BlueRange UN9000 User manual

USER MANUAL

SOLAR POWERED AUTO-DARKENING WELDING HELMET

MODEL NO: UN9000

PART NO: BR9009000

IMPORTANT NOTICE:

Keep these instructions safe for future reference.

Read instructions carefully, follow the safe working practices outlined and heed the

warnings. Failure to do so may lead to personal injury or damage the product.

USER MANUAL

SOLAR POWERED AUTO-DARKENING

WELDING HELMET

MODEL NO: UN9000

PART NO: BR9009000

Page 2

1) Introduction

Auto-darkening welding helmets are designed to protect the eyes and face from sparks, splatter, and harmful

radiation under normal welding conditions. The auto-darkening lter (ADF) automatically changes from a

light to dark state when an arc is struck and returns to the light state when the welding arc disappears.

The Auto-darkening welding helmet comes ready to use. The only thing you need to do before welding is to

adjust the position of the headband and select the correct shade number for your application.

WARNING PLEASE READ THIS MANUAL CAREFULLY BEFORE USING

2) Safety Warning

• Recommended usage period of 3 years from date of rst use. The duration of the helmet depends on

various factors such as usage, cleaning, storage and maintenance. Frequent inspections and replacement

of damaged components is recommended.

• Materials that may come into contact with the wearer’s skin could cause allergic reactions to susceptible

indiduals

• Eye-protectors against high speed particles worn over standard ophthalmic spectacles may transmit

impacts, thus creating a hazard to the wearer.

• If protection against high speed particles at extremes of temperature is required, then the selected eye-

protector should be marked with the letter T immediately aer the impact letter, i.e. FT, BT or AT. If the

impact letter is not followed by the letter T then the eye protector shall only be used against high speed

particles at room temperature.

1. This Auto-Darkening lter welding helmet is not suitable for laser welding and Oxyacetylene welding.

2. Never place this Helmet and Auto-Darkening lter on a hot surface.

3. Never open or tamper with the Auto-Darkening lter.

4. Before operating, please make sure that the function-setting switch is set to the suitable location

(“WELDING” / ”GRINDING”). This Auto-darkening lter welding helmet will not protect against severe

impact hazards.

5. This helmet will not protect against explosive deces or corrosive liquids.

6. Do not make any modications to either the lter or helmet, unless specied in this manual.

7. Should this helmet not darken upon striking an arc, stop welding immediately and contact us.

8. Do not immerse the lter in water.

9. Do not use any solvents on lters’ screen or helmet components.

10.Use only at temperatures: -5°C ~ + 55°C (23°F ~ 131°F )

11.Storing temperature: - 20°C ~ +70°C (-4 °F ~ 158°F )

12.Protect lter from contact with liquid and dirt.

13.Clean lters’ surfaces regularly; do not use strong cleaning solutions. Always keep sensors and solar

cells clean using a clean, lint-free tissue/cloth.

14.Regularly replace the cracked/scratched/pitted front cover lens.

3) Hazard Denitions

Please familiarise yourself with the hazard notices found in this manual. Severe personal injury could occur

if the user fails to follow the aforementioned warnings and/or fails to follow the operating instructions.

!

Page 3

4) Product Features

4.1 The operator can vary the time for the lter to return to the clear state from dark state using knob 3

4.2 Sensitity adjustments can be made while in use for operator convenience using knob 2

4.3 Welding/Grinding operations can be selected by slider switch 4.

4.4 The helmet utilises a high-performance solar cell as the power supply and has a replaceable 3V lithium

4.4 battery as power backup. Users can expect the battery to have a lifetime of more than 5000 hours under

4.4 normal welding conditions

4.5 Variable shade from DIN 5 to 13 is adjusted at by turning shade knob 1.

4.6 The ultra-high performance of the UV/IR ADF prodes full protection for the user’s eyes & face against

4.4 UV/IR radiation during the entire welding process, even in its light state. The UV/IR protection level is

4.4 up to Shade16(DIN) at all times. This enhances user comfort and safety.

