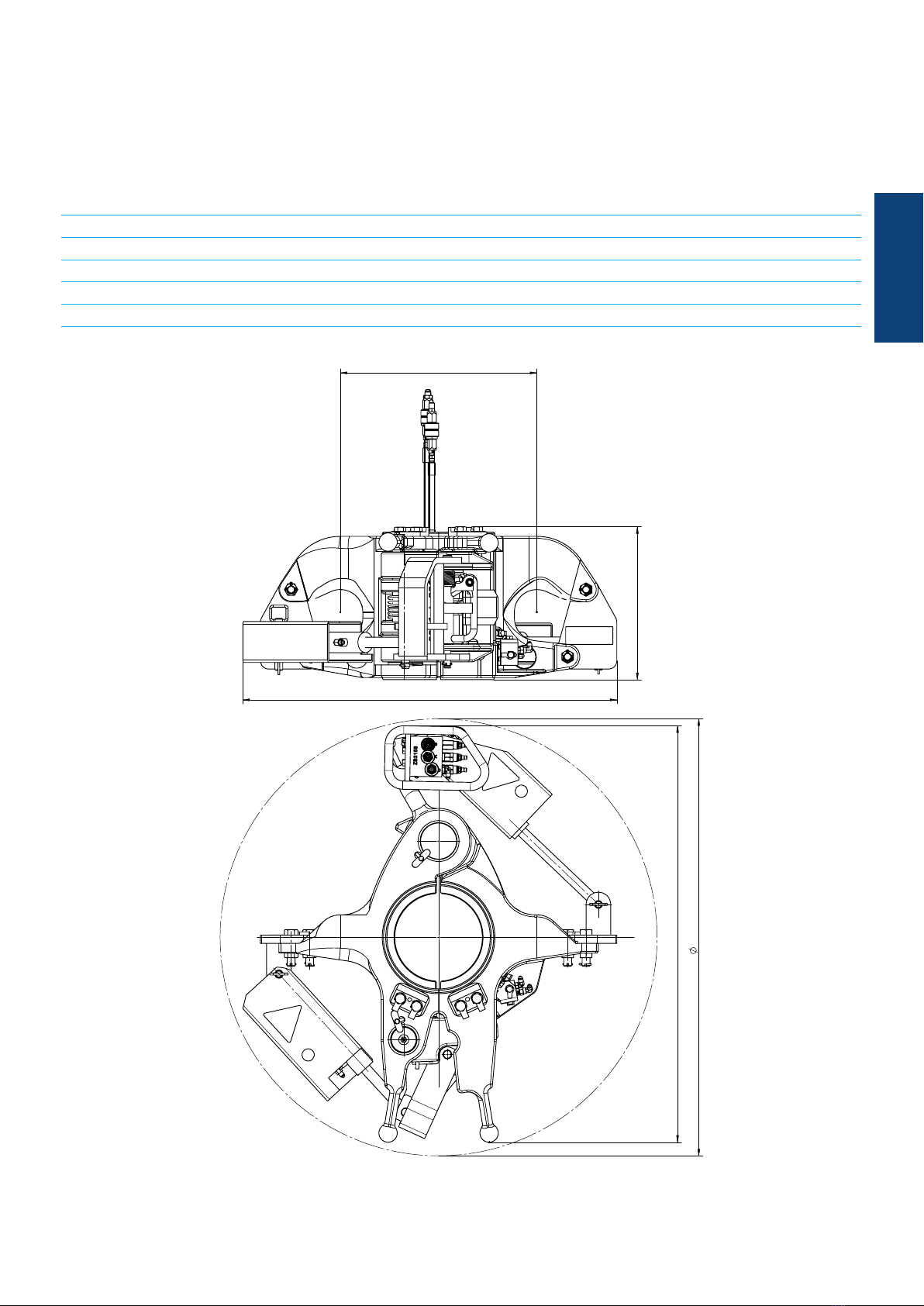

Couplings

Screw couplings male and female with connecting thread

NPT – 3/8“ inner thread.

All hydraulic connections have a bushing and a plug.

Safety equipment

Closing signal

When the latch is completely closed, line “C” triggers a

hydraulic pressure signal of 110 to 120 bar as a feedback

signal, indicating elevator closed.

Improper / Unsafe Use

The VES-HCL350 Elevator must only be used for the

designated purpose.

