BMI Racing Copperhead 12 User manual

1. .050”, 1/16” and 3/32” Allen wrenches

2. A #2 Phillips Screwdriver

3. 3/16” and 11/32” nut drivers

4. A pair of needle nose pliers

5. A pair of slip join pliers

6. A hobby knife

7. A ruler or calipers

8. A file

9. A soldering iron

10. Diff Grease

11. Electric Motor Cleaner Spray

12. 50wt silicon shock oil (for center shock)

13. 10,000wt silicon diff oil (for damper tubes)

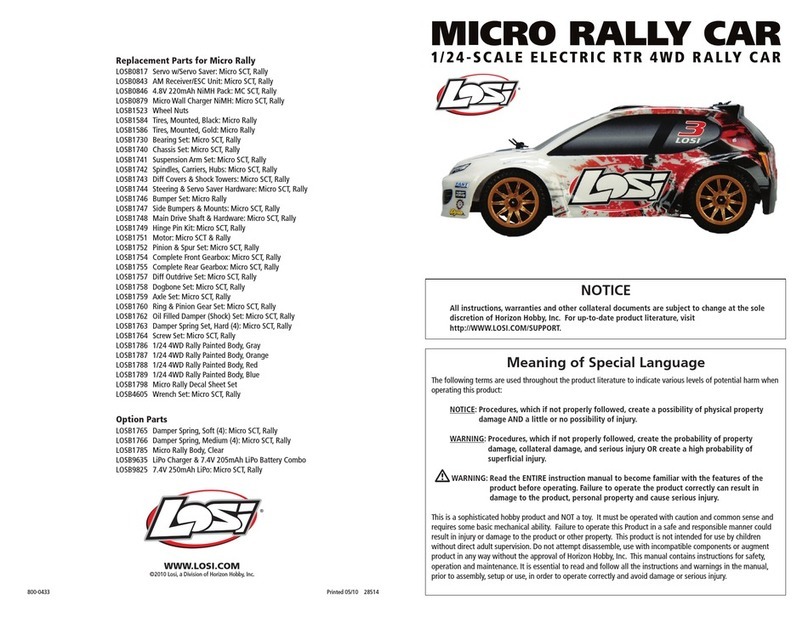

Items needed to assemble your

Copperhead 12

1. Two channel surface Radio system

2. A mini servo*

3. 3.7 volt LiPo battery packs

4. A battery charger

5. A Brushless electronic speed control

6. Brushless electric motor

7. A 64 pitch pinion gear

8. A small servo saver.

9. 1/12

th

scale body

10. 1/12

th

scale tires

Items needed to operate your Copperhead 12

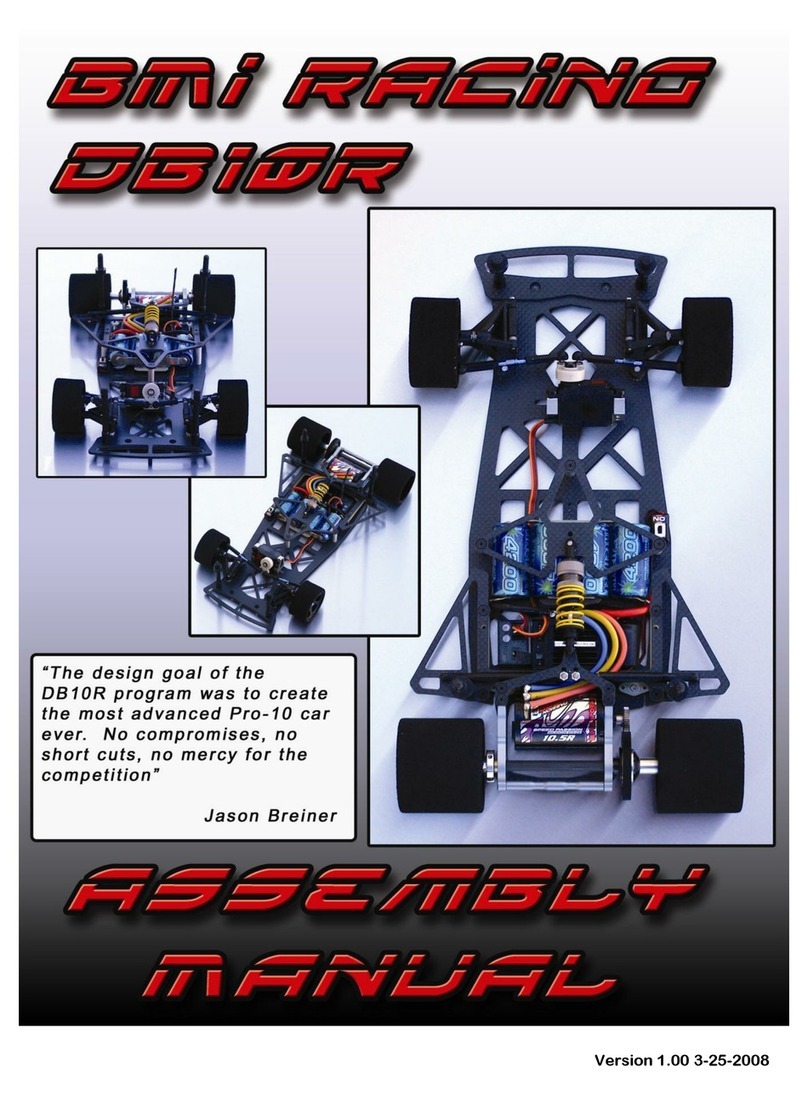

Message from BMI Racing

The Copperhead 12 is a revolutionary step forward in 1/12th scale car design. We spent the last year

refining the proven DB12RR LiPo edition racing machine. The goal of the Copperhead 12 project was to take

the best features of the DB12RR and make a new type of rear suspension that will set new standards for

speed, versatility and ease of use. The Copperhead 12 was designed to be race tuned for any traction level. It

has been proven on lower traction asphalt tracks all the way to the highest traction carpet tracks.

Here at BMI Racing, we put quality before quantity. Unlike a lot of cars available, we make all of our parts in

house. From pivot balls to carbon fiber components, every part is guaranteed to be the highest quality. We do

not sacrifice anywhere on our products. Every part is inspected for quality.

Please read through the instruction manual carefully. Even if you are an experienced R/C racer, there are

some details about the Copperhead 12 that are different than other cars. To get the most out of your kit you

must have it assembled correctly. Have fun building and racing your new race car. As always, we here at BMI