4) Product Features

1 - Dark Shade Control: DIN5-9/9-13

2 - Sensitity Control: Lo to Hi

3 - Delay Time Control: Slow to Fast

4 - Mode Control: Grind, Dark shade DIN5-9, Dark shade DIN9-13

6) Operating Instructions

6.1 Before Welding

6.1.1 Ensure that the internal and external protective lms are removed from the lenses.

6.1.2 Check that the batteries have sucient power to operate the helmet. The lter cartridge can last

6.1.2 for 5,000 working hours powered by the lithium batteries and solar cells. When the battery power is

6.1.2 low, the Low Battery LED indicator will light up. The lter cartridge lens may not work correctly.

6.1.2 Replace the batteries .

6.1.3 Check that the arc sensors are clean and not blocked by dust or debris.

6.1.4 Check for headband tightness before each use.

6.1.5 Inspect all operating parts before use for signs of wear or damage. Any scratched, cracked, or pitted

6.1.2 parts should be replaced immediately before using to avoid severe personal injury.

6.1.6 Select the shade number you require at the turn of a shade knob. Finally, be sure that the shade

6.1.2 number is the correct setting for your application.

① Dark Shade Control : DIN5-9/9-13

② Sensitivity Control: Lo to Hi

③ Delay Time Control: Slow to Fast

④ Mode control: Grind , Dark shade DIN5-9, Dark shade DIN9-13

6.OPERATING INSTRUCTION

6.1.Before welding

6.1.1 Ensure that the internal and external protective films are removed from the

lenses.

6.1.2 Check that the batteries have sufficient power to operate the helmet. The filter

cartridge can last for 5,000 working hours powered by the lithium batteries and

solar cells. When the battery power is low, the Low Battery LED indicator will

light up. The filter cartridge lens may not work correctly. Replace the batteries .

5) Welding Helmet ADF controls

Shade Guide Table

Note:

SMAW - Shielded Metal Arc Welding.

TIG GTAW - Gas Tungsten Arc (GTAW)(TIG).

MIG (Heavy) - MIG on heavy metals.

SAW Shielded Semi - Automatic Arc Welding.

MIG (Light) - MIG on light alloys.

PAC - Plasma Arc Cutting

PAW - Plama Arc Welding

6.2 Sensitity

The sensitity control is set according to the welding process and ambient light.

6.2.1 Low Setting - suitable for high amperage welding and welding in areas with high levels of natural

6.2.1 sunlight.

6.2.2 Medium Setting - suitable for most indoors and outdoors welding.

6.2.3 High Setting - suitable for low amperage welding and welding in areas with low light conditions,

6.2.1 especially for low amperage argon-arc welding.

6.3. Self-Check

6.3.1 Set the lter shading number anywhere between DIN5-9/9-13.

6.3.2 Press the TEST button to see if it switches to the dark state.

6.3.3 Release the Test button to check that the lter returns to the bright state.

6.4. Grinding Mode

The welding helmet can also be used to protect the face during grinding. Switching to Grind mode will

prevent the lter cartridge from darkening when bright sparks are created.

6.5. Delay Time

Delay time refers to the time the cartridge lter is set to change from the dark to bright state aer welding

stops. The delay can be adjusted up to a one second delay.

6.5.1 The minimum delay is set between 0.1 to 0.2 seconds, suitable for spot or short welds.

6.5.2 The maximum delay time is set between 0.85 to 1.0 second, suitable for heavy current welding or

6.2.1 when sible light is produced.

6.5.3 Selections between minimum and maximum are suitable for most indoor and outdoor welding

6.2.1 operations.

Page 4

6.1.3 Check that the arc sensors are clean and not blocked by dust or debris.

6.11.4 Check for headband tightness before each use.

6.1.5 Inspect all operating parts before use for signs of wear or damage. Any

scratched, cracked, or pitted parts should be replaced immediately before using

again to avoid severe personal injury.

6.1.6 Select the shade number you require at the turn of a shade knob . Finally, be

sure that the shade number is the correct setting for your application.

Shade Guide Table

Note:

SMAW-Shielded Metal Arc Welding.

TIG GTAW-Gas Tungsten Arc (GTAW)(TIG).

MIG(Heavy)-MIG on heavy metals.

SAM Shielded Semi-Automatic Arc Welding.

MIG(Light)-MIG on light alloys.

