ES manufacturing MB110 Series User guide

______

Documentation & Warranty Packet

MB110 ( 600 rpm’s)

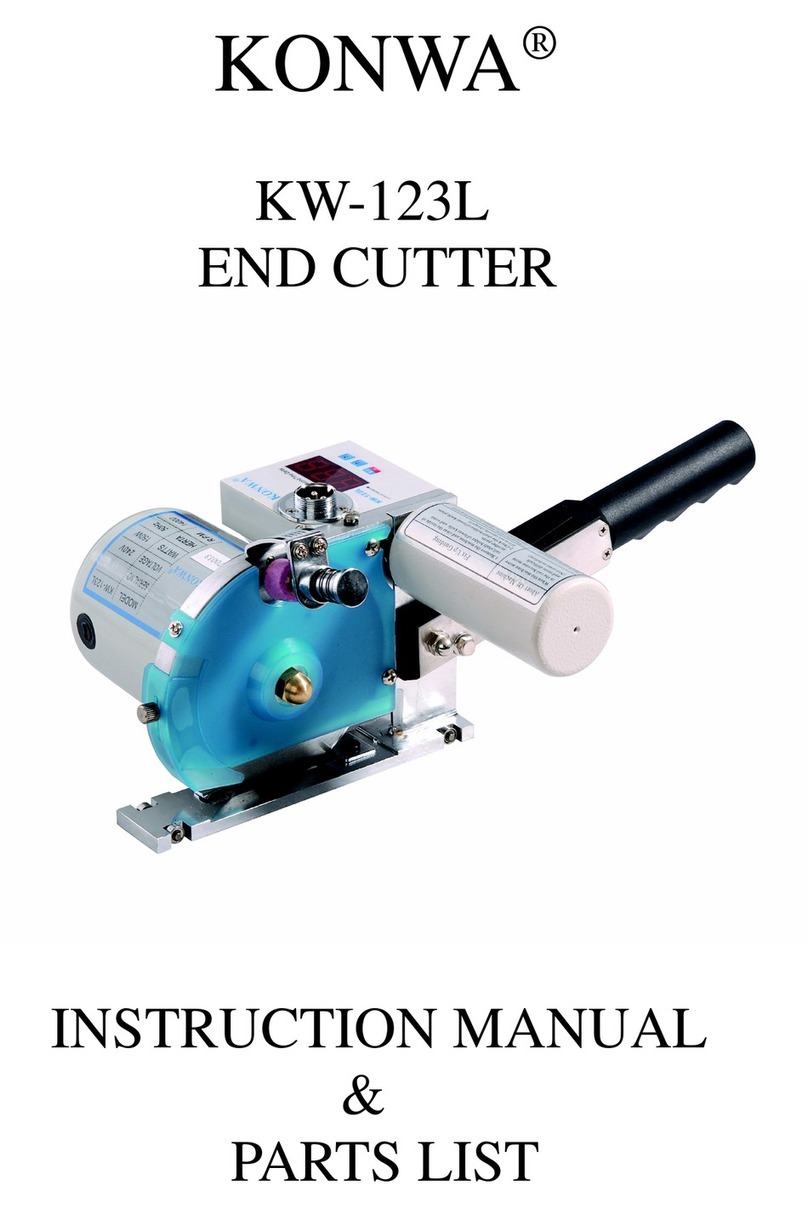

Thank you for purchasing the MB110 If properly operated and

maintained, this Heavy Duty Fiber Cutter will provide years of

trouble free service.WARRANTY

This model MB110 is warranted against defects for a period of 90 days. Keep your

original sales receipt for proof of purchase. ES Mfg., Inc. will replace or repair any

defective part, either directly, or through the distributor, at the option of ES Mfg.

Warranty shall not cover mis-use or damaged caused by the user. ES Mfg. Reserves

the right to inspect the merchandise at our facility, and is not responsible for

transportation cost to ES Mfg. ES Mfg. Is not responsible for damage, loss, lost

production or any other expenses due to the failure of this product. No other warranty

is expressed or implied.

Copyright 2007 ®

ES Manufacturing, Inc.

