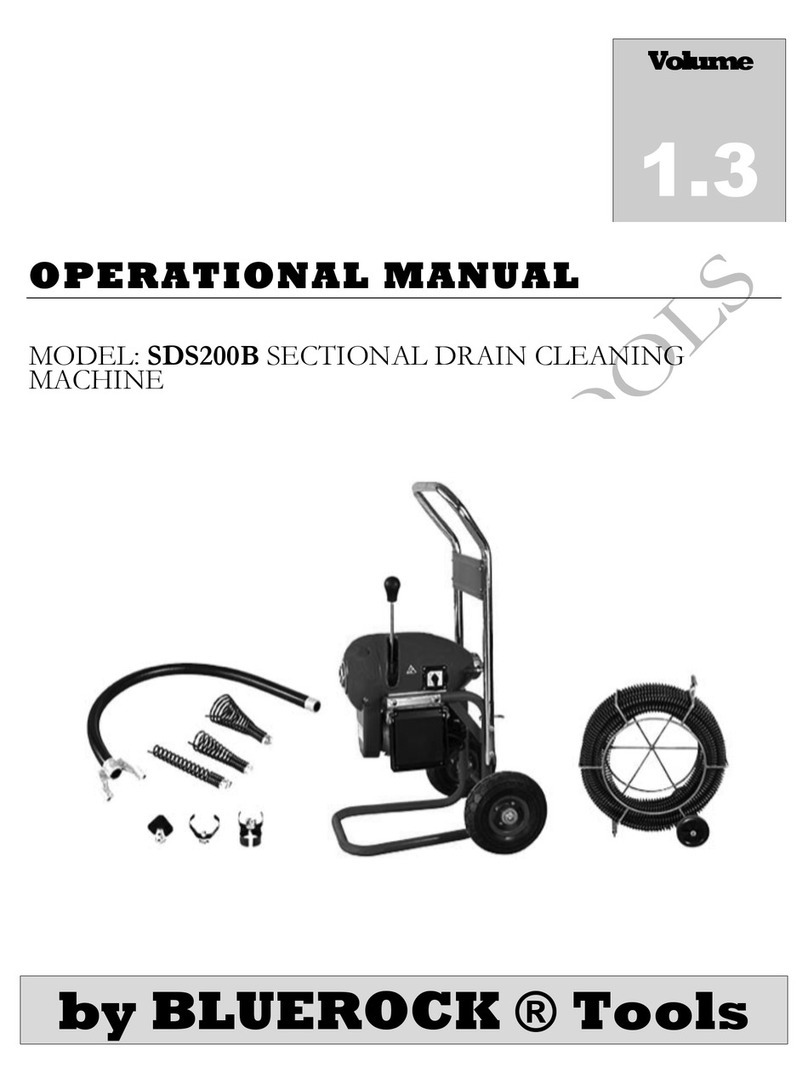

Bluerock Tools SDS200 Quick start guide

OPERATIONAL MANUAL

MODEL: SDS200 SECTIONAL DRAIN CLEANING

MACHINE

by BLUEROCK ® Tools

Volume

1.4

MWS-

SDS200 PIPE DRAIN CLEANER

UNPACKING THE ITEM

Caution: This machine is packed together with items that may be sharp, oily and overly heavy objects. Remove the machine from

the packaging in a safe manner. Check to ensure all accessories are included with the item while unpacking. If any parts are found

to be missing, contact the retailer as soon as possible. Do not throw away the packaging until the item is out of the guarantee

period. Dispose of the packaging in an environmentally responsible manner. Recycle if possible. Keep all plastic bags away from

children due to risk of suffocation.

WEEE - Waste Electrical & Electronic Equipment. Note this machine should be disposed of as electrical & electronic waste.

ãTHE NEWMAN TRADING COMPANY LLC DBA BLUEROCK® TOOLS 2016

1100 SW 16th St • Suite D

Renton, WA 98057

Phone 206.604.8363 • Fax 425.572.5167

www.bluerocktools.com

SDS200 PIPE DRAIN CLEANER

Table of Contents

SAFETY' 1!

PRE-OPERATIONAL SAFETY CHECKS! 1!

OPERATIONAL SAFETY CHECKS! 1!

SPECIFICATIONS' 3!

INCLUDED'ACCESSORIES' 3!

ADDITIONAL'AVAILABLE'ACCESSORIES' 3!

ADDITIONAL ACCESSORIES FOR THIS MACHINE CAN BE FOUND IN BLUEROCK ® TOOLS ONLINE SHOP AT

WWW.BLUEROCKTOOLS.COM OR FROM YOUR LOCAL RETAILER.! 3!

