BlueSpot 07966 User manual

2 PCE HEAVY DUTY PIN TYPE

COIL SPRING COMPRESSOR

User Manual

07966

01

Thank you for purchasing a BlueSpot product, you can find further information on our

range at www.BlueSpot.uk.com. Please ensure that you are using the product correctly

and that all guidance and cautions are followed in accordance with the instructions. Please

retain these instructions for future reference.

General Information

Please make sure that you read these instructions carefully in order to avoid injury when using

the coil spring compressor. Follow all health and safety rules and regulations. If in doubt and

available please contact a more knowledgeable source.

It is inadvisable to leave a coil spring under tension due to the stored energy. Immediately

replace the coil spring onto the shock absorber in order to reduce time that spring is under

tension away from the vehicle and potentially a danger to you or anyone in your workshop.

DO NOT use if damaged.

• Maintain tool in good and clean condition for best and safest performance.

• Keep the work area clean, uncluttered and ensure there is adequate lighting.

• Maintain correct balance and footing. Ensure the floor is not slippery and wear

non-slip shoes.

• Keep children and unauthorised persons away from the work area.

• If the spring compressors are damaged do not use.

• ALWAYS dress appropriately – clothing should be close fitted and long hair tied back.

Jewellery should be removed and shoes should be worn with a non-slip sole.

• ALWAYS wear the correct eye or face protection when operating the spring

compressors.

• ALWAYS wear approved respiratory protection if needed.

• ALWAYS ensure you work in a well ventilated room.

• ALWAYS ensure the coil spring compressors are used as a pair.

• ALWAYS tighten and release the spring compressors evenly and slowly.

• BE AWARE only to use hand tools to tighten/release the spring compressor.

• ALWAYS ensure the locking pins have secured the spring in place before use.

• ALWAYS check and ensure the hooks are connected securely on the spring before

commencing compression.

• DO NOT allow for the spring to become coil bound.

• DO NOT leave a compressed spring unattended.

• NEVER use air tools to compress a spring.

Safe use

• NEVER operate the tool if you are under the influence of drugs or alcohol as this

is dangerous.

• NEVER make modifications to the tool.

• NEVER use the spring compressor for a task that it was not designed for.

• DO NOT operate the spring compressors if you are tired as this could be dangerous.

• ALWAYS stop using the tool straight away if you start to experience discomfort or pain.

Consult with a qualified health professional if needed.

Please make sure that you read these instructions carefully in order to avoid injury when using

the coil spring compressor. Follow all health and safety rules and regulations. If in doubt and

available please contact a more knowledgeable source.

It is inadvisable to leave a coil spring under tension due to the stored energy. Immediately

replace the coil spring onto the shock absorber in order to reduce time that spring is under

tension away from the vehicle and potentially a danger to you or anyone in your workshop.

DO NOT use if damaged.

• Maintain tool in good and clean condition for best and safest performance.

• Keep the work area clean, uncluttered and ensure there is adequate lighting.

• Maintain correct balance and footing. Ensure the floor is not slippery and wear

non-slip shoes.

• Keep children and unauthorised persons away from the work area.

• If the spring compressors are damaged do not use.

• ALWAYS dress appropriately – clothing should be close fitted and long hair tied back.

Jewellery should be removed and shoes should be worn with a non-slip sole.

• ALWAYS wear the correct eye or face protection when operating the spring

compressors.

• ALWAYS wear approved respiratory protection if needed.

• ALWAYS ensure you work in a well ventilated room.

• ALWAYS ensure the coil spring compressors are used as a pair.

• ALWAYS tighten and release the spring compressors evenly and slowly.

• BE AWARE only to use hand tools to tighten/release the spring compressor.

• ALWAYS ensure the locking pins have secured the spring in place before use.

• ALWAYS check and ensure the hooks are connected securely on the spring before

commencing compression.

• DO NOT allow for the spring to become coil bound.

• DO NOT leave a compressed spring unattended.

• NEVER use air tools to compress a spring.

