Fike SRX User manual

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Reverse Acting Rupture Disc Assemblies

Rupture Disc Models: SRX, SRL, Axius, ATLAS, AGT

Holder Models: SRX, SRL/SRL , XL/XL , ATLAS/ATLAS-L

704 SW 10th Street · P. . Box 610 · Blue Springs, Missouri 64013-0610 U.S.A. · (816) 229-3405 · www.fike.com

Page 1

06

-

251

-

1

WARNING

• Read these instructions carefully and completely before

attempting to unpack, install or service the rupture disc

and holder.

• Do not vent a rupture disc assembly to an area where it

would endanger personnel.

• Install the rupture disc assembly in such a way that

equipment in the area will not prevent rupture disc from

opening or be damaged by system discharge.

• A baffle plate on the outlet end of vent piping does N T

necessarily prevent potentially dangerous discharge.

• Piping should be braced to absorb shock when the rupture

disc ruptures.

• Install the enclosed DANGER sign in a conspicuous

location near the zone of potential danger.

• 1” (DN25) Axius is not suitable for liquid systems at burst

pressures less than 20 PSIG (1.38 BARG) with an inlet

piping length greater than 10 IN (25 cm)

• ¾” (DN20) Axius is not suitable for liquid systems at burst

pressures less than 30 PISG (2.07 BARG) with an inlet

piping length greater than 8 IN (20 cm)

• ATLAS not suitable for liquid systems in sizes 14” and

larger.

• Spiral wound gaskets are not suitable for the following

sizes and flange ratings:

• 1” (DN20 & DN25) – All flange ratings

• 1.5” (DN40) – 900-2500 ANSI and JIS 40k, 63k

• 2” (DN50) – 900-2500 ANSI and JIS 30k, 40k, 63k

• 3” (DN80) – JIS 30k, 40k, 63k

• 4” (DN100) – JIS 30k, 40k, 63k

• If the rupture disc features a fluoropolymer liner, do not

remove this component.

NOTE: Rupture disc specifications and year of manufacture

can be found on the rupture disc tag.

TABLE 1 - DISC/HOLDER MODEL COMPATIBILITY

Disc

Model

Holder Model

SRX SRL/

SRL

XL/

XL

ATLAS/

ATLAS-L

SRX

SRL *

Axius **

ATLAS

AGT

*1.5" SRL disc not compatible with 1.5” XL/XL holder

**1.5" Axius disc not compatible with 1.5” SRL/SRL holder

INSPECTION/PREPARATION

A. NEW RUPTURE DISCS

WARNING: Always handle the rupture disc with extreme

caution. Nicks, dents, scratches or foreign material may result

in leakage or affect the burst pressure. Read the rupture disc

tag completely before installing to confirm that the size and

type are correct for your system.

1. Carefully remove the rupture disc from its packaging

container.

2. Inspect the rupture disc for damage. Look for dents,

scratches or dings in the seat area or dents in the dome of

the rupture disc (See Figure 1).

3. If foreign material is present, carefully clean the rupture

disc with a solvent that is compatible with your media.

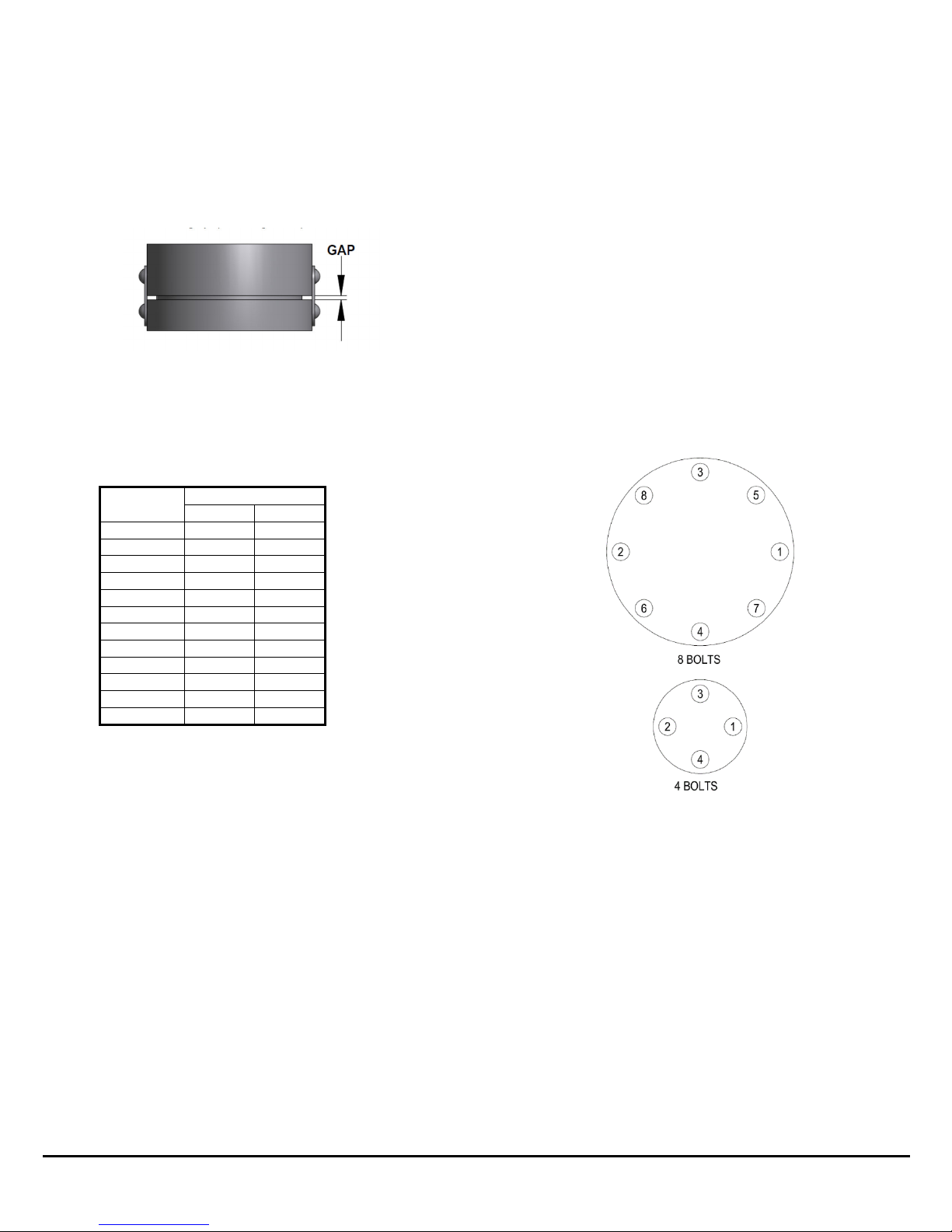

Figure 1 - C eck for Damage

NOTE: Handle rupture disc olders wit care. Damage to

t e rupture disc older could affect t e performance of t e

rupture disc. Do not install or use a rupture disc t at as

been damaged!