OPERATIONS' 4!

PURPOSE! 4!

MACHINE SET-UP! 4!

MACHINE COMPONENTS! 4!

PREPERATION FOR THREADING! 5!

RUNNING THE MACHINE! 8!

TROUBLESHOOTING'11!

CORRECTION'11!

GENERAL'MAINTENANCE'12!

PARTS'LIST'13!

BREAKDOWN'VIEW'14!

SDS200 PIPE DRAIN CLEANER

1

Safety

DO NOT USE THIS MACHINE UNLESS YOU HAVE READ THE OPERATING INSTRUCTIONS!

Safety glasses must be worn at all times in

work areas. Use a full face mask whenever

possible.

Long and loose hair must be

contained.

Appropriate footwear must be worn.

Close fitting/protective clothing

must be worn.

Safety gloves should be worn at all times and

jewelry must not be worn.

Hearing protection should be worn

when using this machine.

Read operational manual prior to use.

PRE-OPERATIONAL SAFETY CHECKS

Ø Examine the power cord and plug for damage.

Ø Examine the body of the machine and inspect for damage or defects.

Ø Examine the cable and cutters to insure they are operable.

Ø Make certain the on/off switch is in the off position before plugging into power to prevent unintentional starting.

OPERATIONAL SAFETY CHECKS

Ø ONLY to be operated by qualified personal who have read instructions.

o NOTE: Failure to read and follow instructions could result in electrical shock, fire, property damage and/or

serious injury!

Ø DO ensure all non-essential people are clear of the immediate work area.

Ø DO keep body parts, clothing & power cords clear of turning pieces. Stay alert and use common since when using

this tool.

Ø DO always wear gloves when using this machine. Make sure not grasp turning cable with rags or gloves that are

loose fitting. Loose fitting gloves or rags can become wrapped around or lodged in-between cable causing serious

injury.

Ø DO always wear eye protection to protect eyes from debris, fluids, chemicals or other compounds.

Chapter

1

SDS200 PIPE DRAIN CLEANER

2

Ø DO always non-slip rubber soled shoes.

Ø DO be extremely careful when cleaning drains where chemical cleaning compounds have been previously used.

Ø DO only use this machine on a properly grounded circuit in accordance with all local and national standards. DO

NOT remove the grounding plug. If in doubt that this machine is properly grounded, consult an electrician.

Ø DO always use relevant safety measures when working electrical machinery. Be aware that working in pipe drains

can cause water puddles, so make sure to use GFCI’s when necessary and personal protection devices like insulated

gloves, shoes and insulated standing pads.

Ø DO remove adjusting keys or wrenches prior to turning machine on.

Ø DO guard against electric shock by preventing body contact with grounded surfaces such as pipes, radiators, ranges,

refrigerators, etc.

Ø DO keep the working area clean and brightly illuminated for optimum operational safety.

Ø DO keep the machine balanced and stable at all times.

Ø DO be mindful that power tools can expose an operator to vibrations transmitted trough contact with the machine.

Prolonged exposure can lead to medical issues, which should be discussed with a medical professional.

Ø DO NOT make adjustments to machine while the machine is running.

Ø DO NOT use cable exceeding 165’ (50M) from the machine. This could damage the machine.

Ø DO NOT leave the machine running when not in use.

Ø DO NOT hold drainpipe by hand or using the body. Always mechanically clamp or secure work pieces that are not

fixed.

Ø DO NOT allow liquids or dust to enter the machine’s ventilation system.

Ø DO NOT operate machine outside of machine specifications.

Ø DO NOT touch moving parts while the machine is running as death or dismemberment could occur.

Ø DO NOT remove machine’s panels while machine is connected to a power source. Only to be removed for service by

qualified personal and put back on the machine after service is complete.

Ø DO NOT allow children or untrained personal to operate machine.

Ø DO NOT use this machine in the rain or a wet environment. If using outdoors, make sure the machine is clean and

dry.

Ø DO NOT operate in the presence of explosive materials as power tools create sparks which may ignite dust or fumes.

Ø DO NOT use on a pipe that may contain a live electrical wire/circuit.

Ø DO NOT use this machine if the ON/OFF switch is broken.

Ø DO NOT operate this machine on the same work surface where welding is being performed. This could result in

severe damage to the machine or personal injury to the user.

