Blohm + Voss Oil Tools FloorHand 9GF-1102 Guide

1

Blohm + Voss Oil Tools, LLC

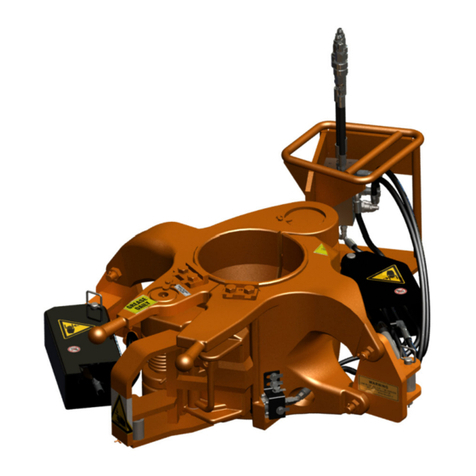

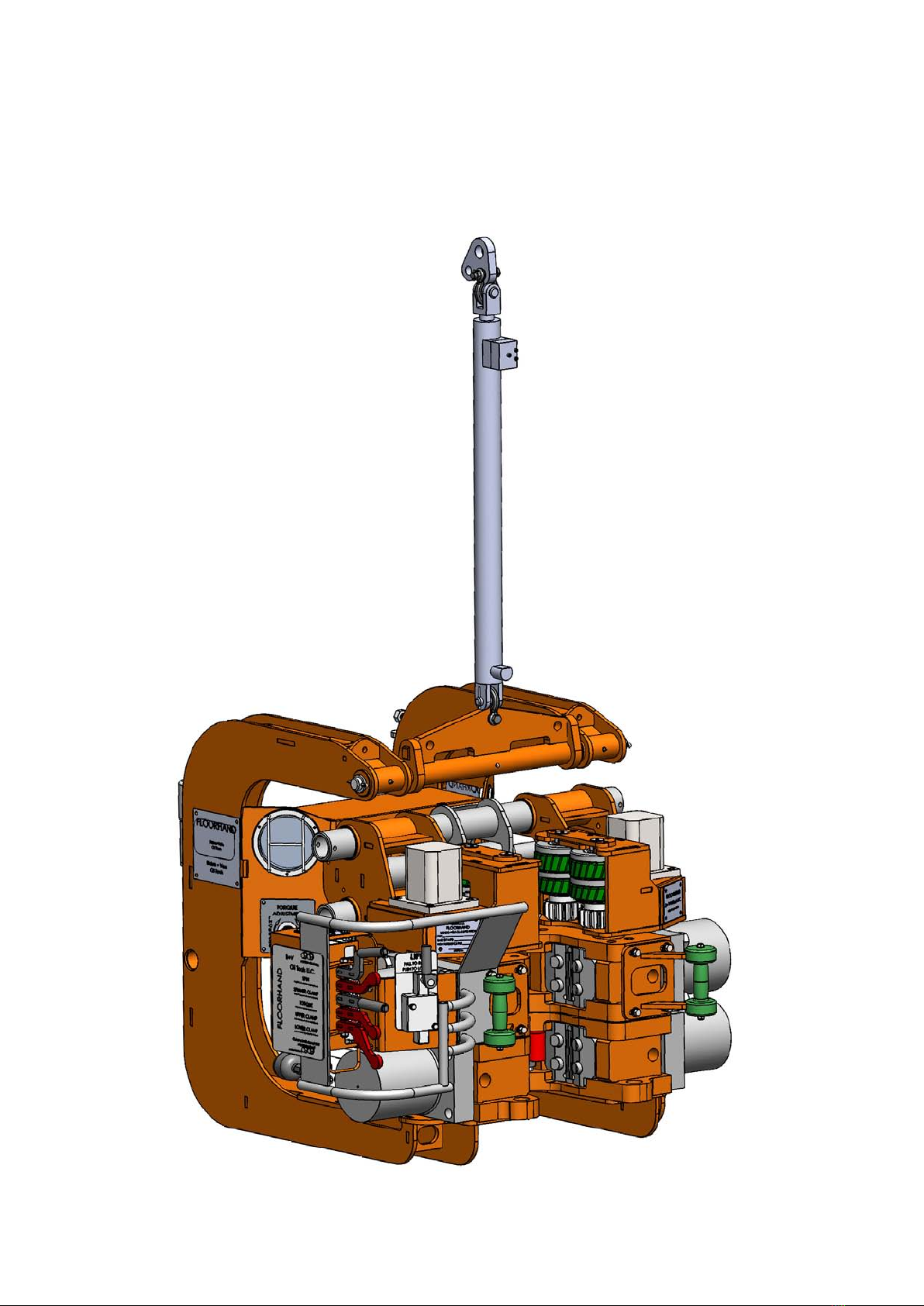

9GF-1102 Cantilever Style FloorHand with

9FM-2050 Hydraulic Lift

Technical Documentation

Manual Rev 000, October 2011.

To be used with Serial Numbers 200+

2

GENERAL INFORMATION

Warnings and Notes

WARNING: A “WARNING”

INDICATES A DEFINITE

RISK OF EQUIPMENT

DAMAGE OR DANGER TO

PERSONNEL. FAILURE TO

OBSERVE AND FOLLOW

PROPER PROCEDURES

COULD RESULT IN SERIOUS

OR FATAL INJURY TO

PERSONNEL, SIGNIFICANT

PROPERTY LOSS, OR

SIGNIFICANT EQUIPMENT

DAMAGE.

NOTE: A “NOTE” indicates

that additional information is

provided about the current

topics.

Intended use of this

manual

WARNING: THIS TECHNICAL

DOCUMENTATION CONTAINS

INSTRUCTIONS ON SAFETY,

INSTALLATION, OPERATION

AND MAINTENANCE. IT

MUST BE STUDIED BEFORE

WORKING WITH THE TOOL.

This manual is

intended for use by eld

service, engineering,

installation, operation, and

repair personnel. Every

effort has been made to

ensure the accuracy of the

information contained herein.

Blohm + Voss Oil Tools, LLC,

will not be held liable for

errors in this material, or for

consequences arising from

misuse of this material.

Anyone using service

procedures or tools, whether

or not recommended by

Blohm + Voss Oil Tools,

LLC, must be satised that

neither personal safety nor

equipment safety will be

jeopardized.

Intellectual property

All rights retained.

No part of this document

may be reproduced in any

form (print, photocopy,

microlm or any other

procedure) or be processed

using an electronic system

without written approval of