PAC-Plasma Arc Cutting

6.2. Sensitivity

The sensitivity control is set according to the welding process and ambient light.

6.2.1 Low Setting- suitable for high amperage welding and welding in areas with

high levels of natural sunlight.

6.2.2 Medium Setting - suitable for most indoors and outdoors welding.

SMAW

SAW

PAC

PAW

MIG (Heavy)

MIG (Light)

TIG GTAW

MAG / (C02)

Welding Current

(A)

Welding Type

0.5 2.5 10 20 40 80 125 175 225 275 350 450

1 5 15 30 60 100 150 200 250 300 400 500

1413

13 14

15

14

15

15

13

15

1211109

121110

1413121110

13

12

11109

1413121110

1413121110

1211

141312111098

Page 5

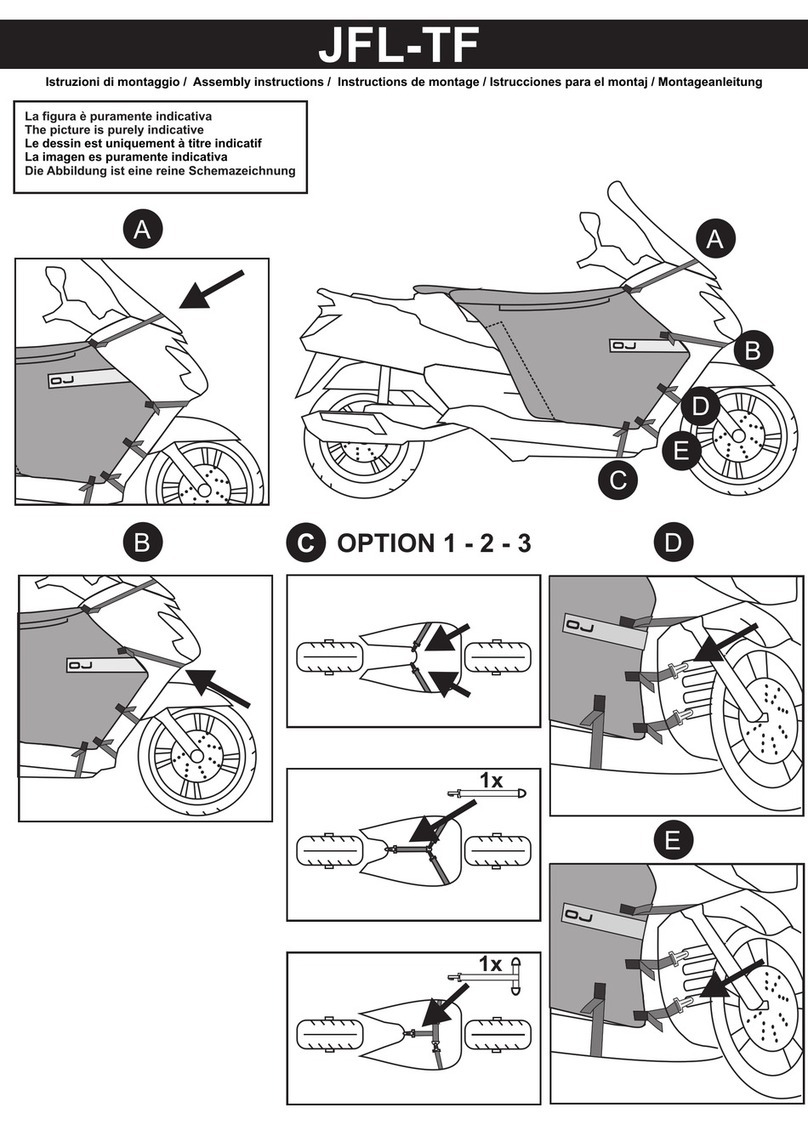

6. 6.Adjust the Headband

6.6.1 Adjust headband for proper position on the head to ensure correct balance and stability. (See No.1).

6.6.2 Adjust the distance between the face and the lens. To adjust, turn the positioning screw forward or

6.2.1 backward. Screw down the screws. (Both sides must be equally positioned for proper sion, See No.2)

6.6.3 Turn the adjusting knob located on the back of the headband le or right to desired tightness.(See

6.2.1 No.3)

6.6.4 Shi the segmental plate with dierent positioning hole to adjust the window angle for clear ew.

6.2.1 (See No.4) Numbers on the adjustment slides indicate set position so both sides can be adjusted

6.2.1 equally.