Ø DO NOT operate this machine on a lower voltage as this could limit the motor life and work efficiency.

o NOTE: Use of long small gauge power extension cords can result in decreased voltage. As local voltages

can vary, it may be a good idea to test the voltage at the end of the extension cord to ensure proper voltage

requirements are met. You might also consult an electrician to make sure the length of cord matches up

with the proper wire gauge for this size motor. Make sure to use outdoor cords when operating outdoors.

Use a GFCI circuit if using in wet locations.

SDS200 PIPE DRAIN CLEANER

3

Specifications

ELECTRICAL DATA

Voltage

110V, 60Hz Induction Motor

Current

10 Amps

Motor Size

1100W

Power Connection

US Standard 3 Prong Grounded Plug and inline GFCI

MECHANICAL DATA

Pipe Capacity

2” to 8” Diameter (50mm-200mm)

Max Run-out

165’ (50M)

Gearbox

Forward and Reverse

Gear Housing

Aluminum

Machine Speed

700RMP

On/Off Switch

Manual

SHIPPING DATA

Shipping Weight

220lbs (100KG)

Shipping Carton

44” x 25” x 28”

Included Accessories

DESCRIPTION

QTY

Instruction Manual

1

1-1/4” Drain Cable 60’. 15’ (4.6M)

x4pcs, 30mm diameter. Sectional

Cables. Soft Shaft (Same as

Ridgid® C11 with 60’ of Cable fits

K-1500 with A62 Carrier).

1

Rubber Safety Hose

1

Cable Bits/Drills

6

Bit Key

1

Accessory Case

1

Additional Available Accessories

Additional accessories for this machine can be found in BLUEROCK ® Tools online shop at

www.bluerocktools.com or from your local retailer.

RIDGID® Marks are trademarks of RIDGID, Inc. and are used for product identification purposes only.

Chapter

2

SDS200 PIPE DRAIN CLEANER

4

Operations

Note

THOROUGHLY READ THROUGH THE ENTIRE MANUAL BEFORE OPERATING THIS MACHINE!

PURPOSE

Ø The purpose of the SDS200 is for cleaning the insides of drainpipes from 2” to 8” in diameter. This is a

heavy-duty professional use machine allowing a single user to easily clean pipes.

Ø This type of sectional drain cleaner uses individually lengths (sections) of cleaning cable. This machine

uses 16’ sections, which can be added or subtracted during cleaning operations.

o Maximum length of any particular run should be 165’ (50M).

MACHINE SET-UP

Ø The machine is designed pre-assembled. The user must only take the item out of the shipping crate.

o CAUTION: This machine is heavy lifting should be avoided whenever possible.

o DO NOT allow the cord or plug to drag along the floor when wheeling between locations.

Ø Make certain the work area is dry.

o DO NOT place the machine in water.

Ø Use barriers to keep non-essential personal away from rotating drain cable or other moving parts.

Ø Place machine away from passageways and make certain the operator is able to see all parts of the work-

piece.

Ø DO NOT set-up or modify the machine in a manner that is not intended.

Ø DO use a user provided functioning GFCI circuit when using this machine.

MACHINE COMPONENTS

Ø The main components of the SDS200 are motor housing, rotating clutch channel and main machine frame

assembly (see figure below). The motor drives the clutch rotationally and acts as the main drive

component of the machine.

o These components must be not be removed except by a qualified technician. Power must be

disconnected prior to any service.

Chapter

3

SDS200 PIPE DRAIN CLEANER

5

Ø The machine has a main on/off switch with a forward and reverse position. These switches operate the

turning mechanism, which turn the machine clutch. When the motor switch is turned on, the user is able

to pull clutch handle, which starts the clutch rotation. When the handle is released the rotation

immediately stops.

PREPERATION FOR USING MACHINE

Ø CAUTION: Before making any adjustments, ensure the main machine switch is in the “O” off position.

Ø CAUTION: Before starting your job, it is vital to be aware of the distance from the sewer inlet pipe to the

main sewer pipe or septic tank. Overrunning the cable into large spaces can cause cable to form “knots”

and prevent the cable from being returned through the smaller pipe line. Avoid going into main sewer lines

farther than 10’. Avoid going into sewer tanks more than 3’.

Ø Clutch operations

o To rotationally engage the clutch, pull the clutch handle down (towards the ground). The user

must hold the handle in the down position to keep the clutch rotating. To disengage the clutch,

allow the clutch handle to move to the up position (towards the ceiling).

o NOTE: Sectional drain cleaners do not spin the drain cleaner cable in/out (towards/away) from the

drain clog. Sections of the cable must be individually connected and manually fed to the point of

the clog. When the drain cleaner end reaches the point of the clog, the user engages the clutch

to spin the cutter in a forward of reverse rotation.