2647 24th Street North

St. Petersburg, FL 33713

US / Canada: 800-55ES-MFG Local / International: 727-323-

4040 Fax: 727-327-9872

OPERATING INSTRUCTIONS, MAINTENANCE & SAFETY

Cutters are precision tools made by master

creaftsman.

In order to maintain this precision and the

adjustments which are essential to satisfactory

operation of your cutter, it is important to

conscientiously follow these instructions.

1.In General

Handle cutter with great care. Do not drop it or

handle it roughly as this will change its

adjustments and may cause serious damage

mechanism.

2.Prior to Starting the Cutting Operation

Firstly set the “ON/OFF” switch to the “off”

position, connect the female plug of the electric

cord with the machine terminal and then tighten

the screw on the female lug. Now connect the

male plug of the electric cord to the electrical

outlet. Prior to starting the cutting operation

remove any obstacle from the path of the base

plate.

3.Cutting Operation

Do not force cutter through material. By nature of

their texture and because of the properties of their

fibers, not all materials can be cut with the same

speed or ease. Trail cutting will readily let you

find the best speed at which the machine is to be

advanced through the material.

4.Sharpening the Blade

1. Connect the plug of the electric cord to the

Power supply.

2. Push the switch to start the machine.

3. Pressing the Push Knob (#21) down for a few

seconds so that the sharpening stone lightly

touches and grinds the blade several times.

5. How to replace Blade

1. Make sure the electrical cord is disconnected

from power source.

2. Turn the screw for finger guard (#4) and

remove finger guard (#5).

3. Remove the blade lock nut (#1) by turning it

(#61,28,29,30).

4. Remove blade (#27) clean and dust or dirt

from machine.

5. Replace dirt blade.

6. How to Replace Carbon Brush

1. While the machine is unplugged.

Remove the two screw (#57) &

pull the cover (#54) upward.

2. Remove the screw cap (#49)

Over the carbon brush and re-

place the carbon brush (#50-1).

3. Put the cover (#54) back into its

original position and tighten the

screw.

4. Check the right and left carbon

brushes from time to time and

always replace both right and left

carbon brushes when worn out.

7. Lubrication and Maintenance

1. Turn the grease cup (#7) clockwise a

little bit to inject the grease into gear

box.

2. Make sure to add grease supplied

with the machine to the grease cup

(#6) when the grease cup is screwed

down to clean the bottom.

3. Always keep the machine clean

and free from remnants.

8. Maintenance and Inspection

1. Keep machine clean by removing all

accumulations of lint, thread and

cuttings from around the knife itself

to clean away from behind it, any

accumulated matter.

2. In addition, add grease to the

grease cup monthly using the

special grease the is supplied

with the machine.

3. From time to time, check the

right and left carbon brushes

and replace when necessary.

4. It is recommended that the

machine be turned off when not in

use.

5. Never put your hands in front of the

blade when operating.

6. Before doing any work on the

machine, be sure to disconnect the

machine from the electrical

outlet.

MB110-115V

600 rpms

.

www.esmfg.com

MB110-001 Adjusting Nut For Blade MB110-025 Worm Gear Washer MB110-049 Cab for Carbon Brush

MB110-002 Spring MB110-026 Worm Gear MB110-050-ASSYCarbon Brush w/Spring

MB110-003 Shaft for Gear MB110-027 Blade MB110-051 Motor Cover

MB110-004 Screw For Finger Guard MB110-028 Lock cover for Blade MB100-052 Snap Ring (E7)

MB110-005 Finger Guard MB110-029 Bearing MB100-053 Bearing

MB110-006 Grease Cup MB110-030 Srew for Blade MB100-054 End Cover

MB110-007 Cap for Grease Cup MB110-031 Bearing MB110-055 Cap for Cover

MB110-008 Gear Box MB110-032 Cap for Bearing MB110-056 Screw

MB110-009 Screw MB110-033 Oil Felt Tube MB110-057 Screw

MB110-010-1 Worm Gear MB110-034 Rollers MB110-058 Screw

MB110-011 Guide Plate MB110-035 Rollers Shaft MB110-059 Handle Fixed Base

MB110-012 Gear Box Fixed Base MB110-036 Rollers Shaft Fix. Plate MB110-060 Handle

MB110-013 Screw MB110-037 Screw MB110-061 Nut For Switch

MB110-014 Sharpening Stone MB110-038 Rollers MB110-062 Switch

MB110-014-ASSYSharpening Stone Ass’y MB110-039 Roller Shaft MB110-063 Nut For Switch

MB110-015 Lock Nut for Stone MB110-040 Base Plate MB110-064 Screw

MB110-016 Snap Ring (E3) MB110-041 Screw MB110-065 Screw

MB110-017 Spring MB110-042 Retaining Ring MB110-066 Screw

MB110-018 Screw MB110-043 Front Cover MB110-067 Plug

MB110-019 Sharpening Stone Bracket MB110-044 Snap Ring MB110-068 Wave Washer

MB110-020 Spring MB110-045 Wave Washer MB110-069 Motor Cover

MB110-021 Push Knob For Stone MB110-046 Beariing MB110-070 Screw For Worm Gear

MB110-022 Screw MB110-047-1 Rotor MB110-071 Cord complete w/Earch

MB110-023 Oil Felt MB110-048-1 Stator MB110-072 Grease

MB110-024 Counter Blade

.

www.esmfg.com

Supplemental instructions for MB110 Fiber Mat Cutters

Thank you for purchasing our MB110 Heavy Duty Cutter for your fiberglass cutting

needs. This tool will give you years of service provided you maintain and care for the

tool properly. Our experience in the composite industry allows us to supplement the

instructions supplied by the manufacturer.

1. Inspect daily the concentricity and condition of the blade. The alignment of the

rotating blade to the carbide counter blade is crucial to the operation of this tool.

Hard items, such as cured composites will damage the blade, the counter blade,

drive gears and possibly the motor. This is a heavy duty textile cutter and is not

meant for cured composites or other hard materials.

2. On or before 150 hours of usage, replace the MB110-050-ASSY. We have

supplied this assembly with your new purchase. This is common with all small

motors. If not changed in a timely, regular manner, critical damage will occur to

the rotor section of the motor. This damage can be fatal and expensive to repair.

Usually to cost of the repair is higher than the cost of a new unit.

3. When replacing the blade, be sure that all surfaces are completely clean. Just

the slightest contamination, especially under the blade will cause damage to the

arbors, blade and counter blade of this unit.

4. Never modify the cord of this unit. It is designed for the correct amperage drawn

from the motor. Any modification of this cord will not only void the warranty, but

create a significant risk of fire or explosion.

5. Use the self sharpening device included with your cutter only when neccessary.

This should be used sparingly, as overuse will cause excessive wear to the

blade.

6. Be sure to lubricate your MB110 daily or every 2 hours of operation, which ever

is greater.

Please take a few

Minutes to fill out

the below warranty

sheet. It will help

us serve you better.

ES MANUFACTURING, INC.

PO BOX 11692

ST. PETERSBURG, FL 33733- 1692 USA

FOLD HERE

Thomas D. Elder

President, ES Manufacturing, Inc.

If you have pictures of the products you make, we would like to

display them at our domestic and international trade shows.

Date of Purchase:_____________________________________

CompanyName:______________________________________

StreetAddress:_______________________________________

City / State / Zip;______________________________________

Phone#:____________________Fax#:____________________

Contact:_____________________________________________

Primary Line of Business:_______________________________

Is this your first ES Mfg., Inc. purchase? Yes No

Who did you purchase this unit from?:_____________________

What was your purchase price?:__________________________

Which was more important in your purchase?:

Simplicity Effectiveness Price Reputation

Would you like a free catalog?: Yes No

Comments:__________________________________________

___________________________________________________

___________________________________________________

Please return this sheet in the enclosed envelope.

ENGINEERED SOLUTIONS

ES MANUFACTURING, INCORPORATED

SAINT PETERSBURG, FLORIDA, U.S.A.

(727) 323-4040 800-55ES-MFG

MB110

This manual suits for next models

2