BlueSpot 07945 User manual

1/2" AIR IMPACT GUN

User Manual

07945

01

Thank you for purchasing a BlueSpot product, you can find further information

on our range at www.BlueSpot.uk.com. Please ensure that you are using the

product correctly and that all guidance and cautions are followed in accordance

with the instructions. Please retain these instructions for future reference.

General Information

Safe use

Please make sure that you read these instructions carefully in order to avoid injury when

using the air gun. Follow all health and safety rules and regulations. If in doubt and available

please contact a more knowledgeable source.

DO NOT use if damaged.

• Maintain tool in good and clean condition for best and safest performance.

• Keep the work area clean, uncluttered and ensure there is adequate lighting.

• Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip

shoes.

• Keep children and unauthorised persons away from the work area.

• If the air gun is damaged do not use. If damage is found the air gun should be repaired

before use.

• ALWAYS check you are able to handle the weight and power of the tool before use. If

you cannot handle the tool comfortably do not use the tool.

• ALWAYS dress appropriately – clothing should be close fitted and long hair tied back.

Jewellery should be removed and shoes should be worn with a non-slip sole.

• ALWAYS wear the correct eye or face protection when operating the air gun.

• ALWAYS wear approved respiratory protection.

• ALWAYS wear ear defenders to protect yourself from the loud noise caused from when

the impact gun is in use.

• ALWAYS wear anti vibration gloves to protect yourself from the vibration caused by the

tool.

• ALWAYS wear a safety helmet if you are using the tool overhead.

• ALWAYS ensure you work in a well ventilated room.

• ALWAYS ensure the hose does not cause a trip hazard when in use.

• ALWAYS ensure the correct safety precautions are taken when using compressed air.

• ALWAYS check and ensure all air connections are properly attached and sealed before use.

• ALWAYS make sure the maintenance of the tool is carried out to prolong use and

performance.

• ALWAYS make sure that the air pressure has been released before disconnecting.

• ALWAYS make sure the machine has fully stopped before disconnecting.

• ALWAYS ensure the tool has cooled down fully before storing as it can be very hot

after use.

• ALWAYS disconnect the air gun fully from the air line before performing any

maintenance or storing.

• ALWAYS make sure the machine is switched off when connecting it to the air supply.

• NEVER operate the tool if you are under the influence of drugs or alcohol as this is

dangerous.

• NEVER carry the tool by the air line.

• NEVER use power tools in potentially explosive atmospheres unless they have been

designed for that purpose. The air gun has not been designed for that atmosphere.

• NEVER make modifications to the tool.

• NEVER direct air at yourself or anyone else.

• DO NOT exceed the maximum air pressure stated on the tool.

• DO NOT operate the air gun if you are tired as this could be dangerous.

• ALWAYS stop using the tool straight away if you start to experience discomfort or pain.

Consult with a qualified health professional if needed.

The BlueSpot 1/2" Air Impact Gun is ideal for everyday use.The wrench features a forward and

reverse gear which can be operated with one hand.The tough constructions makes it ideal for the

most demanding work environments.The built-in regulator allows four torque speeds.

02

Introduction

Safe use (continued)

Please make sure that you read these instructions carefully in order to avoid injury when

using the air gun. Follow all health and safety rules and regulations. If in doubt and available

please contact a more knowledgeable source.

DO NOT use if damaged.

• Maintain tool in good and clean condition for best and safest performance.

• Keep the work area clean, uncluttered and ensure there is adequate lighting.

• Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip

shoes.

• Keep children and unauthorised persons away from the work area.

• If the air gun is damaged do not use. If damage is found the air gun should be repaired

before use.

• ALWAYS check you are able to handle the weight and power of the tool before use. If

you cannot handle the tool comfortably do not use the tool.

• ALWAYS dress appropriately – clothing should be close fitted and long hair tied back.

Jewellery should be removed and shoes should be worn with a non-slip sole.

• ALWAYS wear the correct eye or face protection when operating the air gun.