§ CAUTION: Keep hands and fingers away from the clutch jaws and cutting pieces when

the machine is plugged into a power source. Closing clutch jaws can cause serious

damage to bodily parts.

Ø Main On/Off Switch Operations

o “O” indicates “off” position.

o “L” indicates counter-clockwise rotation.

o “R” indicates clockwise rotation.

SDS200 PIPE DRAIN CLEANER

6

Ø Rubber Safety Hose Operations

o The rubber safety hose is attached to the back of the clutch channel. See figure below.

o CAUTION: The rubber safety hose must be installed. It protects the user from potential

“whipping” action of the end of the sectional cable. Without it installed, damage to persons or

property are possible.

Ø Drain cutter operations

o The drain cutters attach to the end of the drain cleaner cable. These are only attached on the

front side of the machine cable.

o Attach the drain cleaner cutter once the end of the cable has been inserted into the front of the

machine clutch channel.

§ Insert cutter and head facing T groove. The cutter will only install in one direction.

Push in the cutter until the pin locks the coupling.

§ To remove the cutter, use the key (straight metal pin with sharp flat side). Put the key in

the hole on the cutter until the pin depresses. When it is depressed, the cutter should

slide out of the T groove.

o There are a variety of drain cutters available for these units (see cutter/accessory table below).

SDS200 PIPE DRAIN CLEANER

7

§ When deciding which cutter to use, the user should choose a cutter size that is at least

1” smaller than the drainpipe to be cleaned. The style of the tool is determined by the

operational needs of the job. This choice is generally left up to the experience of the

user.

