BOCI BLT641 User manual

BLT641 Product Manual

Brilliant Optical Cutting Instrument

BOCI

BLT641 Product Manual

1

Document History

Number

Date

Version

01

2022/08/19

V1.1

Notice:

Thank you for choosing the BLT intelligent cutting head. This manual provides you with

important information such as product parameters, installation, and maintenance, so please

read this manual carefully before using the product. At the same time, in order to ensure the

safety of operation and the operation of the product in the best condition, please strictly follow

the precautions in the manual.

BOCI is constantly updating/upgrading products, so our company reserves the right to modify

the product models and descriptions in this manual without prior declaration.

Unauthorized disassembly of the product is strictly prohibited without the authorization of

BOCI Technology, otherwise the warranty will be invalid!

BOCI

BLT641 Product Manual

2

Table of Contents

1. Product Description............................................................................................. 4

1.1 Product View...........................................................................................................................................................................4

1.2 Technical parameters ............................................................................................................................................................5

1.3 Meaning of LED indicator......................................................................................................................................................6

2. Gas interface ....................................................................................................... 7

3. Water cooling interface....................................................................................... 8

4. Electrical Interface .............................................................................................. 9

4.1 Bus system............................................................................................................................................................................10

4.2 Non-bus systems..................................................................................................................................................................11

5. Cutting head installation................................................................................... 12

5.1 Preparation before operation..............................................................................................................................................12

5.2 Specific operation process .......................................................................................................................................................13

5.2.1 Preparation of clean bench......................................................................................................................................13

5.2.2 The cutting head is placed in the clean workbench .............................................................................................13

5.2.3 Clean and wipe the fiber interface of the cutting head.........................................................................................14

5.2.4 Check the laser fiber end face.................................................................................................................................14

5.2.5 Tear off the protective film/remove the protective cap.........................................................................................14

5.2.6 Insert the laser fiber interface into the cutting head .............................................................................................15

5.2.7 Wrap and seal............................................................................................................................................................15

5.2.8 Mount the cutting head on the backplane..............................................................................................................16

5.2.9 Installing the ceramic body and nozzle ..................................................................................................................17

5.2.10 Beam centering .......................................................................................................................................................18

Appendix A - Maintenance ................................................................................... 20

BOCI

BLT641 Product Manual

3

1.1 Schematic diagram of product structure ...........................................................................................................................20

1.2 Replace the upper protective lens .....................................................................................................................................22

1.3 Replace the lower protective lens......................................................................................................................................23

Appendix B - Mechanical Dimensions ................................................................ 24

1.1 Cutting head installation size..............................................................................................................................................24

BOCI

BLT641 Product Manual

4

1. Product Description

1.1 Product View

12

11

15

16

13

14

1

10

9

2

3

4

5

6

7

8

Product View (Structure and Interface Description)

1. Optical fiber interface; 9. Nozzle cooling air interface;

2. 1st Upper protective lens; 10. Cutting gas interface;

3. 2nd Upper protective lens; 11. Cooling water outlet;

4. Collimation unit; 12. Cooling water inlet;

5. Focusing unit; 13. Anti-collision screw;

6. 2nd Lower protective lens; 14. Ceramic body lock ring;

7. 1st Lower protective lens; 15. Ceramic body;

8. Working indicator; 16. Nozzle;

BOCI

BLT641 Product Manual

5

1.2 Technical parameters

Cutting head

BLT641

Laser wavelength:

1030-1090nm

Laser power:

15KW

Fiber interface:

QBH,QD,Q+,ADD

Spot magnification:

M=2.0

Focus adjustment range:

±50mm (optical ratio 1:2 100:200)

NA:

Max.0.13 at Fc100

Centering adjustment range:

±1.5mm

Focus acceleration:

7.5m/s²

Cutting gas interface:

ø10, maximum 25bar (2.5Mpa)

Nozzle cooling gas connection:

ø6, maximum 5bar (0.5Mpa)

Water cooling interface:

ø8, maximum 5bar (0.5Mpa), minimum flow 2.0l/min

Operating temperature:

5~55℃

storage temperature:

-25~+55 ℃

size:

472.3x181

weight:

About 11 kg

Notice:

To avoid damage to the cutting head during storage and transportation, pay attention to the

following:

The cutting head should be stored within the allowable temperature and humidity range.

Avoid storage in and near magnetic fields such as permanent magnets or strong alternating

fields.

Avoid collision of the cutting head.

BOCI

BLT641 Product Manual

6

1.3 Meaning of LED indicator

icon

state

meaning

green

Power is normal.

red

Under-voltage alarm: insufficient electrical power.

not

bright

No power supply: There is no power supply, the connection cable is broken, and the

interface is loose.

icon

state

meaning

green

The system is operating normally.

red

Abnormal motor: The current consumption of the motor is too large, and the mechanical

components cannot run smoothly.

not

bright

The cable is broken, and the interface is loose.

icon

state

meaning

green

System communication is normal.

red

System communication is abnormal.

not

bright

The cable is broken, and the interface is loose.

icon

state

meaning

green

The readings of each sensor are normal.

red

There is an abnormal sensor reading.

not

bright

The cable is broken, and the interface is loose.

BOCI

BLT641 Product Manual

7

2. Gas interface

Cutting gas interface

Nozzle cooling gas

connection

Installation connection: cutting gas 1, nozzle cooling gas 2

Notice:

The maximum pressure of cutting gas is 25bar (2.5Mpa).

The cutting gas quality shall meet the requirements of gas quality in accordance with ISO 8573-1:2010:

solid particles - class 2, water - class 4, oil - class 3. The purer the cutting gas, the longer the life of the

protective lens.

The cutting gas pipe diameter (outer diameter) is 10mm, and the nozzle cooling gas pipe diameter

(outer diameter) is 8mm.

BOCI

BLT641 Product Manual

8

3. Water cooling interface

Water cooling water

outlet

Water cooling

water inlet

1A

2A

Installation connection: water-cooled water inlet port 2A, water-cooled water outlet port 1A

Notice:

Deionized/distilled water (conductivity < 10 μS/cm) specified by the laser manufacturer is recommended.

Recommended cooling water setting value: cooling water pressure ≤5bar (0.5Mpa), water flow rate ≥2.0l/min.

Please refer to the dew point table to set the cooling water temperature to prevent condensation on the optical

components.

Dew point temperature at different temperature and humidity

BOCI

BLT641 Product Manual

9

4. Electrical Interface

PWE and aviation plug interface waterproof precautions:

1. PWE interface and air plug interface are equipped with dust plugs from the factory. If

the dust plug does not fall off, the protection level of IP64 can be achieved; at the same

time, when the PWE cable and the air plug cable are well connected, IP64 can also

be achieved;

2. After the dust plug is removed, the protection level of IP64 cannot be achieved. If it

encounters spraying or flushing at this time, it will cause water to enter the product

and affect the function;

3. Ensure that the water circuit is connected well, and the water pipe interface is

tightened before removing the dust plug to prevent the water pipe from accidentally

loosening and water rushing to the interface, causing the product to enter the water;

4. When adjusting the wiring, remove the dust plug for wiring. It is recommended to keep

the removed dust plug of the PWE interface. Install the dust-proof plug as soon as

possible after the stitches are removed to prevent accidental water ingress in the

transfer, water connection and other links.

BOCI

BLT641 Product Manual

10

4.1 Bus system

Hypcut

IPC

master

station

Slave

Station

HyPanel

BCS210E

Power supply

220V AC

BLT641 Cutting head installation

wiring diagram

PWE Line

Notice:

The above wiring operations should only be performed by trained

and professional personnel.

When the cutting head is connected to the BCS210E, the BCS210E

must be powered off.

BOCI

BLT641 Product Manual

11

4.2 Non-bus systems

BCL4500A

Cypcut

IPC

master

station

Slaves

Station

站

Power

24VDC

PWE line

HC plug-in cable

BLT641 Cutting head installation

wiring diagram

Notice:

The above wiring operations should only be performed by trained and professional personnel.

When the cutting head is connected to the BCL4500A, the BCL4500A must be powered off.

BOCI

BLT641 Product Manual

12

5. Cutting head installation

5.1 Preparation before operation

The following objects are required before operation:

Cutting head;

Clean workbench (clean workbench type: vertical purification; cleanliness level: ISO 5, 100; average wind speed ≥

0.4m/s);

Cleaning kit: strong light flashlight, absolute ethanol (or IPA), dust-free purification cotton swab, dust-free cloth,

compressed air dust removal tank (or air blower).

During the installation of the cutting head, dust or dirt may accidentally enter the cutting head, contaminate the optical

lens, and affect its normal functions. To prevent dust or dirt from entering the cutting head, please refer to the following

methods for the installation of the cutting head:

Cutting head

clean workbench

Flashlight Ethanol Dust-free cotton swab

dust-free cloth Compressed air dust removal tank

Purification Kit

Notice:

The above operations can only be carried out by personnel who have received

appropriate training and have professional knowledge.

In order to ensure the normal operation of the laser device and the safety of operators,

please be sure to follow the relevant operating instructions.