• ALWAYS wear approved respiratory protection.

• ALWAYS wear ear defenders to protect yourself from the loud noise caused from when

the impact gun is in use.

• ALWAYS wear anti vibration gloves to protect yourself from the vibration caused by the

tool.

• ALWAYS wear a safety helmet if you are using the tool overhead.

• ALWAYS ensure you work in a well ventilated room.

• ALWAYS ensure the hose does not cause a trip hazard when in use.

• ALWAYS ensure the correct safety precautions are taken when using compressed air.

• ALWAYS check and ensure all air connections are properly attached and sealed before use.

• ALWAYS make sure the maintenance of the tool is carried out to prolong use and

performance.

• ALWAYS make sure that the air pressure has been released before disconnecting.

• ALWAYS make sure the machine has fully stopped before disconnecting.

• ALWAYS ensure the tool has cooled down fully before storing as it can be very hot

after use.

• ALWAYS disconnect the air gun fully from the air line before performing any

maintenance or storing.

• ALWAYS make sure the machine is switched off when connecting it to the air supply.

• NEVER operate the tool if you are under the influence of drugs or alcohol as this is

dangerous.

• NEVER carry the tool by the air line.

• NEVER use power tools in potentially explosive atmospheres unless they have been

designed for that purpose. The air gun has not been designed for that atmosphere.

• NEVER make modifications to the tool.

• NEVER direct air at yourself or anyone else.

• DO NOT exceed the maximum air pressure stated on the tool.

• DO NOT operate the air gun if you are tired as this could be dangerous.

• ALWAYS stop using the tool straight away if you start to experience discomfort or pain.

Consult with a qualified health professional if needed.

1. Oil Point

2. ½” Square Drive

3. Forward / Reverse Button

4. Air Inlet

5. Air / Torque Control

6. Trigger

1

2

3

4

5

6

03

Specification

Parts Diagram

Maximum Operating Pressure

Clutch type

Square drive

Bolt capacity

Maximum torque

Operating pressure / Air consumption

Air Inlet

Minimum hose diameter

Weight

100 PSI

Single hammer

½”

16mm

312NM

90 PSI

¼” BSP inlet

3/8”

2.0KG

04

Operation

Fitting the connector

The air impact gun is supplied with a male airline quick connector. The quick connector can be

fitted by following the instructions below –

1. Remove the protective cover from the air inlet.

2. Apply PTFE tape (not included) in a clockwise direction to the screw threads of the

quick connector to ensure a tight connection.

3. Screw the quick connector into the air inlet. You may need to use a spanner to ensure

there is a tight connection

4. Connect to airline.

5. Carefully pressurise.

Connecting to the air supply

ALWAYS ensure the tool is connected to a clean, dry air supply.

ALWAYS ensure the water is drained from the system daily.

NEVER exceed the maximum operating pressure stated.

Tool Speed

Use the Air / Torque Control to set and adjust the speed of the impact gun.

1 – Minimum speed

4 – Maximum speed

Forward & Reverse

The forward and reverse function can be used to set the direction of the impact gun.The forward

and reverse switch can be set on the front and back of the impact gun.The letters F and R on the

side of the tool will show whether forward or reverse is set.

Forward – Clockwise rotation

Reverse – Anticlockwise rotation

Installing & removing sockets

ALWAYS ensure the impact gun is disconnected from the air supply before installing or removing

the sockets.

Installing

1. Firmly push the socket over the locking ring onto the ½” square drive.

2. Make sure the locking ring engages with the socket.

3. Check the socket is firmly attached and there is a secure connection.

05

Operation (continued)

Removing

1. Pull the socket off the ½” square drive to remove.

Operating the air impact gun

Loosening Nut/Bolt

1. Place the socket over the nut.

2. Hold the impact gun securely in your hand with your finger over the trigger.

3. Place your other hand on the back of the tool to control the torque reaction.

4. Push the forward/reverse switch so the tool is set at reverse.

5. Start the tool by pressing the trigger.

6. When the nut/bolt starts to move release the trigger. Stop the tool.

7. Remove the socket from the nut/bolt.

NEVER increase the operating pressure of the tool to over its maximum. If you cannot loosen/re-

move the nut with the impact gun use a suitable breaker bar.