6.7. Replace Battery

When the battery power is low, the Low Battery LED indicator will light up. The lter cartridge lens

may not work correctly.Replace the Batteries.

5

6.6.3 Turn the adjusting knob located on the back of the headband left or right to

desired tightness.(See No.3)

6.6.4 Shift the segmental plate with different positioning hole to adjust the window

angle for clear view. (See No.4) Numbers on the adjustment slides indicate set

position so both sides can be adjusted equally.

NO.1

NO.2

NO.3

NO.4

6.7. Replace battery

When the battery power is low, the Low Battery LED indicator will light up. The filter cartridge lens

may not work correctly.Replace the Batteries.

6.8 How to install the headgear to welding helmet shell

No.1 No.2 No.3 No.4

6.7. Replace battery

When the battery power is low, the Low Battery LED indicator will light up. The filter cartridge lens

may not work correctly.Replace the Batteries.

6.8 How to install the headgear to welding helmet shell

No.1 No.2 No.3 No.4

6.7. Replace battery

When the battery power is low, the Low Battery LED indicator will light up. The filter cartridge lens

may not work correctly.Replace the Batteries.

6.8 How to install the headgear to welding helmet shell

No.1 No.2 No.3 No.4

6.7. Replace battery

When the battery power is low, the Low Battery LED indicator will light up. The filter cartridge lens

may not work correctly.Replace the Batteries.

6.8 How to install the headgear to welding helmet shell

No.1 No.2 No.3 No.4

NO. 2

NO. 3

NO. 4

NO. 1

NO. 1 NO. 2 NO. 3 NO. 4

Page 6

6.8 How to Install the Headgear to Welding Helmet Shell

6.9. Maintenance

6.9.1. Cleaning and disinfection: Clean lters surfaces regularly; do not use strong cleaning solutions.

6.2.1 Always keep sensors and solar cells clean using a clean lint-free tissue/cloth. You can use alcohol

6.2.1 and cotton to wipe.

6.9.2. Use neutral detergent to clean the welding shell and headband.

6.9.3. Replace outer and inner protection plates periodically.

6.9.4. Don’t immerse the lens in water or any other liquid. Never use abrasives, solvents or oil based

6.2.1 cleaners.

6.9.5. Do not remove the auto-darkening lter from the helmet. Never try to open the lter.

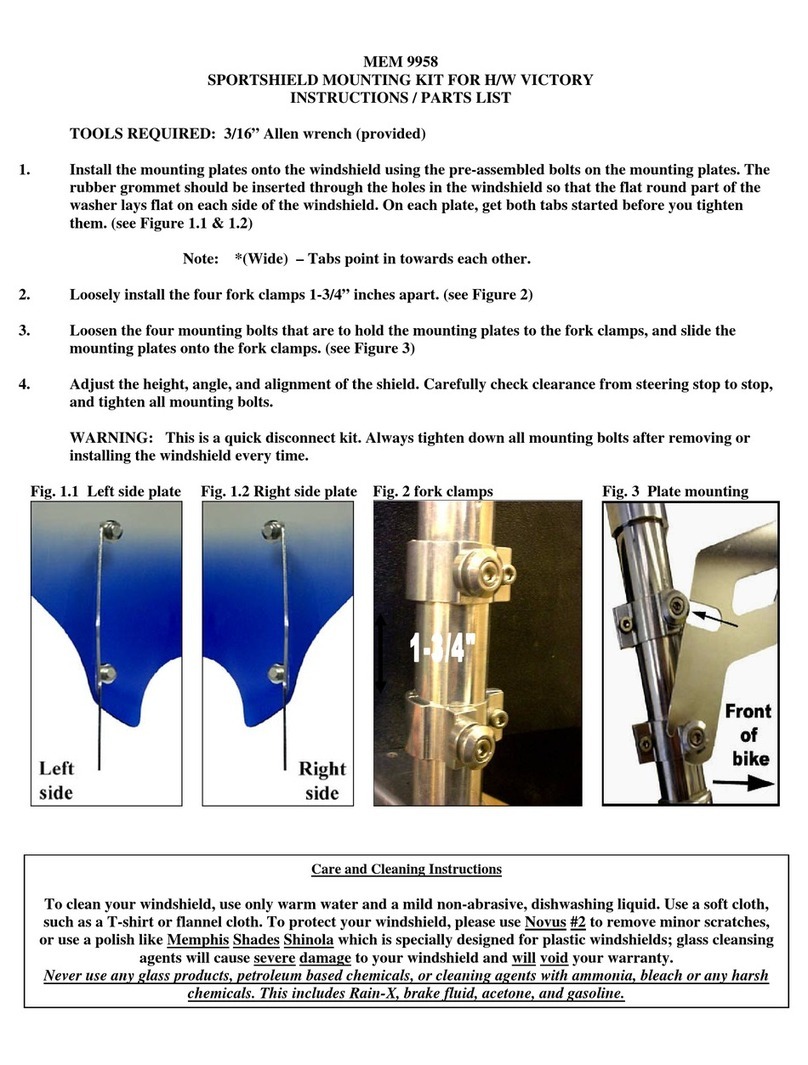

7) Replacing the Battery

1. To replace the battery, slide the battery pannel up and

remove the old battery. Replace with CR2450 lithium battery

2. Be sure Positive ( + ) side of battery faces up (toward inside

of helmet). Reinstall the cover battery plate. press the TEST

button. The lens should ash dark once.

6.7. Replace battery

When the battery power is low, the Low Battery LED indicator will light up. The filter cartridge lens

may not work correctly.Replace the Batteries.

6.8 How to install the headgear to welding helmet shell

No.1 No.2 No.3 No.4

You are all set to begin using the helmet.

6.9. Maintenance

6.9.1. Cleaning and disinfection: Clean filters surfaces regularly; do not use

strong cleaning solutions. Always keep sensors and solar cells clean using a clean

lint-free tissue/cloth. You can use of alcohol and cotton to wipe.

6.9.2. Use neutral detergent to clean the welding shell and headband.

6.7. Replace battery

When the battery power is low, the Low Battery LED indicator will light up. The filter cartridge lens

may not work correctly.Replace the Batteries.

6.8 How to install the headgear to welding helmet shell

No.1 No.2 No.3 No.4

6.7. Replace battery

When the battery power is low, the Low Battery LED indicator will light up. The filter cartridge lens

may not work correctly.Replace the Batteries.

6.8 How to install the headgear to welding helmet shell

No.1 No.2 No.3 No.4

6.7. Replace battery

When the battery power is low, the Low Battery LED indicator will light up. The filter cartridge lens

may not work correctly.Replace the Batteries.

6.8 How to install the headgear to welding helmet shell

No.1 No.2 No.3 No.4

You are all set to begin using the helmet.

6.9. Maintenance

6.9.1. Cleaning and disinfection: Clean filters surfaces regularly; do not use

strong cleaning solutions. Always keep sensors and solar cells clean using a clean

lint-free tissue/cloth. You can use of alcohol and cotton to wipe.

6.9.2. Use neutral detergent to clean the welding shell and headband.

You are all set to begin using the helmet.

6.9. Maintenance

6.9.1. Cleaning and disinfection: Clean filters surfaces regularly; do not use

strong cleaning solutions. Always keep sensors and solar cells clean using a clean

lint-free tissue/cloth. You can use of alcohol and cotton to wipe.

6.9.2. Use neutral detergent to clean the welding shell and headband.

You are all set to begin using the helmet.

6.9. Maintenance

6.9.1. Cleaning and disinfection: Clean filters surfaces regularly; do not use

strong cleaning solutions. Always keep sensors and solar cells clean using a clean

lint-free tissue/cloth. You can use of alcohol and cotton to wipe.

6.9.2. Use neutral detergent to clean the welding shell and headband.

You are all set to begin using the helmet.

6.9. Maintenance

6.9.1. Cleaning and disinfection: Clean filters surfaces regularly; do not use

strong cleaning solutions. Always keep sensors and solar cells clean using a clean

lint-free tissue/cloth. You can use of alcohol and cotton to wipe.

