Blueworks BLH Series User manual

1 | P a g e

2 | P a g e

BLUEWORKS BLH Series

SALT CHLORINE GENERATOR

INSTRUCTIONS READ BEFORE USE

There are basic safety precautions that you need to follow to be safe.

Including,

Cautions

Please note, the total working hours for the CELL should be less than 8

hours total per day. If you are using a variable speed pump for 24 hours

a day be sure to adjust the chlorine output to 25-30%. If the pump is

only running 10 hours per day adjust the chlorine output between

60-80%.

You can use this calculation to calculate the appropriate chlorine output

for your pool, suggest at 6 hours per day.

Pump running 24(Hours a day) *25% (Chlorine Output) =6hr (cell run time per day at 25%).

Pump running 20(Hours a day) *30% (Chlorine Output) =6hr (cell run time per day at 30%).

Pump running 15(Hours a day) *40% (Chlorine Output) =6hr (cell run time per day at 40%).

Pump running 12(Hours a day) *50% (Chlorine Output) =6hr (cell run time per day at 50%).

Pump running 8(Hours a day) *75% (Chlorine Output) =6hr (cell run time per day at 75%).

Start the VS pump on a low speed and kick the speed up until the salt

system works.

If your swimming pool has natural stone as a covering or decorative

layer, please consult stone installation experts for stone maintenance

before installing BLH.

When installing and using this electrical equipment, basic safety

precautions should always be exercised, including the following:

3 | P a g e

WARNING

Risk of Electric Shock. All electrical wiring MUST be in conformance

with all applicable local codes, regulations, and the National Electric

Code ® (NEC®).

WARNING

To reduce the risk of injury, do not permit children to use this product.

WARNING

Higher temperatures may require higher chlorine output to maintain

proper free available chlorine residuals. The actual amount of

chlorination required by your pool can change, and varies according

factors not limited to bather load, rain, temperature, dirt, debris, and

chemical balance.

WARNING

Always turn unit off when operating any plumbing control valves such

as for backwashing, water exhaust, or during operation of spa or water

features if operation restricts water flow to the cell. A build-up of

flammable gases will result in hazardous conditions.

When install the machine, ensure that materials and parts used in

the pool are compatible with the use of chlorinated water and salt.

Avoid high salt levels (above the recommended range).

Ensure that the chlorine generator operates only when the

circulation pump is operating. When installed with a pool

equipment timer, the Control Module must be to the load side of

the timer clock.

4 | P a g e

If additional chlorine is required (due to hot weather), use Sodium

Hypochlorite to maintain an appropriate chlorine residual in the

water.

Proper pool chemistry must be maintained at all times.

A green colored terminal is located inside the wiring compartment.

To reduce the risk of electric shock, this terminal must be

connected to the grounding means provided in the electric supply

service panel with a continuous copper wire equivalent in size to

the circuit conductors supplying the equipment.

One bonding for US models is provided on the external surface. To

reduce the risk of electric shock, connect the local common

bonding grid in the area of the swimming pool, spa, or hot tub to

these terminals with an insulated or bare copper conductor not

smaller than 8 AWG US.

5 | P a g e

Table of Contents

OPERATION

Introduction............................................................6

Switches of Control............................................... 7

Water chemistry.....................................................9

Operation ............................................................14

Installation............................................................18

WARRANTY

Warranty..............................................................22

TROUBLESHOOTING

Troubleshooting...................................................27

6 | P a g e

INTRODUCTION

BLH Salt water chlorination is a process that uses dissolved salt for

the chlorination of swimming pools. The chlorine generator

uses electrolysis in the presence of dissolved salt to produce chlorine

gas or its dissolved forms, hypochlorous acid and sodium hypochlorite,

which are already commonly used as sanitizing in pools.

The BLH is designed for residential swimming pool up to 60,000 gallons

(230,000 liters).

The actual amount of chlorination required to properly disinfect the pool

depends on the bather’s load, rainfall, air temperature, water

temperature,exposure of the pool to the sun, pool surface and

cleanliness.

7 | P a g e

Switches of Control

AUTO: Generally, if the BLH is in “Auto”, it will automatically work

according to the chlorine output settings.

SUPER CHLOR: The “Super Chlor” function is the process of

temporarily increasing the free chlorine levels in the pool for the

8 | P a g e

purpose of increased sanitation power. It's often necessary when the

pool water is cloudy, free chlorine levels to fall below optimum

levels. Switch to “ON”. It will work 100%, remember to back to “Auto”

when you have desired chlorine.

OFF: In “OFF” , the BLH stops outputting chlorine.

NOTE: During the maintenance, please turn the power off the

circuit breaker. The OFF switch is not to be used.

OUTPUT LEVEL CONTROL

Adjust this setting to increase or decrease the chlorine output level

percentage.

9 | P a g e

WATER CHEMISTRY

For any pools, it is significant to maintain proper water chemistry of the

pool water, including pH, calcium levels, and alkaline content,

especially to maintain proper levels of salt and stabilizer. It helps to

prevent corrosion or scaling and to bring better experience for pool

users. It is recommended that pool water be professionally tested a

minimum of twice per 3 months and adjust the water chemistry in time.

