BLUCHER SARATOGA CBRN PROTECTIVE COVERALL User manual

INSTRUCTION MANUAL

CBRN PROTECTIVE COVERALL

POLYPROTECT 12

Applicable for

BLÜCHER®Style No.: 549252

Issue: 2013

Class 1

Type 5

EN 1073-2: 2002

0158

DIN EN ISO

13982-1 2011-02

Instruction Manual CBRN Protective Coverall, Issue 2013 Page 2 of 20

Paragraph of

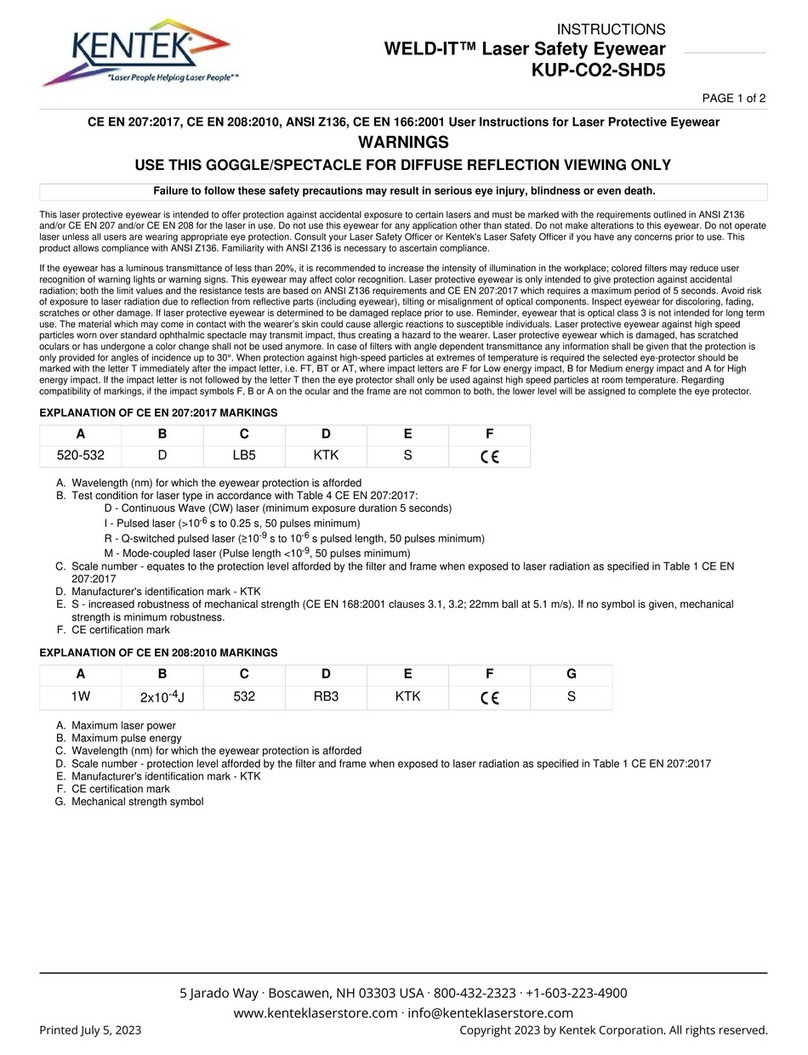

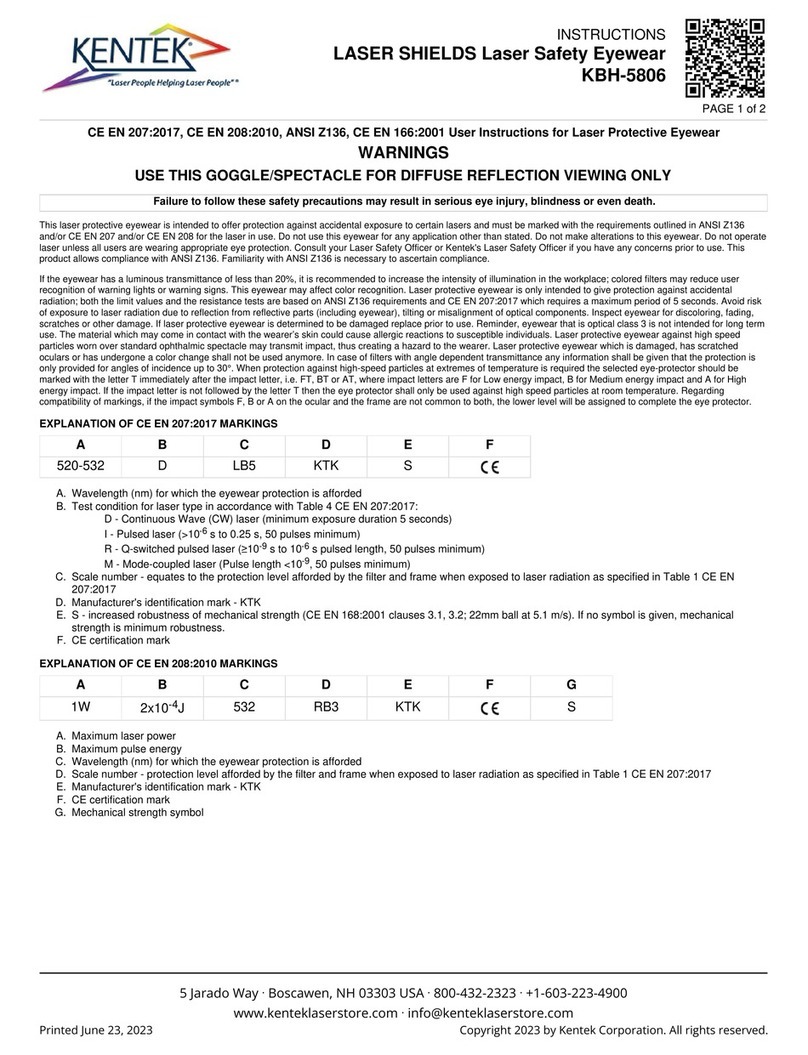

DIN EN 14325:2004 Title Class

4.4 Abrasion resistance 2

4.5 Flex cracking

resistance 6

4.7 Trapezoidal

tear resistance 6

4.10 Puncture resistance 2

5.5 Seam strength 5

© by BLÜCHER®GmbH 2013 Page 3 of 20

This manual is addressed to all persons responsible for the

CBRN protective coverall and/or working with the CBRN

protective coverall.

This manual must be

• read

• understood

and

• followed during all activities

This is a precondition for

• safe working with the CBRN protective garment

• trouble free handling

We recommend keeping this manual always with you all times.

®

Instruction Manual CBRN Protective Coverall, Issue 2013 Page 4 of 20

Danger to life and limb:

• if not used according to the intended purposes

• if used incorrectly by untrained persons

• in case of nonobservance of the instructions given in

this manual

Important instructions and remarks in this manual are

emphasized with the following words:

is stated for working operational procedures

which must be exactly followed in order to avoid any

danger to persons

stands for technical requirements which have to

be observed in particular

stands for important information

The CBRN protective coverall is only suitable for use within the range