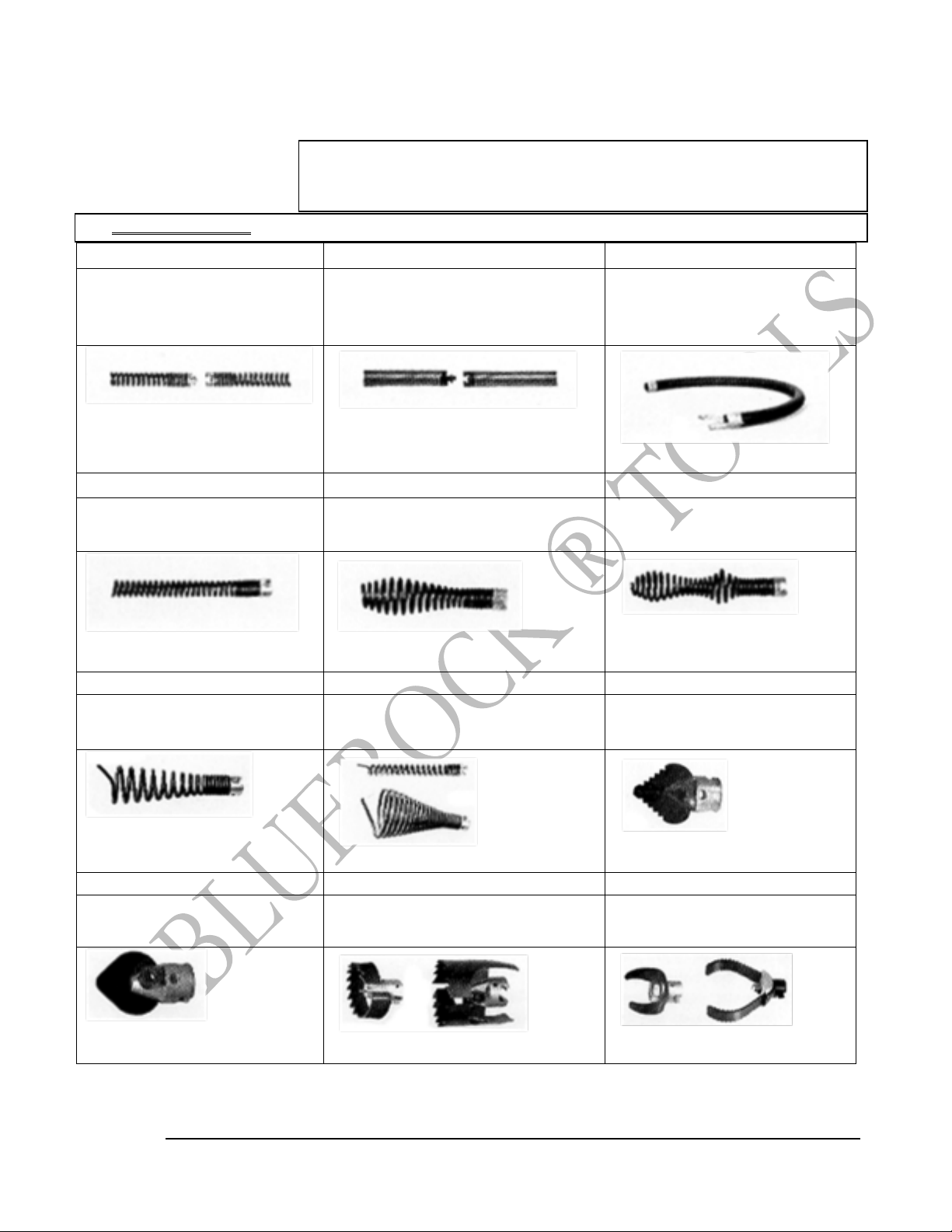

Ø Cutter/Accessory Table

Sectional Elastic Soft Shell Cable

Sectional Elastic Strong Shell Cable

Rubber Safety Hose

Made with high quality spring wire, assures

sufficient mechanical flexibility, as well as

bending resistance, twisting resistance and

durability resistance. It can be connected for

any length.

A Shaft made in heavy load with intensive wires.

Enhanced mechanical strength and twisting

resistance, suitable for complicated working

environment.

This safety hose is made to prevent injuries

from rotating flexible shaft and assure

personal safety.

Straight Helical Cutter

Olive Shaped Helical Cutter

Flexible Olive Shaped Helical Cutter

For exploring the pipe blockage. Usually

used in the first step

For guiding the flexible shaft through the

complicated path and drilling through the blockage.

Best for it's guide function.

For pipes that are hard to drill. Good

flexibility and optimal guiding function.

Funnel Shaped Helical Cutter

Collection Helical Cutter

4 Edge Saw Cutter

Used in the second step of cutting to

effectively remove the blockage residue left

on the pipe wall by straight helical cutting.

For collecting the broken cable or drill in the pipe.

Used to remove hard materials like chemical

deposits.

Spade Shaped Cutter

Helical Cutter Saw

C-Shaped Cutter

Used to remove the grease and gunk from

the pipe wall or used in the second step to

remove residues on the pipe wall.

For removing blockages like roots, branches, debris

or grease from pipes

For removing materials like cream, soap etc.

that adhere to the pipe wall.

SDS200 PIPE DRAIN CLEANER

8

RUNNING THE MACHINE

Ø Do all pre-operational and operational safety checks from Chapter 1.

Ø Consider your security and stability as well as the orientation of the machine in the work area.

o Consider the work surface material, condition, strength, density and rigidity. These factors

directly affect the tools operation and user safety.

Ø Ensure the machine handle is free of grease or oil.

Ø Inspect the cable and couplings for damage or wear. Cable should be replaced when they are severely

corroded. Worn cable can be identified when the outside of the coil becomes flat.

o CAUTION: Worn or damaged cables can be extremely dangerous. If they break they can cause

serious injury.

Ø Inspect the cutter edges for sharpness or damage. Dull or damaged cutters can lead to binding and cable

breakage.

Ø If on a wall location (clean out), position the machine so that the front of the machine is as level to the

sewer inlet as possible. If on a ground location (floor clean out), position the machine with the output

approximately 2 feet from the sewer inlet.

o CAUTION: Too much room in between sewer inlet and front of machine can result in the cable

kinking and/or twisting, which can lead to cable breakage.

Ø Feed a section of cable into the front of the machine (see figure below). Make sure the cable goes into the

clutch carriage from the front of the machine. Fully feed the section all the way through leaving

approximately 1 foot remaining at the front.

o CAUTION: DO NOT couple more than one cable section at a time. Multiple sections should not be

allowed to come out the back of the machine (on the rubber safety hose side).

Ø Select appropriate cutter for the specific clog and pipe being cleaned. Install the cutter (see above section

for specifics on installing the cutter).

Ø User should be positioned in a way to safely keep control of the cable. They should be able to easily

release clutch handle and on/off switch.

o The user should also be in a position where they have a hand on the cable between the front of

machine and pipe inlet to control the cable twisting action when an obstruction is reached.

Ø Place cable into the pipe being cleaned and push cable in until it reaches a point where it stops.

Ø Plug the machine into power source.

Ø Make sure to put on safety equipment.

Ø Pull enough extra cable through the machine until it forms a half circle between the front of machine and

the sewer inlet line.