Remember to tell the pool store service staff that you are using a salt

chlorine generator.

IDEAL CHEMICAL LEVELS

Saturation Index

The “saturation index,” or the “stability index,” is a numerical value

indicating whether or not water is balanced.

Saturation Index = pH + TF + CF + AF – 12.1

10 | P a g e

Ideal Salt Levels & Pool Size

Use the table below to help determine the amount of salt and pool

size.The ideal salt level is between 3000-4000 ppm.

11 | P a g e

Type of Salt to Use

Use evaporated, granular non-iodized salt (sodium chloride). The purer

the salt (at least 99%).

Improve the life and performance of the electrolytic cell. Water softening

salt (also called water conditioner)

Granules are an economical way to buy large amounts of salt. However,

only NaCl salt with a purity of at least 99% can be used. The pill is a

compressed form of evaporated salt and may take longer to dissolve.

Avoid using salt with an anti-caking agent, which may cause

discoloration.

When adding salt to the pool, it’s best to pour the required salt into the

shallow end of the pool and run filter and pump at the same time to

circulate the water and dissolve the salt. Do not pour the salt bag into the

water because the chemicals and ink on the bag will Disturb water

balance. In summer, salt may take 24-48 hours to dissolve, while in

winter it takes longer. Fine grain The salt will dissolve faster than

compressed tablets.

In any swimming pool, do not add salt directly to the skier or directly to

the main drain. Due to the high concentration of salt and reduced pump

flow, this will shut down or shorten the life of the cells.

If the addition is incorrect, please turn off BLH immediately for 24 hours

while the pump and filter are still running. This will help distribute the salt

evenly. The salt display may take up to 24 hours to respond to changes in

salt concentration.

12 | P a g e

Adding Salt

POUNDS and (Kg) OF SALT NEEDED FOR 3400 PPM

13 | P a g e

To ensure BLH working well, swimming pool stabilizer to protect and

extend the life of chlorine generator. Use the chart to see how to reach

ideal 80 ppm.

POUNDS and (Kg) OF STABILIZER (CYANURIC ACID) NEEDED

FOR 80 PPM

14 | P a g e

OPERATION

By familiarizing yourself with the operation of the BLH generator, you

can achieve maximum performance for your pool. When chemical

levels are in the recommended range, there are FOUR factors that you

can control. Filter time each day, amount of salt in the pool, the output

of chlorine you set, and stabilizer level in the water will directly impact

the amount of chlorine the BLH will generate.

When you just begin to set the model, it will take you days to find ideal

chlorine output, you can start at a high setting and then turn down.

Indicators and Diagnostic Displays

15 | P a g e

POWER: Power illuminated, model is in power.

GENERATION: Model in normal operation, the LED will be steady. If it

is flashing, check the pool water chemicals.

SUPER CHLOR: The generator runs at 100% capacity which can

produce enough chlorine to clear up moderate cloudiness, but the

generator is forced to overwork. It will be automatically switched to the

original output after 24- hour SUPER CHLOR operation.

REMOTE: Controlled by remote models (not available)

CHECK CELL: If “Check Cell” LED is flashing and salt level is above

2700ppm, 500hr cell count down timer is active. Once cleaned, hold

down “System Status” button (3-5seconds) to reset timer for 500hrs.

HIGH SALT: When it is on or flashing, BLH is warning that the water

salinity is too high to work.

CHECK SALT: When it is on or flashing, BLH salinity is too low to work.

NO FLOW: When it is on, flow switch detect that there is no flow

through the cell. If it is flashing, the flow is restored.

DIAGNOSTIC DISPLAY

Average Salt Level (default as 2800ppm)

1. Water Temperature (xx degrees Fahrenheit or Celsius)

2. Cell Voltage (20-30VDC)

3. Cell Amperage (How is the cell working,fine or not)

4. Desired Output % (% of cell time ON)

5. Instant salinity

6. Product name sent to the pool automation Control display

(AL0-5=product branding)

16 | P a g e

7. Software revision level

8. Cell type (F-3,F-9,C-9,F-15,C-15,T-15)

BLH20: F-3 BLH30: F-9 BLH40: F-15

9. Salt Calibration (E000)

10. End of the loop (-EE)

Spring Start-up

When reopening the pool after long term, check all water chemistry

before power on the BLH.

Maintenance

When checking other water chemistry levels, always monitor the salinity

level of the swimming pool.

After the system runs for a period of time, it will eventually need to clean

the cells due to the scaling of natural minerals.

You will be notified by opening "CHECK CELL" Light. When lit, cleaning

the cell with a cleaning stand is better.

Important information: The frequency of cleaning depends on your

water chemistry and water saturation index.

For most people, only need to clean a few times per season. Faster

mineral accumulation must be long-term high saturation index,chemical

imbalance may lead to rapid fouling. Consult Swimming pool

professionals.