of purposes set out in section 2.

© by BLÜCHER®GmbH 2013 Page 5 of 20

The CBRN protective coverall shall be worn together with a breathing

protective mask (respirator) and breathing protective filter (filter

canister), CBRN protective gloves and CBRN overboots (=personal

CNBC protection equipment). The nominal protection factor IL class 1

of EN 1073-2 was achieved with respirator M2000 of Dräger Safety AG

& Co. KGaA, Lübeck. If other masks used the nominal protection factor

IL class 1 of EN 1073-2 can not be guaranteed.

The CBRN protective coverall is put on (outside of the contaminated

area) when

• danger from a specific chemical warfare agent must be assumed

or

• a mission or task has to be fulfilled in a contaminated area.

The CBRN protective coverall protects against all known skin

damaging and skin penetrating specific chemical warfare agents

(according to section 5).

The CBRN protective coverall should not be used when

in contact with acids or alkalines.

Instruction Manual CBRN Protective Coverall, Issue 2013 Page 6 of 20

The CBRN protective coverall must be worn in the

correct size in order to provide complete protection.

A

Body Height

Short Regular Long

B

Chest

XXS 73-80

150-155 ----- -----

XS 81-88

156-161 ---- -----

S 89-96

162-167

168-173

174-179

M 97-104

168-173

174-179

180-185

L 105-112

174-179

180-185

186-191

XL 113-120

180-185

186-191

192-197

© by BLÜCHER®GmbH 2013 Page 7 of 20

The CBRN protective coverall is manufactured from an air

permeable two layer textile fabric compound:

• The outer layer (shell fabric) is impregnated with an oil and water

repellency treatment.