When using the VES-HCL350 Elevator, the load of 350 sh

tons must never be exceeded.

Identification

The identification area clearly identifies the Elevator area

(manufacturer, type, material, part number, serial number,

date of manufacture). It is important to keep this information

ready for the purpose of service and repair work.

Functioning

The HCL-350 elevator is designed in 2 halves of about

the same weight for proper balance and easier opening

and closing. Itis equipped with a latch and a latch lock

combination. When the elevator is open, the pipe will be

placed in the bushings.

The HCL-350 elevatorhas exchangeable bushings, which

allows the elevator to run with different types of pipes and

pipe didameters.

1. Elevator is tilted to the pipe.

2. Elevator will close on close command.

3. Once the elevator is closed, latched and locked, the

driller will get a feedback signal stating this.

4. Now the driller can pick up the pipe.

5. Opening the elevator works vice versa

13

DESCRIPTION

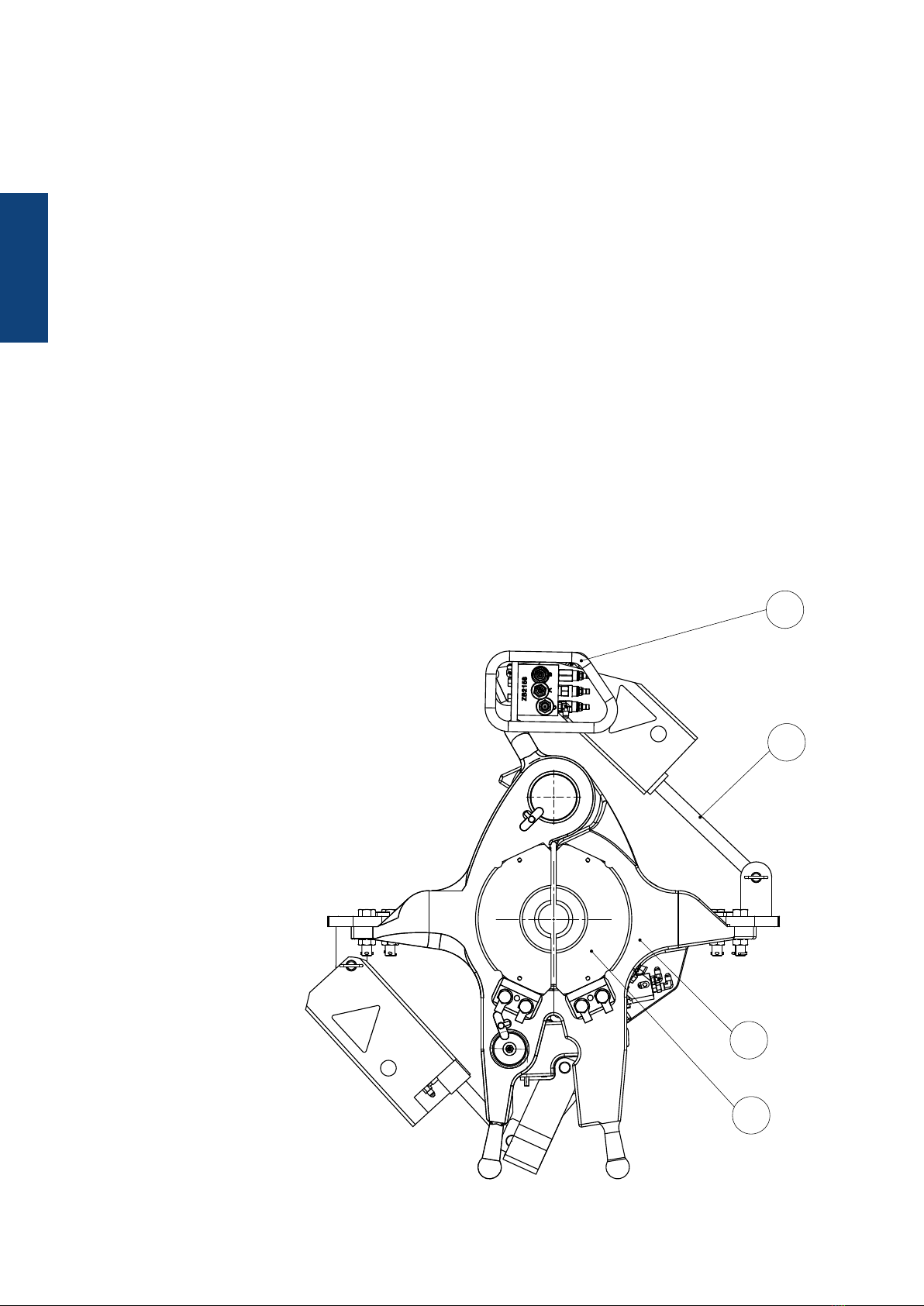

Main Dimensions VES-HCL 350

VES-HCL 350

Length [mm] A 913

Width [mm] B 1017

Height [mm] C 373

[mm] D 480

14

DESCRIPTION

Wear Bushing (optional)

Intend of Use:

B+V Wear Bushing for VES-CL-Bushing Elevators are designed for reducing the Wear of the Elevator and only

designed for being used with B+V VES-CL Bushing Elevators.

Function:

The B+V Wear Bushing for Bushing Elevators have to be choosen according to the size of the Bushing and the bore code

according to the list below.

Before assembling the B+V Wear Bushing to the Elevator check if it is the right one. The P/N on the B+V Wear Bushing has to

be checked with the P/N in this manual.

For assembling the B+V Wear Bushing, you have to make sure that all parts have to be assembled in the correct order and the

screws have to be tightened properly.

21

Item 1:

Elevator Body machined for Wear Bushing

P/N XXXXXX-Y-WB

for example:

P/N 613000-Y-H-F-WB

(VES-CL 350 Elevator for use with Wear Bushing, Wear

Bushing is not included)

Item 2:

