Blohm + Voss Oil Tools Gray Chain 3570 Guide

1

Blohm + Voss Oil Tools, LLC

GRAYCHAIN 3570 PNEUMATIC

9G-3570AIR

Technical Documentation

2

GENERAL INFORMATION

Warnings and Notes

WARNING: A “WARNING”

INDICATES A DEFINITE

RISK OF EQUIPMENT

DAMAGE OR DANGER TO

PERSONNEL. FAILURE TO

OBSERVE AND FOLLOW

PROPER PROCEDURES

COULD RESULT IN SERIOUS

OR FATAL INJURY TO

PERSONNEL, SIGNIFICANT

PROPERTY LOSS, OR

SIGNIFICANT EQUIPMENT

DAMAGE.

NOTE: A “NOTE” indicates

that additional information is

provided about the current

topics.

Intended use of this

manual

WARNING: THIS TECHNICAL

DOCUMENTATION CONTAINS

INSTRUCTIONS ON SAFETY,

INSTALLATION, OPERATION

AND MAINTENANCE. IT

MUST BE STUDIED BEFORE

WORKING WITH THE TOOL.

This manual is intended

for use by eld service,

engineering, installation,

operation, and repair

Manufacturer & Agents World Wide

personnel. Every effort has

been made to ensure the

accuracy of the information

contained herein. Blohm

+ Voss Oil Tools, LLC, will

not be held liable for errors

in this material, or for

consequences arising from

misuse of this material.

Anyone using service

procedures or tools, whether

or not recommended by

Blohm + Voss Oil Tools,

LLC, must be satised that

neither personal safety nor

equipment safety will be

jeopardized.

Intellectual property

All rights retained. No part

of this document may be

reproduced in any form

(print, photocopy, microlm

or any other procedure)

or be processed using an

electronic system without

written approval of Blohm +

Voss Oil Tools, LLC

All information contained

in this manual is based

upon the latest product

information available at the

time of printing.

Dependent on ongoing

technical improvements

(ISO 9001) “Blohm + Voss

Oil Tools, LLC” reserves the

right to change the design

and specications without

announcement.

The values specied in

this manual represent the

nominal values of a unit

produced in series. Slight

deviations in the case of

the individual devices are

possible.

NOTE: In the event of

problems that cannot be

solved with the aid of this

manual, please contact

one of the addresses listed

below.

General remarks

As with all rig equipment, the

GrayChain 3570 Pneumatic

Drill Pipe Spinner must be

operated in accordance

with accepted rig safety

practices and procedures. All

operators should be familiar

with all safety precautions

Limited Warranty

The warranty provided will

be void if the GrayChain is

either:

1. Repaired or serviced by

a service facility which

was not authorized by

Blohm + Voss Oil Tools,

LLC.

2. Replacement parts not

manufactured by Blohm

+ Voss Oil Tools, LLC are

used.

3. Modications were made

to the GrayChain which

were not approved by

Blohm + Voss Oil Tools,

LLC.

and recommended

installation and operating

procedures, including the

information provided in this

manual and any other safety

publications by Blohm +

Voss Oil Tools, LLC Listed

on the next page are safety

considerations and warnings

found throughout this

manual:

Premier Sea & Land Pte Ltd

54 Loyang Way

Singapore 508747

Phone: +65-6543-1433

Fax: +65-6543-1219

enquiries@mtqpremier.com.sg

HI-Energy Service

Hamriyah Free Zone

Sharjah, UAE

Phone: +971-55-2308-252

Fax: +971-4-2980-862

bdm@hi-energyservices.com

Blohm + Voss is a trademark of Blohm + Voss Shipyards GmbH®

Blohm + Voss Oil Tools GmbH

Hermann-Blohm-Straße 2

20457 Hamburg

Germany

Phone: +49-40-3119-1162

Fax: +49-40-3119-8196

oiltools@blohmvoss.com

www.blohmvoss-oiltools.com

Blohm + Voss Oil Tools, LLC

11355 FM 830

Willis, Texas 77318

United States of America

Phone: +1-936-856-4995

Fax: +1-936-856-7487

BVOT@blohmvoss.com

www.blohmvoss-oiltools.com

3

Safety issues

WARNING: ONE SHOULD

AVOID CREATING IGNITION

SOURCES, LIKE HEAT, AS A

RESULT OF THE USE OF THE

TOOL WITH OTHER TOOLS

OR EQUIPMENT.