Blohm + Voss Oil Tools, LLC

All information

contained in this manual

is based upon the latest

product information available

at the time of printing.

Dependent on ongoing

technical improvements

(ISO 9001) “Blohm + Voss

Oil Tools, LLC” reserves the

right to change the design

and specications without

announcement.

The values specied in

this manual represent the

nominal values of a unit

produced in series. Slight

deviations in the case of

the individual devices are

possible.

NOTE: In the event of

problems that cannot be

solved with the aid of this

manual, please contact

one of the addresses listed

below.

General remarks

As with all rig

equipment, the FloorHand

must be operated in

accordance with accepted

rig safety practices and

procedures. All operators

should be familiar with all

safety precautions and

recommended installation

and operating procedures,

including the information

provided in this manual and

any other safety publications

by Blohm + Voss Oil Tools,

LLC Listed on the next page

are safety considerations

and warnings found

throughout this manual:

CE Marking

The tool complies with

the Machinery Directive

2006/42/EC and the

Directive 2014/34/EU

“Equipment and protective

systems in potentially

explosive atmospheres”

The marking is as follows:

CE Ex II 2G T5

Patents

The following patent

numbers apply:

U.S. 11/404,317

U.S. 11/890,582

U.S. 11/732,813

Limited Warranty

The warranty provided will

be void if the FloorHand is

either:

1. Repaired or serviced by

a service facility which

was not authorized by

Blohm + Voss Oil Tools,

LLC.

2. Replacement parts not

manufactured by Blohm

+ Voss Oil Tools, LLC are

used.

