Blue Hawk SGY-NR-KITV User manual

ATTACH YOUR RECEIPT HERE

Serial Number Purchase Date

ITEM #0461680

MODEL #SGY-NR-KITV

FRAMING NAILER

WITH PALM NAILER

1

service department at 1-877-888-8225, 8 a.m. - 8 p.m., EST, Monday - Friday.

Questions, problems, missing parts? Before returning to your retailer, call our customer

R

www.lowes.comAB1319

Français p. 14

Español p. 27

TABLE OF CONTENTS

IMPORTANT

PRODUCT SPECIFICATIONS

.Safety Information ................................................................................................................... 5

Read and follow all safety rules and operating instructions before using product. Retain this manual

for future reference.

.Troubleshooting................................................. ....................................................................... 10

Package Contents .................................................................................................................. 3

Product Specifications ............................................................................................................... 2

..Operating Instructions...................................... ....................................................................... 7

..Care and Maintenance................................... ........................................................................ 10

.

Exploded Views ............................................... ........................................................................ 12

.

Warranty .................................................................................................................................. 12

2

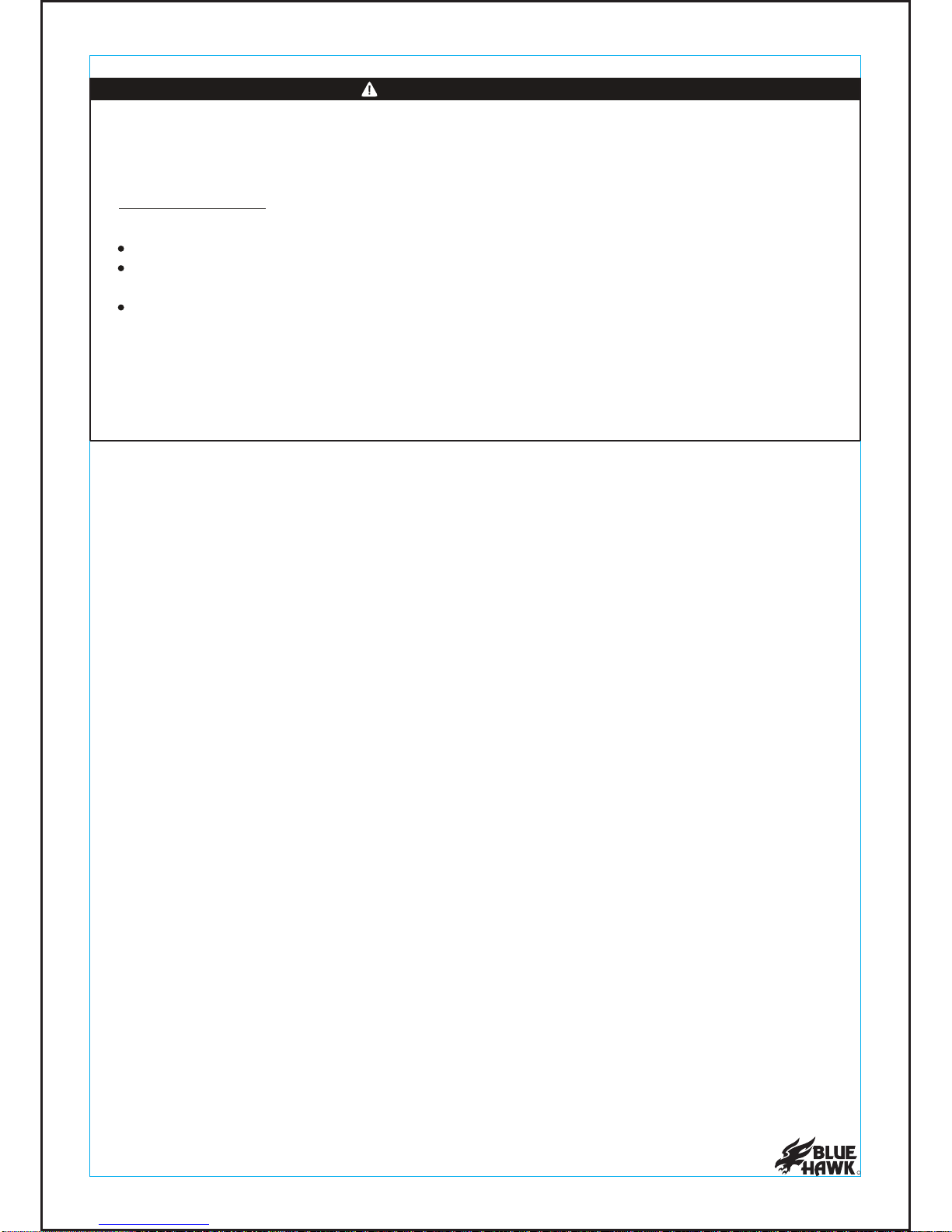

Nail capacity

Nail length

Operating pressure

Air inlet

Dimensions

Weight

Nail shank dia.

DESCRIPTION

2 x 30 pcs.

2 in. - 3-1/2 in.

80 - 120 PSI (5.5 - 8.2 bar)

1/4 in. N.P.T.

19.68 in. × 14.92 in. × 4.21 in.