B. NEW HOLDER

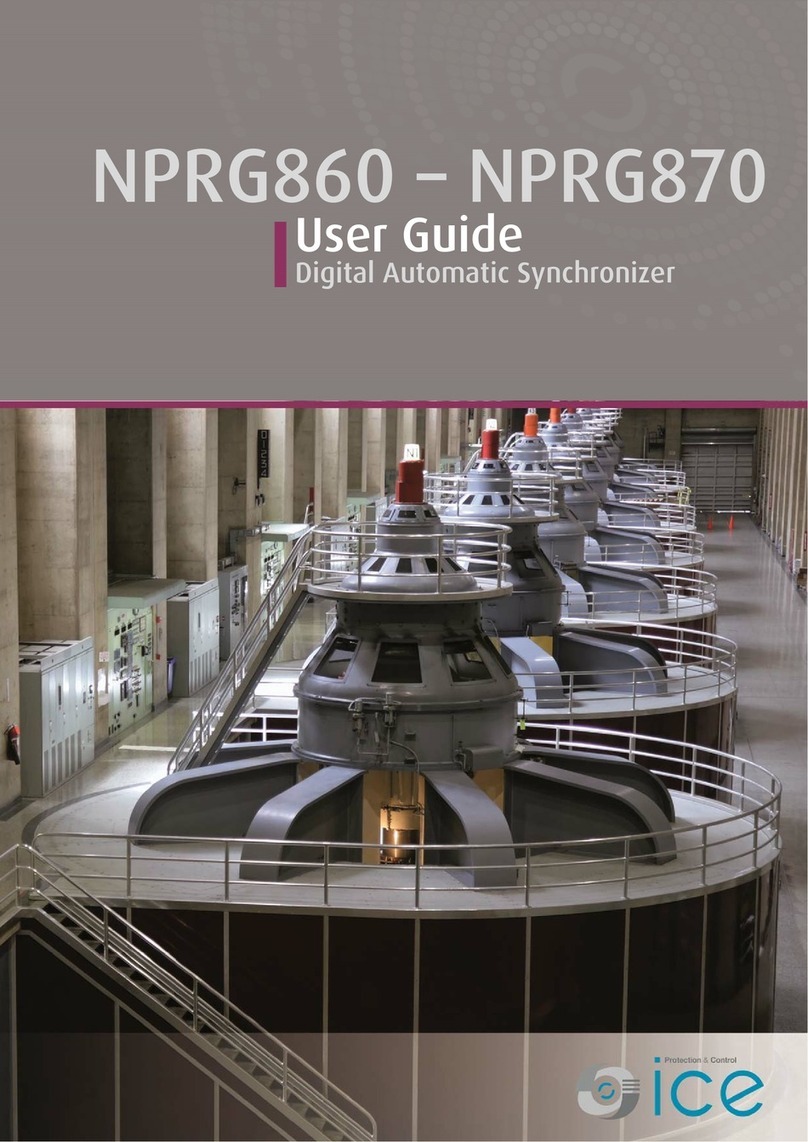

1. Carefully take the rupture disc holder apart by removing

the sideclips or capscrews and discard the white shipping

protector (See Figure 2).

2. Inspect the seat area for scratches, dents, nicks or dirt.

Flaws may adversely affect sealing and burst pressure.

3. If necessary, clean dust or dirt on the seat area with a

solvent that is compatible with your media.

Figure 2 - Insert Holder (Top) and Pre-torqueable Holder

C. EXISTING HOLDER

1. For insert style holders, carefully remove the rupture disc

assembly from piping.

2. Separate rupture disc holder components.

3. Remove old rupture disc.

4. Inspect the seat area of the rupture disc holder. Look for

scratches, nicks, corrosion or deposits left from the media.