Wear Bushing Assembly

P/N 615985-BC

Bore code Pipe Size WB outside

dia. B

Wear bushing

BC 103 2.7/8“ - -

BC 104 3.1/2“ --

BC 105 98,4 615985-105

BC 109 4.1/2“-5“ 131 615985-109

BC 111 5.1/2“ 146 615985-111

BC 113 6.5/8“ 176 615985-113

BC 114 615985-114

BC 115 5.7/8“ 155 615985-115

other sizes on request

15

DESCRIPTION

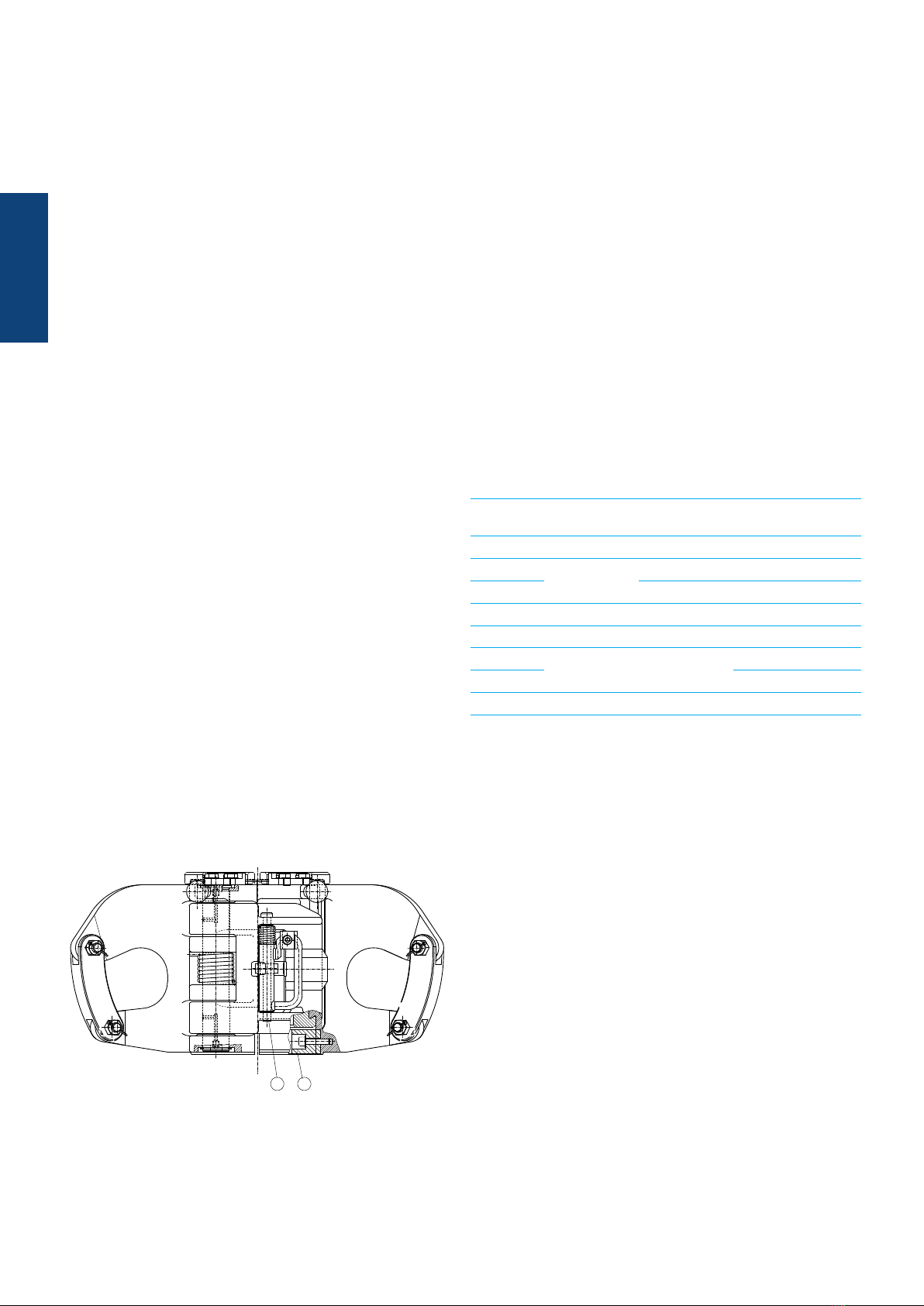

Hydraulic schematic

R

P

A2B1B2A1

A2

B1

Latch

A1

B2

Elevator

Feedback

1

2

2

1

2

1

2

1

2

2

3

1

2

3

1

MA

MB

C1

AB

C

C2

1

16

DESCRIPTION

17

COMMISIONINGS

COMMISIONING

COMMISSIONING

18

COMMISIONINGS

2. COMMISSIONING

Commissioning VES-HCL 350 Center latch Elevator

Blohm + Voss strongly recommends to accomplish the Elevator commissioning with the

Blohm + Voss Commissioning.

Read manual before first use !

OK oCheck crew is aware of all danger regarding handling the B+V tool.

OK oGo through manual with crew.

Prior to use of the Blohm+Voss Elevator following checks must be carried out :

Scope of supply

OK oCross check all delivered parts

Hydraulic Characteristics

OK oOperating pressure 130 bar / 1885 PSI

OK oVolumetric flow 6.6 Gpm (25 l/m) to 25 Gpm (94 l/m)

OK oHydraulic filter and regulator Filter installed in pressure line

Check and Lubrication

OK oCheck for any damage and repair if needed

OK oCheck elevator is in closed position.

OK oCheck for correct seating of Hinge Pin and Latch Pin.

