ROUSH CleanTech Gen 4 Blue Bird Vision Propane

Service and Diagnosc Manual, 6.8L Ford Engine

46.8L Gen 4 Blue Bird Vision Propane Service and Diagnosc Manual

_____________________________________________________________________________________________________________

____________________________________________________________________________________________________________

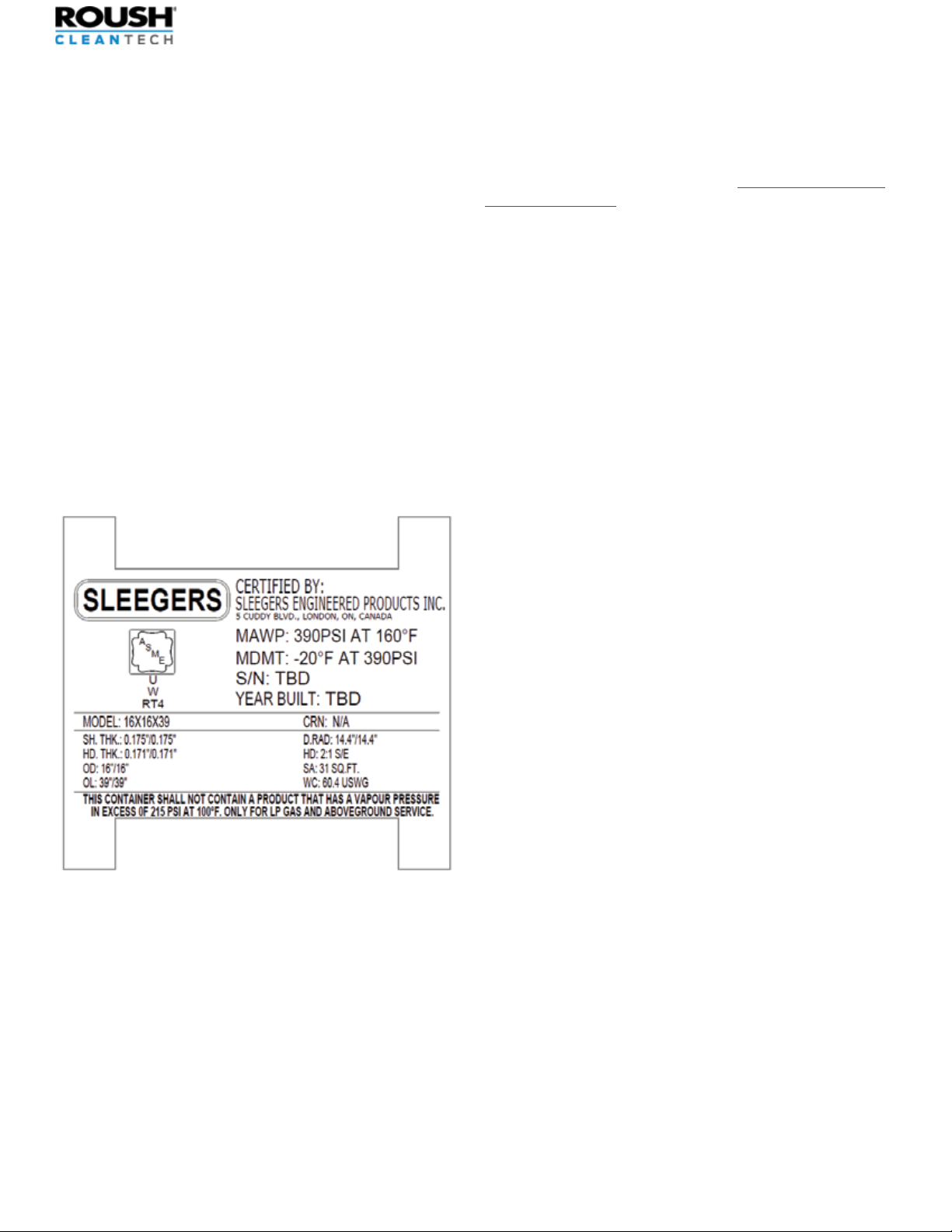