(500 × 379 × 107 mm)

8.36 lbs.

2.87 mm - 3.33 mm

SPECIFICATION

Nail capacity

Nail length

Operating pressure

Air inlet

Dimensions

Weight

Nail head

DESCRIPTION

1 pcs.

2 in. - 3-1/2 in.

70 - 100 PSI (4.8 - 6.9 bar)

1/4 in. N.P.T.

4.05 in. × 2.08 in. × 4.05 in.

(103 × 53 × 103 mm)

0.81 lbs.

3 mm - 7.5 mm

SPECIFICATION

FRAMING NAILER

PALM NAILER

R

www.lowes.com

PACKAGE CONTENTS

QUANTITY

1

1

1

1

1

PART

A

B

C

D

E

DESCRIPTION

Air Deflector

Cylinder Cover

Gun Body

Drive Guide

Depth Adjustment QUANTITY

1

1

PART

F

G

DESCRIPTION

Magazine

Air Plug

3

16 GA FINISH NAILER

A

C

D

E

F

G

B

R

www.lowes.com

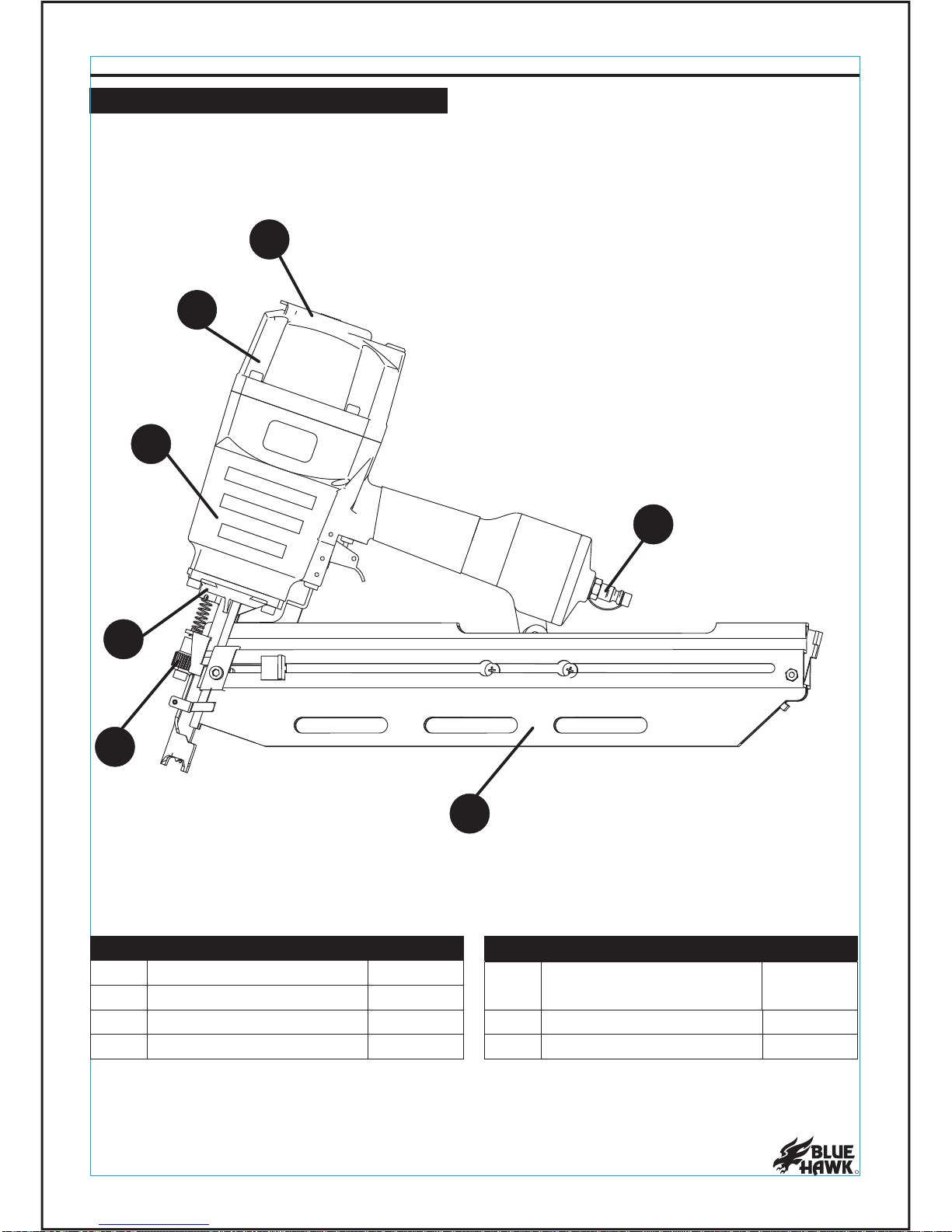

PACKAGE CONTENTS

QUANTITY

1

1

1

1

1

PART

A

B

C

D

E

DESCRIPTION

Cylinder Cover

Bolt

Gun Body Fix Set

Air Inlet Plug

QUANTITY

PART DESCRIPTION

4

PALM NAILER

A

B

C

D

E

R

www.lowes.com

A

ra

Always be aware of air hose tripping hazard for anyone in the work area, especially if a long air

hose is used in work area.