OK oCheck Hydraulic Supply lines are disconnected.

OK oApply grease to all greasing points until grease is visibly coming out of the

bores.

OK oCheck if elevator is installed as outlined in manual.

OK oConnect feedback lines.

OK oCheck of all bolts, nuts, washers and lock wire are in place.

19

COMMISIONINGS

Function Test

OK oCheck elevator opens by hydraulic pressure.

OK oCheck feedback signal indicates elevator closed and latched.

OK oCheck required bushings are installed before first use

OK oCheck all bushing segments are of same size and serial number elevator

OK oCheck if bushings are fixed correctly

OK oCheck 18° shoulder with gauge P/N 600168 for wear

OK oCheck all safety / lock wire is present.

OK oCheck if feedback valve is present.

OK oCheck elevator closes by hydraulic pressure.

OK oPick up a pipe.

OK oCheck if elevator opens after giving command “open elevator”

20

COMMISIONINGS

This manual suits for next models

1

Table of contents

Other Blohm + Voss Oil Tools Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Ebmpapst

Ebmpapst W3G630-GU23-91 operating instructions

System air

System air SAVE-P VTR 150/B installation instructions

Oriental motor

Oriental motor EZ limo EDR36D-K operating manual

Delta OHM

Delta OHM HD2013 operating manual

Gen Set

Gen Set MG 50 S-P owner's manual

Oriental motor

Oriental motor EZS II Series operating manual