704 SW 10th Street · P. . Box 610 · Blue Springs, Missouri 64013-0610 U.S.A. · (816) 229-3405 · www.fike.com

Page 2

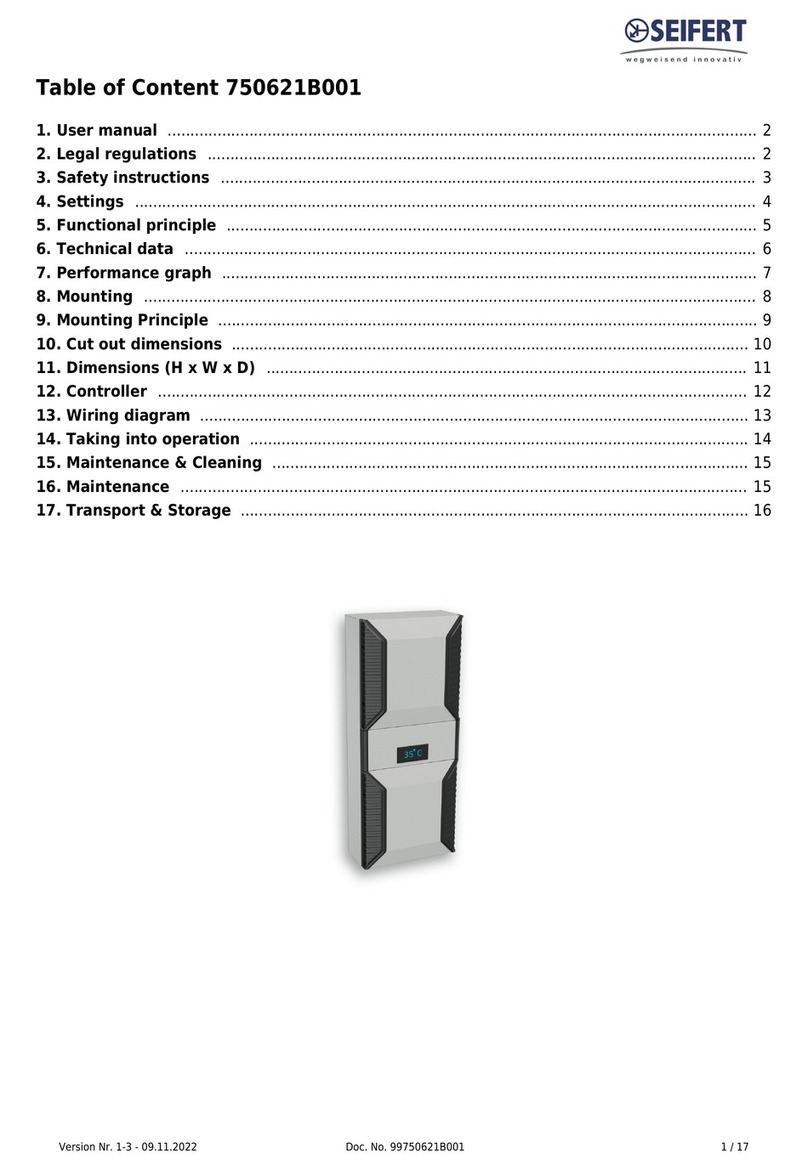

5. Check to make sure the gasket faces of the assembly are

flat by placing a straight edge across the face. If faces are

not flat, holder is not suitable for use (See Figure 3).

Figure 3 - Measuring for Flatness

6. If necessary, clean the seat area with a solvent that is

compatible with your media. If this does not remove dirt,

hand polish the seat area with Scotch Brite fine emery

cloth or #0000 steel wool. D N T MACHINE THE

RUPTURE DISC H LDER! If scratches, nicks, corrosion,

or deposits cannot be removed by hand, contact the

factory.

ASSEMBLY

WARNING: Before attempting to assemble the rupture disc

and rupture disc holder, confirm that the seat area of the

rupture disc is designed to fit the rupture disc holder.

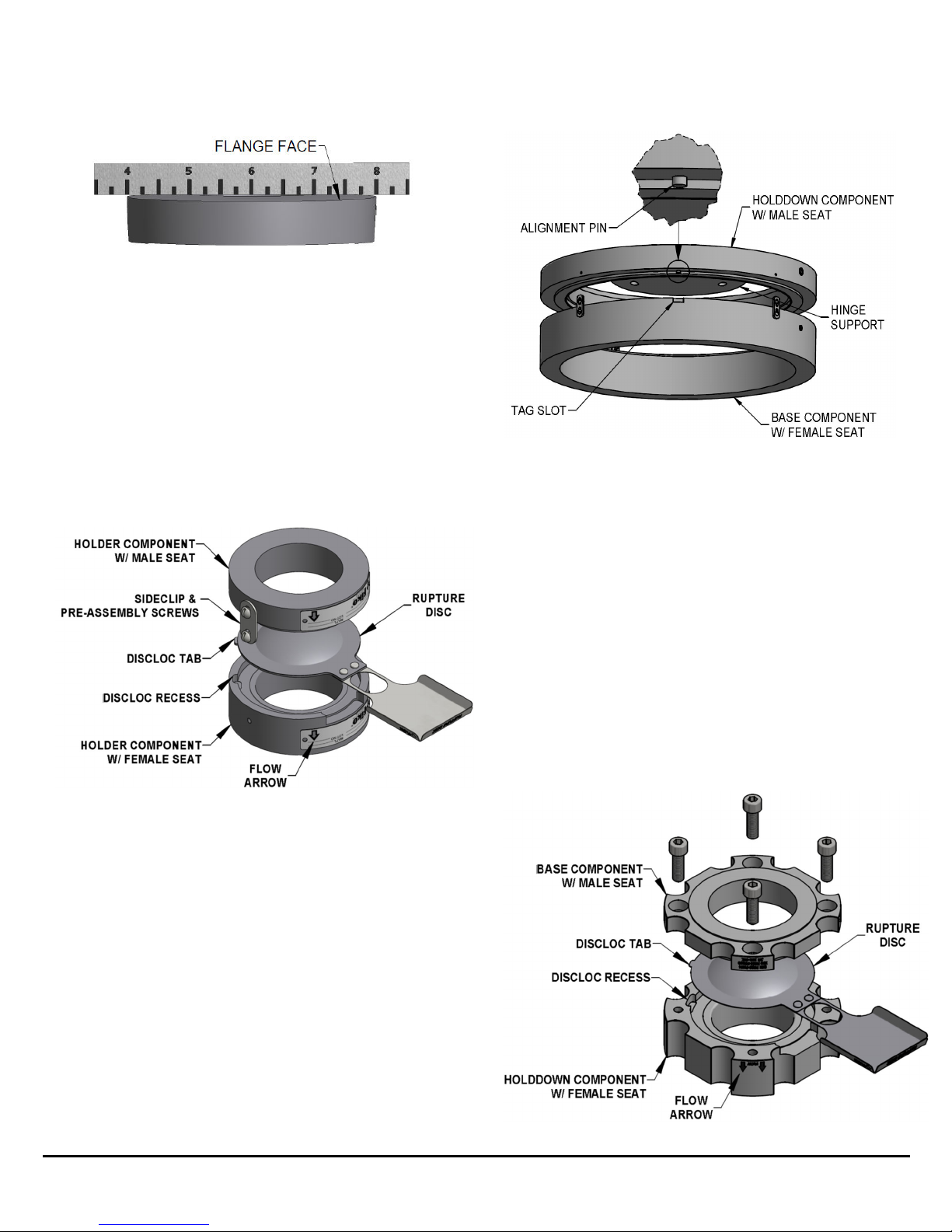

1. Place holder component with female seat on a work

surface (See Figures 4, 5, & 6).

Figure 4 - Insert Holder

2. If the holder was supplied with an optional o-ring groove,

install an o-ring into the groove of the component with the

female seat. Note: Use of an o-ring is for improved sealing

and is not required for proper function of the rupture disc

assembly. Do not install an o-ring unless the holder is

designed to accept these components by Fike!

3. Place rupture disc into holder component with female seat

with flow arrow on tag pointing in the same direction as

holder component with female seat flow arrow.

DiscLoc

TM

tab, if present, must seat properly in recess.

4. If the holder was supplied with an optional o-ring groove,

install an o-ring into the groove of the component with the

male seat. Note: Use of an o-ring is for improved sealing

and is not required for proper function of the rupture disc

assembly. Do not install an o-ring unless the holder is

designed to accept these components by Fike!