Racing appreciate your support

With Regards,

Jason Breiner

BMI Racing

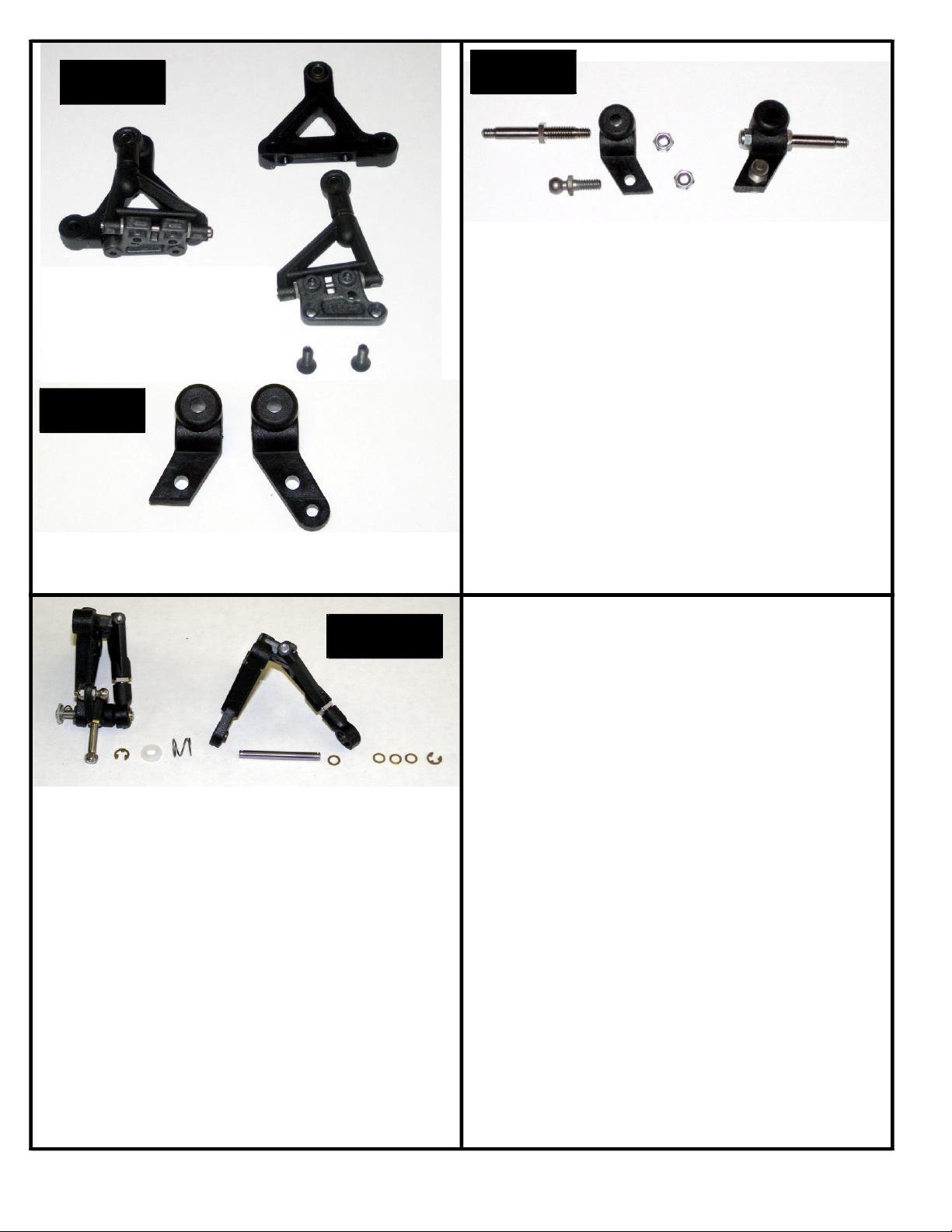

Front suspension assembly

Locate your lower front suspension arms and

the hard anodized alloy pivot balls. Note that the

arms are symmetrical. At this time you must pick

which one will become the left and right arms as this

will determine how you pop the pivot ball into the

arms.

Pop the pivot balls into the arms with the

shoulder on the ball facing up. Do this by placing the

ball on a hard flat surface and placing the arm over

the ball. Carefully push the arm down over the pivot

ball. Be careful. It will take a lot of force.

Special Note:

The Copperhead 12 uses IRS hard anodized alloy

pivot balls and the new IRS lower suspension arms.

If the balls are tight in the lower arms carefully

squeeze them with pliers until the ball just begins to

move freely

Locate your upper suspension arm rod ends.

Note that the top side of the rod end opening is

smaller than the bottom

With a hobby knife, carefully chamfer the top

of the rod ends opening. This creates clearance for

the king pin shims that will go here later. This will

ensure there is no binding in the suspension.

The inset picture shows a finished rod end.

Step 1

Step 2

Locate the two remaining hard anodized alloy pivot

balls and snap them into the upper arm rod ends with

the shoulder on the ball facing down. As with the lower

arms, squeeze the rod ends if the balls do not move

freely.

Locate the upper suspension arms, the upper arm

turnbuckles and assemble as shown above.

We prefer to thread the right hand thread portions

of the turnbuckles into the rod ends and the left

hand thread into the upper arms.