Carry tool by the handle only.

Always keep the tool pointed away from yourself and others.

Do not keep the trigger depressed during loading of fasteners.

Always disconnect tool from air supply before loading fasteners to prevent any accidental firings

during connection.

Unintentional firing of fasteners may cause personal injury.

Disconnect tool from air supply hose and close the compressor before performing any

maintenance.

Never use a tool that is leaking air, has missing or damaged parts or requires repair.

Only use parts and accessories recommended by the manufacturer.

Read this manual and all operating instructions thoroughly before loading or unloading fasteners

or any other use of the tool. Failure to follow safety or operating instructions could result in

serious personal injury.

Do not drive fastener on scaffolding, ladders, and similar construction materials for which it’s not

intended.

Make sure all screws are securely tightened before use.

DO NOT CONNECT TOOL TO COMPRESSED AIR THAT EXCEEDS 120 PSI.

To avoid unintentional firing of tool, always be aware when safety part of trigger is depressed.

Keep hands and body away from rear area of gun to safely guard against possible injury.

SAFETY INFORMATION

NEVER USE OXYGEN, COMBUSTIBLES OR ANY OTHER BOTTLED GAS AS A POWER

SOURCE, as they can cause explosions and serious personal injury.

Keep chi ldren away. Children must never be allowed in the work area. Do not let them handle

brad nailer nails, fasteners, air hoses or any other equipment or tool.

Dress properly.Do not wear loose clothing or jewelry as they can be caught in moving parts.

Protective, electrically nonconductive clothes and nonskid footwear are recommended when

working. Wear restrictive hair covering to contain long hair.

Protect your eyes.Wear safety glasses or a face shield when using this product.

Protect your hearing. Noise can harm your hearing.

Always wear ear protection to safeguard your

Keep proper footing at all times. Do not overreach as slipping, tripping, and/or falling can be a

major cause of serious injury and/or death. Be aware of excess hose left in the working area or

work surface. Do not abuse hoses or connectors. Never carry the tool by the hose or yank it to

disconnect it from power supply. Keep hoses away from heat, oil, and sharp edges. Check hoses

for weak or worn connections before each use and make certain that all connections are secure.

hearing.

5

R

www.lowes.com

6

WARNING

SOME DUST CREATED BY PAINT SPRAYING, POWER SANDING, SAWING,

GRINDING, DRILLING, AND OTHER RELATED ACTIVITIES IS KNOWN TO THE

STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, AND OTHER

REPRODUCTIVE HARM. A LISTING OF CHEMICALS CAN BE OBTAINED FROM

www.oehha.ca.gov UNDER PROPOSITION 65. SOME EXAMPLES OF THESE

CHEMICALS ARE:

LEAD FROM LEAD BASED PAINTS

PRODUCTS

CRYSTALLINE SILICA FROM BRICKS, CEMENT AND OTHER MASONRY

ARSENIC AND CHROMIUM FROM CHEMICALLY TREATED LUMBER

YOUR RISK FROM THESE EXPOSURES VARIES, DEPENDING ON HOW OFTEN

YOU DO THIS TYPE OF WORK. TO REDUCE YOUR EXPOSURE TO THESE

CHEMICALS WORK IN A WELL VENTILATED AREA, AND WORK WITH APPROVED

SPECIALLY DESIGNED TO FILTER MICROSOPIC PARTICLES.