3. Modications were made

to the FloorHand which

were not approved by

Blohm + Voss Oil Tools,

LLC.

Manufacturer & Agents World Wide

Blohm + Voss Oil Tools

Hermann-Blohm-Straße 2

20457 Hamburg, Germany

Phone: +49(0)40/3119-1826/1162

Fax: +49(0)40/3119-8194

oiltools@blohmvoss.com

www.blohmvoss-oiltools.com

Premier Sea & Land Pte. Ltd.

Shaw Centre

1, Scotts Road #19-12

228208 Singapore

Republic of Singapore

Phone: +65-6734-7177

Fax: +65-6734-9115

enquiries@mtqpremier.com.sg

Blohm + Voss Oil Tools, LLC

7670 Woodway, Suite 266 Houston, Texas

77063

United States of America

Phone: +1-713-952-0266

Fax: +1-713-952-2807

BVOT@blohmvoss.com

www.blohmvoss-oiltools.com

3

Safety issues

WARNING: ONE SHOULD

AVOID CREATING IGNITION

SOURCES, LIKE HEAT, AS A

RESULT OF THE USE OF THE

TOOL WITH OTHER TOOLS

OR EQUIPMENT.

WARNING: THE WARNING

PLATES, SIGNS AND LABELS

MUST BE PRESENT ON THE

TOOL. DO NOT REMOVE

THE LABELS. IF THEY ARE

MISSING, REPLACING IS

MANDATORY.

WARNING: ALL WARNING

PLATES, SIGNS AND

LABELS ATTACHED TO

THE EQUIPMENT MUST BE

OBSERVED.

WARNING: DO NOT USE

THE TOOL FOR ANY OTHER

PURPOSE THAN MAKING UP

AND BRAKING OUT WITHIN

ITS SPECIFICATION.

NOT RE-USE THEM. ALWAYS

REPLACE THEM WITH NEW

SAFETY ELEMENTS.

WARNING: KEEP HANDS

AND ARMS CLEAR OF

ALL MOVING PARTS

WHEN CONNECTING,

DISCONNECTING OR

OPERATING THE UNIT.

WARNING: ALWAYS WEAR

PROTECTIVE GEAR FOR

EYES, HEAD, HANDS AND

FEET.

WARNING: WHEN SERVICING

UNIT, BE SURE ALL POWER

IS OFF AND SUPPLY LINES

ARE DISCONNECTED AND

INTERNAL PRESSURE IS

BLED FROM THE TOOL.

WARNING: LUBRICATE UNIT

ONLY WHEN SUPPLY LINES

ARE DISCONNECTED AND

H.P.U IS OFF AND TAGGED

OUT. VERIFY THAT SYSTEM

PRESSURE IS -0- PSI.

WARNING: ALWAYS USE

LIFTING APPARATUS

(SLINGS, CABLES,

SHACKLES AND THE

LIKE) THAT HAVE BEEN

INSPECTED AND ARE IN

GOOD CONDITION AND ARE

PROPERLY SIZED. ENSURE

THAT ALL RIGGING AND

LIFTING PROCEDURES

ARE IN ACCORDANCE

WITH ACCEPTED

OILFIELD PRACTICES AND

STANDARDS.

WARNING: ALWAYS

CHECK THE UNIT FOR

LOOSE FASTENERS AND

HYDRAULIC CONNECTIONS

AS WELL AS ANY OTHER

DAMAGE PRIOR TO TURNING

ON THE POWER UNIT.

WARNING: FAILURE TO

CONDUCT ROUTINE

MAINTENANCE COULD

RESULT IN EQUIPMENT

DAMAGE OR INJURY TO

PERSONNEL.

WARNING: THE TOOL MUST

ONLY BE SERVICED BY

TRAINED B+V PERSONNEL

OR BY AUTHORIZED

PERSONNEL.

WARNING: WHILE WORKING

WITH THE EQUIPMENT,

WEAR PERSONAL

PROTECTION EQUIPMENT.