5. Carefully align and place holder component with male seat

onto rupture disc with flow arrow in the same direction as

disc and holder component with female seat flow arrows.

CAUTION: Be careful to not allow the male seat

component to strike or damage the dome of the rupture

disc!

Figure 5 – Alignment pin fitting in tag slot. (ATLAS sizes

14” and larger”)

WARNING: For ATLAS sizes 14” and larger, ensure that

the alignment pin in the holddown fits into the tag slot of

base (see Figure 5) and check the gap (see Figure 7).

Fragmentation or leaking can occur if this feature is not

aligned properly.

6. Rotate component with male seat to align sideclip holes.

7. If holder configuration is Insert, install sideclips and tighten

securely.

8. If holder configuration is TQ, turn assembly over to access

capscrew holes (depending on design).

Note: It may be beneficial to move/tilt or support the

holder to first install a few capscrews evenly around the

perimeter before turning the assembly over.

9. If holder configuration is TQ or TQ+, lubricate uncoated

capscrews with a light oil such as SAE grade 20. Lubricate

both the threads and the underside of the head. Install

lubricated capscrews and tighten until recessed and snug

in the holder (see Figure 6).

704 SW 10th Street · P. . Box 610 · Blue Springs, Missouri 64013-0610 U.S.A. · (816) 229-3405 · www.fike.com

Page 3

Figure 6 – Pre-torqueable Holder

(TQ+ configuration s own)

10. Check gap between base and holddown. The gap must be

the same size on all sides of the assembly. This can be

assured by measuring the distance between the holddown

and base at various places around the circumference of

the assembly. Adjust pre-assembly screws if necessary to

provide an even gap (See Figure 7).

Figure 7 - Gap Inspection

11. If holder configuration is TQ or TQ+, torque capscrews to

values shown in Table 2 using crisscross pattern in 20%

increments until the full torque is achieved on all

capscrews.

Note: Torque values are based on a nut factor, K = 0.20.

12. If holder configuration is TQ or TQ+, reconfirm the gap per

step 10 after the capscrews are torqued per Table 2.

INSTALLATION

1. Place gaskets on top and bottom of assembly. Gaskets

subject to relaxation or cold flow are not recommended for

use with the holder assembly. Spiral wound gaskets are

not suitable for certain sizes and flange ratings. Reference

warning notes on page 1.

2. Carefully slide rupture disc assembly between companion

flanges.

WARNING: For installations directly under a pressure relief

valve that utilize a spool/spacer, ensure spool/spacer is

installed between the outlet of the holder and inlet of the

pressure relief valve. SRL , XL , and ATLAS-L holder

sizes 12” and smaller are not suitable for direct-coupling to a

pressure relief valve; they must utilize a high-profile holddown,

spool, or a suitable spacer. Atlas holders 14” and larger

require a spool piece if under a pressure relief valve. Refer to

Fike Technical Bulletin TB8105 for code requirements.

WARNING: Double check the orientation of the rupture disc.

Verify flow arrows on the holder and disc tag are pointed in the

same direction as process flow.

3. If necessary, clean threads on studs and nuts. Wire

brushing is usually sufficient. il studs with a light oil such

as SAE grade 20. Do not use studs and nuts that show

evidence of galling.

4. Finger-tighten flange studs and nuts.

5. Refer to Appendix A to obtain torque value. Locate

nominal disc size and flange rating. This is the

recommended torque value.