level the dash fuel gauge will read full. The pressure in the tank is

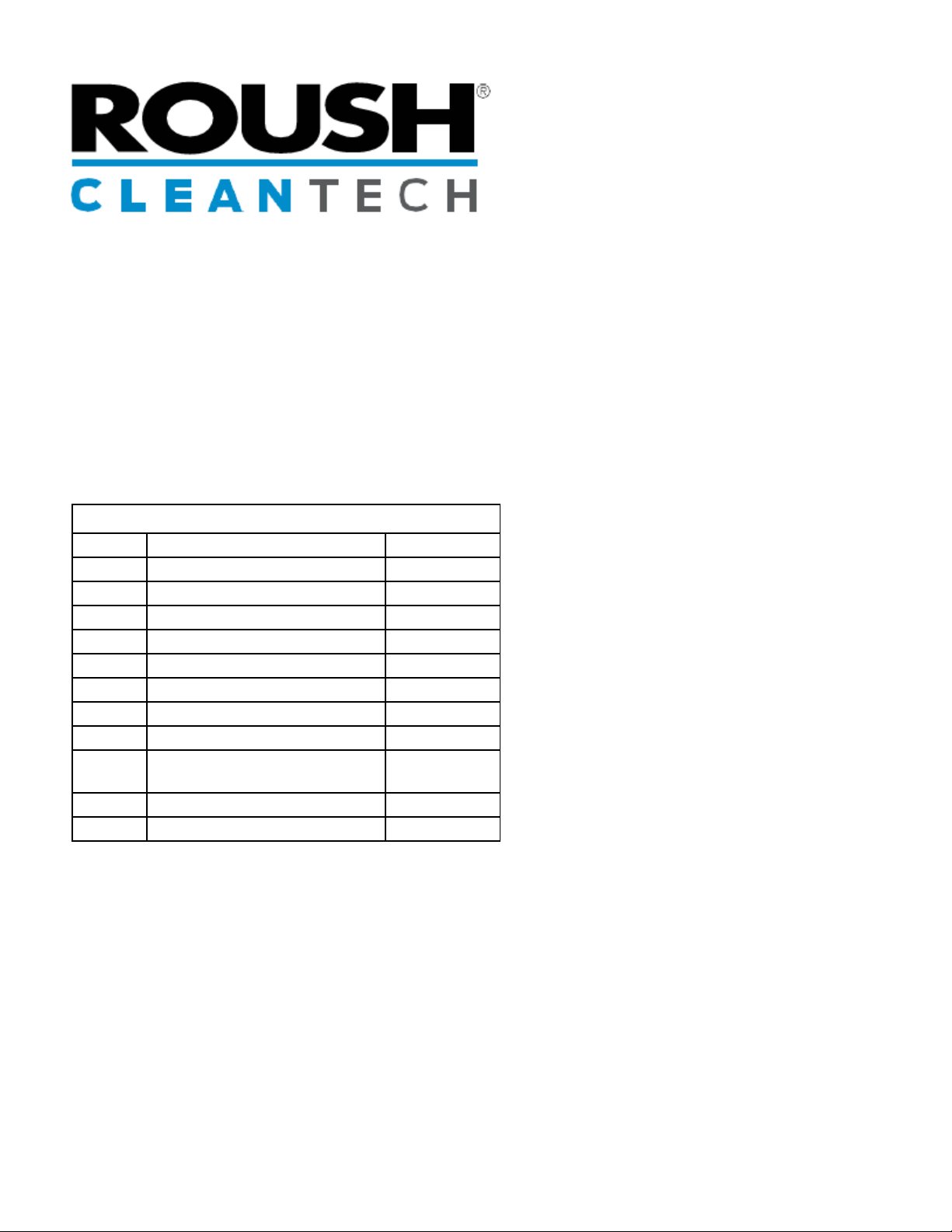

Maintenance

ROUSH CleanTech Customer Success

SAFETY INFORMATION

INTRODUCTION

propane fuel system installed on the Ford 6.8L V10 engine. For any

Propane

observed when working on or around propane-powered equipment

or storage tanks.

web address is .

ROUSH CleanTech Propane Fuel System Overview

to the engine in a vapor

liquid propane into the engine.