Blue Giant STRONGARM RVR303 User manual

ACTUAL PRODUCT MAY NOT APPEAR EXACTLY AS SHOWN

STARTING FROM JULY 19, 2021 / SERIAL # 0. ISSUE DATE: OCTOBER 26, 2021 REV. 1.0 (PART # 038-953EI)

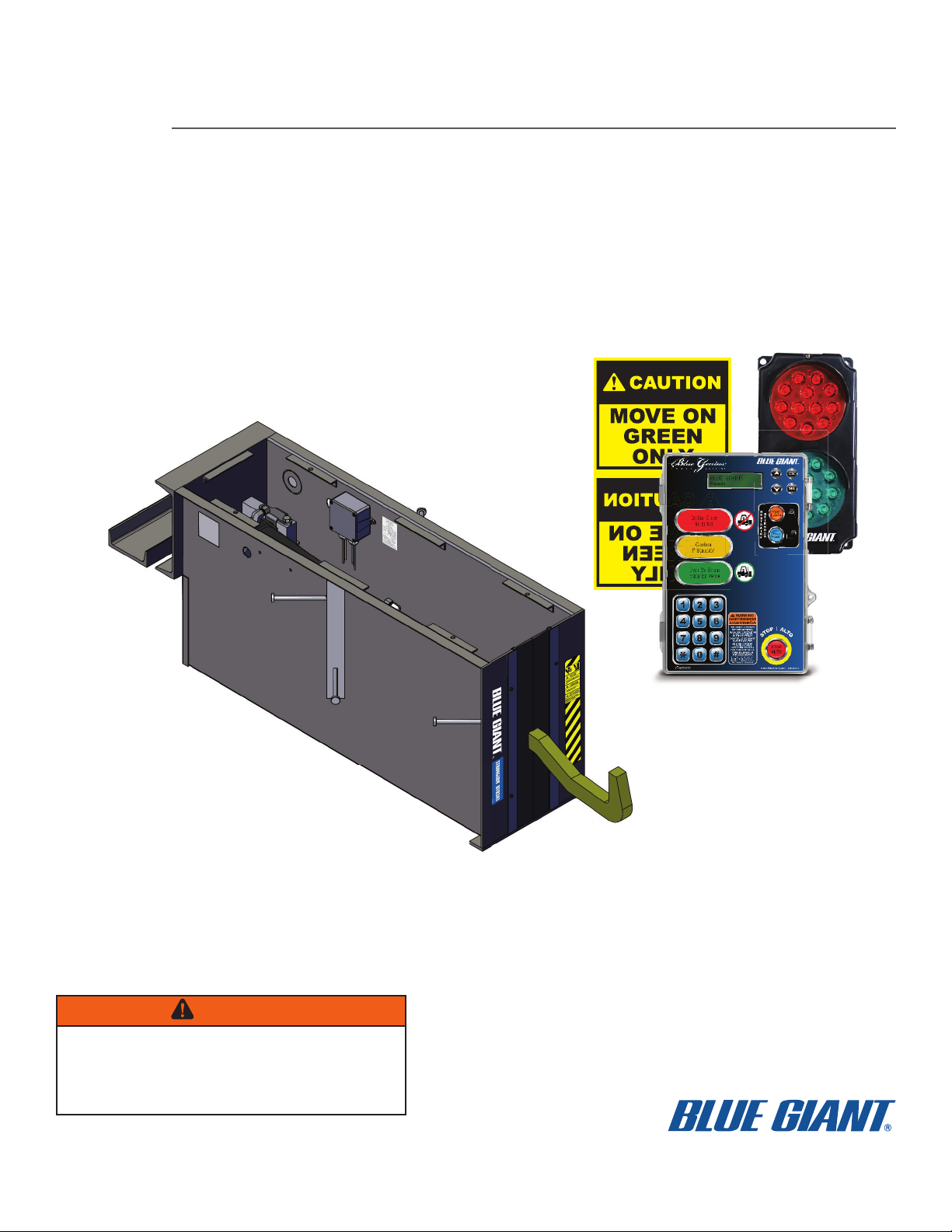

STRONGARM™ RVR303 VEHICLE RESTRAINT

WITH BLUE GENIUS™ TOUCH CONTROL

INSTALLATION & TECHNICAL MANUAL

WARNING

Do not operate or service this product unless you have

read and fully understand the entire contents of this

manual. Failure to do so may result in property damage,

bodily injury, or death.