Tightening Nut/Bolt

1. Set the torque setting. Check the nut/bolt can withstand the torque setting.

2. By hand tighten the nut/bolt as much as you can.

3. Place the socket over the nut.

4. Hold the impact gun securely in your hand with your finger over the trigger.

5. Place your other hand on the back of the tool to control the torque reaction.

6. Push the forward/reverse switch so the tool is set at forward.

7. Start the tool by pressing the trigger.

8. Tighten the nut.

9. Remove the impact gun and socket.

BE CAREFUL not to overtighten. After using the impact gun use a calibrated torque wrench to

torque the nut to the correct value.

NEVER increase the operating pressure of the tool to over its maximum.

ALWAYS make sure that the air pressure has been released before disconnecting.

Problem Possible Causes Solution

- Perform the daily

maintenance instructions

- Check and set the air

pressure to 90 PSI

- Operate the impact gun in

short bursts

- Check the

fittings/connections to the

impact gun. PTFE tape can

be used to ensure a secure

connection

- Check the hose for air leaks

and repair

Impact gun is

running slowly

- Mechanism blocked by dirt

- The pressure is wrong

- The air flow is blocked

- Possible air leak

- Perform the daily

maintenance instructions on

the impact gun

- Take the impact gun to be

repaired

Impact gun runs at

normal speed but

loses power

under load

- Clutch worn or sticking

- Motor parts worn

- Take the impact gun to be

repaired

Impact gun will not

shut off

- Throttle valve ‘O’ ring

broken or unseated

Impact gun has seized - Mechanism blocked by

dirt or rust

- Perform the daily

maintenance instructions on

the impact gun

- Gently tap the tool with a

soft mallet

- Disconnect the tool from

the airline. Rotate the drive

manually

06

Troubleshooting

Notes

ContactDistance to Spot Size

ALWAYS ensure the air gun has been disconnected from the air supply and air pressure

released before carrying out any cleaning or maintenance.

• Clean the machine body with a dry cloth.

Cleaning & Maintenance

07

ContactDistance to Spot SizeCleaning & Maintenance (continued)

Daily Maintenance

• Disconnect from the air supply.

• Pour roughly 14ml of oil into the air inlet.

• Connect the impact gun to the air supply.

• Run the impact gun for 2-4 seconds at a low speed so the oil is distributed through the tool.

We recommend using air tool oil.

NEVER use normal engine oil.

Weekly Maintenance

• Disconnect from the air supply.

• Open the oil point on the impact gun with the hex key supplied in the box.

• Pour a few drops of air tool oil into the oil point.

• Secure the seal of the oil point with the hex key.

• Connect the impact gun to the air supply.

• Run the impact gun for 2-4 seconds at a low speed so the oil is distributed through the tool.

We recommend using air tool oil.

NEVER use normal engine oil.

ALWAYS ensure there is an air filter fitted to the impact gun at all times. If the tool is in

constant use a combined fitter must be fitted to the tool.

Notes

ContactDistance to Spot Size

ALWAYS check and adhere to national regulations when disposing of any tools that are no

longer functional and cannot be repaired.

• Contact your local waste disposal authority for information on how to correctly dispose

of tools.

• DO NOT dispose of power tools with domestic waste.

• DO NOT incinerate.

Disposal

08

Contact

Find out more about the BlueSpot® Lifetime Guarantee at www.BlueSpot.uk.com

Tel: 0800 093 0115

Email: [email protected]

Orme Business Centre,

Greenacres Road,

Oldham,

OL4 3NS

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and

packaging should be sorted, taken to a recycling centre and disposed of in a manner which

is compatible with the environment. When the product becomes completely unserviceable

and requires disposal, drain any fluids (if applicable) into approved containers

and dispose of the product and fluids according to local regulations.

Environmental Protection

Notes

ContactDistance to Spot Size

Dispose of this product at the end of its working life in compliance with the EU Directive on

Waste Electrical and Electronic Equipment (WEEE). When the product is no longer required,

it must be disposed of in an environmentally protective way. Contact your local solid waste

authority for recycling information.

WEEE Regulations

09

ContactDistance to Spot SizeDisposal

Notes

Table of contents

Other BlueSpot Tools manuals

BlueSpot

BlueSpot 35111 User manual

BlueSpot

BlueSpot M3-M10 User manual

BlueSpot

BlueSpot 07901 User manual

BlueSpot

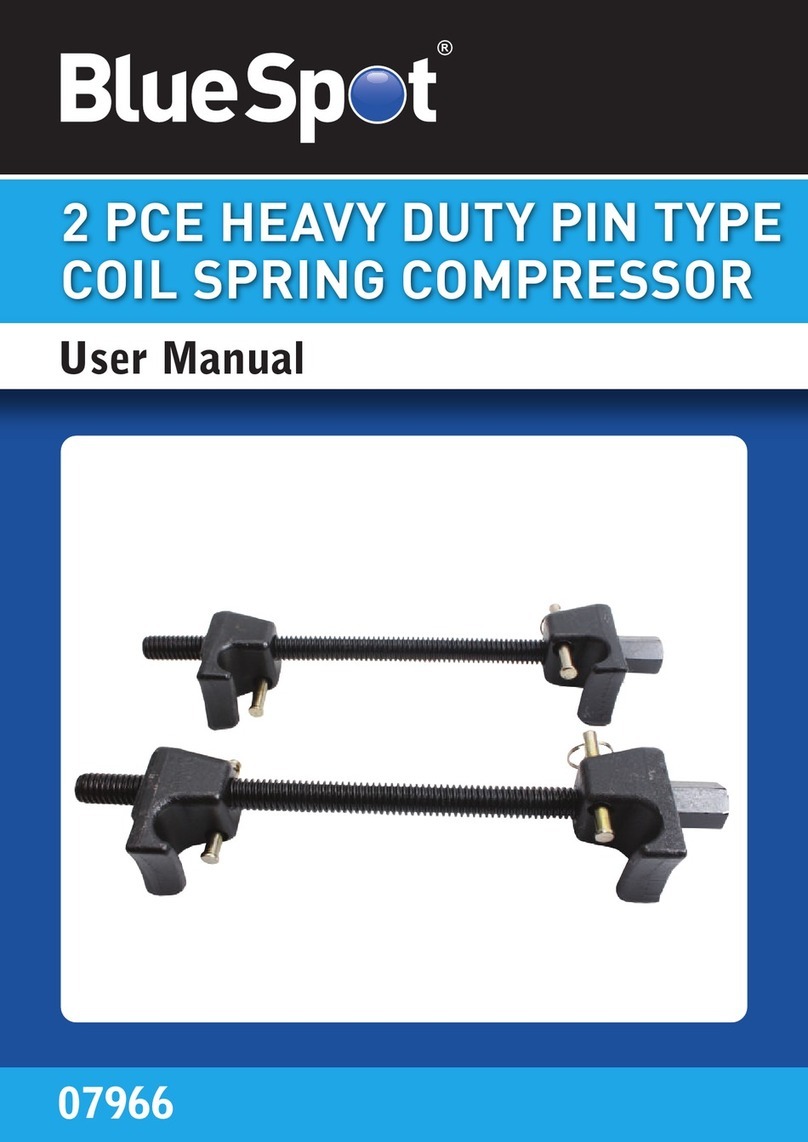

BlueSpot 07966 User manual

BlueSpot

BlueSpot 07951 User manual

BlueSpot

BlueSpot 07903 User manual

BlueSpot

BlueSpot 07914 User manual

BlueSpot

BlueSpot 19532 User manual

BlueSpot

BlueSpot 07902 User manual

BlueSpot

BlueSpot 07962 User manual