02

Safe use (continued)

• NEVER operate the tool if you are under the influence of drugs or alcohol as this

is dangerous.

• NEVER make modifications to the tool.

• NEVER use the spring compressor for a task that it was not designed for.

• DO NOT operate the spring compressors if you are tired as this could be dangerous.

• ALWAYS stop using the tool straight away if you start to experience discomfort or pain.

Consult with a qualified health professional if needed.

The BlueSpot 2 PCE Heavy Duty Pin Type Coil Spring Compressor is an essential tool for quickly

and securely compressing springs on vehicles when repairing or replacing the shocks, springs or

struts. Manufactured from heat treated carbon steel for increased durability. Suitable for use with

coil springs with a diameter less than 16mm.

These coil spring compressors feature a heavy duty hook with an extra safe pin that locks onto

the spring to give you an additional level of safety when compressing the spring.

Introduction

Parts Diagram

3

4

2

1

1

2

3

4

Locking pins

Screw thread

Thread puller hook

Non-Threaded puller hook

03

Operation

BE AWARE we do not recommend using this spring compressor for double diameter, dual rate

or progressively wound suspension springs.

ALWAYS ensure you refer to the spring manufacturer’s specification to ensure you do not

exceed the maximum loading of the spring.

BE AWARE some modern Macpherson strut suspension springs are fitted with a considerable

pre-load.

It is inadvisable to leave a coil spring under tension due to the stored energy. Immediately

replace the coil spring onto the shock absorber in order to reduce time that spring is under

tension away from the vehicle and potentially a danger to you or anyone in your workshop.

ALWAYS ensure you have followed all of the safety precautions and instructions before

beginning and that you are wearing the correct protective head, eye and hand wear.

ALWAYS ensure that extreme care and caution is taken to avoid injury.

ALWAYS keep the spring compressor lubricated.

The following instructions are for removing a strut spring from a MacPherson style strut

assembly which has been removed from the vehicle.

1. Adjust the head of the screw to move the threaded puller hook to the end of the screw.

2. Ensure the locking pins are in the unlocked position. Place the threaded puller hook

around the spring (refer to the example below).

3. At the opposite end attach the non-threaded puller hook to fit around the spring.

Ensure that they are an equal distance apart and parallel to each other.

4. Tighten the head of the screw until it contacts the non-threaded puller hook.

5. Lock the locking pins into the locking position on both the threaded and non-threaded

puller hooks.

6. Repeat the process above with the second spring compressor.

7. Make sure they are securely attached before continuing.

8. Tighten each compressor slightly in 10mm increments. For each turn of the spanner

make sure to equally apply the same to the other side of the spring.This will take up

the tension of the spring and secure the compressor at the extended position.

ALWAYS ensure that you have applied the same tightening to both sides of the spring

so you do not cause damage or personal injury.

9. A distance of 30-40mm between the compressed coil and the cap should allow enough

clearance for removal of the spring.

10. NEVER store a compressed coil spring for ANY length of time. Loosen the screws on

the spring compressors EVENLY to reduce pressure.

04

Operation

Cleaning & Maintenance

ALWAYS keep the spring compressor lubricated.

• Clean the tool with a dry cloth if needed.

Storage

Store the spring compressors in a cool dry area that is out of reach of children.

Disposal

Always check and adhere to national regulations when disposing of any tools that are no

longer functional and cannot be repaired.

• Contact your local waste disposal authority for information on how to correctly

dispose of tools.

Screw Head

Locking Pins in

locked position

Screw

Strut Spring

Threaded

puller hook

Non-Threaded

puller hook

05

Notes

Contact

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories

and packaging should be sorted, taken to a recycling centre and disposed of in a manner

which is compatible with the environment. When the product becomes completely unser-

viceable and requires disposal, drain any fluids (if applicable) into approved containers and

dispose of the product and fluids according to local regulations.

