8MN-662

EasyStreet

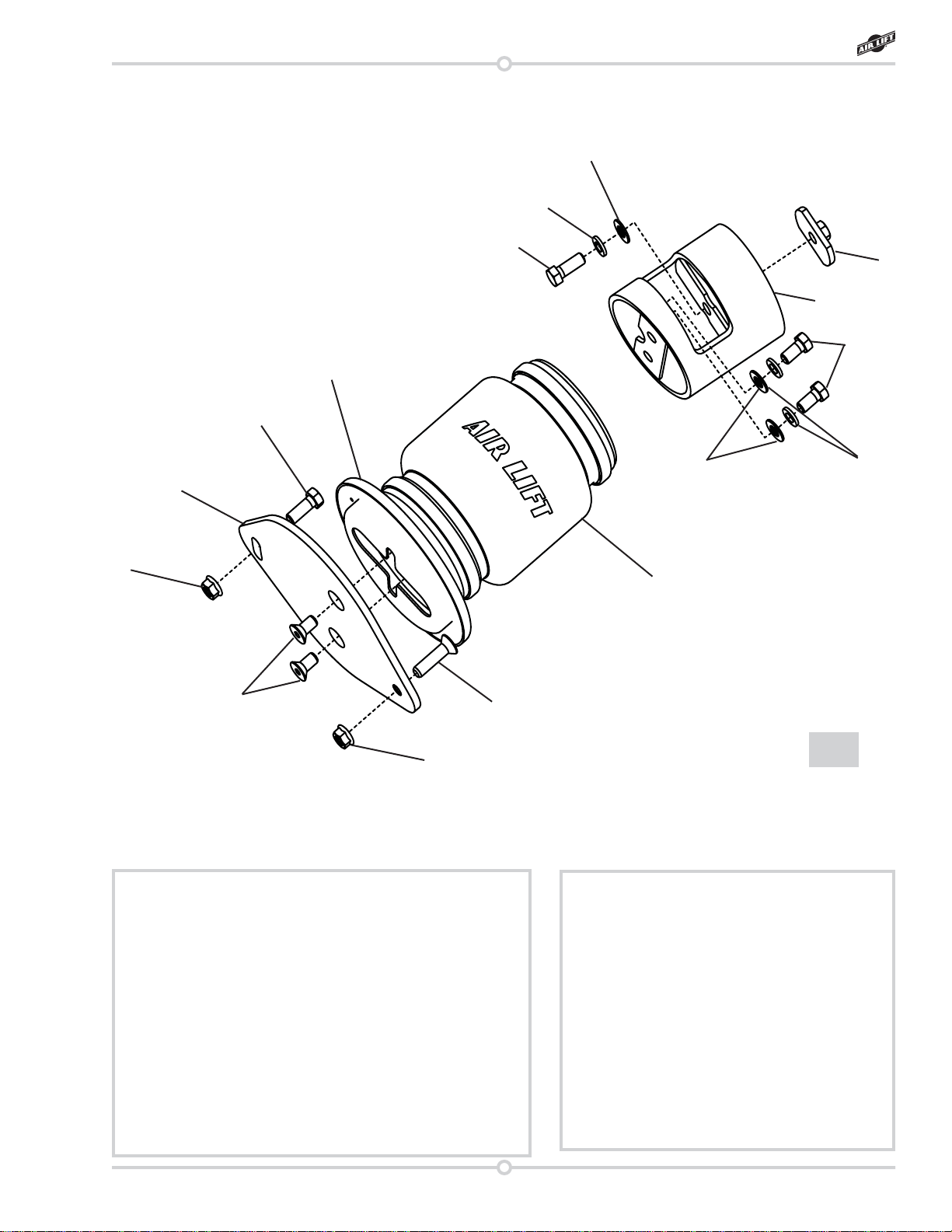

Replacement Information

If you need replacement parts, contact the local dealer or call Air Lift customer service at

(800) 248-0892, ext.1. Most parts are immediately available and can be shipped the same

day.

Contact Air Lift Company customer service at (800) 248-0892, ext. 1, first if:

• Parts are missing from the kit.

• Need technical assistance on installation or operation.

• Broken or defective parts in the kit.

• Wrong parts in the kit.

• Have a warranty claim or question.

Contact the retailer where the kit was purchased:

• If it is necessary to return or exchange the kit for any reason.

• If there is a problem with shipping if shipped from the retailer.

• If there is a problem with the price.

Contact Information

Ifyouhaveanyquestions,commentsorneedtechnicalassistancecontactourcustomerservice

departmentbycalling(800)248-0892,ext. 1, Monday through Friday, 8 a.m.to5p.m.Eastern

Time. For calls from outside the USA or Canada, our local number is (517) 322-2144.

For inquiries by mail, our address is PO Box 80167, Lansing, MI 48908-0167. Our shipping

address for returns is 2727 Snow Road, Lansing, MI 48917.

www.airliftcompany.com.