SAFETY EQUIPMENT, SUCH AS A RESPRIATOR OR DUST MASKS WHICH ARE

R

www.lowes.com

7

OPERATING INSTRUCTIONS

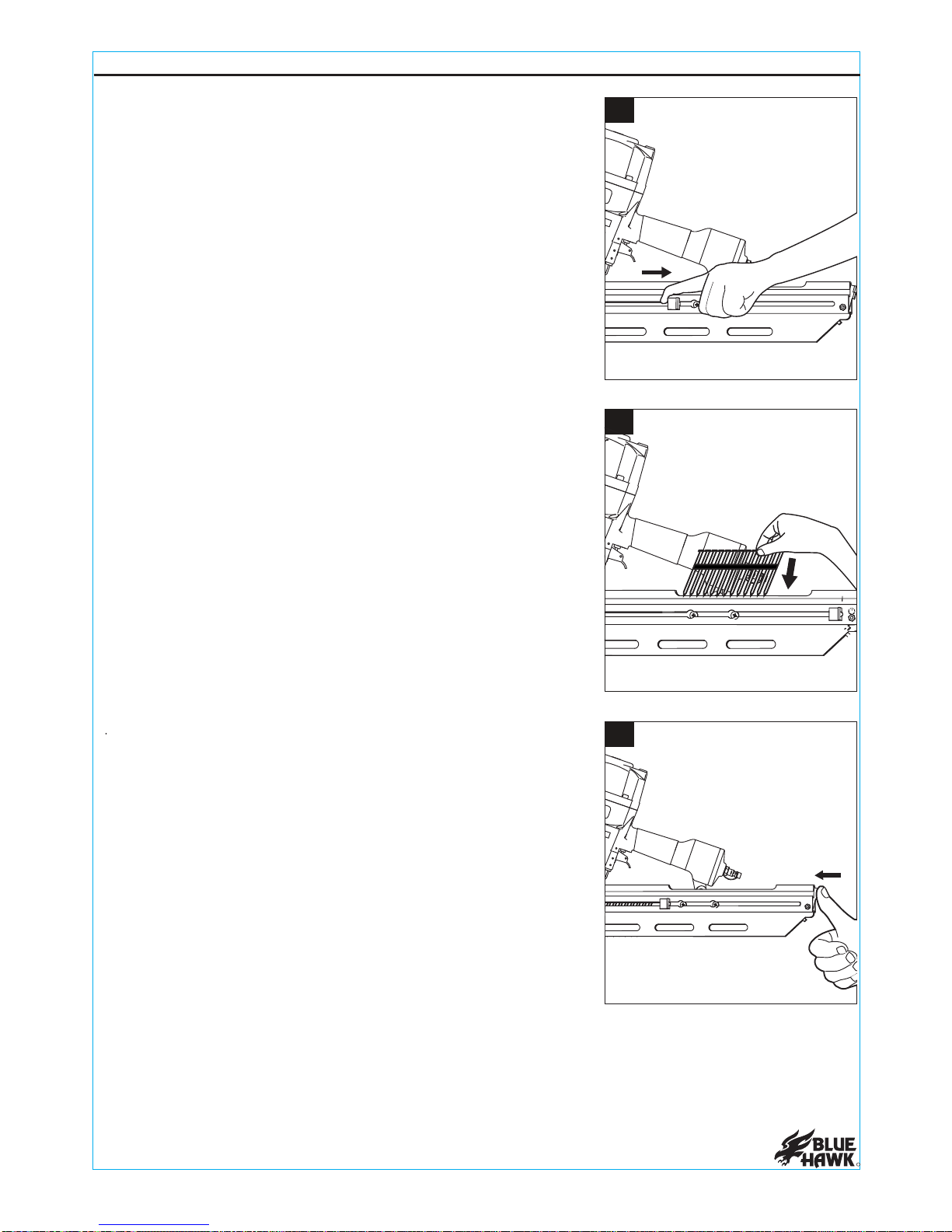

1

3

2

FRAMING NAILER

BEFORE LOADING OR UNLOADING FASTENERS, MAKE

SURE THE TOOL IS DISCONNECTED FROM THE AIR

SUPPLY, THE TRIGGER IS NOT DEPRESSED, AND THE

TOOL IS NOT POINTING TOWARD ANYONE.

1. Pull back on nail switch release latch until you hear the latch

click and it’s locked in place.

2. Insert nails into magazine.

NOTE: Before inserting any nails into the gun, make sure you are

using the proper nail with the proper nail gun. If the incorrect

nail is used bodily injury or property damage may occur. Make

sure that the nail is facing the proper direction with the tip facing

down toward the bottom of the magazine and the head of the

nail facing up toward the top of the magazine. Please consult

your retailer if you have any questions on which nail is the correct

one to be used with this tool or how to place the nails properly

into the magazine.

3Press forward on the nail switch release latch so that it slides

forward until it makes contact with the inserted fasteners. It’s

recommended to test fire the fastener on a scrap piece of wood

to make sure the depth setting on the nailer is set properly.

R

www.lowes.com

OPERATING INSTRUCTIONS

4. Air supply

5. Loading fasteners and operating

When connecting air supply, always keephands and body away from discharge area of tool.

A filter regulation-lubrication (not included) is required and should be located as close to the

Make sure the air pressure is set at the correct range of 80 - 120 PSI before using. Never

exceed 130 PSI.

tool as possible.

Not all components shown are included.

Place five or six drops of pneumatic tool oil (not included) into the air inlet. If you use an

automatic inlet oiler, check and add oil if necessary.

Check and replace any damaged or worn parts on the tool.

Make sure the magazine is empty of all fasteners and the hose has a rated work

pressure, then connect the tool to air compressor using a 3/4 in. ID hose.

Regulate the air pressure to obtain 5 - 8 bardepending on working demands and

characteristics of workpiece.

Before loading the fasteners, disconnect the tool from the air supply. Gripping the tool firmly,

pull the pusher back and engage the latch.

Insert a strip of fasteners keeping point down.

Orient and slide this strip of fasteners forward to the front of the magazine.

Release the latch and pusher. Slide the pusher against the nails.

Test the driving depth in a sample piece of wood before using. If the fasteners are being

driven too far or not far enough, adjust the regulator to provide less air pressure or more air

pressure.

Tool

Quick

Quick

Coupler Quick

Coupler

Air Hose Regulator

Air

Compressor

Connector Quick Oiler Filter

Connector

4

8

Never operate tool unless safety nose is in contact with workpiece. Do not operate tool

without fasteners or damage to tool may result.

Never fire fasteners into air because fasteners may injure operator or others and damage to

tool may result.

R

www.lowes.com

9

OPERATING INSTRUCTIONS

1

PALM NAILER

2. Air supply

3. Loading fasteners and operating

When connecting air supply, always keephands and body away from discharge area of tool.