STRONGARM™ RVR303 VEHICLE RESTRAINT — INSTALLATION & TECHNICAL MANUAL

3ISSUE DATE: OCTOBER 26, 2021 REV. 1.0 (PART # 038-953EI)

Table of Contents

Table of Contents

1.0 GENERAL SITE CHECKLIST FOR VEHICLE RESTRAINT 5

1.0 GENERAL SITE CHECKLIST FOR VEHICLE RESTRAINT 5

2.0 INTRODUCTION 6

2.0 INTRODUCTION 6

2.1 WARRANTY INFORMATION 6

2.1 WARRANTY INFORMATION 6

2.2 EXCLUSION OF LIABILITY 7

2.2 EXCLUSION OF LIABILITY 7

2.3 MANUFACTURER’S NOTE 7

2.3 MANUFACTURER’S NOTE 7

2.4 INSTALLER’S GUIDELINES 7

2.4 INSTALLER’S GUIDELINES 7

3.0 SAFETY MESSAGE COLOR IDENTIFICATION 8

3.0 SAFETY MESSAGE COLOR IDENTIFICATION 8

3.1 OPERATIONAL SAFETY WARNINGS 8

3.1 OPERATIONAL SAFETY WARNINGS 8

4.0 LOCKOUT / TAGOUT PROCEDURE AND RULES 10

4.0 LOCKOUT / TAGOUT PROCEDURE AND RULES 10

4.1 ELECTROSTATIC SENSITIVE DEVICE PROTECTION POLICY 11

4.1 ELECTROSTATIC SENSITIVE DEVICE PROTECTION POLICY 11

5.0 INSTALLATION LAYOUT 12

5.0 INSTALLATION LAYOUT 12

6.0 TOOLS REQUIRED FOR INSTALLATION 16

6.0 TOOLS REQUIRED FOR INSTALLATION 16

6.1 RECOMMENDED EQUIPMENT FOR RIGGING OR HOISTING 18

6.1 RECOMMENDED EQUIPMENT FOR RIGGING OR HOISTING 18

7.0 GENERAL DESCRIPTION 19

7.0 GENERAL DESCRIPTION 19

8.0 EQUIPMENT COMPONENT ILLUSTRATIONS 20

8.0 EQUIPMENT COMPONENT ILLUSTRATIONS 20

8.1 COMPONENTS AS SHIPPED CHECKLIST 20

8.1 COMPONENTS AS SHIPPED CHECKLIST 20

9.0 INSTALLATION GUIDELINES 22

9.0 INSTALLATION GUIDELINES 22

9.1 RESTRAINT INSTALLATION 22

9.1 RESTRAINT INSTALLATION 22

9.2 HOIST RESTRAINT WELDMENT BODY 22

9.2 HOIST RESTRAINT WELDMENT BODY 22

9.3 LEVELING AND SHIM PLACEMENT 22

9.3 LEVELING AND SHIM PLACEMENT 22

9.4 CONCRETE FORMS AND BRACING FOR THE RESTRAINT 23

9.4 CONCRETE FORMS AND BRACING FOR THE RESTRAINT 23

9.5 HOIST CYLINDER ASSEMBLIES (OPTIONAL) 23

9.5 HOIST CYLINDER ASSEMBLIES (OPTIONAL) 23

10.0 CONTROL STATION INSTALLATION 26

10.0 CONTROL STATION INSTALLATION 26

10.1 POWERPACK HARDWARE INSTALLATION 26

10.1 POWERPACK HARDWARE INSTALLATION 26

10.2 ELECTRICAL CONDUIT INSTALLATION 28

10.2 ELECTRICAL CONDUIT INSTALLATION 28

10.3 REMOTE I/O JUNCTION INSTALLATION 29

10.3 REMOTE I/O JUNCTION INSTALLATION 29

10.4 POWERPACK ELECTRICAL INSTALLATION 30

10.4 POWERPACK ELECTRICAL INSTALLATION 30

10.5 POWERPACK MOTOR WIRING 31

10.5 POWERPACK MOTOR WIRING 31

10.6 HYDRAULIC AIR BLEEDING 31

10.6 HYDRAULIC AIR BLEEDING 31

10.7 OIL TYPES 31

10.7 OIL TYPES 31

10.8 INSTALLING THE EXTERIOR DRIVER TRAFFIC LIGHT 32

10.8 INSTALLING THE EXTERIOR DRIVER TRAFFIC LIGHT 32

10.9 INSTALLING THE EXTERIOR DRIVER WARNING SIGN 33

10.9 INSTALLING THE EXTERIOR DRIVER WARNING SIGN 33

10.10 LIP GUIDE FOR AFTERMARKET (LEGACY) DOCKS 34

10.10 LIP GUIDE FOR AFTERMARKET (LEGACY) DOCKS 34

10.11 SENSOR RANGE ADJUSTMENT 35

10.11 SENSOR RANGE ADJUSTMENT 35

11.0 ELECTRICAL WIRING INSTALLATION 36

11.0 ELECTRICAL WIRING INSTALLATION 36