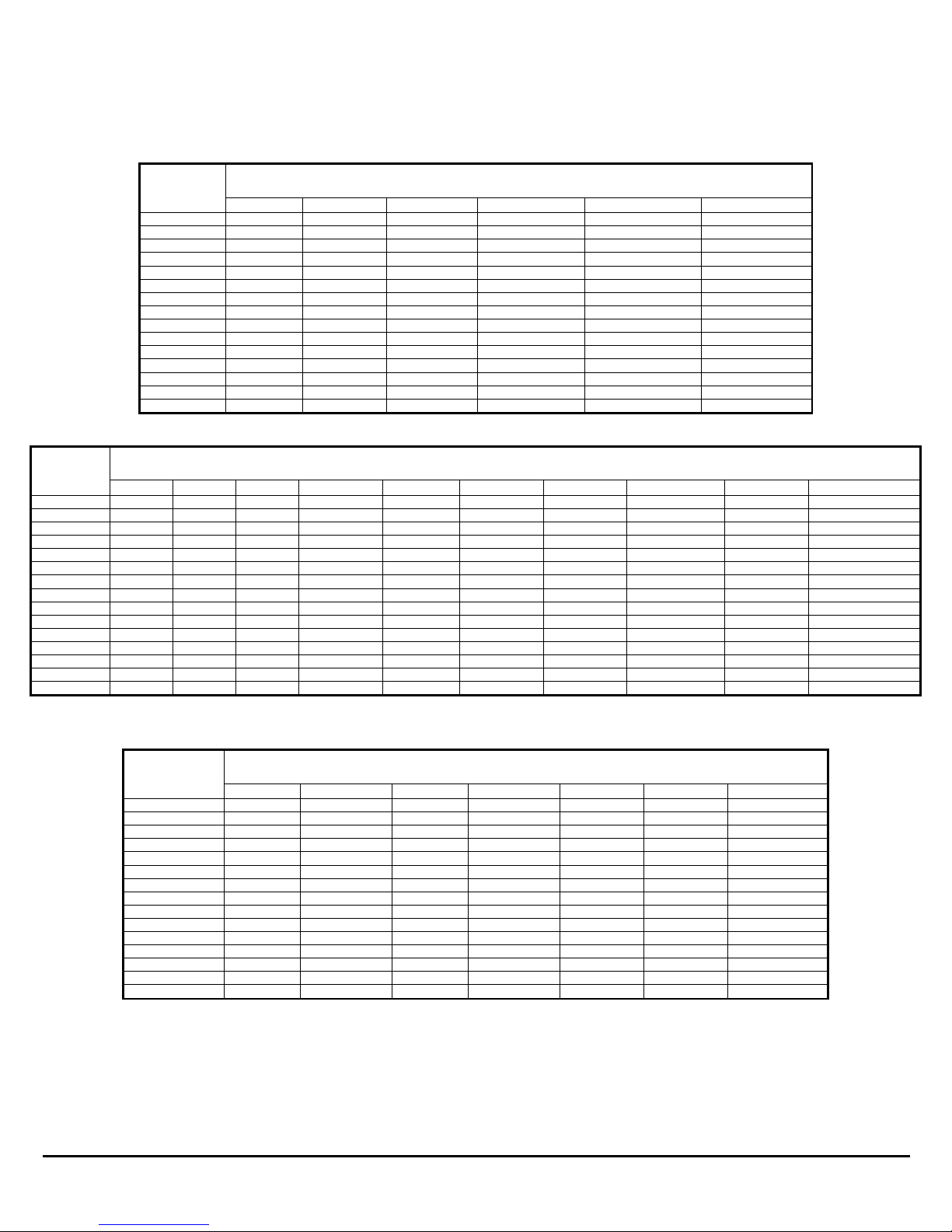

6. Using the crisscross pattern shown in Figure 8, apply

torque in 4 steps of 25% increments. For example, if the

torque required from Appendix A is 100 ft-lb, the torque

should be applied in 25 ft-lb increments. Apply 25 ft-lb to

each nut, then 50 ft-lb, then 75 ft-lb, etc. For larger

quantities of bolts than shown below, use a similar

crisscross pattern.

NOTE: Follow the torque instructions in this document

unless a specific torque requirements is stated on the

Rupture Disc and/or Rupture Disc Holder Tag.

Figure 8 - Bolt Tig tening Sequence

7. After recommended torque has been achieved, perform a

final tightening in a clockwise bolt-to-bolt fashion to ensure

that all studs have equal loading.

CHECK GAP BETWEEN BASE AND H LDD WN AFTER

EACH T RQUE STEP. MAINTAIN AN EQUAL DISTANCE

BETWEEN C MPANI N FLANGE FACES N ALL SIDES.

8. Experience has shown that, in some installation

conditions, it may be necessary to re-torque the flange

bolting after the system has operated through normal

pressure and temperature cycles. Under normal operating

conditions, the rupture disc is recommended to be

replaced yearly. Severe operating conditions may require

that the rupture disc be replaced more often.

Capscrew

Size

Torque

ft-lb N-m

1/4” 4 5

5/16” 8 11

3/8” 12 16

7/16” 20 27

1/2” 30 41

5/8” 60 81

3/4” 100 136

7/8” 160 217

M8 10 14

M10 17 23

M12 29 39

M24 221 300

Table 2

–

TQ & TQ+ Capscrew Torque

704 SW 10th Street · P. . Box 610 · Blue Springs, Missouri 64013-0610 U.S.A. · (816) 229-3405 · www.fike.com

Page 4

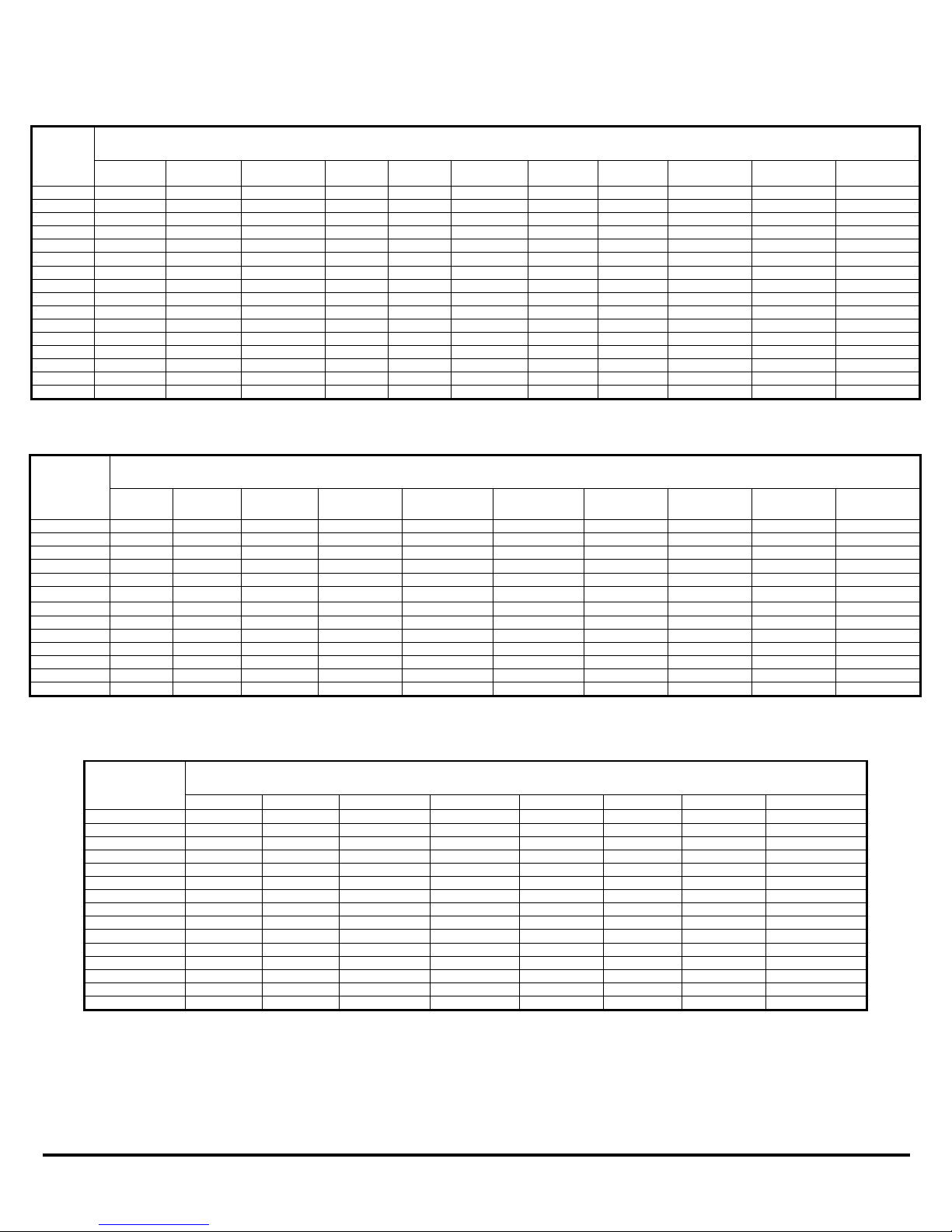

Appendix A – Stud Torque Values

NOTE: Torque values in Appendix A are based on a nut factor K= 0.2. Adjustment to the torque should be considered if the installation

utilizes bolting/lubrication with a nut factor other than K= 0.2. The following expression may be used for correction:

Equation 1: T

2

= (T

1

/K

1

)*K

2

where T

1

and K

1

are the Fike default torque and nut factor values.