6.9.2. Use neutral detergent to clean the welding shell and headband.

8

6.9.3. Replace outer and inner protection plates periodically.

6.9.4. Don’t immerse the lens in water or any other liquid. Never use abrasives,

solvents or oil based cleaners.

6.9.5. Don’t remove the auto-darkening filter from the helmet. Never try to open the

filter.

7.. Replacing the Battery

1. To replace the battery, remove

the ADF from Cartridge, then remove

the Lithium battery from the holder

and remove the old battery. Replace

with CR2450 lithium battery

2. Be sure Positive ( + ) side of

battery faces up(toward inside of

helmet).

Reinstall the cover battery plate. press the TEST button. The lens

should flash dark once.

8. Technical specifications

Model BR9009000

Viewing Area 100×97mm

Cartridge Size 133×114×10mm

Light state DIN4

Dark state DIN5-9/9-13

Switch time 1/25000 S

Sensitivity Variable adjusted by external knob

Delay 0.1S ~1.0S Variable adjusted by external knob

Arc sensor 4

TIG Amps Rated AC/DC TIG, > 5amps

Grind Yes (DIN4)

ADF Self-check Yes (TEST Button)

Low Battery Yes (Red LED)

Power supply Solar cells & Replaceable Lithium battery

(2 CR2032)

On/Off Fully Automatic

Sensitivity Control Variable adjusted by external knob

Page 7

8) Technical Specications

9) Troubleshooting

Auto-darkening lter does not darken or ickers

• Outer or inner protection plate is soiled or damaged. (Clean or replace the plate)

• Sensors are soiled. (Clean the sensor’s surface)

• Welding current is too low. (Press “SENSITIVITY” then select “High”)

Slow response

• Operating temp is too low. (Do not use at temperatures below -5°C or 23°F)

Poor Vision

• Front/inside cover lens and/or lter lens are soiled. (Change the lenses)

• There is insucient ambient light

• Shade number is incorrectly set. (Reset the shade number)

Welding Helmet Slips

• Headband is not adjusted properly. (Readjust headband)

WARNING Operator must stop using the auto–darkening lter welding helmet immediately and

contact the supplier if the above-mentioned problems cannot be corrected.

Model BR9009000

Viewing Area 100 x 97mm

Cartridge Size 133 x 114 x 10mm

Light State DIN4

Dark State DIN5-9/9-13

Switch Time 1/25000 S

Sensitity Variable adjusted by external knob

Delay 0.1S~1.0S Variable adjusted by external knob

Arc Sensor 4

TIG Amps Rated AC/DC TIG, > 5amps

Grind Yes (DIN4)

ADF Self-Check Yes (TEST Button)

Low Battery Yes (Red LED)

Power Supply Solar cells & Replaceable Lithium battery (CR2450)

On/O Fully Automatic

Sensitity Control Variable adjusted by external knob

UV/IR Protection Up to DIN 16 at all time

Operate Temp. -5°C~+55°C (23°F ~ 131°F )

Store Temp. -20°C~+70°C (-4 °F ~ 158°F )

Weight 550g±15g

!

Page 8

10) Replacing the Protective Lens & Parts List

Protective lenses list

11) Product Warranty

11.1. The manufacture’s sole obligation under this warranty is limited to making replacement of repairs, or

11.1. refund of the purchase price for the products with defects.

11.2. This warranty does not cover product malfunctions or damage resulting from products tampering,

11.1. misuse or abuse. Please follow the operating instructions carefully to maintain this warranty. Failure

11.1. to do so will void the warranty. The manufacturer shall also not be held liable for any indirect or

11.1. consequential damages arising out of the use of this product.

11.3. This product has a 12 month warranty from the purchase date.

The warranty is in addition to any consumer rights you may have under UK law.

12) Principal Safety Standards

(EU) 2016/425 CE EN166, EN175 & EN379, from DIN CERTCO

Number of the standard: EN 379, EN 175, EN 166

Page 8

Front Protective Lens

Part Number Description

BR9009010 Outside Lens

BR9009020 Inside Lens

BR9009030 CR2450 Lithium Battery

IMPORTANT:

We reserve the right to update our product specication, data and parts with out notice, as

part of our continuous improvement policy.

