LP0197

R&G Racing

Unit 1, Shelley’s Lane, East Worldham, Alton, Hampshire, GU34 3AQ

Tel: +44 (0)1420 89007 Fax: +44 (0)1420 87301 www.rg-racing.com Email: info@rg-racing.com

5

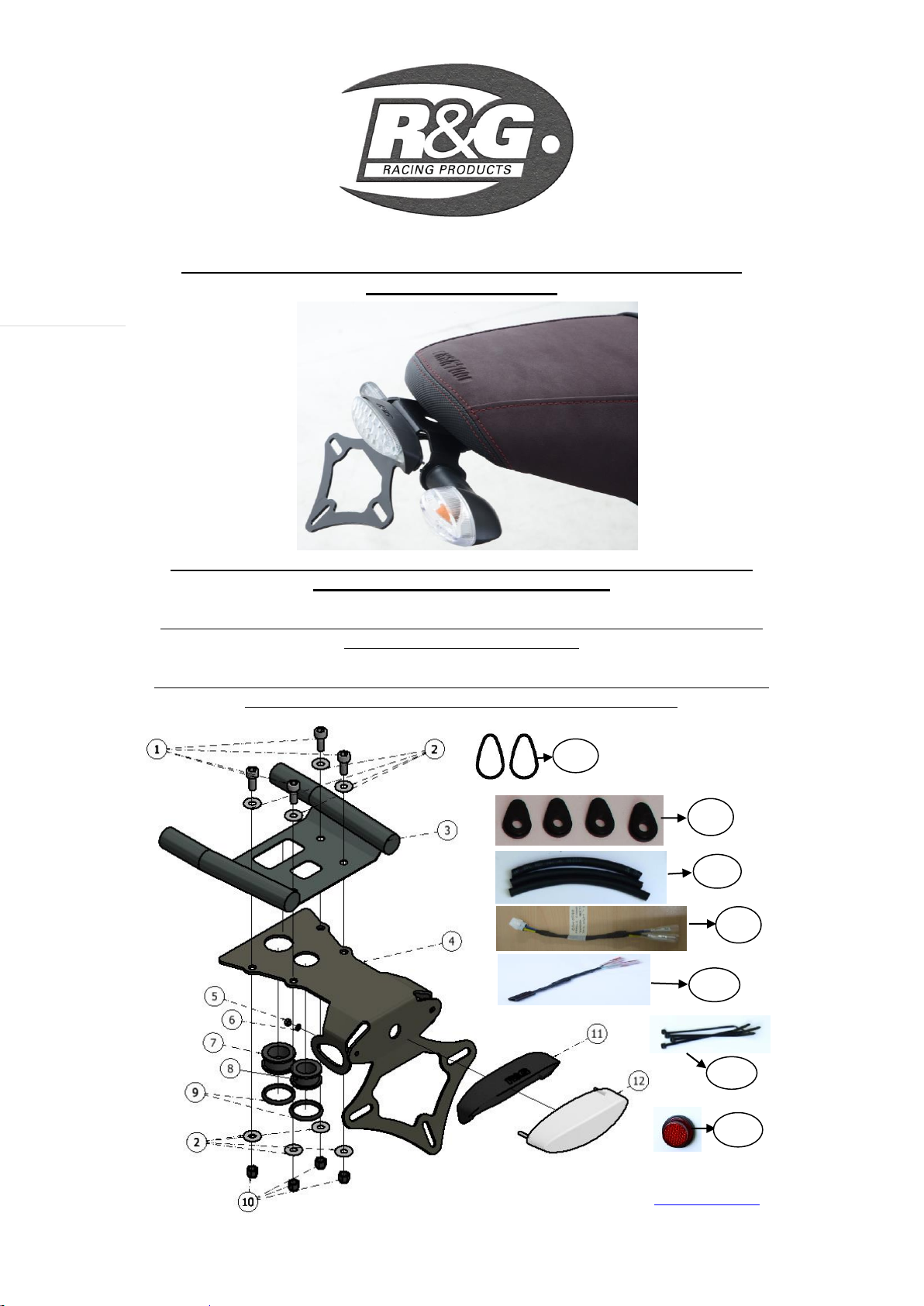

Fit the original indicator with the adapter to the new licence plate bracket (Item 4) and re-

fit the spreader. Ensure that the adapter (Item 13) is sitting on the outside of the licence

plate bracket (Item 4).

Repeat the procedure for the other indicator.

If fitting R&G mini indicators (R&G product code RG370=bulb, RG371=LED or RG372 = Aero LED

If fitting the R&G Mini Indicators, cut the heat-shrink tube (Item 15) into a suitable

length and insert the two wires coming from the indicator through. Please leave at least

50mm of wires uncovered by the heat shrink tube as bullet connectors are needed to be

attached to it. Position and crimp male bullet connectors to the exposed wires, ensuring

the connections are secured and the exposed wire end is in contact with the bullet

connector. Using a suitable heating resources, shrink the heat-shrink tube.

Using an indicator connector (Item 17) from the kit, plug in the female connectors into

the male connectors just fitted on the indicator wires.

Use the indicator adapters (item 14) on either side of the bracket and tighten the

assembly.

Repeat procedure to the other mini indicator.

Fitting the Tail Light

From the kit, take the Tail light unit (Item 12) and its shroud (Item 11). Insert the tail light

into the shroud by aligning the two studs at the back of the tail light into the two holes

provided on the shroud. Mount the whole assembly into the new licence plate bracket

(Item 4) and secure with M3 washers (Item 6) and M3 Nuts (Item 5). Tighten the M3 nuts

(Item 5).

Cut the Heat-shrink tube (Item 15) into a suitable length and feed the three wires through,

please leave at least 50mm of wires uncovered by the heat shrink tube as bullet

connectors are needed to be attached to it. Using a suitable heating resources, shrink the

heat-shrink tube.

Using suitable tool, install the male bullet connectors onto the exposed wiring from the

tail light unit. Crimp the bullet connector, check for tightness and make sure the exposed

wire is in contact with the bullet connector. Repeat this procedure to all three wires.

Plug in the Tail light resistor (Item 20) from the kit onto the male bullet connector just

fitted on the tail light unit. Please connect the wires in the orientation below:

RESISTOR YELLOW ------------------YELLOW (TAIL LIGHT)

RESISTOR RED -------------------------RED (TAIL LIGHT)

RESISTOR BLACK---------------------BLACK (TAIL LIGHT)

From the kit, take the 26mm rubber grommet (Item 7) and fit the O-ring (Item 9) provided

over it as shown in picture 8.

Gently squeeze the rubber grommet and insert it into a larger hole on the licence plate

bracket (Item 4) as arrowed in picture 9. Ensure that the O-rings sits below the licence

plate bracket (Item 7).

Repeat the procedure to the other rubber grommet (Item 8)

Gently push all the wiring (Both indicators and tail light wiring) through the smaller

rubber grommet (Item 8) as shown in picture 10.

Bring the whole assembly towards the sub-frame, gently insert the larger rubber grommet

(Item 7) over the key lock (labelled A in picture 11). For an easier fitment, rub a thin

layer of wd40 or equivalent around the outer surface of the key lock and slide the rubber

grommet (item 7) in.