NOTE: Torque values in Tables 1 to 3 are recommended values, but may be increased up to 50% to achieve an increased gasket seal.

If the torque values are unsatisfactory, consult factory.

Nominal

Pipe Size

(in)

Torque by Flange Rating

(ft-lb [N-m])

150 ANSI 300 ANSI 600 ANSI 900 ANSI 1500 ANSI 2500 ANSI

.75 30 [41] 60 [81] 60 [81] N/A N/A N/A

1” 30 [41] 60 [81] 60 [81] 160 [217] 160 [217] 160 [217]

1.5 30 [41] 100 [136] 100 [136] 245 [332] 245 [332] 355 [481]

2 60 [81] 60 [81] 60 [81] 160 [217] 160 [217] 245 [332]

3 60 [81] 100 [136] 100 [136] 160 [217] 355 [481] 500 [678]

4 60 [81] 100 [136] 160 [217] 355 [481] 500 [678] 800 [1,085]

6 100 [136] 100 [136] 245 [332] 355 [481] 680 [922] 2,200 [2,983]

8 100 [136] 160 [217] 355 [481] 680 [922] 1,100 [1,491] 2,200 [2,983]

10 160 [217] 245 [332] 500 [678] 680 [922] 2,000 [2712] 4,400 [5,966]

12 160 [217] 355 [481] 500 [678] 680 [922] 2,200 [2,983] 5,920 [8,026]

14 245 [332] 355 [481] 680 [922] 800 [1,085] 3,180 [4,312] N/A

16 245 [332] 500 [678] 800 [1085] 1,100 [1,491] 4,400 [5,966] N/A

18 355 [481] 500 [678] 1100 [1491] 2,000 [2712] 5,920 [8,026] N/A

20 355 [481] 500 [678] 1100 [1491] 2,200 [2,983] 7,720 [10,467] N/A

24 500 [678] 800 [1085] 2000 [2712] 4,400 [5,966] 11,651 [15,797] N/A

Nominal

Pipe Size

(in [mm])

Torque by Flange Rating

(ft-lb [N-m])

PN 6 PN 10 PN 16 IS PN 20 PN 25 PN 40 IS PN 50 DIN PN 63/64 DIN PN 100 IS PN 100/110

.75 [DN20] 23 [31] 28 [37] 28 [37] 32 [44] 45 [61] 45 [61] 60 [82]

N/A

N/A

60 [82]

1” [DN 25] 23 [31] 28 [37] 28 [37] 32 [44] 45 [61] 45 [61] 60 [82] 60 [82] 60 [82] 60 [82]

1.5 [DN 40] 28 [37] 37 [50] 37 [50] 32 [44] 84 [114] 84 [114] 105 [142] 105 [142] 105 [142] 105 [142]

2 [DN 50] 45 [61] 60 [82] 60 [82] 60 [82] 121 [164] 121 [164] 60 [82] 151 [205] 181 [246] 60 [82]

3 [DN 80] 60 [82] 30 [41] 30 [41] 60 [82] 84 [114] 84 [114] 105 [142] 105 [142] 126 [171] 105 [142]

4 [DN 100] 121 [164] 60 [82] 60 [82] 60 [82] 105 [142] 105 [142] 105 [142] 173 [235] 195 [264] 173 [235]

6 [DN 150] 84 [114] 105 [142] 105 [142] 105 [142] 189 [256] 189 [256] 105 [142] 433 [587] 289 [391] 260 [352]

8 [DN 200] 84 [114] 105 [142] 70 [95] 105 [142] 173 [235] 195 [264] 173 [235] 410 [555] 410 [555] 372 [505]

10 [DN 250] 115 [157] 144 [196] 173 [235] 173 [235] 347 [470] 385 [523] 260 [353] 693 [939] 756 [1,025] 520 [705]

12 [DN 300] 144 [196] 144 [196] 173 [235] 173 [235] 336 [455] 373 [505] 373 [505] 650 [881] 768 [1,041] 520 [705]

14 [DN 350] 192 [261] 144 [196] 173 [235] 260 [352] 466 [632] 513 [695] 372 [504] 875 [1,187] 1,094 [1,484] 700 [950]

16 [DN 400] 192 [261] 231 [314] 260 [353] 260 [353] 650 [881] 709 [961] 520 [705] 1,024 [1,388] N/A 819 [1,110]

18 [DN 450] 249 [337] 239 [323] 268 [364] 373 [505] 624 [846] 680 [922] 520 [705] N/A N/A 1,119 [1,517]

20 [DN 500] 249 [337] 298 [405] 373 [506] 372 [504] 624 [846] 737 [999] 520 [705] N/A N/A 1,120 [1,518]

24 [DN 600] 378 [512] 425 [576] 520 [705] 520 [705] 907 [1,230] 1,134 [1,537] 819 [1,110] N/A N/A 2,016 [2,733]

Nominal Pipe

Size (in [mm])

Torque by Flange Rating

(ft-lb [N-m])

JIS 5 JIS 10 JIS 16 JIS 20 JIS 30 JIS 40 JIS 63

.75 [DN20] N/A 28 [37] 28 [37] 60 [82] N/A N/A N/A

1” [DN 25] 23 [31] 37 [50] 37 [50] 60 [82] 60 [82] 60 [82] 75 [102]

1.5 [DN 40] 28 [37] 37 [50] 37 [50] 84 [114] 105 [142] 105 [142] 115 [157]

2 [DN 50] 45 [61] 60 [82] 60 [82] 60 [82] 60 [82] 60 [82] 75 [102]

3 [DN 80] 60 [82] 30 [41] 30 [41] 105 [142] 105 [142] 105 [142] 115 [157]

4 [DN 100] 60 [82] 60 [82] 75 [102] 105 [142] 115 [157 115 [157] 173 [235]

6 [DN 150] 84 [114] 105 [142] 77 [104] 115 [157] 126 [171] 157 [214] 289 [391]]

8 [DN 200] 105 [142] 70 [95] 77 [104] 159 [215] 173 [235] 217 [294] 372 [505]