11.1 BLUE GENIUS™ CONTROL STATION WIRING LAYOUT 37

11.1 BLUE GENIUS™ CONTROL STATION WIRING LAYOUT 37

11. 2 W IR ING DI AGR A MS 38

11.2 WIRING DIAGRAMS 38

11.3 BLUE GENIUS CONTROL STATION WIRING LAYOUT 38

11.3 BLUE GENIUS CONTROL STATION WIRING LAYOUT 38

11.4 WIRING DIAGRAM—115V SINGLE PHASE 38

11.4 WIRING DIAGRAM—115V SINGLE PHASE 38

11.5 WIRING DIAGRAM—208-575V THREE PHASE 39

11.5 WIRING DIAGRAM—208-575V THREE PHASE 39

12.0 PRE-COMMISSIONING INSPECTION CHECKLIST 40

12.0 PRE-COMMISSIONING INSPECTION CHECKLIST 40

12.1 COMMISSIONING AND START-UP PROCEDURES 41

12.1 COMMISSIONING AND START-UP PROCEDURES 41

12.2 BLUE GENIUS™ V2 MENU ACCESS 41

12.2 BLUE GENIUS™ V2 MENU ACCESS 41

12.3 BLUE GENIUS™ V2 LEARN PROCEDURE 41

12.3 BLUE GENIUS™ V2 LEARN PROCEDURE 41

12.4 BLUE GENIUS™ V2 TESTING 42

12.4 BLUE GENIUS™ V2 TESTING 42

12.5 POWERPACK OIL TYPES 42

12.5 POWERPACK OIL TYPES 42

STRONGARM™ RVR303 VEHICLE RESTRAINT — INSTALLATION & TECHNICAL MANUAL

4 ISSUE DATE: OCTOBER 26, 2021 REV. 1.0 (PART # 038-953EI)

13.0 TROUBLESHOOTING 43

13.0 TROUBLESHOOTING 43

13.1 VEHICLE RESTRAINT TROUBLESHOOTING 43

13.1 VEHICLE RESTRAINT TROUBLESHOOTING 43

13.2 BLUE GENIUS™ LCD MESSAGES 43

13.2 BLUE GENIUS™ LCD MESSAGES 43

1.0

1.0

GENERAL SITE CHECKLIST FOR VEHICLE RESTRAINT

GENERAL SITE CHECKLIST FOR VEHICLE RESTRAINT

Use this chart to prepare the site for installation.

Yes No Comments

1Review site conditions. Have you completed and reviewed

site survey report? FF

2Is there enough room to mount the RVR303 under the dock?

i.e. dock wall face. FF

3Is the electrical power present to hook up to?

i.e. on inside wall near control install location FF

4Was the conduit(s) installed and properly

positioned? FF

5Did you check to see if the proper voltage is

supplied? FF

6

When un-packing, were all the parts included?

See “8.1 COMPONENTS AS SHIPPED CHECKLIST” on

page 20.

FF

7

Do you have all the tools needed to complete the job? This

includes ladder(s), safety equipment and personal safety

devices. See “6.0 TOOLS REQUIRED FOR INSTALLATION”

on page 16.

FF

8

Do you have all the anchors for the exterior driver traffic

light, warning sign and control box?

Supplied by: You, contractor, installer

FF

9Have you read this installation manual and fully understood

it? FF

10

Do you have the Blue Giant technical support number?

1.800.872.2583. Before calling, make sure to have serial #

of equipment.

FF

11

Do you know what ESD "Electrostatic Sensitive

Device" is and how to handle? See “4.1 ELECTROSTATIC

SENSITIVE DEVICE PROTECTION POLICY” on page 11.

FF

STRONGARM™ RVR303 VEHICLE RESTRAINT — INSTALLATION & TECHNICAL MANUAL

5ISSUE DATE: OCTOBER 26, 2021 REV. 1.0 (PART # 038-953EI)

Other manuals for STRONGARM RVR303

1

Table of contents

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction