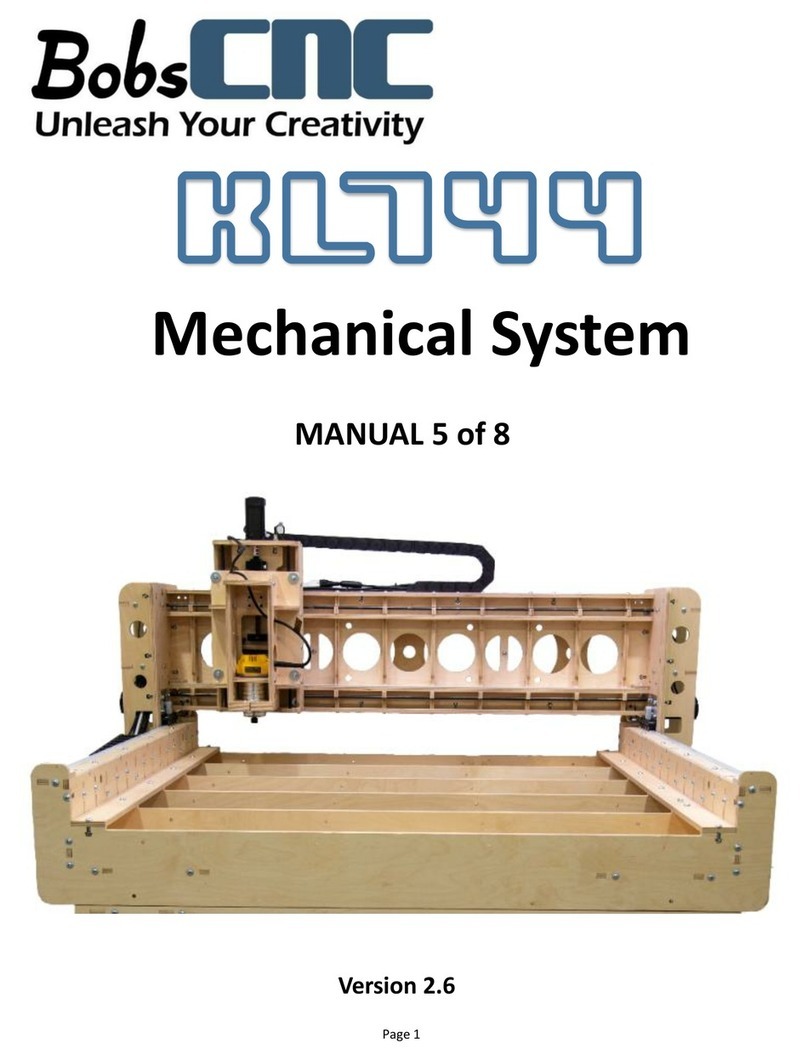

BobsCNC QUANTUM MAX User manual

Assembly Manual

Rev 1.00

To Quantum Max

1

Welcome to the Family.

We’re excited that you purchased the Quantum to Quantum

Max CNC Router Kit from BobsCNC, and we know you’re just

as excited to put it together. This manual gives you step by

step instructions to ensure your success in assembling the

Quantum Max CNC Router and provides all the information

you need to get your machine up and running.

Before beginning the assembly, take all the time you need to

completely review the manual. It’s good to be familiar with

the entire assembly process before diving in. Be sure to

check out the recommended tools you’ll need for the

assembly.

Welcome to the BobsCNC family. It’s time to… Unleash Your

Creativity!

Version 0.37

2

Contents

Information/Warning Boxes.........................................................................................................................5

Safety Precautions and Warnings ..............................................................................................................6

Getting Started..................................................................................................................................................7

Required Tools to Assemble the Quantum CNC Kit: .....................................................................7

To Operate the BobsCNC Quantum CNC Router, you need will need: ..................................7

Recommended for the electronic setup include: ............................................................................7

Assembly Recommendations: .....................................................................................................................8

Removing Quantum components .............................................................................................................9

Illustrated Step by Step Instructions ....................................................................................................9

Quantum MAX X-Frame Assembly......................................................................................................... 14

Required Wood Components.............................................................................................................. 14

Required Hardware.................................................................................................................................. 15

Final Assembly................................................................................................................................................ 36

Required Hardware.................................................................................................................................. 36

Illustrated Step by Step Instructions ................................................................................................. 36

Wire Harness................................................................................................................................................... 46

Wood Components ................................................................................................................................. 46

Required Hardware.................................................................................................................................. 46

Illustrated Step by Step Instructions ................................................................................................. 46

T-Slot Spoilboard .......................................................................................................................................... 49

Wood Components ................................................................................................................................. 49

Required Hardware.................................................................................................................................. 49

Illustrated Step by Step Instructions ................................................................................................. 49

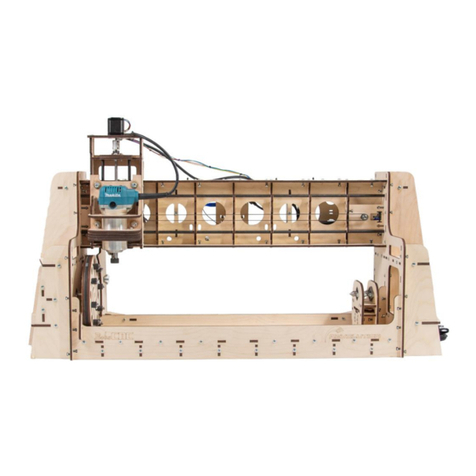

Completed Views .......................................................................................................................................... 54

Tramming......................................................................................................................................................... 56

3

Clamping System .......................................................................................................................................... 58

Wood Components (Included with Kit)............................................................................................ 58

Required Hardware.................................................................................................................................. 58

Congratulations! You Just Completed the Assembly of Your BobsCNC Quantum CNC

Router................................................................................................................................................................ 59

Appendix .......................................................................................................................................................... 60

Firmware Values........................................................................................................................................ 60

Quantum Washer Size Table ................................................................................................................ 61

4

BobsCNC Quantum Specifications

Feature list

The assembled footprint:

Length: 63" (1600 mm)

Width: 40" (1016 mm)

Height: 22”(560 mm)

Assembled Weight: 50 lbs.

Cutting Area:

X: 50.5" (1283 mm)

Y: 24" (610 mm)

Z: 3.8" (98 mm)

Safety is always the First Priority. Always wear proper

protective equipment and use "safety sense" when

assembling and operating your Quantum Series CNC

Router.

5

Information/Warning Boxes

CAUTION Indicates a possible risk of

injury that can result from failure to follow

this instruction

WARNING Indicates the possible

damage to the machine, its components,

the work piece, or injury that can result

from failure to follow this warning.

DANGER Indicates a serious risk of

bodily harm, injury and death. This is a

serious warning and should not be

ignored. Any work must be carried out

with extreme caution.

TIPs Contains helpful information,

shortcuts, and hints to simplify assembly

and make machine operation easier and

safer.

TIP

T

6

Safety Precautions and Warnings

BobsCNC Routers have a 110 v. Power Supply and use bits that spin at 30,000

rpm with cutting edges that are sharp and hazardous. The operator must

understand the potential hazards and is responsible to take appropriate

safety precautions before operating the Router.

•Only use extension cords rated for 20 amps plugged into a dedicated

outlet.

•Inspect the machine before every use for maintenance issues: loose

fasteners, belts, etc.

•Do not operate the machine with dull or damaged router bits.

•Always unplug machine after each use and when cleaning the router or

changing router bits.

•Remove rings, bracelets, watches, necklaces before using the machine.

•Wear snug fitting clothing and/or roll up long sleeves to prevent snagging.

•Use appropriate personal protective equipment (PPE) when operating

machine including safety glasses and hearing protection.

•Keep hands, hair and clothing away from the moving parts of the machine.

•Do not operate the machine when under the influence of alcohol or

prescription medications.

•Make certain the workpiece is clamped securely in place before starting

the machine.

•Never leave the machine running unattended.

•Children must be supervised by adults when operating the machine.

•Do not operate the machine in the presence of flammable materials.

•Keep floors clean, dry, and free of debris to eliminate slip and/or trip

hazards.

•Have a suitably rated fire extinguisher on hand when the machine is in

operation.

7

Getting Started

Required Tools to Assemble the Quantum CNC Kit:

Metric Socket Set

#1, #2 and #3 Phillips Screw Drivers

Needle Nose Pliers

Set of Metric Allen Wrenches

Pliers

Utility Knife

Clear Nail Polish or LOCTITE 242

Scissors

Blue Painter’s Tape

To Operate the BobsCNC Quantum CNC Router, you need will need:

Computer with control software for GRBL.

Materials for Projects.

1/4” Shaft Router bits.

Recommended for the electronic setup include:

Multimeter to correctly connect the Power Supply and to set the

current for the Stepper Motors (a great tool for general electronic

trouble shooting).

8

Assembly Recommendations:

Use a large, flat, clean work surface for assembling your Quantum

Max.

All Screws (unless noted) should be installed snug, then rotated 1-2

½ turns.

Apply LOCTITE 242™or clear fingernail polish to all M4 X 16 mm

Machine Screws that are used to secure plywood pieces. Machine

Screws that are secured with Lock Nuts do not need LOCTITE™.

Light sanding of the wood components may be performed if desired.

Painting or applying stain with a clear coat will provide extra

protection to the wood components.

Clean the rails with acetone to remove rust preventative and apply a

light coat of PTFE (Teflon®) lubricant.

We recommend using strips of 1-inch blue painter’s tape behind the

T-Slots to help hold the Nuts in place during assembly.

Lock Nuts are never used to secure components that have T-Slots.

They are only used to mount components where the Nut is not

held in a T-Slot.

CAUTION This kit contains numerous small

components that pose a choking risk for small

children and pets. Keep kit pieces in a secure

location out of the reach of small children and

pets.

9

Removing Quantum components

Illustrated Step by Step Instructions

Step 1 Remove and discard spoilboard

Step 1a Remove all M4x16 Machine Screws, then

remove all MDF and Aluminum T-Slots from

the X Frame Assembly.

10

Step 2 Remove Gantry Assembly and X parts.

Step 2a Loosen and remove the Belts by

loosening the two M5 Machine Screws

as shown.

NOTE: Keep the Belt Retainer parts to rebuild the longer Belts.

11

Step 2b Remove the Frame End Support by

removing all sixteen M4 x 16 Machine

Screws. Retain Frame End Support.

Step 2c Loosen both sides of the Gantry Side

Bearings by adjusting the Eccentric

Spacers so that the bottom Bearings

rotate freely.

Rotate Clockwise

Rotate Counter-Clockwise

12

Step 2d Cut all the zip ties holding wires to the

Wire Harnesses on the X Frame

Assembly.

Step 2e Slide the Gantry to the front and gently

remove the Gantry from the machine.

Step 2f Remove all 4 X Rails.

13

Step 2g Remove both Frame Corner Supports

and Belt Support from each side of the X

Frame Assembly. Retain all four of the

Frame Corner Supports and Both Belt

Supports.

Finished view of Quantum X Frame ready to be lengthened.

14

Quantum MAX X-Frame Assembly

Required Wood Components

Part #

Description

Qty

Photo

QX1

Rail Support

8

QX2

Torsion Arm

2

EQX2

Extension Torsion

Arm

2

QX3

Inner Frame Mid

Support

2

QX4

Outer Frame Mid

Support

1

EQX4

Extension Frame Mid

Support

1

EQX5

Extension Frame Side

Support

2

QX7

Wire Harness Support

2

15

EQX8

Extension Frame

Corner Support

4

QX9

Torsion Plate

2

EQX10

Extension Frame Side

Brace

2

EQX12

Extension Coupling

Plates

2

Required Hardware

Part

#

Description

Qty

Photo

H14

M4 x 16 Machine

Screw

182

H15

M4 Nut

182

16

Illustrated Step by Step Instructions

Step 1 Attach two Extension Frame Supports to Quantum Frame.

Step 1a Attach two Extension Frame Corner Supports

(EQX8) on the Torsion Arms (QX2). Note the

notch in the Corner Support should be

oriented toward the front and the center of

the Assembly.

Step 2a Align the slots in the Frame Corner Supports

(QX8) with the tabs on the Torsion Arms

(QX2). Slide in place and secure with four M4

x 16 Machine Screws. Repeat for each of the

corners.

Only install the top Supports. The Bottom

Supports will be installed in a later step.

17

.

Step 2 The following steps will cover building the Front X Frame

Assembly.

18

WARNING There are two long and two

short Torsion Arms in the Max Front X-Frame

Assembly. The long Torsion Arms are located

on the front of the Assembly. The short

Torsion Arms are located at the rear of the

Assembly.

Step 2a Use strips of painter’s tape to cover all the T-Slot

cutouts in each of the four Torsion Arms (QX2 and,

EQX2) and Torsion Plates (QX9) as shown.

19

Step 2b Turn the Torsion Arms over and install a M4 Nut in

each of the T-Slots as shown below.

Cover the installed M4 Nuts with strips of painter’s

tape.

This will hold the nuts in place to make it easier to

connect the Torsion Arms (QX2 and EQX2) to the

Torsion Plate (QX9).

Step 2c Align the tab of the Torsion arm (QX2) with the

corresponding slot in the Torsion Plate (QX9).

Notice how the rectangular notch is oriented. Make

sure the cutout in each of the arms is oriented in the

same way in the Assembly.