Ø Hold the cable loosely in the gloved hand.

SDS200 PIPE DRAIN CLEANER

9

Ø Turn the main machine switch to the “on” position (“R” for general cutting forward clockwise).

o NOTE: The machine will turn on, but the cable will not spin yet (until the clutch handle is

depressed.

Ø With gloved hand on the cable, pull down the clutch handle with the opposite hand. Push down on the half

circle of the cable until the cable advances downwards.

o NOTE: A quick action up or down on the clutch handle is preferred so as to keep the three-jaw set

in the clutch from wearing out too quickly.

Ø As soon as the cable half circle has advanced forward and there is no longer slack in the circle, release the

handle clutch so it stops spinning the cable.

Ø Pull 8”-10” of cable out with the gloved hand to form another half circle.

Ø Repeat the feeding process until resistance or obstruction is encountered. This will be the blockage. The

can identify the blockage by difficulty feeding cable and a cable twisting motion in the operators hands.

Ø If more cable is required to reach an obstruction, the following procedure should be followed.

o Turn machine off.

o Loop the end of the cable that is currently in the line back in the line to secure it from moving.

o Insert another section of line through the front of the machine (female end first). Keep 1’ of the

line out.

o Attach the cable in the line to the cable in the machine.

o Proceed with feeding cable operations.

Ø If the cable becomes overloaded in the clog, relieve the load tension by pulling back on the cable with

short jerking motion to free the cutter. Slowly advance the cutter forward into the clog. Repeat the

process until the clog is free.

o NOTE: Make sure cutters are always spinning when progressing into an obstruction and do not

force the cable. Progress and time taken in a clog depends on the nature of the obstruction and

cutters being used.

o CAUTION: DO NOT allow tension to build up in the drain cleaning cable. This can happen if the

cutter has stopped rotating due to a blockage, but the motor clutch and cable continue to spin.

This can cause a lot of torque on the cable causing it to suddenly twist potentially wrapping

around an arm or hand. Be extremely aware when cutting through a blockage. Cut slowly and

carefully when feeding the cable.

o NOTE: If the tool gets stuck in an obstruction and the manual dislodging procedure will not work,

there is a special procedure that can be tried using the reverse “L” counter-clockwise switch on

the on/off switch.

§ The “L” reverse procedure should only be used to free an obstruction. Running the

machine in reverse can cause damage to the drain cleaning cable. Only switch to “L”

after motor has come to a complete stop. Switch to “L” engage clutch handle only until

cable is free. Release as soon as tool is free of obstruction. Turn unit off and turn to

“R” and commence normal cutting operation.

§ WARNING: Never operate the machine in “L” reverse position for any other purposes.

Operating in reverse can cause damage to the cable and operator.

Ø Once obstruction is clear, turn the machine to “off “position.

Ø To retrieve the cable from the sewer line, the following process should be followed.

o Leave the machine in the “R” forward cutting position.

o Engage the clutch.

SDS200 PIPE DRAIN CLEANER

10

o With gloved hand, pull the cable out or hold cable against the edge of the sewer inlet pipe until a

half circle is formed in the cable.

§ This essentially threads the cable out of the pipe.

o Release clutch.

o Push excess cable back through the machine from front to back.

§ Remember to turn off machine and disconnect sections as they come out.

§ When a section of cable is removed, insert the cable back into the cable carrier. Make

sure to reconnect the sections of cable to the last section of cable in the carrier.

o Repeat this operation until cable is fully out.

o Turn off machine. Disconnect Power. Remove safety hose.

o After using this machine, clean and flush cables, couplings and cutters with water.

SDS200 PIPE DRAIN CLEANER

11

Troubleshooting

Note

SERVICING SHOULD ONLY BE DONE BY A QUALIFIED TECHNICIAN.

DON’T FORGET TO UNPLUG POWER TO UNIT PRIOR TO SERVICE!

PROBLEM

CAUSE

CORRECTION

Motor does not

start

Machine unplugged

Plug into power source

Fuse blown

Replace the fuse

Capacitor blown

Replace capacitor

Bad on/off switch

Replace Switch

The cutters will not

cut

Cutting blade is dull

Replace or sharpen blade

Cutter is damaged

Replace cutter

Too much force being applied

Cut slower

Cable is not

turning

Main channel is rusted

Take apart and remove rust

Clutch is worn down

Replace clutch

Handle not pressed down all the way

Engage clutch handle down all the way

The cable spins,

but does not move

forward or reverse

This is a non-automatic forward/reverse drain

cleaner. This is a sectional type drain cleaner.