BOCI

BLT641 Product Manual

13

5.2 Specific operation process

5.2.1 Preparation of clean bench

Prepare the clean bench, start it up and ensure its functionality:

1. Check that the equipment is clean and qualified (checks the cleanliness of the dust particle counter ), and confirm

that the FFU purification unit is within the validity period (measure the average wind speed in the working area, when the

wind speed cannot reach 0.3m/s, the FFU purification unit must be replaced);

2. Check whether each switch is running normally, and check whether the fan is running normally;

3. It is strictly forbidden to install unnecessary items in the clean working area to ensure that the clean air flow is

not disturbed;

4. For clean workbenches that are newly installed or have not been used for a long time, please use a clean cloth

and anhydrous ethanol to wipe them clean before use;

During operation:

1. Turn on the power, and pull the glass sliding door of the clean workbench to the lowest position (leaving a gap

of about 10cm);

2. Start the fan, it is recommended to purify the clean table for about 30 minutes in advance;

3. Turn on the light source of the clean workbench.

5.2.2 The cutting head is placed in the clean workbench

Put the cutting head horizontally inside the clean workbench.

Clean table type: vertical

purification; cleanliness class: ISO

5, 100; average wind speed ≥

0.4m/s

Notice:

To prevent dust from contaminating the core area of the

cutting head, please ensure the integrity of the special

protective film/cap for the optical fiber interface before

plugging and unplugging the optical fiber.

BOCI

BLT641 Product Manual

14

5.2.3 Clean and wipe the fiber interface of the cutting head

Wipe the fiber interface of the cutting head with a clean cloth and anhydrous ethanol.

5.2.4 Check the laser fiber end face

Remove the protective cap of the laser fiber, and irradiate the end face of the fiber with a strong flashlight to observe

whether there is any pollution; if it is clean, you can directly insert the fiber;

5.2.5 Tear off the protective film/remove the protective cap

Remove the special protective cap/protective plug for the optical fiber interface on the cutting head.

BOCI

BLT641 Product Manual

15

5.2.6 Insert the laser fiber interface into the cutting head

Align the fiber optic plug with the red dot, insert it into the unlocked fiber optic port, and ensure that it is inserted as far

as it will go. Rotate the lock cap until it tightly locked.

5.2.7 Wrap and seal

After inserting the optical fiber, wrap and seal the interface between the optical fiber and the cutting head with tape.

Lock

BOCI

BLT641 Product Manual

16

5.2.8 Mount the cutting head on the backplane

The cutting head can be installed on the Z-axis backplane of the machine tool through four screws A, B, C, and D.

When fixing the cutting head on the machine, it must be ensured that the cutting head is locked and there is no obvious

movement.

Notice:

To achieve affective sealing, it is recommended to wrap the tape

at least three times for sealing.

BOCI

BLT641 Product Manual

17

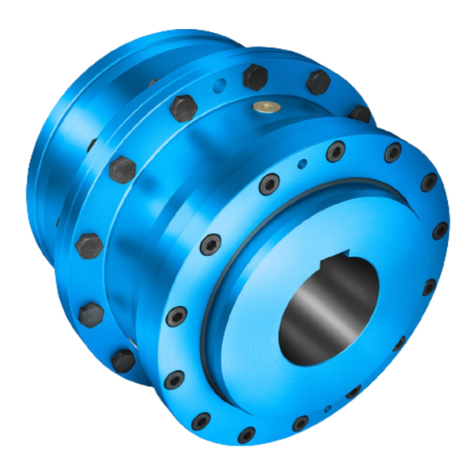

5.2.9 Installing the ceramic body and nozzle

Install the ceramic body and secure with the locking ring, then install the nozzle.

A

B

C

D

ceramic body

locking ring

nozzle

Tighten the nozzle on the ceramic body

by hand,

Use a wrench to tighten the ceramic

locking ring.

BOCI

BLT641 Product Manual

18

5.2.10 Beam centering

Adjust the XY centering knob to make the focal point in the center of the nozzle by low-power dotting.

Tape

Fail

Relative position of laser beam

pass

The conditioned laser beam

must be in the center of the

nozzle.

X/Y

adjustment

screw

BOCI

BLT641 Product Manual

19

Manual alignment operation:

1. Make sure the laser beam is turned off.

2. Place scotch tape under the nozzle.

3.

Click to trigger a low-power laser pulse and assess the position of the laser beam relative to the

nozzle through the penetration of the tape.

4. Adjust the X/Y centering screws to center the laser beam on the nozzle.

BOCI

Table of contents

Other BOCI Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Ultra Optics

Ultra Optics Mini2 Operation and maintenance manual

GSi

GSi RSG1212GM-X21 installation manual

National Flooring Equipment

National Flooring Equipment Trolley-10 OPERATING & SERVICE MANUAL

SIP

SIP Winntec 09807 Y440105 manual

ABB

ABB HT569930 Operation manual

CIMLINE

CIMLINE 105 Owner's/operator's manual