We accept no liability for any incorrect use of this product.

PROTECT THE ENVIRONMENT

When this product reaches the end of its useful/working life it should be

recycled in line with local policies and regulations. Take the product to your

recycling centre to be disposed of in an enronmentally friendly manner

Document UN9000 Dated 1st May 2023 - Rev1.2

Imported by BLUERANGE 76 Regent Road, Bootle, Merseyside, L20 1BL

This manual suits for next models

1

Table of contents

Other BlueRange Motorcycle Accessories manuals

Popular Motorcycle Accessories manuals by other brands

KTM

KTM TOURATECH 22112929044 Fitting instructions

R&G

R&G LP0197BK Fitting instructions

hepco & becker

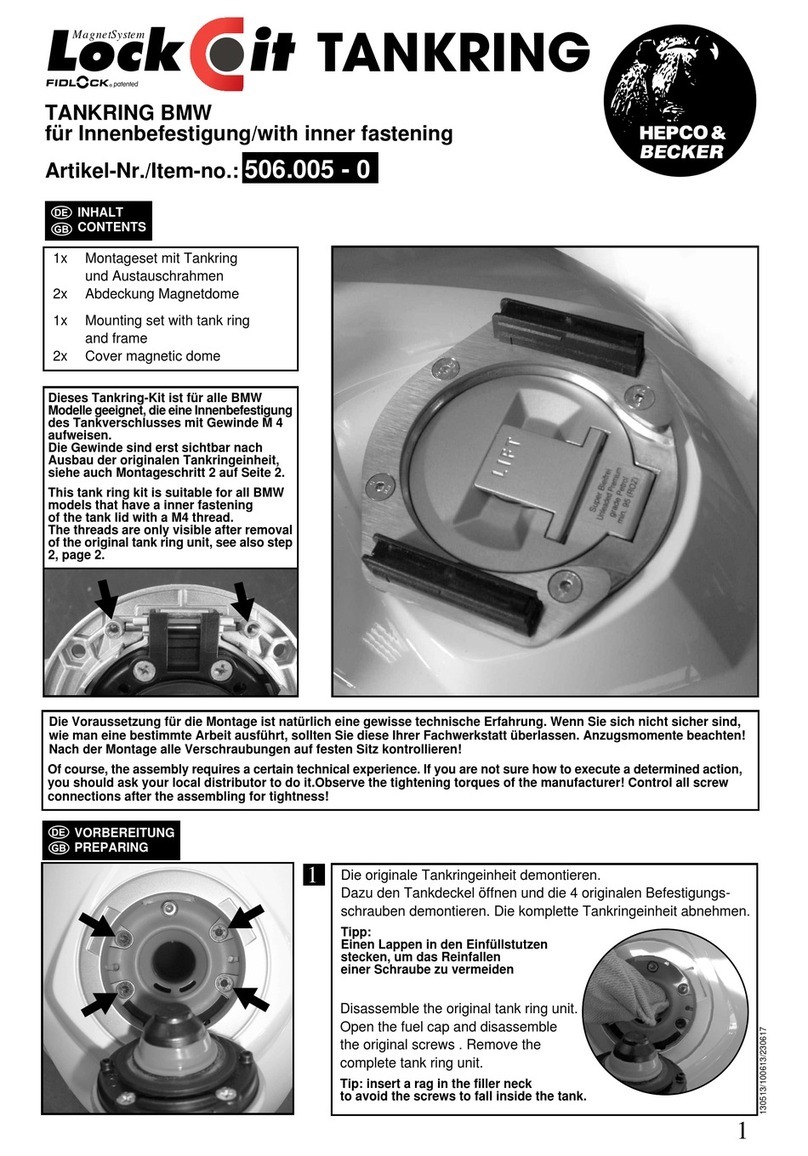

hepco & becker LOCK IT 506.005 Series manual

Parkside

Parkside PSHL 2 A2 Operation and safety notes translation of the original instructions

Ducati

Ducati 96480931A manual

SUOMY

SUOMY TIMELESS Instructions for user