Basic Welding Machine and Cables

The choice of welding machine is based mostly

on the following factors:

•primaryvoltage,e.g.240Voltor380Volt

•outputamperagerequired,e.g.140amps

•outputrequired,e.g.ACorDC+/-

•dutycyclerequired,e.g.35%@140amps

•methodofcooling,e.g.air-cooledor

oil-cooled method of output amperage

control, e.g. tapped secondary lugs

•orinnitelyvariablecontrol.

For example, the Smootharc MMA130 connects

to 240Volt supply (10 amps Input), has an output

of130ampsDC@35%dutycycle.

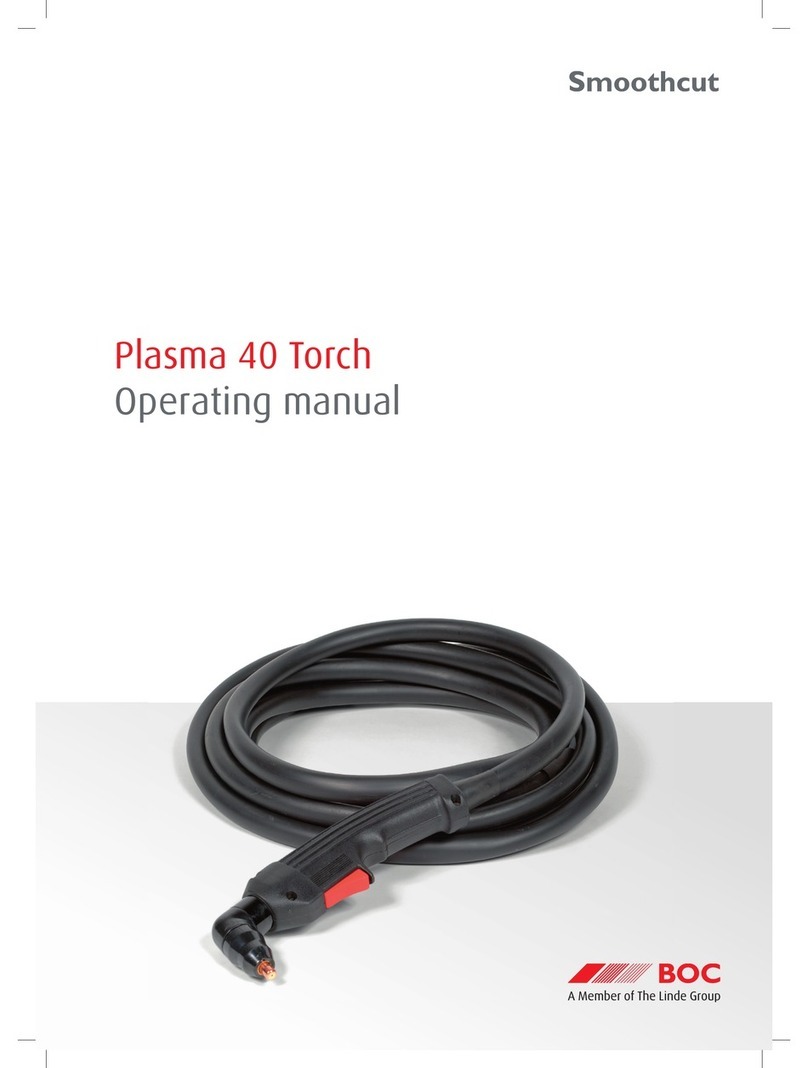

Having decided on a welding machine, appropriate

accessories are required.These are items such as

welding cables, clamps, electrode holder, chipping

hammer, helmet, shaded and clear lenses, scull cap,

gloves and other personal protective equipment.

BOC stocks a huge range of personal protective

equipment.This combined with BOC’s

extensive network ensures fast reliable service

throughout the South Pacific.

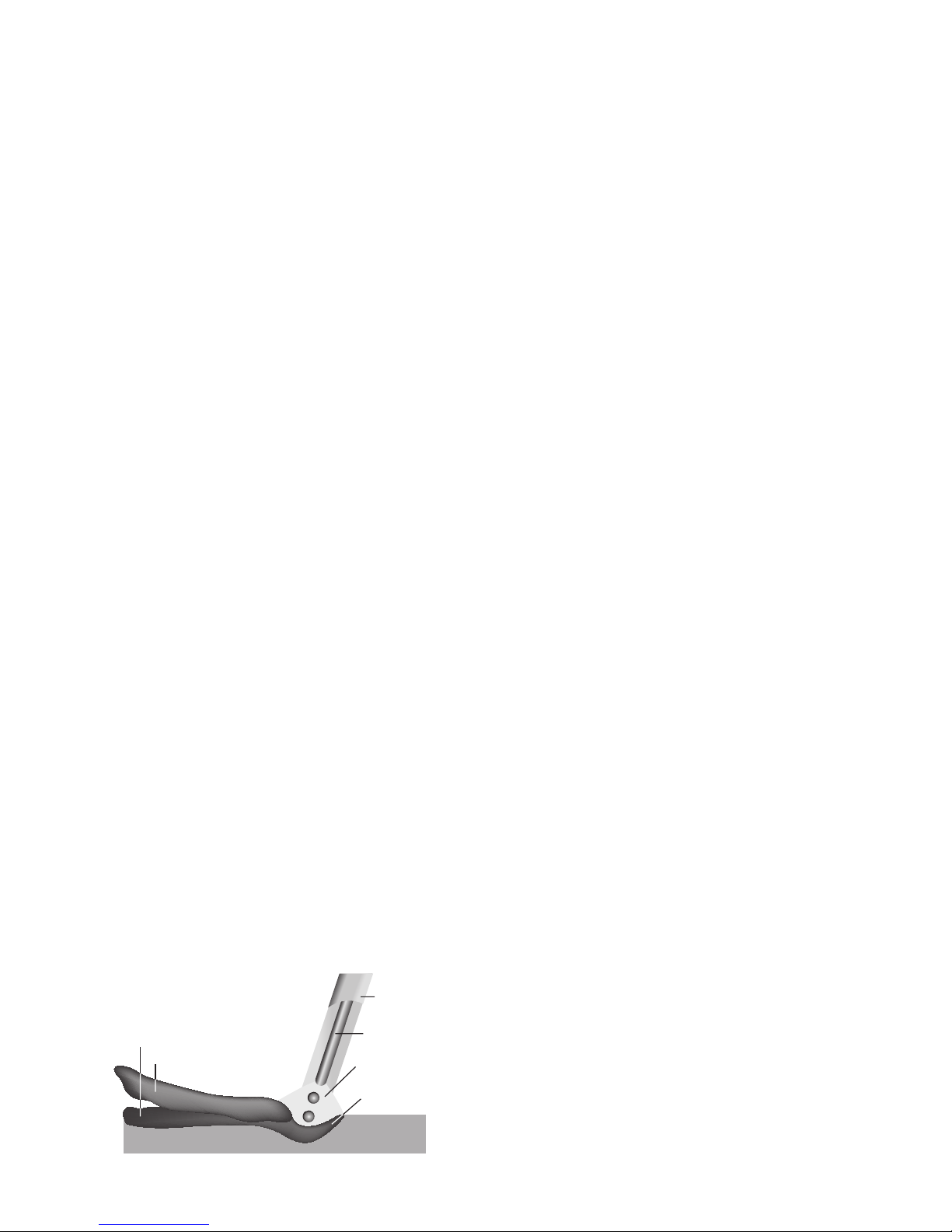

2.4 Welding Technique

Successful welding depends on the

following factors:

•selectionofthecorrectelectrode

•selectionofthecorrectsizeofthe

electrode for the job

•correctweldingcurrent

•correctarclength

•correctangleofelectrodetowork

•correcttravelspeed

•correctpreparationofworktobewelded.

2.5 Electrode Selection

As a general rule the selection of an electrode

is straight forward, in that it is only a matter of

selecting an electrode of similar composition

to the parent metal. It will be found, however,

that for some metals there is a choice of several

electrodes, each of which has particular properties

to suit specific classes of work. Often, one

electrode in the group will be more suitable for

general applications due to its all round qualities.

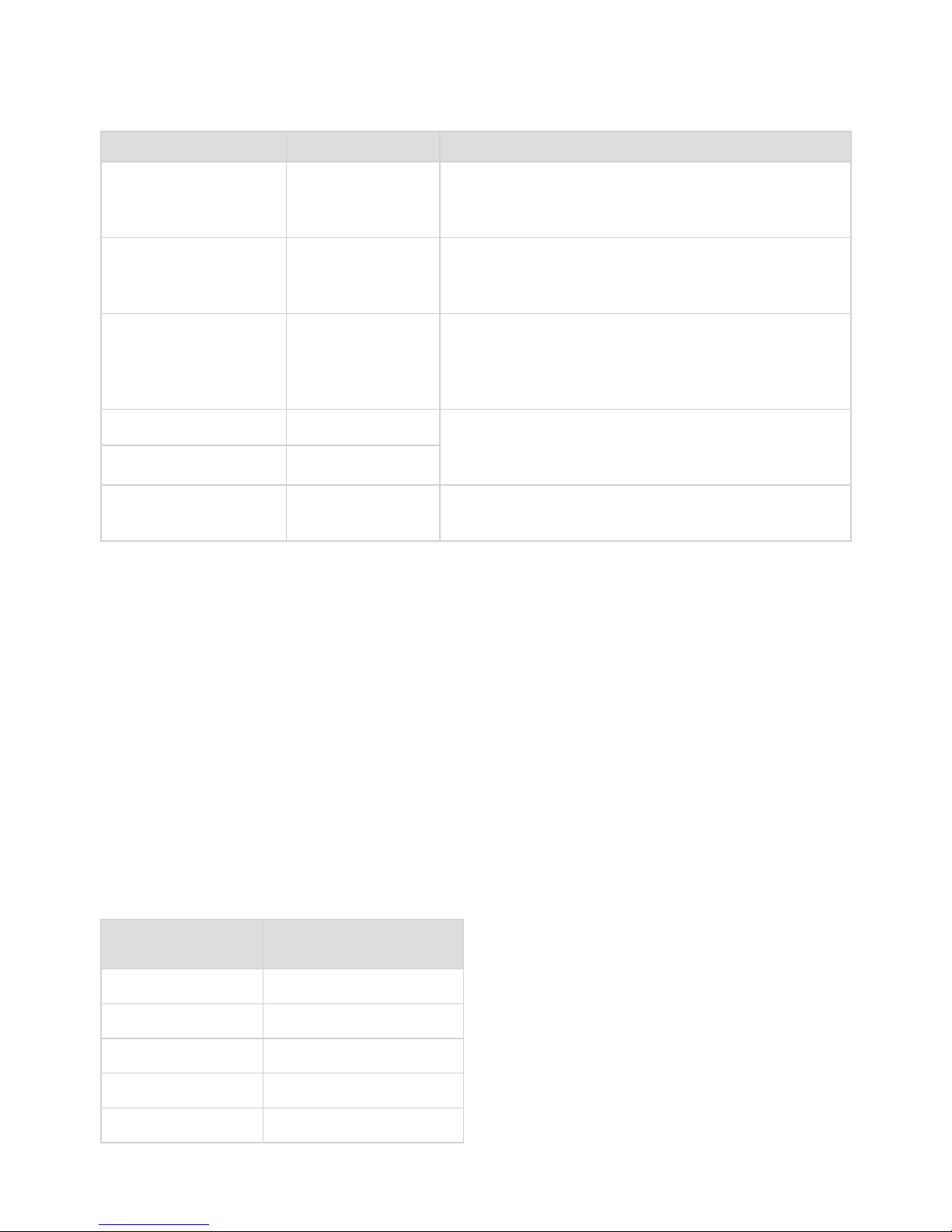

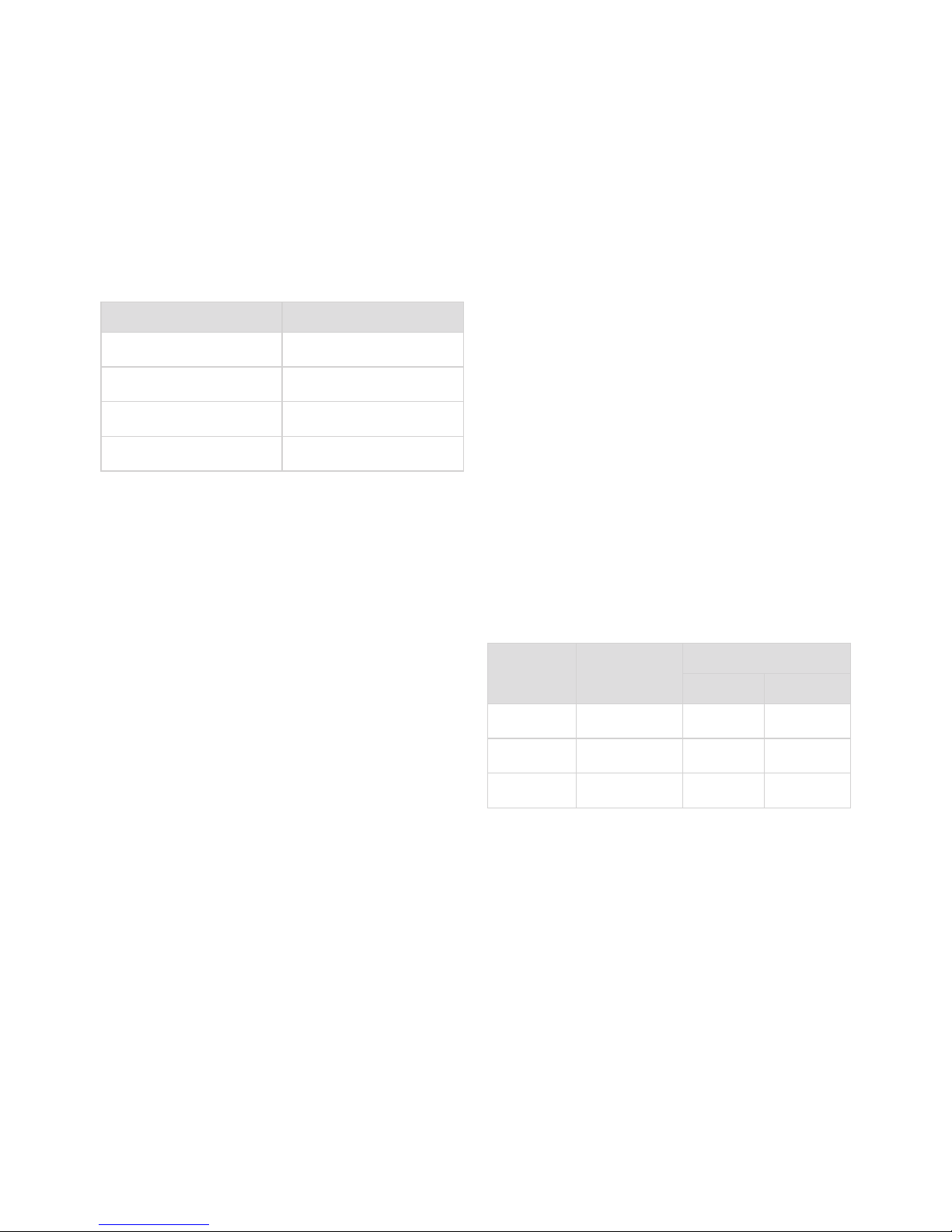

The table (page 9) shows just a few of the wide

range of electrodes available from BOC with

their typical areas of application.

For example, the average welder will carry out

most fabrication using mild steel and for this

material has a choice of various standard BOC

electrodes, each of which will have qualities

suited to particular tasks. For general mild steel

work, however, BOC Smootharc 13 electrodes

will handle virtually all applications. BOC

Smootharc 13 is suitable for welding mild steel in

all positions using AC or DC power sources. Its

easy-striking characteristics and the tolerance it

has for work where fit-up and plate surfaces are

not considered good, make it the most attractive

electrode of its class. Continuous development

and improvement of BOC Smootharc 13 has

provided in-built operating qualities which

appeals to the beginner and experienced

operator alike. For further recommendations

on the selection of electrodes for specific

applications, see table page 9.