It does not go in and out automatically

Consult the operating manual for procedures on

standard operating procedures

Damaged Cable

Dull cutters

Replace cutters

Cutters not assembled in correct sequence

Put cutters in correct sequence

Low quality pipe

Make sure only pipe of good quality is used

Bad quality or insufficient thread cutting oil

Use only thread cutting oil in adequate quantity

Pipe turns while

threading

3-jaw clutch not tight

Tighten handwheel clutch

3-jaw clutch teeth dirty

Clean with wire brush

3 jaw clutch teeth damaged or dull

Replace 3-jaw clutch

Cable broken in the

Pipe

Incorrect operations

See operational protocols. Get drill with helical

shaft and extension to collect the broken cable

Prolonged use in “L” Reverse

Cable is stuck

Pipe has many turns and is very long

Increase push/pull force during operations

Change direction/angle of the cable

Cable will not cut

through blockage

Blockage too hard

Gently push and pull the cable rotating

clockwise. Have patience, sometimes

obstructions take a while to clear

Use a different set up, smaller or larger. Operator

experience comes into play on this

Complicated path to the blockage

Find a shorter route to the blockage

Chapter

4

SDS200 PIPE DRAIN CLEANER

12

General Maintenance

Note

SERVICING SHOULD ONLY BE DONE BY A QUALIFIED TECHNICIAN.

DON’T FORGET TO UNPLUG POWER TO UNIT PRIOR TO SERVICE!

Ø Inspect electrical cords and electrical connections.

Ø Keep machine clean and free of debris.

Ø Flush cables with water after each use. Occasionally lubricate cables and couplings.

Ø Check for misalignment, binding and breakage of all moving parts. If damaged, repair tool before use.

Ø Check the cutters for sharpness or damage.

Ø Clean clutch teeth with wire brush. Check the attrition on the 3-jaw clutch. If the points are worn, replace with

identical piece.

Ø After each use coat all moving parts (including clutch driver) with corrosion resistant oil.

Occasional Maintenance

Ø Check brushes for wear and replace if worn.

Ø Grease rocker arms and main bearings every 3-6 months.

Ø Grease main bearings thru grease fitting inside clutch handle slot.

Ø After a lot of use, clutch jaws may need to be replaced.

o Remove the screws that hold the front guard to the housing. Remove screws that hold the nosepiece on.

o Slide out clutch driver and replace jaws.

o Put nosepiece assembly and guards back on.

§ WARNING: DO NOT operate machine with guards removed.

Ø After a lot of use, the V-Belt may need to be tightened.

o Remove V-Belt Guard

o Loosen locknut, turn bolt until V-Belt tightens. Tighten lock nut back up. Replace guard.