Note:

The arms have a bottom and a top. They have

small circular impressions on the bottoms.

Step 3

Step 4

Step 5

Locate the 5 degree reactive caster upper

suspension mounts, upper suspension hinge pin,

e-clip and nylon caster spacers.

Assemble as shown.

Make sure the upper suspension arms pivots

freely. If there is any binding at all, the car may

handle poorly. If the upper arms are tight, use the

back of a hobby knife to scrape the front and back

of the reactive caster blocks and the inside of the

upper suspension arms to make more clearance

for the caster spacers. Take your time here and

get it right!

Special Note:

The Copperhead 12 uses IRS upper hinge pins

and does not require setscrews in the upper

suspension arm mounts.

Step 6

Attach the upper

suspension arm assembly

to the lower suspension

arms as shown with 4-40 x

½” screws.

Locate the left and right steering spindles. Trim the

steering arms length to the line molded on the part as

shown.

Step 7

Step 8

Locate the titanium front axles, four 4-40 alloy lock

nuts, and two alloy pivot balls.

Thread the titanium axles into the steering

spindles. Note that the threads on the axles that

go into the spindles are left hand. After the axles

are fully seated tighten an alloy 4-40 lock nut onto

the threaded stub coming out the back of the

spindle.

Thread the alloy pivot balls into the holes on the

steering arms and secure them with alloy 4-40 lock

nuts. Remember these are alloy pivot balls so

make the nuts snug. They are strong enough to

last a few racing seasons; but if you crank them

down, you can snap them.

Step 9

1. Snap an e-clip on to one end of the king pin.

2. Slide 3 shims onto the king pins against the

e-clip.

3. Pass this through the pivot ball in the upper

suspension arms rod end.

4. Place one more shim on the king pin.

5. Slide the steering spindle onto the king pin.

6. Slide the king pin through the pivot ball in the

lower suspension arm.

1. Slide the .020” spring and nylon retainer

onto the king pin and snap an e-clip on the

bottom of the king pin.

2. Repeat for the other side of the front

suspension.

Locate 2 steel 1/8” king pins,10 1/8” shims, 4 e-

clips and 2 .020” springs.

Special notes:

Make sure the steering arms on the spindle

are pointing towards the rear of the car as

shown in the picture.

The axle is offset in the spindle.

Make sure the axle is closest to the lower

suspension arm. As shown in the picture to

the left

It is important that the king pin slide

freely in all of the parts including the

steering spindle. When you thread the axle

into the spindle, it may swell the king pin

bore and make it tight on the spindle. You

can try to use a 1/8” drill to open it up but

the best solution is to use a 1/8” reamer.

You can order the reamer from:

www.mcmaster.com. The part number is

2995A61

Step 10

Locate four 8-32 x 5/8” screws and 4 nylon lower suspension arm spacer. Use 1 thin and 1 thick nylon spacer

under each pad on the arms.

Pass a screw through the chassis and slide a nylon riser over the screw. Start threading the screw into the

lower suspension arm but do not tighten it. Pass another screw through the chassis and slide a nylon riser over

that screw. Start threading the screw into the other hole on the lower suspension arm. Tighten both screws.

Repeat on the other side.

Special Note:

In testing, we found we preferred to not use any suspension brace, strap or tube to connect the left and right

suspension assemblies. This was true on high traction carpet tracks to low bite asphalt tracks. You can add

or remove lower arm spacers to adjust ride height and to compensate for tire wear.

Locate two flex plates*, 2 flex plate pivot ball

housings w/ the pivot balls installed, and 4 2-56

button head screws.

1.Slide pivot ball housing through the flex plate so

the flex plate encloses the boss on the lower side of

the housing.

2.Pass the 2-56 screws through the pivot ball

housing from the top so they thread into the flex

plate.

Rear suspension assembly

Step 11

This manual suits for next models

3

Table of contents

Other BMI Racing Motorized Toy Car manuals