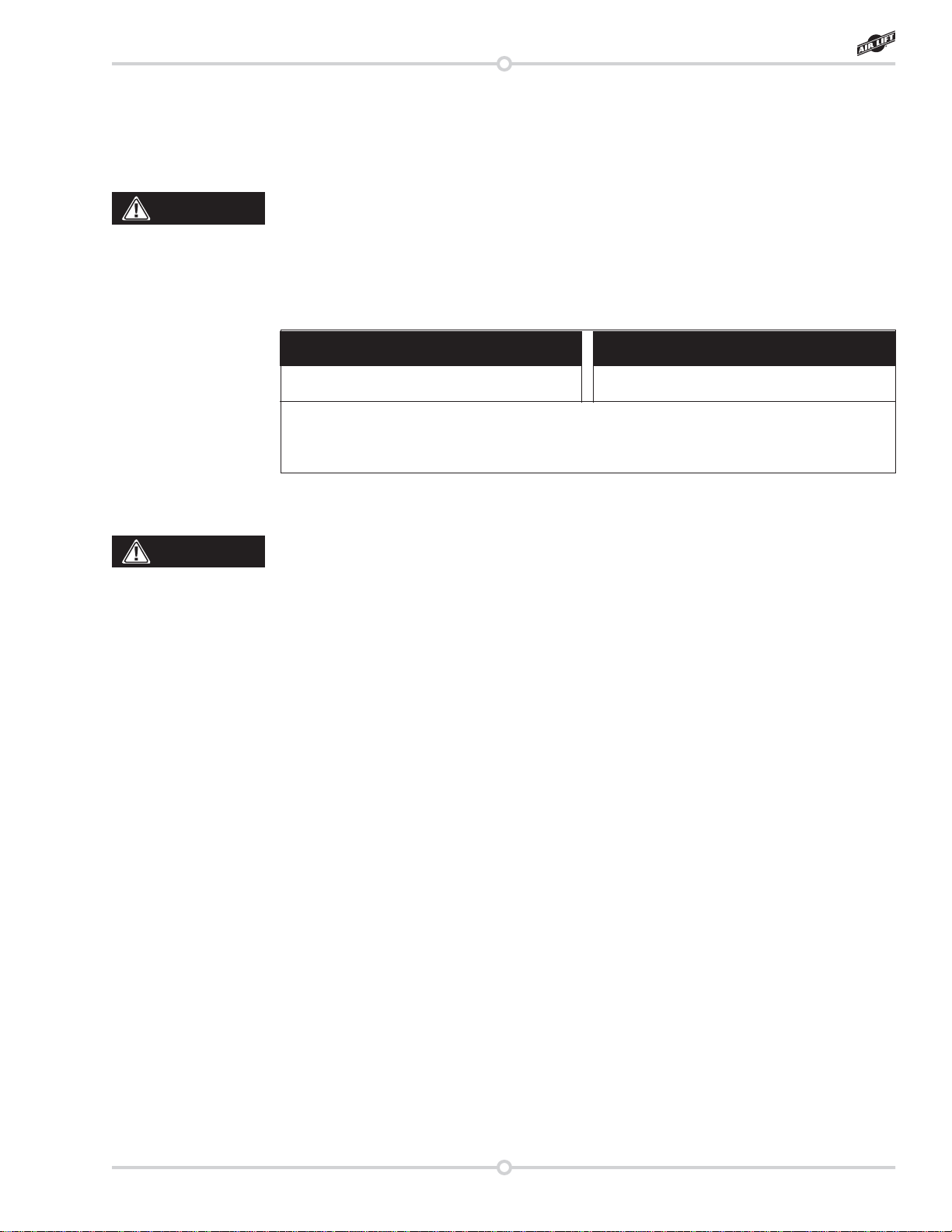

Air Lift 1000*......................2 Year Limited

SureSet*.............................2 Year Limited

Super Duty*.......................2 Year Limited

Other Accessories............2 Year Limited

Ride Control*.....................2 Year Limited

SlamAir..............................2 Year Limited

Ride Control Plus*..............2 Year Limited

Load Controller (I)*.............2 Year Limited

SmartAir*.............................2 Year Limited

Load Controller (II)*............2 Year Limited

EasyStreet Systems...........1 Year Limited

RoadTamer Systems..........2 Year Limited

*The purchase of an Air Lift Load Controller II, SmartAir Automatic Leveling System or SureSet Load

Controller System with a Super Duty, Ride Control, or AirLift 1000 extends the air springs’ warranty

from two years to a Limited Lifetime Warranty to the original purchaser of thecovered systems. All

other above listed warranty requirements will apply. (PrimaryAir and EasyStreet air spring systems

are excluded from this offer.)

Productfailuresresulting from abnormaluse ormisuseareexcluded from this warranty.The

loss of use of the product, loss of time, inconvenience, commercial loss or consequential

damages is not covered. The consumer is responsible for installation/reinstallation (labor

charges) of the product. Air Lift Company reserves the right to change the design of any

product without assuming any obligation to modify any product previously manufactured.

This warranty gives you specific legal rights and you may also have other rights that may

varyfromstateto state. Some states do notallow limitationson how longan implied warranty

lasts or allow the exclusion or limitation of incidental or consequential damages. The above

limitation or exclusion may not apply to you. There are no warranties, expressed or implied

including any implied warranties of merchantability and fitness, which extend beyond this

warranty period. There are no warranties that extend beyond the description on the face

hereof. Seller disclaims the implied warranty of merchantability. (Dated proof of purchase

required.)