10 [DN 250] 144 [196] 159 [215] 173 [235] 308 [418] 385 [523] 385 [523] 756 [1,025]

12 [DN 300] 144 [196] 119 [161] 130 [176] 298 [404] 373 [505] 447 [607] 709 [961]

14 [DN 350] 212 [287] 159 [215] 217 [294] 465 [631] 465 [631]] 558 [757] 1,021 [1,385]

16 [DN 400] 212 [287] 231 [314] 289 [392] 591 [801] 709 [961] 709 [961] 1,102 [1,495]

18 [DN 450] 273 [370] 239 [323] 298 [404] 567 [769] N/A N/A N/A

20 [DN 500] 273 [370] 298 [404] 372 [504] 567 [769] N/A N/A N/A

24 [DN 600] 378 [512] 394 [534] 472 [641] 756 [1,025] N/A N/A N/A

Table 1

–

Stud Torque Values

–

ASME

(SRX, SRL

/SRLO

, XL

/XLO

)

Table

2

–

Stud Torque Values

–

EN/

ISO/DIN (SRX, SRL

/SRLO

, XL

/XLO

)

Table 3

–

Stud Torque Values

–

JIS

(SRX, SRL

/SRLO

, XL

/XLO

)

704 SW 10th Street · P. . Box 610 · Blue Springs, Missouri 64013-0610 U.S.A. · (816) 229-3405 · www.fike.com

Copyright © Fike Corporation All Rights Reserved.

P/N 06-251-1-26 May, 2018 Specifications are subject to change without notice. Page 5

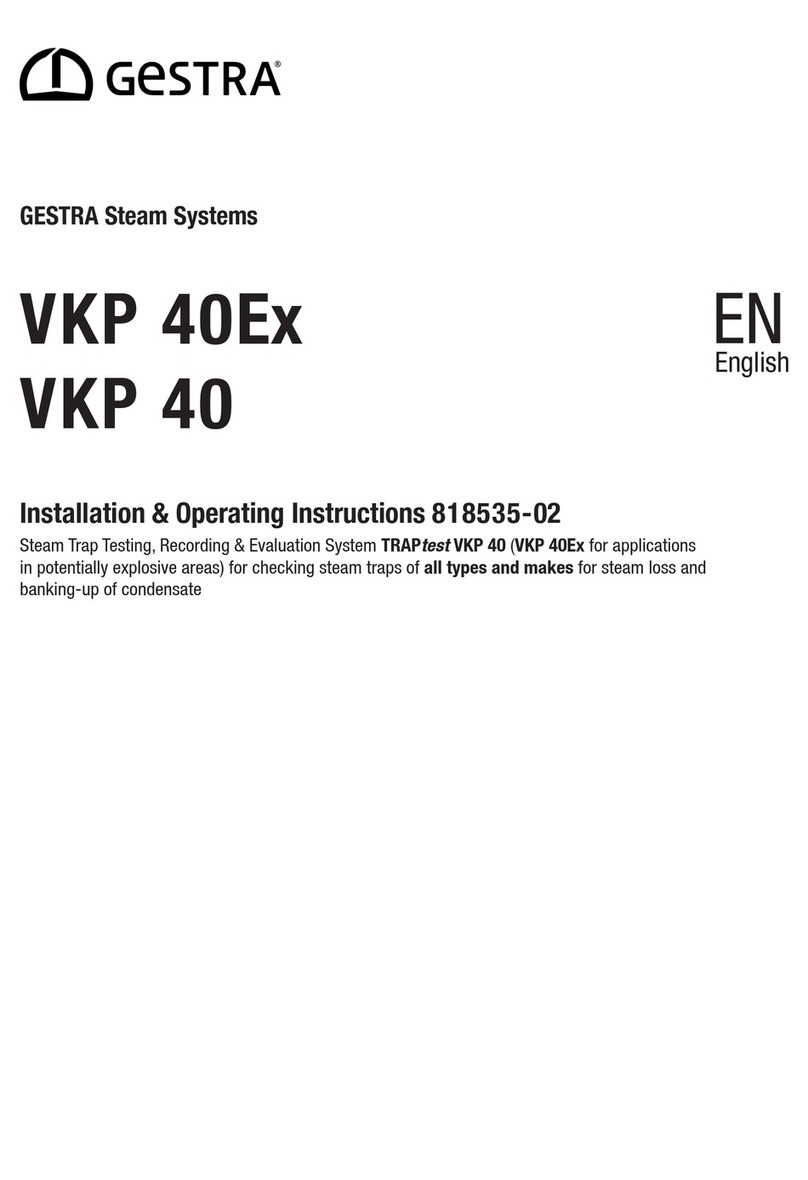

NOTE: Torque values for Atlas sizes 14” and larger in Tables 4 to 6 were determined by considering ASME PCC-1 and ASME Section

VIII Division 1 Mandatory Appendix II guidelines. Torque values in Appendix A are based on a nut factor K= 0.2. Adjustment to the

torque should be considered if the installation utilizes bolting/lubrication with a nut factor other than K= 0.2. The following expression

may be used for correction:

Equation 1: T

2

= (T

1

/K

1

)*K

2

where T

1

and K

1

are the Fike default torque and nut factor values.

Nominal

Pipe

Size (in)

Torque by Flange Rating

(ft-lb [N-m])