Rectangular Notch

Other manuals for QUANTUM MAX

1

Table of contents

Other BobsCNC Control System manuals

Popular Control System manuals by other brands

Gentex

Gentex HomeLink 2-Button Programming and information guide

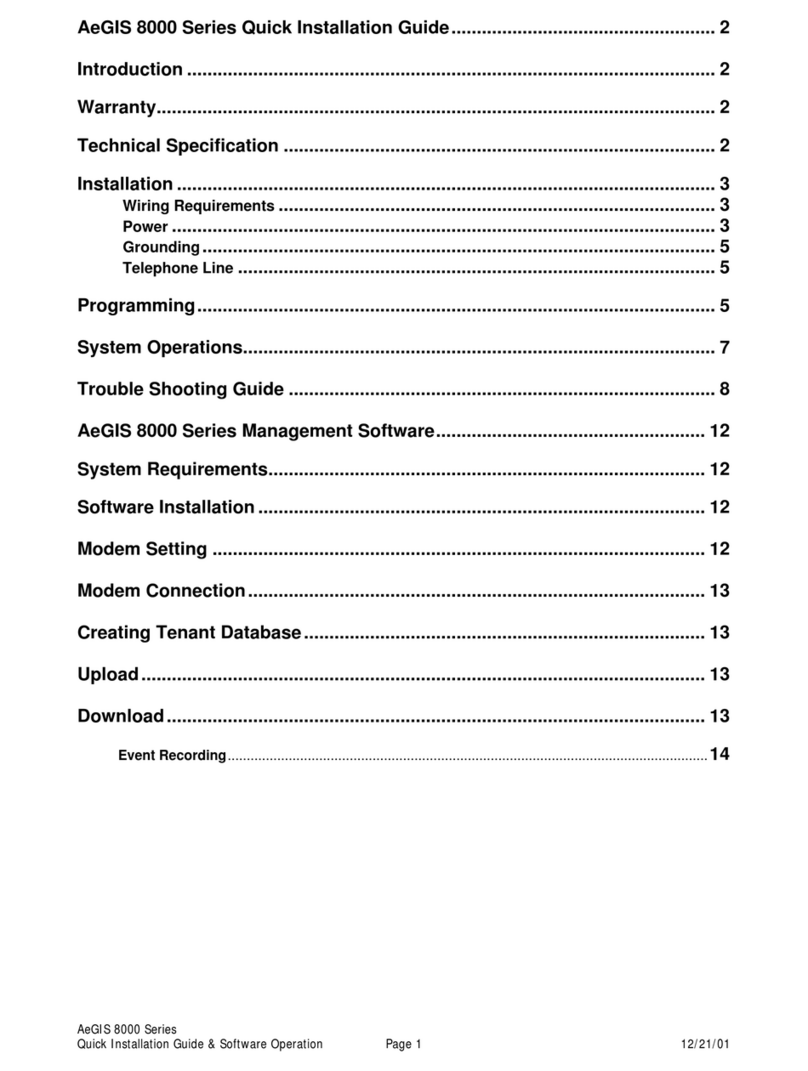

PACH & COMPANY

PACH & COMPANY AeGIS 8000 Series Quick installation guide

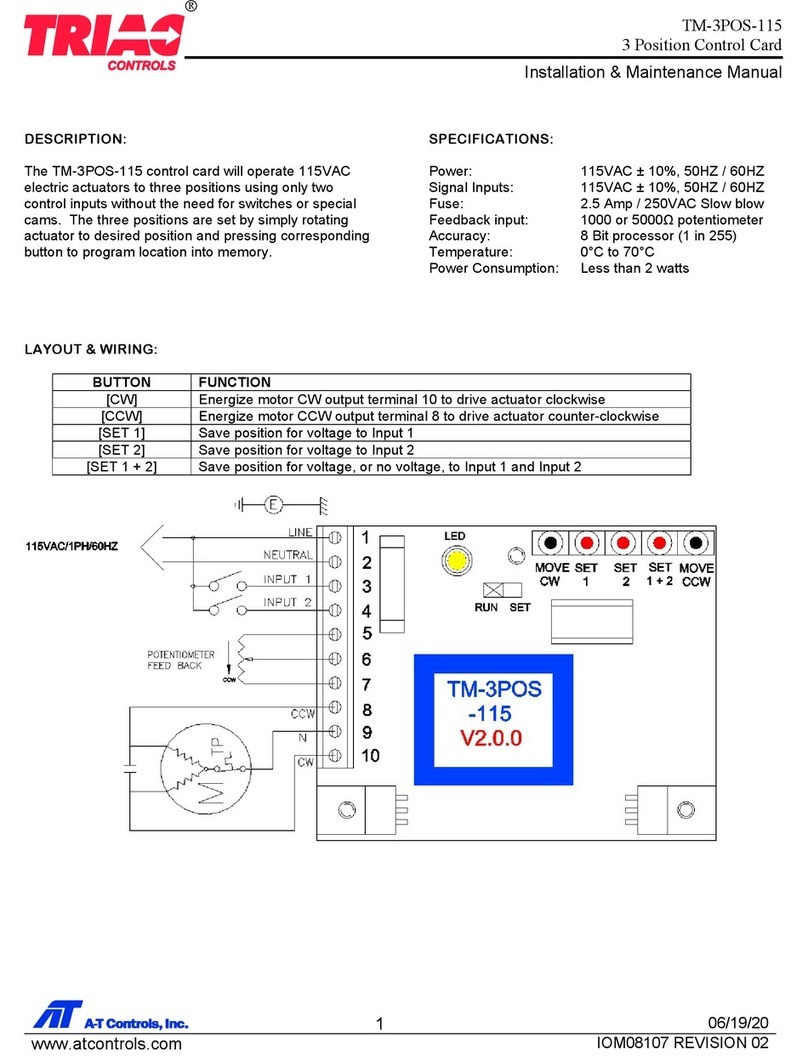

A-T Controls

A-T Controls TRIAG M-3POS-115 Installation & maintenance manual

ECOFOREST

ECOFOREST ecoSMART e-source USER, INSTALLER AND TECHNICAL SERVICE MANUAL

EOS

EOS LSG 18 Assembly and operating instruction

baltur

baltur ETAMATIC OEM Quick start up guide