A filter regulator-lubrication (not included) is required and should be located as close to the

Make sure the air pressure is set at the correct range of 70 - 90 PSI before using. Never

exceed 100 PSI.

tool as possible.

Not all components shown are included.

Insert one piece of required nail into fixed set. Use one hand to hold the nail and the other

hand to hold the body of the tool. Press the tool until ram pin upwards 1 mm and attach

movement in succession.

Use clean, dry and regulated compressed air at 70-90 PSI.

After the nail is steady, remove the hand holding the nail and continue to drive the nail into

place.

Place some drops of lubrication into the air inlet before use, and clean the tool after use.

Tool

Quick

Quick

Coupler Quick

Coupler

Air Hose Regulator

Air

Compressor

Connector Quick Oiler Filter

Connector

2

KEEP YOUR HAND AND FINGERS AWAY FROM THE BASE

OF PALM NAILER WHILE IN USE. BEFORE PERFORMING

ANY MAINTENANCE, MAKE SURE THE TOOL IS

DISCONNECTED FROM THEAIR SUPPLY.

When setting a nail, it is recommended that the sides of the nail

are held under the head of the nail

When holding the nail properly, align the head of the nail with

the fix set at the base of the palm nailer. Make sure the nail is

aligned properly. Slightly apply pressure to the top of palm nailer

and the palm nailer will begin to fire. Once the nail is slightly

inserted into the surface pull your hand away from the nail. Keep

consistent pressure on the top of the palm nailer to continue to

drive the nail deeper into the surface.

NOTE: The palm nailer is designed to continuously fire when the

nail head and fix set make contact until the nail is flush into the surface you plan to nail into. You

can set a nail to any depth. To stop the nailer, release pressure from the top of the palm nailer.

R

www.lowes.com

CAREANDMAINTENANCE

TROUBLESHOOTING

10

Nail gun must be well-cleaned and lightly lubricated before storing

Place 2 to 6 drops of pneumatic tool oil into the air inlet before each work day or after 2 hours of

continuous use depending on the characteristicsof workpiece or type of fasteners.

Inspect trigger and safety mechanism to ensure system is safe and functional. Make sure there

are no loose or missing parts and no binding or sticking parts.

WARNING: If any of the following problems occur during operation, stop using the tool

immediately or serious personal injury could result. Only a qualified person or an

authorized service center can perform repairs or replacement of tool.

Disconnect tool from air supply before attempting repair or adjustment. When replacing O-rings

or cylinder, lubricate with air tool oil before assembly.

Air leak near top of

tool or in trigger area. 1. O-rings in trigger valve ar

e damaged.

2. Trigger valve heads are damaged.

3. Trigger valve stem, seal or O-ring

are damaged.

1. Check and replace O-ring.

2. Check and replace trigger valve heads.

3. Check and replace trigger valve

stem, seal or O-ring.

Air leak near bottom of

tool. 1. Loose screws.

2. Worn or d

amaged O rings or bumper.

-

1. Tighten screws.

2. Check and replace O-rings or bumper.

Air leak between body

and cylinder cap. 1. Loose screws.

2. Worn or damaged O-rings or seals. 1. Tighten screws.

2. Check and replace O-rings or bumper.

Blade driving fastener

too deep. 1. Worn bumper.

2. Air pressure is too high. 1. Replace bumper.

2. Adjust the air pressure.

Tool: cannot drive

fastener or operates

sluggishly.

1. Inadequate air supply.

2. Inadequate lubrication.

3. Worn or damaged O

-

rings or seals.

4. Exhaust port in cylinder head is

blocked.

1. Verify adequate air supply.

2. Place 2 to 6 drops of oil into air inlet.

3. Check and replace O-rings or seal.

4. Replace damaged internal parts.

Tool skips fasteners. 1. Worn bumper or damaged spring.

2. Dirt in front plate.

3. Dirt or damage prevents fasteners

from moving freely in magazine.

4. Worn or dry O

-

ring on piston or

lack of lubrication.

5. Cylinder cover seal leaking.

1. Replace bumper or pusher spring.

2. Clean drive channel on front plate.

3. Magazine needs to be cleaned.

4. O-ring needs to be replaced.

5. Lubricate cylinder cover seal.

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTIONS

Tool jams. 1. Incorrect or damaged fasteners.

2. Damaged or worn driver guide.

3. Magazine or nose screw loose.

4. Magazine is dirty.

2. Check and replace the driver.

3. Tighten the magazine.

4. Clean the magazine.

1. Change and use correct fastener.

If your tool is used without the in-liner automatic oiler (not included), regular lubrication is required.

Store nail gun in a dry and safe place, out of reach of children

Storing

R

www.lowes.com

Clearing a jammed nail gun:

Disconnect the tool from the air supply before performing any maintenance. Once air supply is

disconnected, pull back on the nail switch release latch. Remove any fastener(s) or nail(s) which

are in the magazine. Insert a flathead screwdriver (not included) into the driving mechanism of the

nail gun and push the driving mechanism back into the gun body. This should free the fastener/nail

jam. Remove any bent fastener or nail from the gun body or driver guide and/or nail plate. Once

bent fastener or nail is removed, reinsert the fastener(s) or nail(s) into the magazine. Close the nail

switch release latch so that there is pressure on the fastener(s)/nail(s). Reconnect the air supply

to the nail gun.