150

ANSI

300

ANSI

600

ANSI

900

ANSI

1500

ANSI

2500

ANSI

Series B

75

Series B

150

Series B

300

Series A

150

Series A

300

1” 30 [41] 60 [81] 60 [81] 160 [217] 160 [217] 160 [217] N/A N/A N/A N/A N/A

1.5 30 [41] 100 [136] 100 [136] 245 [332] 245 [332] 355 [481] N/A N/A N/A N/A N/A

2 60 [81] 60 [81] 60 [81] 160 [217] 160 [217] 245 [332] N/A N/A N/A N/A N/A

3 60 [81] 100 [136] 100 [136] 160 [217] 355 [481] 500 [678] N/A N/A N/A N/A N/A

4 60 [81] 100 [136] 160 [217] 355 [481] 500 [678] 800 [1,085] N/A N/A N/A N/A N/A

14 459 [622] 682 [925] 1,323 [1,794] N/A N/A N/A N/A N/A N/A N/A N/A

16 459 [622] 968 [1,312] 1,581 [2,144] N/A N/A N/A N/A N/A N/A N/A N/A

18 682 [925] 968 [1,312] 2,275 [3,084] N/A N/A N/A N/A N/A N/A N/A N/A

20 682 [925] 968 [1,312] 1,593 [2,160] N/A N/A N/A N/A N/A N/A N/A N/A

24 968 [1,312] 984 [1,334] 1,947 [2,640] N/A N/A N/A N/A N/A N/A N/A N/A

26 N/A N/A N/A N/A N/A N/A N/A 189 [256] 871 [1,181] 484 [656] 1,365 [1,851]

28 N/A N/A N/A N/A N/A N/A N/A 159 [216] 527 [715] 419 [568] 1,493 [2,024]

30 N/A N/A N/A N/A N/A N/A N/A 154 [209] 722 [979] 418 [567] 1,556 [2,110]

32 N/A N/A N/A N/A N/A N/A N/A 150 [203] 958 [1,299] 703 [953] 1,968 [2,668]

36 N/A N/A N/A N/A N/A N/A N/A 260 [353] 1,365 [1,851] 703 [953] 2,652 [3,596]

42 N/A N/A N/A N/A N/A N/A N/A 321 [435] 2,020 [2,739] 703 [953] 1,593 [2,160]

Nominal

Pipe Size

(in [mm])

Torque by Flange Rating

(ft-lb [N-m])

PN

1, 2 & 6 PN 10 PN 16 IS

PN 20 PN 25 PN 40 IS

PN 50

DIN

PN 63/64

DIN

PN 100

IS

PN 100/110

1” [DN 25] 23 [31] 28 [37] 28 [37] 32 [44] 45 [61] 45 [61] 60 [82] 60 [82] 60 [82] 60 [82]

1.5 [DN 40] 28 [37] 37 [50] 37 [50] 32 [44] 84 [114] 84 [114] 105 [142] 105 [142] 105 [142] 105 [142]

2 [DN 50] 45 [61] 60 [82] 60 [82] 60 [82] 121 [164] 121 [164] 60 [82] 151 [205] 181 [246] 60 [82]

3 [DN 80] 60 [82] 30 [41] 30 [41] 60 [82] 84 [114] 84 [114] 105 [142] 105 [142] 126 [171] 105 [142]

4 [DN 100] 121 [164] 60 [82] 60 [82] 60 [82] 105 [142] 105 [142] 105 [142] 173 [235] 195 [264] 173 [235]

14 [DN 350] N/A 224 [304] 349 [473] 575 [780] 612 [830] 893 [1,211] 816 [1,106] 1,259 [1,707] 2,126 [2,882] 1,333 [1,807]

16 [DN 400] N/A 310 [420] 460 [624] 575 [780] 781 [1,059] 963 [1,306] 1,116 [1,513] 1,646 [2,232] N/A 1,646 [2,232]

18 [DN 450] N/A 240 [325] 288 [390] 816 [1,106] 670 [908] 815 [1,105] 1,116 [1,513] N/A N/A 2,313 [3,136]

20 [DN 500] N/A 277 [376] 354 [480] 816 [1,106] 608 [824] 1,058 [1,434] 1,116 [1,513] N/A N/A 1,948 [2,641]

24 [DN 600] N/A 374 [507] 460 [624] 1,116 [1,513] 807 [1,094] 1,326 [1,798] 1,085 [1,471] N/A N/A 1,864 [2,527]

28 [DN 700] N/A N/A 483 [655] N/A 775 [1,051] N/A N/A N/A N/A N/A

32 [DN 800] N/A N/A 593 [804] N/A N/A N/A N/A N/A N/A N/A

36 [DN 900] N/A N/A 593 [804] N/A N/A N/A N/A N/A N/A N/A

Nominal Pipe

Size (in [mm])

Torque by Flange Rating

(ft-lb [N-m])

JIS 2 JIS 5 JIS 10 JIS 16 JIS 20 JIS 30 JIS 40 JIS 63

1” [DN 25] N/A 23 [31] 37 [50] 37 [50] 60 [82] 60 [82] 60 [82] 75 [102]

1.5 [DN 40] N/A 28 [37] 37 [50] 37 [50] 84 [114] 105 [142] 105 [142] 115 [157]

2 [DN 50] N/A 45 [61] 60 [82] 30 [41] 60 [82] 60 [82] 60 [82] 75 [102]

3 [DN 80] N/A 60 [82] 30 [41] 38 [51] 105 [142] 105 [142] 105 [142] 115 [157]

4 [DN 100] N/A 60 [82] 60 [82] 75 [102] 105 [142] 115 [157] 115 [157] 173 [235]

14 [DN 350] N/A N/A 309 [419] 612 [830] 816 [1,106] N/A N/A N/A

16 [DN 400] N/A N/A 387 [525] 816 [1,106] 816 [1,106] N/A N/A N/A

18 [DN 450] N/A N/A 387 [525] 735 [997] 735 [997] N/A N/A N/A

20 [DN 500] N/A N/A 387 [525] 816 [1,106] 816 [1,106] N/A N/A N/A

24 [DN 600] N/A N/A 571 [774] 1,111 [1,506] 1,185 [1,607] N/A N/A N/A

26 [DN 650] N/A N/A 775 [1,051] N/A N/A N/A N/A N/A

28 [DN 700] N/A N/A 735 [997] N/A N/A N/A N/A N/A

30 [DN 750] N/A N/A 816 [1,106] N/A N/A N/A N/A N/A

32 [DN 800] N/A N/A 735 [997] N/A N/A N/A N/A N/A

36 [DN 900] N/A N/A 775 [1,051] N/A N/A N/A N/A N/A

Table 4

–

Stud Torque Values

–

ASME

(

ATLAS/ATLAS

-

LO

)

Table 5

–

Stud Torque Values

–

EN/ISO/DIN

(

ATLAS/ATLAS

-

LO

)

Table 6

–

Stud Torque Values

–

JIS

(

ATLAS/ATLAS

-

LO

)

Other manuals for SRX

1

This manual suits for next models

8

Table of contents

Other Fike Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Jäger

Jäger Z80-M450.61 S5 manual

dunkermotoren

dunkermotoren AMETEK BG 75 dMove Translation of the original function and connection guide

Baileigh

Baileigh Hare&Forbes MSS-14H Operator's manual

GESTRA

GESTRA VKP 40Ex Installation & operating instructions

LSI

LSI GS Series installer and user manual

CTS

CTS ART 100 instruction manual