Find out more about BlueSpot® products at www.BlueSpot.uk.com

Tel: 0800 093 0115

Email: [email protected]

Orme Business Centre,

Greenacres Road,

Oldham,

OL4 3NS

Table of contents

Other BlueSpot Tools manuals

BlueSpot

BlueSpot 07945 User manual

BlueSpot

BlueSpot 07967 User manual

BlueSpot

BlueSpot M3-M10 User manual

BlueSpot

BlueSpot 07903 User manual

BlueSpot

BlueSpot 35111 User manual

BlueSpot

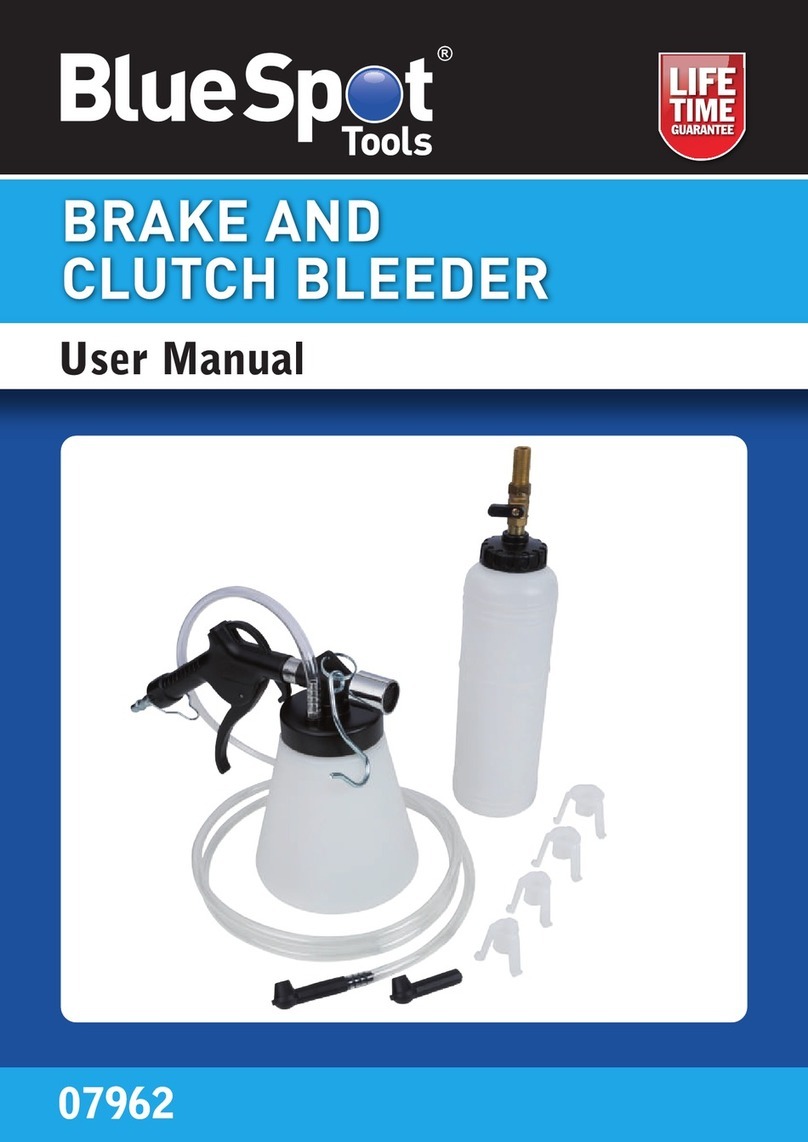

BlueSpot 07962 User manual

BlueSpot

BlueSpot 07914 User manual

BlueSpot

BlueSpot 07901 User manual

BlueSpot

BlueSpot 07902 User manual

BlueSpot

BlueSpot 19532 User manual

Popular Tools manuals by other brands

LockMasters

LockMasters LKMRT1KIT instructions

ReelCraft

ReelCraft 6800 Series Installation and operating instructions

Sealey

Sealey VS779.V4 manual

BorMann

BorMann BWR5110 owner's manual

Desoutter

Desoutter PT Series Servicing and operating instructions

Würth

Würth 0891 110 500 Translation of the original operating instructions