WARNING: THE WARNING

PLATES, SIGNS AND LABELS

MUST BE PRESENT ON THE

TOOL. DO NOT REMOVE

THE LABELS. IF THEY ARE

MISSING, REPLACING IS

MANDATORY.

WARNING: ALL WARNING

PLATES, SIGNS AND

LABELS ATTACHED TO

THE EQUIPMENT MUST BE

OBSERVED.

WARNING: DO NOT USE

THE TOOL FOR ANY OTHER

PURPOSE THAN MAKING UP

AND BRAKING OUT WITHIN

ITS SPECIFICATION.

REPLACE THEM WITH NEW

SAFETY ELEMENTS.

WARNING: KEEP HANDS

AND ARMS CLEAR OF

ALL MOVING PARTS

WHEN CONNECTING,

DISCONNECTING OR

OPERATING THE UNIT.

WARNING: ALWAYS WEAR

PROTECTIVE GEAR FOR

EYES, HEAD, HANDS AND

FEET.

WARNING: WHEN SERVICING

UNIT, BE SURE ALL POWER

IS OFF AND SUPPLY LINES

ARE DISCONNECTED AND

INTERNAL PRESSURE IS

BLED FROM THE TOOL.

WARNING: LUBRICATE UNIT

ONLY WHEN SUPPLY LINES

ARE DISCONNECTED VERIFY

THAT SYSTEM PRESSURE IS

-0- PSI.

WARNING: ALWAYS USE

LIFTING APPARATUS

(SLINGS, CABLES,

SHACKLES AND THE

LIKE) THAT HAVE BEEN

INSPECTED AND ARE IN

GOOD CONDITION AND ARE

PROPERLY SIZED. ENSURE

THAT ALL RIGGING AND

LIFTING PROCEDURES

ARE IN ACCORDANCE

WITH ACCEPTED

OILFIELD PRACTICES AND

STANDARDS.

WARNING: ALWAYS

CHECK THE UNIT FOR

LOOSE FASTENERS AND

HYDRAULIC CONNECTIONS

AS WELL AS ANY OTHER

DAMAGE PRIOR TO TURNING

ON THE POWER UNIT.

WARNING: FAILURE TO

CONDUCT ROUTINE

MAINTENANCE COULD

RESULT IN EQUIPMENT

DAMAGE OR INJURY TO

PERSONNEL.

WARNING: THE TOOL MUST

ONLY BE SERVICED BY

TRAINED B + V PERSONNEL

OR BY AUTHORIZED

PERSONNEL.

WARNING: WEAR PERSONAL

PROTECTION EQUIPMENT

WHILE WORKING WITH THE

EQUIPMENT.

WARNING: IF ANY

SAFETY ELEMENTS (LIKE

SAFETY ROPES, WIRE,

SAFETY SHEETS, PLATES

OR WASHERS) WERE

DISASSEMBLED DUE TO

MAINTENANCE WORK, DO

NOT RE-USE THEM. ALWAYS

Revision History Table

REV. SECTION SUB-SEC. PARA. CHANGE REQUEST # DATE AUTHORIZED BY

Draft All All All N/A 10/01/10 KJ

0All All All N/A 03/19/12 KJ

4

SPARE PARTS INDEX

TABLE

OF CONTENTS INTRODUCTION SPECIFICATIONS INSTALLATION OPERATION ASSEMBLIES

MAINTENANCE

& INSPECTION

TABLE OF CONTENTS

GENERAL INFORMATION 2

Revision History Table 3

TABLE OF CONTENTS 4

INTRODUCTION 6

About this manual 7

Using the Manual 7

Location of I.D. Numbers 7

Safety First 8

Buying Replacement Parts and Repair 8

SPECIFICATIONS 9

Specications 10

Pneumatic Requirements 10

Palletized Shipping Data 10

Operational Settings 10

INSTALLATION 12

Hanging the Spinner 13

Attaching to the Mast 13

Attaching the Fixed Line 13

Back Up Cables 14

Connecting the Air Line 14

Shut Off Valve 14

Balancing Screw 14

OPERATION 15

Operation 16

Changing Pipe Sizes 16

Additional Adjustment 17

Tension Adjustment 17

Oversized Roller 17

Troubleshooting 19

MAINTENANCE 20

Chain (9G-93) 21

Initial Steps to Installing a Replacement Chain 21

Installing a Replacement Chain 21

Drive Roller Sub Assembly 22

Idler Sprocket Sub Assembly 23

Grease quality 23

Lubrication 24

Lubrication Chart 24

Lubrication Points 25

5

SPARE PARTSINDEX TABLE

OF CONTENTS

INTRODUCTIONSPECIFICATIONSINSTALLATIONOPERATIONASSEMBLIES MAINTENANCE

& INSPECTION

ASSEMBLIES 26

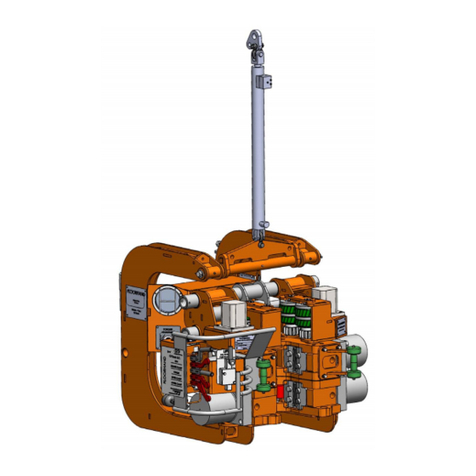

9G-3570AIR 27

CASE ASSEMBLY 9G-1022ASSM 28

MOTOR/MOUNT SUB ASSEMBLY 9G1084-2 30

93 INCH SILENT CHAIN 9G-93 35

GRAYCHAIN IDLER ROLLER PIN ASSEMBLY 9G-1050 36

IDLER ROLLER SHAFT WITH 3-1/2 ROLLER 9G-1050-ASSY 37

3 1/2” OD IDLER ROLLER ASSEMBLY 9G1051-B 38

4” OD OVERSIZED IDLER ROLLER ASSEMBLY 9G1051-2 38

RIGHT DOOR ASSEMBLY 9G-13035-1 39

LEFT DOOR ASSEMBLY 9G-13035-2 41

FRONT AND REAR PINS 9G-13055 / 9G-13052 43

DRIVE ROLLER SUB ASSEMBLY 9G-13023 44

IDLER SPROCKET SUB ASSEMBLY 9G-13070 45

THROTTLE VALVE SUB ASSEMBLY 9G6000ASSM3570 46

DOOR VALVE/PLUMBING SUB ASSEMBLY 9G6006ASSM3570 47

RIGHT MANIFOLD ASSEMBLY 9G1022-36ASSMR 48

LEFT MANIFOLD ASSEMBLY 9G1022-36ASSML 49

AIR CYLINDER SUB ASSEMBLY 9G-4051H 50

FILTER & LUBRICATOR SUB ASSEMBLY 9G4102-1 51

HEAVY DUTY DUAL SPRING HANGER ASSEMBLY 9G-50274 52

1-1/4 X 20-0 SUPPLY HOSE ASSEMBLY 9GSUPPLYHOSE 53

MISCELLANEOUS PARTS 54

SPARE PARTS 56

RECOMMENDED SPARE PARTS FOR ONE YEAR OF USE 57

INDEX 58

INTRODUCTION

6

INTRODUCTION

INTRODUCTION

7

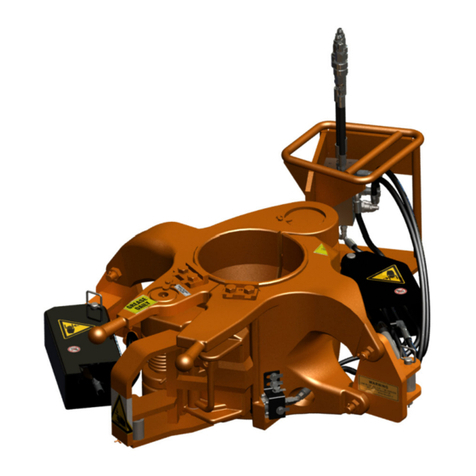

The Gray Chain 3570 AIR offers the ultimate in simplicity and rugged design.

Designed to be compact and self contained; the GrayChain 3570 does not require a

stand-alone power pack. All the gripping pressure and spinning torque are generated at the

drill pipe spinner. In standard rig installations a spring hanger assembly is provided.

Keep in climate controlled environment where possible. The GrayChain 3570 should be

palletized and covered to be kept dry and free from moisture. The GrayChain 3570 should

be inspected for any rust or corrosion especially after storage and before use. All points of

any type of rust or corrosion should be properly maintained or replaced prior to start up.

Apply grease to all lubrication points prior to start up. Any parts showing signs of rust or

corrosion should be thoroughly inspected prior to operation.

About this manual

The purpose of this manual is to help you get the best value from your GrayChain 3570.

It can do so in several ways. It can help you decide what work needs to be done through

scheduled maintenance and it offers repair procedures to follow when trouble occurs which

will add to the longevity of your tool. This technical documentation contains instructions

on safety, installation, operation and maintenance for the tool. It must be studied before

working with the tool. This manual is intended for use by eld service, engineering,

installation, operation, and repair personnel. Every effort has been made to ensure the

accuracy of the information contained herein. Blohm+Voss Oil Tools LLC is not liable for

errors in this material, or for consequences arising from misuse of this material. Anyone

using service procedures or tools, whether or not recommended by Blohm+Voss Oil Tools

LLC, must be thoroughly satised that neither personal safety nor equipment safety will be

jeopardized.

Using the Manual

The manual is divided into chapters. References to the left or the right side of the wrench

assume that the operator is standing behind the wrench. The front of the wrench is the

position furthest from the operator. The back or the rear is closest to the operator. Even

though we have prepared this manual with extreme care, neither the publisher nor the

author can accept responsibility for any errors in, or omissions from, the information

given.

Location of I.D. Numbers

This very important identication number is stamped on a plate and is attached to the top

rear of the unit. The plate will list the name and location of the manufacturer and also the

identication number of the tool.

INTRODUCTION

8

Safety First

Regardless of how enthusiastic you may be about beginning the job at hand, take the time

to ensure that your safety is not jeopardized. A moment’s lack of attention may result in an

accident, as can failure to observe certain simple safety precautions. The possibility of an

accident will always exist. Be aware of your environment and adhere to your company’s

safety guidelines. Above all else, please use common sense.

Buying Replacement Parts and Repair

The phone number, fax number and address can be found in the Table of Contents manual.

Should you need replacement parts or repair services, please contact Blohm+Voss Oil

Tools, LLC or certied service partners, distributors and agents.

SPECIFICATIONS

9

SPECIFICATIONS

SPECIFICATIONS

10

Specications

Pneumatic Requirements

Pneumatic supply pressure (max.) 110 psi (758 kPa) - 6.89 bar

Pneumatic supply pressure (min.) 100 psi (689 kPa) - 6.89 bar

Power Requirements 240 cfm @ 100 psi (6.8 sm3/min @ 689 kPa)

Air Hoses 1-1/4” X 20’

Length (B) 46 in (117 cm)

Width (A) 35 in (88.9cm)

Height (C) 50 in (127 cm)

Weight 850 lbs (386 kg)

Palletized Shipping Data

Length 48 in (1,219.2 mm)

Width 48 in (1,219.2 mm)

Height 56 in (1,422.4 mm)

Weight 850 lbs (386 kg)

Operational Settings

Average Torque 1,250 ft-lbs (1,695 Nm)

Average rpm 100 rpm

SPECIFICATIONS

11

Dim. A Dim. B Dim. C Weight Power Requirements AVG. RPM AVG. Torque

35 in

88.9 cm

46 in

117 cm

50 in

127 cm

850 lbs

386 Kg

240 ft3/min @100 psi

6.80 m3/min @ 689 kPa 100 RPM

1,250 ft lbs

1,694.75 Nm

B

A

C

Figure 1

INSTALLATION

12

INSTALLATION

INSTALLATION

13

Hanging the Spinner

The GrayChain 3570 should be hung using a wire rope that is ½” or greater and that is in

accordance with acceptable practices. Attach the wire rope through the shackle at the top

of the spring hanger assembly.

Use of the GrayChain 3570 without the spring hanger assembly will shorten the life of the

tool and cause improper operation which may lead to accidents. Disregard if there is a

counterbalance in use.

The position of the spinner should be located between the rotary table and drawworks

(toward the off-driller side) about four feet back from the center of the rotary table. It should

hang four to ve feet above the oor as to contact the drill pipe and not the tool joint. The

spinner should be easily pulled on and off the drill pipe and be completely out of the way

when not in use.

The GrayChain 3570 will rotate drill pipe in

both directions and consequently swing in

either direction. The GrayChain 3570 must

be equipped with two backup lines. These

two backup lines or cables need to be

attached to derrick legs or a comparable

structure. Attachment should be made

so that the swinging movement of the

spinner is restricted to less than 1’ in either

direction.

Attaching to the Mast

Using a ½” hang-off cable attached to the

mast (as high as possible) will allow an easy

free swing around the wellbore. The higher

up the xed line is, the easier it will be to

maneuver the GrayChain 3570 to its desired

location.

Attaching the Fixed Line

Use a cross member to attach the xed line to position the hang-off

cable about 2’ to 3’ from the pipe centerline. Across from the driller is where the GrayChain

3570 should be positioned.

WARNING: THE USE OF ONLY ONE BACKUP LINE CAN CAUSE

THE SPINNER TO SWING INTO THE OPERATOR OR FLOOR

PERSONNEL AND WILL CAUSE INJURY. USE TWO BACKUP

CABLES!

WARNING: CHECK ALL SPRING HANGER ASSEMBLY

SHACKLES AND LOCK COTTER PINS FOR TIGHTNESS.

WARNING: CHECK SPRING SAFETY CABLES FOR

SOUNDNESS, (TWO REQUIRED). THE SPRING HANGER

ASSEMBLY IS NECESSARY TO ALLOW THE SPINNER TO RISE

AND FALL WITH THREADED TOOL JOINT MOVEMENTS

Figure 2

INSTALLATION

14

Back Up Cables

The two lugs at the back of the GrayChain

3570 are to be used with two back up

cables. The two lugs at the end of the

GrayChain 3570 are to be used with two

back up cables. These two cables will

restrict the rotational movement to 1’ in

either direction. It is very important that

these cables do not cross. Using only one cable would allow the possibility of the GrayChain

3570 swing into the operator causing injury.

Connecting the Air Line

In an area that is easily accessible and well protected, run a 1½” air line up to the rig oor.

This will aid in maintenance. Typically a 1½” airline should be run. A valve is required at this

point in order to shut-off air when maintenance to the tool is required. Install a 1¼”, 200

psi minimum, air hose from the valve to the spinner. Keep the hose and piping as short as

possible with as few ttings as possible. Blowing out the line prior to installation will remove

debris or moisture from the system.

Connect the air line. As listed in the

description, the GrayChain 3570 requires

optimum 100 psi air pressure. When

installing, use the least amount of ttings

as possible and route the air directly from

the supply keeping the distance as short as

possible.

Shut Off Valve

Use a 1¼” shut-off valve attached to the

supply line.

Balancing Screw

The tool can be leveled by turning the

leveling screw atop the stationary hanger.

Level the spinner by turning the balance

screw.

Figure 3

Figure 4

OPERATION

15

OPERATION

OPERATION

16

Operation

1. With the doors open, swing the GrayChain into position on the drill pipe. Bring the 3570

to the correct height. Approximately 12” above the tool joint, position the 3570 onto the

pipe making sure that you do not run the tool on the pipe upset or tool joint.

2. Close the doors, clamping the spinner onto the drill pipe. This is accomplished by

pushing the door valve handle in. The door valve is located on the bottom left of the

spinner.

3. Activate the rotation of the drilling by pulling the throttle valve handle out. Rotation of

the drill pipe can be changed (spin in, spin out) by reversing the position of the Quick

Disconnects located at the motor.

4. Open the Spinner doors by pulling the door valve lever. The 3570 can now be safely

swung away from the pipe.

Changing Pipe Sizes

The GrayChain 3570 has a unique and easy method to set up the spinner for various drill

pipe sizes.

1. Shut off all air to the spinner and bleed off any residual pressure in the door cylinders.

This is accomplished be activating the door valve after the source air has been shut

completely off.

2. To change the pipe sizes simply release the Safety Pin below the chain case. Pull the

adjust roller shaft out of the top of the case.

3. Locate the roller and roller shaft in one of the ve designated slots for the appropriate

drill pipe size.

4. Replace the Safety Pin on the lower shaft. Restore the air supply.

Figure 5

OPERATION

17

Additional Adjustment

Tension Adjustment

When the chain stretches or is getting too worn to obtain a proper bite, loosen the 1” Hex

Head Cap Screws on the motor mount, loosen the lock bolt on the Chain Retainer and move

the motor toward the rear of the spinner. Reposition chain retainer and retighten lock bolt.

Oversized Roller

If motor is adjusted all the way to the rear and proper bite is still not obtained, replace

standard idler roller with the 4” spare oversized idler roller located inside the case on left

side. This should allow you to operate until a new chain is purchased.

NOTE: Always check chain for tightness. Do not allow for

slack. Motor capscrews must be tight.

NOTE: Take the time to make sure the back up lines are

properly attached and that safety regulations are observed.

OPERATION

18

Figure 6

OPERATION

19

Problem: Cause: Solution:

Spinner does not clamp or

clamps slowly on drill pipe

(or unclamp).

Lack of air pressure. Air supply should be 100-125 psi @240

CFM.

Air hose, both supply and cylinder hoses

are free, not pinched and without leaks.

Check all connections for leaks or

restrictions.

Check Filter, clean and drain as required.

Check lubricator level

(SAE 10 non-detergent oil).

Fault door valve. Remove valve and install valve repair kit

or replace valve.

Air leaking across

cylinder piston.

Remove and install cylinder repair kit.

Door valve exhaust

blocked.

Check for obstruction blocking the door

valve exhaust port. Remove and clean.

Air motor does not

operate or

operates slowly.

Lack of air pressure. See above solutions under

“Lack of Air Pressure”

Check quick disconnects at air

motor for both supply and

exhaust.

Exhaust mufers

clogged.

Remove and clean or replace.

Troubleshooting

OPERATION

20

Problem: Cause: Solution:

Air motor lacks

lubrication.

Place several drops of SAE 10

non-detergent oil directly in motor supply

ports; restart.

Air motor failure. Remove air motor and install motor

repair kit or replace.

Motor mount loose

on case, allowing

chain to bunch and

lock.

Disconnect air supply line. Loosen

capscrews on motor mount and move

it as far back as possible. Straighten

chain and tighten. If chain has become

stretched, remove one link and/or

replace chain.

Bearing failure in

drive chain.

Check drive roller bearings and idler

sprocket bearing; remove and replace as

necessary.

Drive rollers slip on drill

pipe.

Oily or greasy drive

rollers.

Wash with rigwash soap and water.

Door pins in forward

holes for large

diameter drill pipe.

Move door pins to rear position. See

(Installation Section).

Pressure rollers

seized.

Repair or replace if necessary.

Drive rollers are

worn.

Remove and inspect replace as

necessary.

Faulty door valve. Remove valve and install repair kit.

Unusual or uneven wear

on pressure and / or drive

roller.

Drive roller bearing

failure.

Replace bearings in drive roller bearing

housing.

Bearing failure in

pressure roller.

Replace bearings.

Spinner not hanging

level.

Level spinner with balancing screw.

This manual suits for next models

1

Table of contents

Other Blohm + Voss Oil Tools Industrial Equipment manuals