17 | P a g e

How to clean the cell?

Important information: If there is severe mineral accumulation, more

than one cleaning may be required to dissolve the remaining solids.

After cleaning, carefully inspect the cell plate with bright light. If you see

any remaining scale, debris or physical blocked in the salt cell, please

repeat the cleaning process as needed. If it is "check cell"come back

soon after cleaning,

1) Confirm that the salinity is within the range

2) Ensure that the cell is fully filled with water

3) Verify the cell type setting of the system

Before removing the cell for cleaning or replacement:

1) Turn off all power sources of all swimming pool equipment and close

the water supply line valve (if applicable).

2) Unplug the cell cable connecting to the control box.

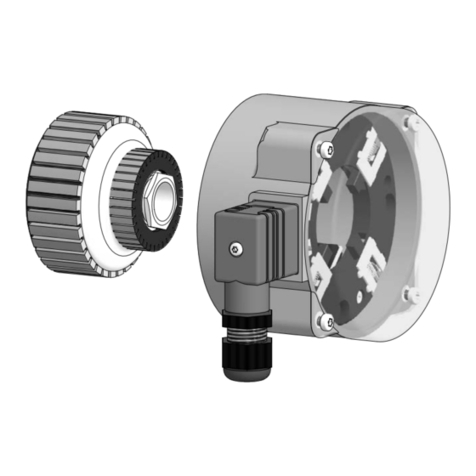

3) Loosen the threaded ring around the joint at the junction of the pool

and the pipes.

To clean the cell with mineral deposits:

1) Cleaning stand and adjust the direction of the cell vertically. Place on

the ground and stabilize to keep it upright.

2) In a separate bucket, mix one part of muriatic acid with four parts of

water. Pour this acid solution directly to cell. Make sure that the

cleaning water completely covers the components inside the cell.

3) Wait for the foaming to stop. Let the solution soak for no more than

fifteen minutes.

4) Properly dispose of the acid solution, and use a hose to wash away

the remaining debris from the pool.

18 | P a g e

5) Look inside the unit and check if there is no debris or scale residue. If

necessary, repeat steps 2-4.

6) Re install the cell into the PVC return pipe.

Note: If you do not currently have a cleaning cap or cleaning rack, you

can fully immerse the cell in a five-gallon bucket.

ALWAYS POUR ACID INTO WATER-NEVER POUR WATER INTO ACID.

BE SURE TO WEAR PROTECTIVE GLASSES, CLOTHING, AND CHEMICAL

RESISTANT GLOVES.

INSTALLATION

Before installation, make sure all the water chemistry is in normal

range.

Using 2-inch pipes and should be performed by qualified personnel in

case there is a 1.5-inch pipe, a reducer can be used to fit the system;

be sure to pay attention to any changes.

Check each measurement carefully before cutting.

Mounting the BLH Control

Install the control box as close as possible to the pump and filter system.

For safety reasons, please do not install the control box within 10 feet of

the edge of the pool and comply with all applicable regulations. Verify

cell and flow switch cable can reach the control box.

As with most electronic devices, avoid using the controller above the

heater or in a tightly enclosed or insulated space can avoid excessive

heat accumulation and also avoid being close to acid chemicals, it may

damage the control.

Use screws to fix the mounting bracket of the control box on the wall or

19 | P a g e

vertical bracket comfortably horizontally.

At least 3 feet above the ground. Hang the control on the bracket.

Mounting the Flow Switch, and Cell.

Flow switch, confirm that the arrows on the flow switch (located on the

side) point in the same direction of water flow.

The Cell and Flow Switch cables have easy plug-in connectors in the

control, the diagram below for the location of these connections.

20 | P a g e

Plumbing

These instructions apply to 2-inch pipe (typical). Make sure to choose

with existing pool pipe size (1.5 inches or 2 inches), and discard other

unnecessary joints.

For articulated connections, you will also use the included 2" to 1.5"

reducer bushing to accommodate the flow switch. For 1½"

installations,be sure to pay attention to any new or other measurements

before cutting the tube.

Other manuals for BLH Series

1

Table of contents

Other Blueworks Portable Generator manuals

Popular Portable Generator manuals by other brands

Teknoware

Teknoware TKT66 Installation and maintenance instructions

Wacker Neuson

Wacker Neuson GV 7000A Operator's manual

Briggs & Stratton

Briggs & Stratton 14000 Series installation instructions

Baumer

Baumer GTR 9 Mounting and operating instructions

Champion

Champion 100460 Operator's manual

Wanco

Wanco WSP12 Operator's manual

DANA

DANA Brevini P1510 Series Assembly instructions

Juntek

Juntek JDS2800-60M quick start guide

Lincoln Electric

Lincoln Electric OUTBACK 200 CE Operator's manual

CAMPAGNOLA

CAMPAGNOLA POWER 58 quick guide

Homelite

Homelite HGCA4500 Series quick start guide

Wacker Neuson

Wacker Neuson GP 4000 Operator's manual