PHOENIX CONTACT

Please observe the following notes

User group of this manual

The use of products described in this manual is oriented exclusively to qualified electricians

or persons instructed by them, who are familiar with applicable standards and other

regulations regarding electrical engineering and, in particular, the relevant safety concepts.

Explanation of symbols used and signal words

How to contact us

Internet Up-to-date information on Phoenix Contact products and our Terms and Conditions can be

found on the Internet at:

phoenixcontact.com

Make sure you always use the latest documentation.

It can be downloaded at:

phoenixcontact.net/products

Subsidiaries If there are any problems that cannot be solved using the documentation, please contact

your Phoenix Contact subsidiary.

Subsidiary contact information is available at phoenixcontact.com.

Published by PHOENIX CONTACT GmbH & Co. KG

Flachsmarktstraße 8

32825 Blomberg

GERMANY

Should you have any suggestions or recommendations for improvement of the contents and

layout of our manuals, please send your comments to:

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety measures that follow this symbol to avoid possible

injury or death.

There are three different categories of personal injury that are indicated with a

signal word.

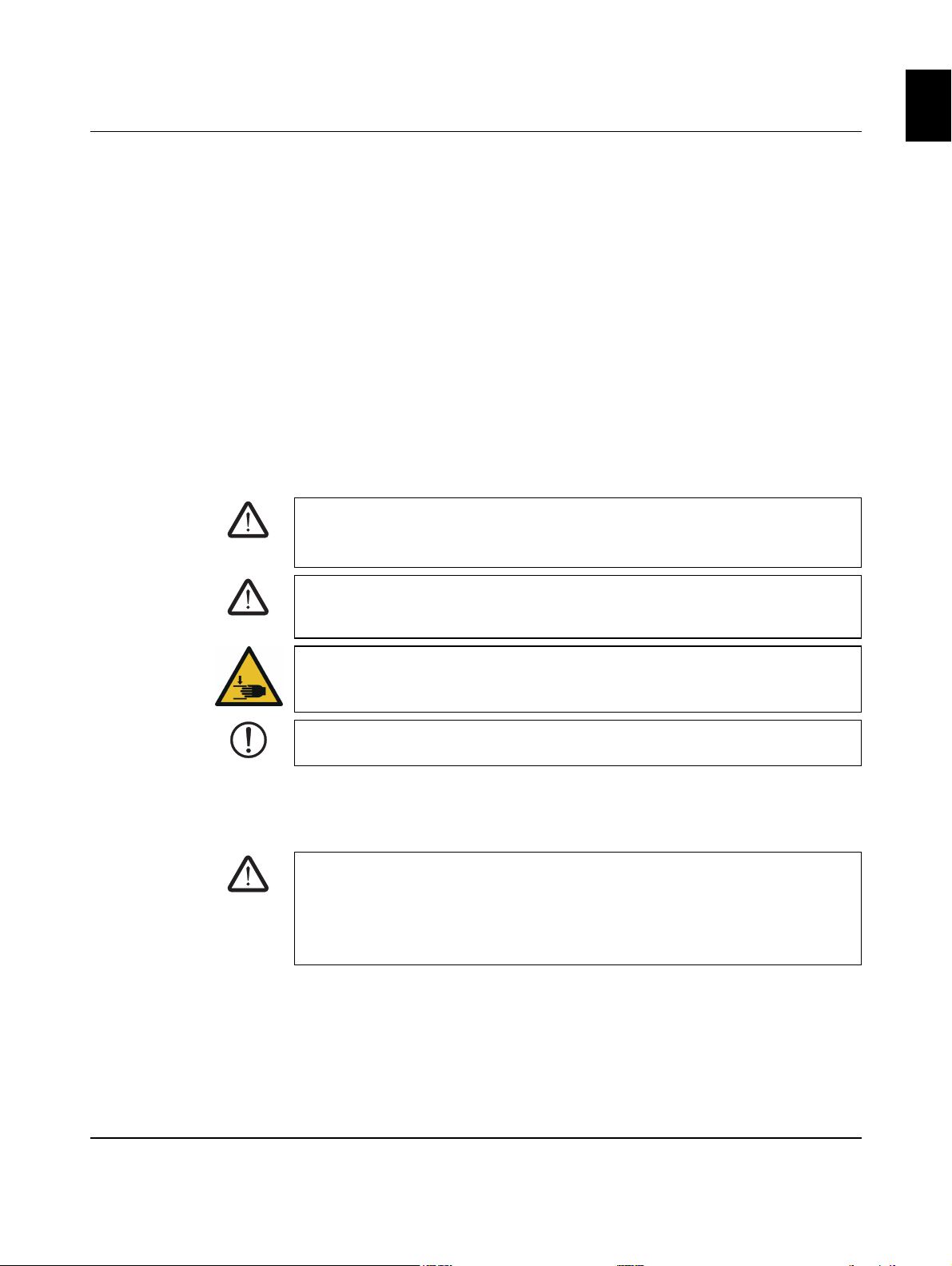

DANGER This indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING This indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION This indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

This symbol together with the signal word NOTE and the accompanying text

alert the reader to a situation which may cause damage or malfunction to the

device, hardware/software, or surrounding property.

This symbol and the accompanying text provide the reader with additional

information or refer to detailed sources of information.