WARNING: IF ANY

SAFETY ELEMENTS (LIKE

SAFETY ROPES, WIRE,

SAFETY SHEETS, PLATES

OR WASHERS) WERE

DISASSEMBLED DUE TO

MAINTENANCE WORK, DO

Revision History Table

REV. SECTION SUB-SEC. PARA. CHANGE REQUEST # DATE AUTHORIZED BY

Draft All All All N/A 10/01/10 KJ

0 All All All N/A 03/19/12 KJ

4

TABLE

OF CONTENTS

TABLE OF CONTENTS

DESCRIPTION COMMISSIONING INSTALLATION OPERATIONS SPARE PARTS

MAINTENANCE

& INSPECTION DRAWINGS INDEX

TABLE OF CONTENTS 4

DESCRIPTION 6

General Components 7

Wrenches 7

Spinner 7

Frame 7

Controls 7

Lift Cylinder 8

Specications 9

Hydraulic Requirements 9

Shipping Data (Approximately allowing for crate or pallet) 9

COMMISSIONING 12

FloorHand Commissioning Procedure 14

INSTALLATION 17

Normal Rig Move Removal and Installation 18

Lifting 18

Attaching to the Lift Cylinder 19

Locating the HPU and attaching the Hydraulic Lines 19

Attaching the Hydraulic Lines 20

Make Up Torque Adjustment 21

Rig-Up/ Rig-Down 22

FloorHand Wrench Torque Chart 23

OPERATIONS 24

Controls 25

Making a Connection 27

Breaking a Connection 35

Troubleshooting 41

MAINTENANCE & INSPECTION 50

Grease Quality 51

Lubrication 51

Removal of Die-block 54

Replacement of Tong Dies 54

Replacement of Centering Buttons 55

Replacing Spinner Drive Rollers 56

Frequency 59

Inspection 59

5

TABLE

OF CONTENTS

DESCRIPTIONCOMMISSIONINGINSTALLATIONOPERATIONSSPARE PARTS MAINTENANCE

& INSPECTION

DRAWINGSINDEX

Hydraulic System Inspection 59

Dismantling Inspection 59

Check Category I (Ongoing Observation) 60

Check List Category II (Daily) 60

Check List Category III (Every Year) 61

Check List Category IV (Every 2 years) 61

Inspection Categories acc. to API RP 8B 62

Periodic Inspection 62

Inspection Check Lists 63

SPARE PARTS 64

Recommended Spare Parts for One Year Operation 65

DRAWINGS 66

CANTILEVER STYLE FLOORHAND WITH 9FM-2050 HYDRAULIC CYLINDER 68

CANTILEVER FRAME ASSEMBLY 9FH-10001 69

FLOORHAND COMBINATION MANIFOLD 9FH-01539 72

FLOORHAND RETURN MANIFOLD 9FH-01540 73

SPINNER SUB ASSEMBLY 9FH-10302 74

DOUBLE DRIVE ROLLER ASSEMBLY 9FH-01407 76

IDLER GEAR ASSEMBLY 9FH-01287 77

DRIVE ROLLER GEAR ASSEMBLY 9FH-01408 78

UPPER WRENCH SUB ASSEMBLY ORFS 9FH-10201 79

REMOVABLE SPINNER POST ASSEMBLY 9FH-01520 82

LOWER WRENCH SUB ASSEMBLY ORFS 9FH-10101 83

DIE BLOCK ASSEMBLY 9FH-01060 85

2-7/8 ADAPTER KIT ASSEMBLY 9FH-10703 86

2-7/8 DIE BLOCK ADAPTER ASSEMBLY 9FH-01445 87

WINCH AND MOUNTING ASSEMBLY 9FH-10701 88

SERVICE KIT 9FH-10841 89

LOW RANGE TORQUE CYLINDER CHART 90

FLOORHAND COMPLETE HYDRAULIC SCHEMATIC 91

HYDRAULIC SCHEMATIC 92

INDEX 93

Table of contents

Other Blohm + Voss Oil Tools Industrial Equipment manuals