11

www.lowes.com ®

WARRANTY

1-YEAR LIMITED WARRANTY

The manufacturer warrants this product against defects in materials and workmanship for

one year from date of purchase. If within this period a product is found to be defective in

material or workmanship, the product must be returned with a copy of the bill of sale as proof

of purchase to the place of purchase. The manufacturer will, at its option, repair, replace or

refund the purchase price to the consumer. This warranty does not cover the product becoming

defective due to misuse, accidental damage, improper handling and/or installation and specifically

excludes liability for direct, incidental or consequential damages. As some states do not allow

exclusions or limitations on how long an implied warranty lasts, the above exclusion and limitation

may not apply to you. This warranty gives you specific rights and you may also have other rights

which vary from state to state.

12

EXPLODED VIEWS

1

25 Cylinder

Copper Collar

Safety Nose Case

Magazine

Bolt

Washer

Nut

Washer Case

Drive Nail Bar

Bolt

Spacer

Bolt

Safety Pipe

Pusher

Spring

Latch Spring

Release Latch

Pin

Spring Core

Safety Pipe Case

Bolt

Nut

Flat Washer

Fixed Seat

Bolt

Rubber Handle Case

Trigger Valve Guide

O-ring

O-ring

O-ring

Switch Spring

Switch Pipe

O-ring

O-ring

Switch Seat

Pin

Trigger

O-ring

Safety Spacer

Pin

Safety Guide

Pin

Compressed Spring

Safety Yoke

Bolt

Spring Washer

Safety Nose

Compressed Spring

O-ring

Drive Guide

Spring Washer

Bolt

Pin

Bolt

Plate

Flat Washer

56

2

33

Bolt

Air Deflector

Deflector Rubber

Spring

Spring wire

Bolt

Spring Washer

Washer

Cylinder Core

Bolt

Cylinder Cover

Head Valve Piston

O-ring

O-ring

Spring Washer

Spring Seat

Compressed Spring

Collar

O-ring

Main Piston

O-ring

O-ring

O-ring

O-ring

Fix ring

Sealing Ring 57

3

34

65

4

35

66

5

36

67

6

37

68

7

38

69

8

39

70

9

40

71

10

41

72

11

42

73

12

43

74

13

44

75

14

45

76

15

46

77

16

47

78

17

48

79

18

49

80

19

50

81

20

51

82

83

84

85

86

87

21

22

23

24

52

53

54

55

61

62

63

64

58

59

60

No. Description Description DescriptionQty. Qty. Qty.No. No.

1

1

1

1

1

1

1

4

6

5

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

31

Bumper Outer Lane

Bumper

Cylinder Washer

Gun Body

Trigger Valve Seat

26

27

28

29

30 1

32 1

1

1

1

1

12

1

1

1

4

4

1

1

11

2

1

1

1

1

1

1

1

1

2

1

1

2

3

1

1

1

2

1

1

1

1

1

1

1

1

1

2

3

1

2

1

1

End Cap Washer

End Cap

Washer

Bolt

Air Plug

Air Piug Case

88

89

90

91

92

93

1

1

3

1

3

1

Adj. Block

94 1

Adj. Nut

Steel Ball

Bolt

Pin Case

Stop Collar

95

96

97

98

99

1

2

1

1

1

1

1

1

4

3

1

1

1

2

1

1

FRAMING NAILER

R

www.lowes.com

13

EXPLODED VIEWS

1Air Plug Case

Washer

Fix Set

Magnet

Spring

Bolt

Cylinder

O-ring

O-ring

Piston

Bumper

Sealing Washer

Gun Body

Air Inlet Plug

29

Bolt

Spring Wahser

Cylinder Cover

O-ring

Washer

O-ring

Slip Set

Seal Ring

310 17

411 18

512 19

613 20

714 21

815 22

16

No. Description Description DescriptionQty. Qty. Qty.No. No.

4

4

11

1

1

2

1

1

2

11

1

1

1

1

1

1

1

1

1

1

FRAMING NAILER

BLUE HAWK

is a registered

trademark of

L. F., LLC. All

Rights Reserved.

R

Printed in China

R

www.lowes.com

ARTICLE #0461680

MODÈLE #SGY-NR-KITV

CLOUEUSE DE

CHARPENTE AVEC

CLOUEUSE PORTATIVE

14

R

www.lowes.com

JOIGNEZ VOTRE REÇU ICI

Numéro de série Date d’achat

Des questions, des problèmes, des pièces manquantes? Avant de retourner l’article au

détaillant, appelez notre service à la clientèle au 1 877 888-8225, entre 8 h et 20 h (HNE),

du lundi au vendredi.

TABLE DES MATIÈRES

IMPORTANT

CARACTÉRISTIQUES DU PRODUIT

.Consignes de sécurité ............................................................................................................... 18

Avant d’utiliser cet article, lisez et suivez toutes les consignes de sécurité et le mode d’emploi.

Veuillez conserver ce manuel pour vous y référer ultérieurement.

.Dépannage................................................................................................................................. 23

Contenu de l’emballage ............................................. .............................................................. 16

Caractéristiques du produit ......................................... ................................................................. 15

..Mode d’emploi.................................................. ....................................................................... 20

..Entretien......................................................... ........................................................................ 23

.

