1

Introduction ................................................................. 3

Forward ........................................................................ 4

Reporting Safety Defects ........................................... 4

Coach Identification ................................................... 4

Inspection..................................................................... 5

Operator's Compartment........................................... 7

Tilt & Telescoping Steering ........................................ 8

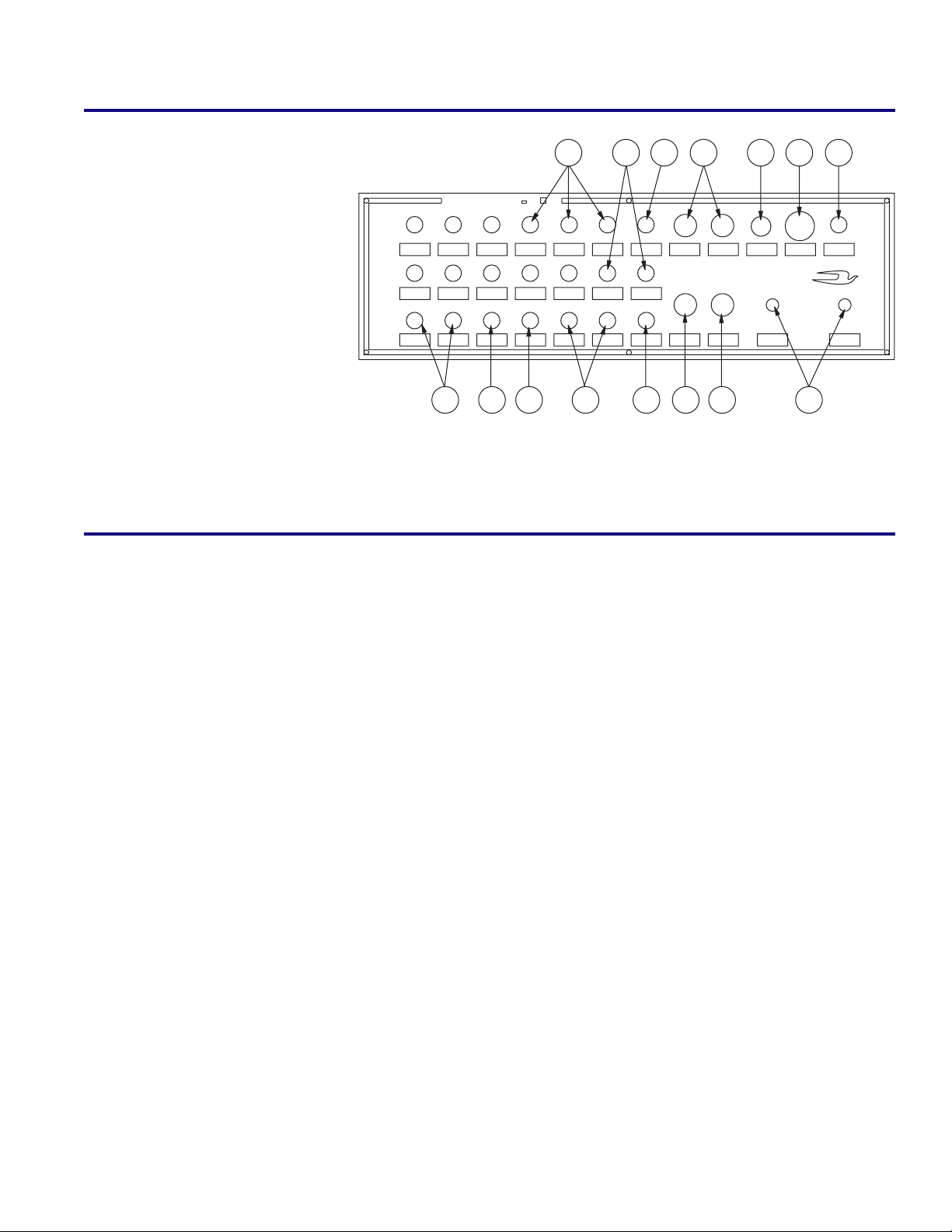

Instrument Panel & Controls .................................... 8

Switch Panel ................................................................ 9

Destination Signs ........................................................ 9

Seats & Seat Belts ...................................................... 10

Electrical Systems ..................................................... 13

Light Bulb Data ......................................................... 14

Doran Warning Light Monitor ................................ 15

Circuit Breakers ......................................................... 19

Mirrors & Mirror Adjustment ................................. 20

Emergency Equipment............................................. 22

Emergency Exit ......................................................... 24

Transpec Safety Vent ................................................ 24

Wheelchair Lifts ........................................................ 25

Stop Arms .................................................................. 25

Front Access ............................................................... 28

Access Doors ............................................................. 29

Body Tie Down.......................................................... 29

Towing or Pushing ................................................... 30

Doors .......................................................................... 30

Vandal Locks ............................................................. 34

Keeping Your Vehicle Looking New ...................... 35

Engine Access ............................................................ 36

Heaters ....................................................................... 38

Windows & Windshields ......................................... 45

Windshield Wipers ................................................... 49

Lower Side Panel Repair Procedure ...................... 50

Spare Tire Location & Removal .............................. 50

Tires, Wheels & Rims ............................................... 52

Jacking Instructions .................................................. 54

Engine Operating Instructions................................ 54

Noise Emissions Warranty ...................................... 56

Fuel & Lubricant Requirements ............................. 57

Compressed Natural Gas ........................................ 57

Manual Five Speed Transmission........................... 65

Allison Automatic Transmission ............................ 65

Two Speed Rear Axle Shift Control ........................ 70

Air Brakes .................................................................. 73

Hydraulic System ..................................................... 75

Hydraulic Clutch Controls &

Adjustment for Manual Transmissions ............ 77

Radiator Fans............................................................. 78

Shutters ...................................................................... 79

Cooling System ......................................................... 79

All American Pitman Arm....................................... 79

Front Axle Stop & Steering Gear

Automatic Poppet Adjustments ........................ 80

Wheelbearing Adjustments ..................................... 81

Rear Axle Vent ........................................................... 81

Ridewell Vehicle Air Suspension ............................ 82

Scheduled Maintenance ........................................... 86

Maintenance Service Keys ....................................... 89

Quick Reference Maintenance Charts.................... 90

Cummins Engine Maintenance Chart ................... 90

John Deere 8.1 CNG Engine Maint. Chart ............ 91

Suspension Maintenance Chart .............................. 92

Engine Belt Chart ...................................................... 92

Axle Maintenance Chart .......................................... 93

Brake Maintenance Chart ........................................ 94

Chassis Component Maintenance Chart ............... 95

Body Component Maintenance Chart ............. 96, 97

Wheelchair Lift Maintenance Chart ....................... 97

General Data .............................................................. 98

Index ........................................................................... 99

TABLE OF CONTENTS