• The inner layer (filter laminate) is a laminated composite consisting

of the following layers:

◦Non woven fabric (covering layer = layer next to the shell fabric)

◦Activated carbon spheres (adsorptive layer)

◦Warp knitted fabric (lining fabric = layer next to the skin)

Shell fabric: 100 % PA

Filter laminate: Covering layer: 100 % PA

Adsorptive layer: 100 % activated carbon SARATOGA®

Lining fabric: 100 % PES

CO = Cotton, PES = Polyester, PA = Polyamide

SARATOGA®is a registered trademark of BLÜCHER®GmbH

Instruction Manual CBRN Protective Coverall, Issue 2013 Page 8 of 20

The two layer textile fabric compound as mentioned in section 4.1

offers protection against specific chemical warfare agents according

to “TNO-PML test methods for air-permeable and air-impermeable

CNBC protective materials (PML 2004-PU2)”.

• Laid drop diffusive flow test

(10 g HD/m2, 10 cm2, 1 μl drops, 12 hours)

• Vapour test

(55 mg HD/m3, 1 m/sec, 12.56 cm2, 12 hours)

Nominal protection factor IL class 1 of EN 1073-2

• Before use, check the CBRN protective coverall for

completeness and proper condition

• The CBRN protective coverall ensures the necessary

protection only if the personnel:

◦master the timely and intended use of the

protective coverall.

◦are psychologically and physically able to carry out

missions under CBRN protection at any time.

• Aschemicalprotectiveequipmentmaycauseheat

strain of the wearer it is recommended that sweat

management underwear is used and that rest periods

of sufficient duration are scheduled.

© by BLÜCHER®GmbH 2013 Page 9 of 20

• The accumulated wear time in a non-contaminated environment is

20 calendar days.

• The lifetime of the suit after opening the original bag is 100 calendar

days.

• The storage in the unopened and undamaged original package will

be guaranteed for 10 years (according to section 8.).

• The suit is washable for 6 times (according to section 7.1).

The assistance of a second person is necessary

when putting on (donning) the CBRN protective

coverall.

Do not exceed the washing and wear time limits

Note the

• date on which the CBRN protective coverall was

removed from the factory sealed bag.

• days the CBRN protective coverall has been worn.

• number of washing and drying cycles the CBRN pro-

tective coverall has gone through.

Once , the CBRN protective coverall

A re-use of a contaminated CBRN protective coverall

is strictly forbidden.

Instruction Manual CBRN Protective Coverall, Issue 2013 Page 10 of 20

Fig. 1: Putting on the CBRN protective coverall

6.2.1 Adjusting the protective coverall

Fig. 1, sequence 1

1. Put on the protective coverall.

2. Wearing the attached socks step into the CBRN overboots.

3. Pull down the leg overlap to cover the CBRN overboots.

© by BLÜCHER®GmbH 2013 Page 11 of 20

6.2.2 Adjusting the protective coverall

Fig. 1, sequence 2

1. Tighten the draw-strings at the hem by using the cord lock.

6.2.3 Putting on the respirator and sealing the hood

Fig. 1, sequence 3 and 4

1. Close the zip fastener.

2. Put on the respirator with filter canister.

3. Pull the hood of the protective coverall over the head and tighten

it against the respirator with the elasticated hood seal.

4. Close the front flap.

6.2.4 Sealing the coverall sleeves

Fig. 1, sequence 5

1. Put on the textile gloves.

2. Put your thumb through the thumb loop.

3. Pull over the rubber gloves.

4. Pull down arm overlap to wrist.

5. Close hook and loop fasteners.

Follow the instructions for the respirator.

The responsible head of the operation must determine

the type of filter canister to be used.

Check tight fit of the hood on the respirator and adjust it

if necessary.

Instruction Manual CBRN Protective Coverall, Issue 2013 Page 12 of 20

Check for a tight fit of the coverall sleeves on the

protective gloves, and adjust if deemed necessary.

While taking off the CBRN protective coverall,

the assistance of a second person wearing

protection equipment (respirator and filter canister,

protective gloves and body protection equipment)

is necessary.

Observe the following strictly when taking off (doffing) a

contaminated CBRN protective coverall:

• Take off the equipment only out of the contaminated

area and only outside, however, if possible in a

protected, draught-free place which is, if possible,

covered with a roof.

• Observe the direction of the wind when taking off the

equipment.

Avoid contact of the unprotected underwear and the skin

with the possibly contaminated outer layer of the CBRN

protective coverall.

© by BLÜCHER®GmbH 2013 Page 13 of 20

Fig. 2: Taking off a contaminated CBRN protective coverall

Instruction Manual CBRN Protective Coverall, Issue 2013 Page 14 of 20

When taking off contaminated CBRN protective coverall the following

sequence is recommended:

1. Pull the overlap above the ankle (Fig. 2, sequence 1).

2. Open the CBRN overboots and shake the CBRN overboots off.

3. Open the hook and loop fasteners of the arm sleeves

(Fig. 2, sequence 2).

4. Open the hook and loop fasteners of the hood.

5. Open the front flap and zip fastener on the front of the protective

coverall (Fig. 2, sequence 4).

6. Take the outside of the hood in both hands and pull it completely

down the back.

7. Open the draw-strings of the hem.

8. Take the sleeve and at the same time the CBRN protective glove

and pull them half way off from the hand (Fig. 2, sequence 3).

9. Pull the second sleeve and the second CBRN protective glove off

as described under number 8.

10. Take the upper part of the CBRN protective coverall by both hands

from inside and drop it making sure you are standing down wind

(Fig. 2, sequence 4). At the same time while standing down wind

shake one CBRN protective glove off and pull the arm out of the

sleeve. Shake the second CBRN protective glove off and pull the

arm out of the arm sleeve.

11. Take the inside of the lower part of the CBRN protective coverall

with both hands and push it down off.

12. Reach with both hands under the strips of the respirator on the

head and throw the respirator off down wind (Fig. 2, sequence 6).

13. Take off the textile inner gloves.

The respirator is only to be removed when the signal has

been given that there is no danger of contamination.

© by BLÜCHER®GmbH 2013 Page 15 of 20

6.4.1 Transport

Transport a contaminated CBRN protective coverall only in suitable

packaging (e.g. a plastic bag) and make sure it is sufficiently labelled.

6.4.2 Disposal

Disposing of the contaminated CBRN protective coverall is to be

conducted in compliance with the relevant and valid environmental

regulations.

Do not touch a contaminated CBRN protective coverall

with unprotected skin or the underwear.

Instruction Manual CBRN Protective Coverall, Issue 2013 Page 16 of 20

CBRN protective coveralls but have

become very dirty during training operations

as long as the 6 washing and drying cycles are not exceed

within the 20 calender days wear time.

After each washing cycle, cut off the corresponding

portion of the blue label. Check the suit according

to section 7.2.

7.1.1 Instruction for care

Follow the instructions given on the care label.

Before washing and drying, engage all zippers and

fastener tapes, to minimize the risk of rips, tears

ore other damage during laundering.

The CBRN protective coverall may not be pierced, e.g.

with pins or badges, etc.

After 7 washing and drying cycles , the CBRN protective

coverall may only be used as a training suit –

© by BLÜCHER®GmbH 2013 Page 17 of 20

Washing: 40 °C fine washing - gentle wash

cycle. Fill drum only half

Detergent:

Only use mild washing detergents

Do not use softeners

Rinsing: Rinse twice thoroughly after

washing

Spin-drying: Spin-dry for approx. 20 sec. after

washing, max. 1100 rpm, detergent

AATCC1193, dosage 0,25g/l

Chlorination:

Ironing: Iron moderately hot (maximum ironing

temperature: 150 °C)

Dry cleaning:

Drying: Drying in a tumbler moderately hot

Instruction Manual CBRN Protective Coverall, Issue 2013 Page 18 of 20

Visual check to be conducted:

• after each usage

• after any care procedure acc. to section 7.1

Check the shell fabric (outer layer) and the filter laminate (inner layer)

for damage such as:

• holes

• tears

• abrasion

Visible damage and changes in the personal CBRN

protective equipment reduce the protection performance.

Mark damaged parts and exchange them immediately.

As long as the CBRN protective coverall is kept in its

original and factory sealed bag, there is no need for

maintenance.

© by BLÜCHER®GmbH 2013 Page 19 of 20

Store the coverall in its original factory sealed bag in a

clean and dry environment without direct exposure to

sunlight and heat.

Copyright©2013 by BLÜCHER®GmbH

All rights reserved. No part of this instruction manual may be

reproduced in any form without the prior written permission of

BLÜCHER®GmbH.

BLÜCHER®GmbH

Mettmanner Str. 25

40699 Erkrath | Germany

tel +49 211 92 44 0

fax +49 211 92 44 211

info@bluecher.com

www.bluecher.com

Table of contents