Vues éclatées ........................................................................................................................... 25

.

Garantie ................................................................................................................................... 24

15

Capacité de clous

Longueur du clou

Pression de fonctionnement

Entrée d’air

Dimensions

Poids

Diamètre des clous à tige

Capacité de clous

Longueur du clou

Pression de fonctionnement

Entrée d’air

Dimensions

Poids

DESCRIPTION

2 x 30 pièces

2 po à 3 1/2 po

2 po à 3 1/2 po

5,5 bars à 8,2 bars (80 lb/po² à 120 lb/po²)

1/4 po NPT

19,68 po × 14,92 po × 4,21 po

(500 × 379 × 107 mm)

3,79 kg

2,87 mm à 3,33 mm

3 mm à 7,5 mm

CARACTÉRISTIQUES

1 pièce

4,8 bars à 6,9 bars (70 lb/po² à 100 lb/po²)

1/4 po NPT

4,05 po × 2,08 po × 4,05 po

(103 × 53 × 103 mm)

0,37 kg

CLOUEUSE DE CHARPENTE

CLOUEUSE PORTATIVE

R

www.lowes.com

DESCRIPTION CARACTÉRISTIQUES

Tête du clou

CONTENU DE L’EMBALLAGE

QUANTITÉ

1

1

1

1

1

PIÈCE

A

B

C

D

E

DESCRIPTION

Déflecteur

Couvercle du cylindre

Corps du pistolet

Guide d’enfoncement

Dispositif de réglage de

la profondeur

QUANTITÉ

1

1

F

G

DESCRIPTION

Magasin

Entrée d’air

16

CLOUEUSE DE FINITION DE CALIBRE 16

A

C

D

E

F

G

B

R

www.lowes.com

PIÈCE

CONTENU DE L’EMBALLAGE

QUANTITÉ

1

1

1

1

1

PIÈCE

A

B

C

D

E

DESCRIPTION

Couvercle du cylindre

Verrou

Corps du pistolet Ensemble de fixation

Raccord d’entrée d’air

17

CLOUEUSE PORTATIVE

A

B

C

D

E

R

www.lowes.com

PIÈCE DESCRIPTION QUANTITÉ

18

Lisez attentivement ce guide et tous les modes d’emploi avant de charger ou de décharger

les fixations ou d’utiliser l’appareil de quelque façon que ce soit. Le non-respect des

consignes de sécurité et du mode d’emploi peut entraîner des blessures graves.

www.lowes.com

CONSIGNES DE SÉCURITÉ

MA

ra

a

Soyez toujours conscient du danger de trébucher sur le tuyau d’air, surtout s’il est long, pour

tous ceux qui se trouvent dans l’aire de travail.

Tenez toujours l’outil uniquement par la poignée.

Ne pointez jamais l’outil vers vous ni vers les autres.

Ne gardez pas la gâchette enfoncée lors du chargement des fixations.

Débranchez toujours l’outil de l’alimentation en air avant de charger les fixations afin d’éviter un

déclenchement imprévu des fixations lors de la connexion.

Le déclenchement accidentel des fixations pourrait entraîner des blessures.

Débranchez l’outil du tuyau d’alimentation en air et fermez le compresseur avant d’effectuer tout

entretien.

N’utilisez jamais un outil qui présente une fuite d’air, auquel il manque des pièces, dont des

pièces sont endommagées ou qui nécessite une réparation.

N’utilisez que des pièces et des accessoires recommandés par le fabricant.

N’enfoncez pas la fixation sur un échafaudage, une échelle ou tout autre matériau de construction

similaire pour lequel elle n’est pas conçue.

Assurez-vous que toutes les vis sont serrées fermement avant l’utilisation.

NE BRANCHEZ PAS L’OUTIL À DE L’AIR COMPRIMÉ QUI DÉPASSE 120 LB/PO².

Ne laissez pas la gâchette enfoncée sur le mécanisme de mandrin de sécurité afin d’éviter un

déclenchement accidentel de l’outil.

Gardez toujours les mains et le corps éloignés

de l’arrière du pistolet pour vous protéger de toute

blessure.

N’UTILISEZ JAMAIS D’OXYGÈNE, DE COMBUSTIBLES NI AUCUN AUTRE GAZ

EMBOUTEILLÉ COMME SOURCE D’ALIMENTATION, puisqu’ils peuvent provoquer une

Gardez les enfants à l’écart. Ne laissez jamais un enfant accéder à l’aire de travail. Ne laissez

Habillez-vous convenablement. Ne portez pas de vêtements amples ni de bijoux, car ils risquent

Protégez vos yeux. Portez des lunettes de sécurité ou un écran facial lorsque vous utilisez ce

Protégez votre ouïe – le bruit peut la détériorer.