Chapter

5

SDS200 PIPE DRAIN CLEANER

13

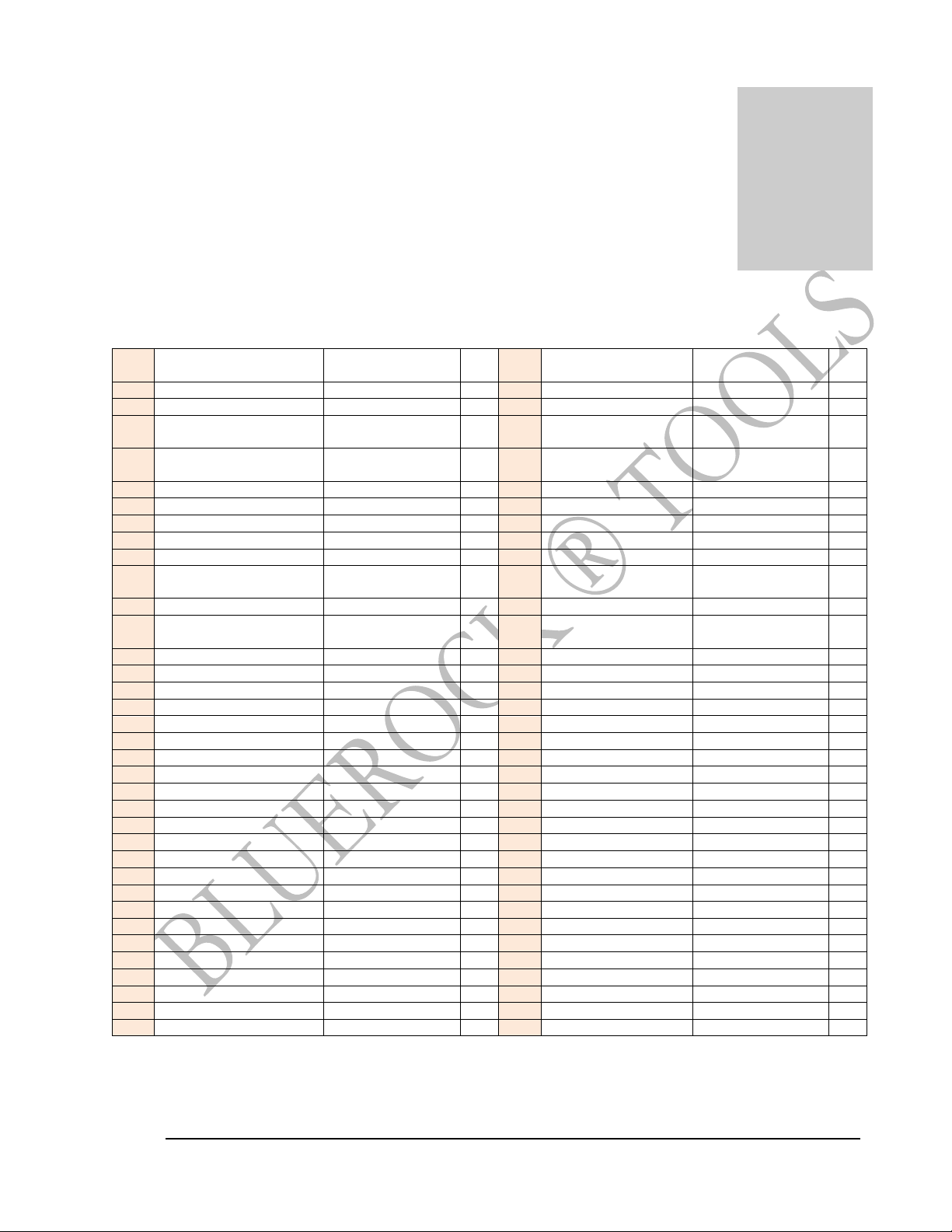

Parts List

Part

Description

Specification

Qt

y

Par

t

Description

Specification

Qt

y

1

Hull

1

36

Strain relies

M12 Plastic

4

2

Inner hexagon screw

M5*35

2

37

Protective shield

Φ74*74*69 PA6

1

3

Gland

1

38

Insertion

74*74*1.5mm

rubber

1

4

Inner hexagon screw

M6*50

2

39

Guard

74*74*40mm

plastic

1

5

Inner hexagon screw

M6*30

2

40

Switch

10A/400v

1

6

Brakes

3

41

Conducting wire

1.0mm

1

7

Belt

0-528 rubber

1

42

Stay

2

8

Washer

Φ6

3

43

Anchor plate

1

9

Rocker arm set

3

44

Screw

M10*30

2

10

Perforated cylindrical

pin

Φ6*45

3

45

Nut

M10

1

11

Cotter

Φ2*16

3

46

Bolt

1

12

Support

135*72*20mm

ABS

3

47

Motor

750W/230V

1

13

Half-round head screw

M5*8

3

48

Flat key

6*30

1

14

Tension spring

3

49

Small Pulley

1

15

Damper

1

50

Damper

1

16

Driving shaft

1

51

Screw

M5*103

3

17

Clutch cone

1

52

Washer

Φ10

4

18

Bearing

8112

1

53

Spring washer

Φ10

4

19

Cam

1

54

screw

M10*20

4

20

Handle

1

55

Fixed wire reel

4

21

Ball

1

56

Nut

M10

4

22

Plate assembly

1

57

Spring washer

Φ10

4

23

Inner hexagon screw

M8*30

3

58

Support

2

24

Jockey pulley

2

59

Wheel

70kg 8"

2

25

Pin

8*30

2

60

Ring

2

26

Sleeve pipe

Φ50*185 plastic

1

61

Nut

M12

2

27

Yoke

1

62

Stand

1

28

Casing

1

63

Rubber feet

2

29

Ball bearing

208

1

64

Screw

M5*10

1

30

Bearing end cover

1

65

Spring washer

Φ5

1

31

Screw

M8*30

1

66

Earth Lead

Φ5

1

32

Guide hose pin

2

67

Main Axle Assembly

1

33

Strain relies

M16 Plastic

1

34

Mains cable

1.02/250V rubber

1

35

Name Plate

1

Chapter

6

SDS200 PIPE DRAIN CLEANER

14

Breakdown View

Table of contents

Other Bluerock Tools Cleaning Equipment manuals