2.2 Control of the Process

The main control parameters for the MMA

process are:

• current and

• operator technique

The current range is determined by the

electrode type and size. Deposition rate

increases with current for a given electrode

diameter but the maximum current is limited by

the coating material and the ability to control

both the weld pool and the molten slag.

Increasing the current also increases the level of

fume and the arc radiation.A high level of manual

dexterity is required to coordinate the movement

of the electrode to match the burn-off rate and

maintain a constant arc length. Some electrodes

are designed for 'touch' or contact welding (the

electrode coating rests on the workpiece during

welding) and this simplifies the production of

fillet welds.Additional skills are required to

control fusion characteristics and bead profile

(electrode angle, travel speed and weave patterns

must be carefully chosen), particularly for

positional welding.

2.3 Features of the Process

The most important characteristic of the

MMAW process is its overall flexibility.The wide

range of electrode types allows the weld metal

to be matched to the application, which may be

particularly useful in repair and jobbing shop

environments. Relatively simple equipment is

required and the capital cost is low.

The quality of the welded joint depends almost

entirely on the welder, and availability of

suitably qualified welders may cause production

bottlenecks. In addition the process is

intermittent, as the electrode must be changed

at regular intervals, placing a natural limit on the

productivity of the process.

2.4Applications of MMAWelding

The process is applied widely in the fabrication

and repair of plain carbon and low alloy steels.

It has been used in the construction of power

stations, pipelines and offshore structures.

Stainless steel, inconel, nickel and a wide

range of surfacing electrodes are available, and

these may be used in low volume production,

maintenance and repair situations.

2.5 MMA Electrode

Characteristics

The characteristics of the MMAW process are

largely determined by the electrode coating

material that controls the following important

features:

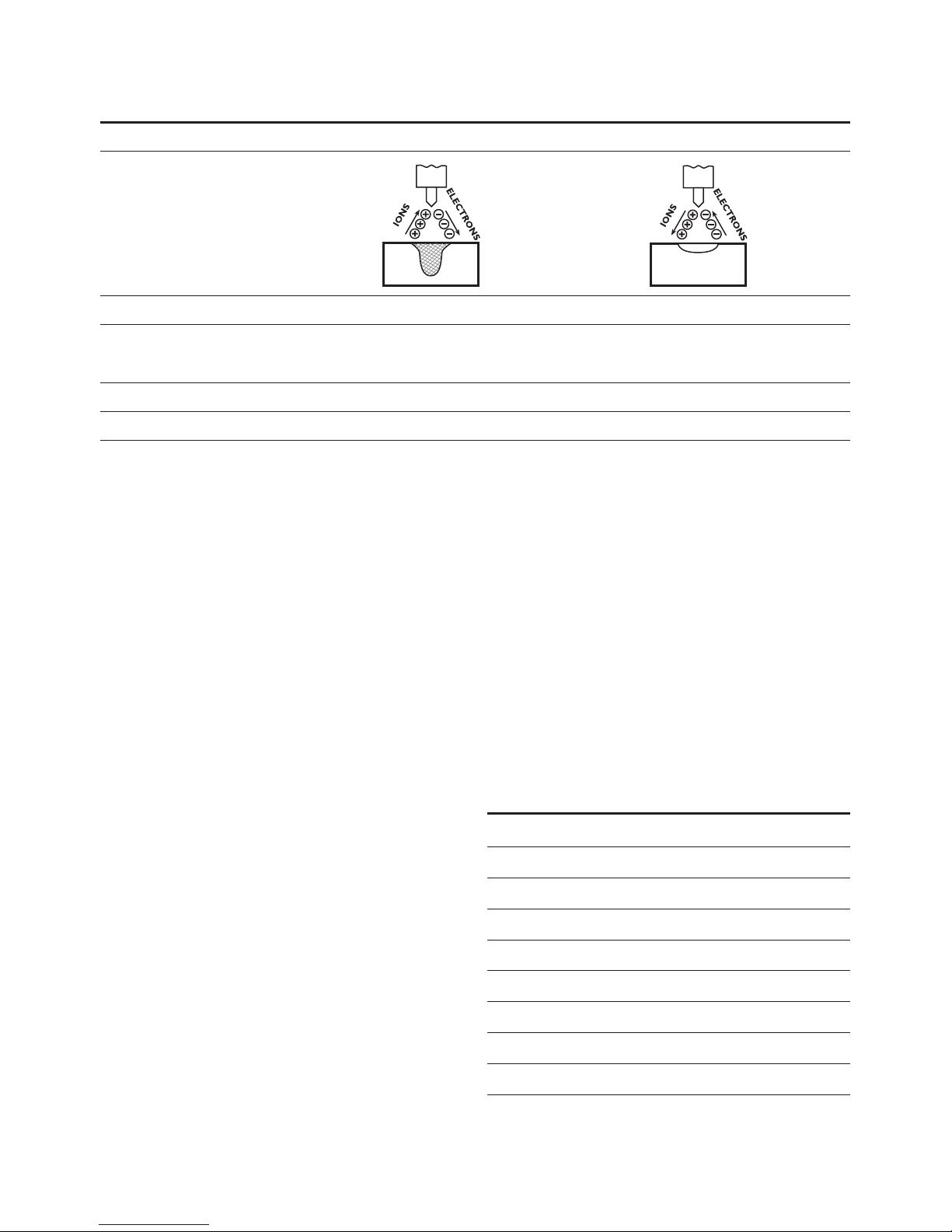

Arc

Certain chemicals may be added to the coating

material to stabilise the arc (e.g. rutile or potassium

silicate), improve metal transfer and reduce spatter.

These additions also provide a useful reduction

in the operating voltage required for the electrode.

Shielding

Shielding is provided by gases generated by the

decomposition of constituents such as calcium

carbonate or cellulose and by liquid slags which

protect the weld pool surface.

Weld pool control

The slag fluidity is usually the factor that

determines the ease of positional welding. Rapidly

freezing slags may be used to provide support

for the weld pool in vertical and overhead welding.

Alloying

The coating material can provide a useful source

of alloying elements or additions that control the

weld metal chemistry (such as deoxidisers).This

enables a wide range of weld metal properties to

be achieved by modifying the coating whilst using

a standard core wire.

7