Portez toujours des protecteurs auditifs pour

Gardez une posture sécuritaire en tout temps. Ne vous étirez pas pour étendre votre portée;

AVERTISSEMENT

pas les enfants manipuler la cloueuse de finition, les clous, les fixations, les tuyaux à air, de

l’équipement ou des outils.

de se prendre dans les pièces mobiles. Des vêtements de protection non conducteurs et des

chaussures antidérapantes sont recommandés pour le travail. Couvrez vos cheveux s’ils sont

longs.

produit.

préserver votre ouïe.

vous risqueriez de glisser, de trébucher ou de tomber et de subir des blessures graves ou

mortelles. Faites attention à l’excédent de tuyau laissé dans l’aire de travail ou sur la surface de

travail. Ne faites pas un usage abusif des tuyaux ou des connecteurs. Ne transportez jamais

l’outil en le tenant par le tuyau et ne le tirez jamais sur le cordon d’alimentation pour le

débrancher. Tenez les tuyaux éloignés des sources de chaleur, de l’huile et des objets coupants.

Vérifiez si les raccords des tuyaux sont faibles ou usés avant chaque utilisation et assurez-vous

qu’ils sont bien solides.

explosion ou causer des blessures graves.

www.lowes.com

19

LES RISQUES LIÉS À L’EXPOSITIONÀ CES PRODUITS VARIENT SELON LE

NOMBRE DE FOIS OÙVOUS PRATIQUEZ CES ACTIVITÉS. AFIN DE LIMITER

VOTRE EXPOSITIONÀ CES PRODUITS CHIMIQUES, TRAVAILLEZ DANS UN

ENDROIT BIENVENTILÉ ET UTILISEZ DE L’ÉQUIPEMENT DE SÉCURITÉ

APPROUVÉ, TELQU’UN APPAREIL RESPIRATOIRE OU UN MASQUE

ANTIPOUSSIÈRE CONÇUS SPÉCIALEMENT POUR FILTRER LES PARTICULES

MICROSCOPIQUES.

A VERTISSEMENT

LA POUSSIÈRE CRÉÉE PENDANT LE PONÇAGE, LE SCIAGE, LE POLISSAGE, LE

PERÇAGE ET D'AUTRES ACTIVITÉS PEUT CONTENIR DES PRODUITS CHIMIQUES

RECONNUS PAR L'ÉTAT DE LA CALIFORNIE COMME ÉTANT LA CAUSE DE CANCERS,

D'ANOMALIES CONGÉNITALES ET D'AUTRES PROBLÈMES LIÉS AUX FONCTIONS

AU www.oehha.ca.gov, CONFORMÉMENT À LA PROPOSITION 65. VOICI

QUELQUES-UNS DE CES PRODUITS CHIMIQUES :

DU PLOMB PROVENANT DE PEINTURES À BASE DE PLOMB;

DE LA SILICE CRISTALLINE PROVENANT DE LA BRIQUE, DU CIMENT OU

D'AUTRES MATÉRIAUX DE MAÇONNERIE;

DE L'ARSENIC ET DU CHROME PROVENANT DU BOIS D'ŒUVRE TRAITÉ AVEC

UN PRODUIT CHIMIQUE.

REPRODUCTRICES. VOUS POUVEZ OBTENIR LA LISTE DES PRODUITS CHIMIQUES

20

MODE D’EMPLOI

1

3

2

CLOUEUSE DE CHARPENTE

AVANT DE CHARGER OU DE DÉCHARGER DES CLOUS,

ASSUREZ-VOUS QUE L’OUTIL EST DÉBRANCHÉ DE

L’ALIMENTATION EN AIR, QUE LA GÂCHETTE N’EST PAS

ENFONCÉE ET QUE L’OUTIL N’EST POINTÉ VERS

PERSONNE.

1. Tirez sur le verrou de déblocage des clous jusqu’à ce que

vous entendiez un déclic et qu’il soit verrouillé en position.

2. Insérez les clous dans le magasin.

REMARQUE : Avant d’insérer des clous dans le pistolet,

assurez-vous d’utiliser les clous adéquats avec le bon pistolet.

L’utilisation de clous inadéquats peut causer des blessures

corporelles ou entraîner des dommages matériels. Assurez-vous

que les clous sont dans la bonne direction : la pointe du clou doit

être dirigée vers le bas du magasin et la tête du clou doit être

dirigée vers le haut du magasin. Veuillez consulter votre

détaillant si vous voulez savoir quels clous peuvent être utilisés

avec quels outils ou pour savoir comment placer les clous

adéquatement dans le magasin.

3Poussez le verrou de déblocage des clous de façon à ce

qu’il glisse vers l’avant jusqu’à ce qu’il soit en contact avec les

clous à l’intérieur. Il est recommandé de tester les clous sur une

retaille de bois en premier afin de s’assurer que le réglage de

profondeur de la cloueuse est réglé adéquatement.

R

www.lowes.com

Table of contents

Languages:

Other Blue Hawk Nail Gun manuals

Popular Nail Gun manuals by other brands

Metabo HPT

Metabo HPT NR 3675DD Instruction and safety manual

EXTOL PREMIUM

EXTOL PREMIUM 8894580 Translation of the original user manual

DeWalt

DeWalt XR Li-Ion DCN680D2 Original instructions

Performance Tool

Performance Tool M643 owner's manual

Hitachi

Hitachi VH650 - Fencing Nailer, Full Head instruction manual

Parkside

Parkside PET 25 B1 Operation and safety notes