PUSHCORP, INC.

AFD92 Manual 4

2.0 General Overview

T e PushCorp 90 Series Passive AFD was designed as a lower cost alternative to t e

1200 Series Active Force Device. As suc t e 90 Series is a very basic unit t at still

provides outstanding performance. To increase force accuracy t e 90 Series uses low

friction glass pneumatic cylinders wit grap ite pistons and linear ball bearings. T e 90

Series may be supplied to apply only a positive force, t e AFD91, or bot positive and

negative forces, t e AFD92. It is offered in eit er robotic or table top mounting

configurations.

T e 90 Series requires t e user to supply at least one pressure regulator to control

t e force output. If an AFD92 is specified t en two pressure regulators are required.

T e device’s low friction components mean t at t e force output resolution and

repeatability is ig ly dependent on t e pressure regulator accuracy. T e pressure

regulator can be manual or electrically adjustable based on t e user’s application

requirements. If only one force level is required and t e AFD orientation does not

c ange, a manual pressure regulator is sufficient. If t e force and/or AFD orientation

c anges during t e process, t en an electrically controlled proportional pressure

regulator is required. In some cases t e process equipment weig t must be taken into

account so t at a constant force can be applied regardless of t e AFD orientation. T is

situation requires calculation of t e regulator pressure based on t e process equipment

weig t and AFD orientation. T e Carriage position of t e AFD92 can be monitored by

connecting to a DC power source and an analog input device using a Pus Corp ig -

flex cable.

All t ese features combine to make t e PushCorp 90 Series Adjustable Force Devices

rugged, reliable, and capable of delivering consistent results in any number of industrial

applications.

3.0 Installation

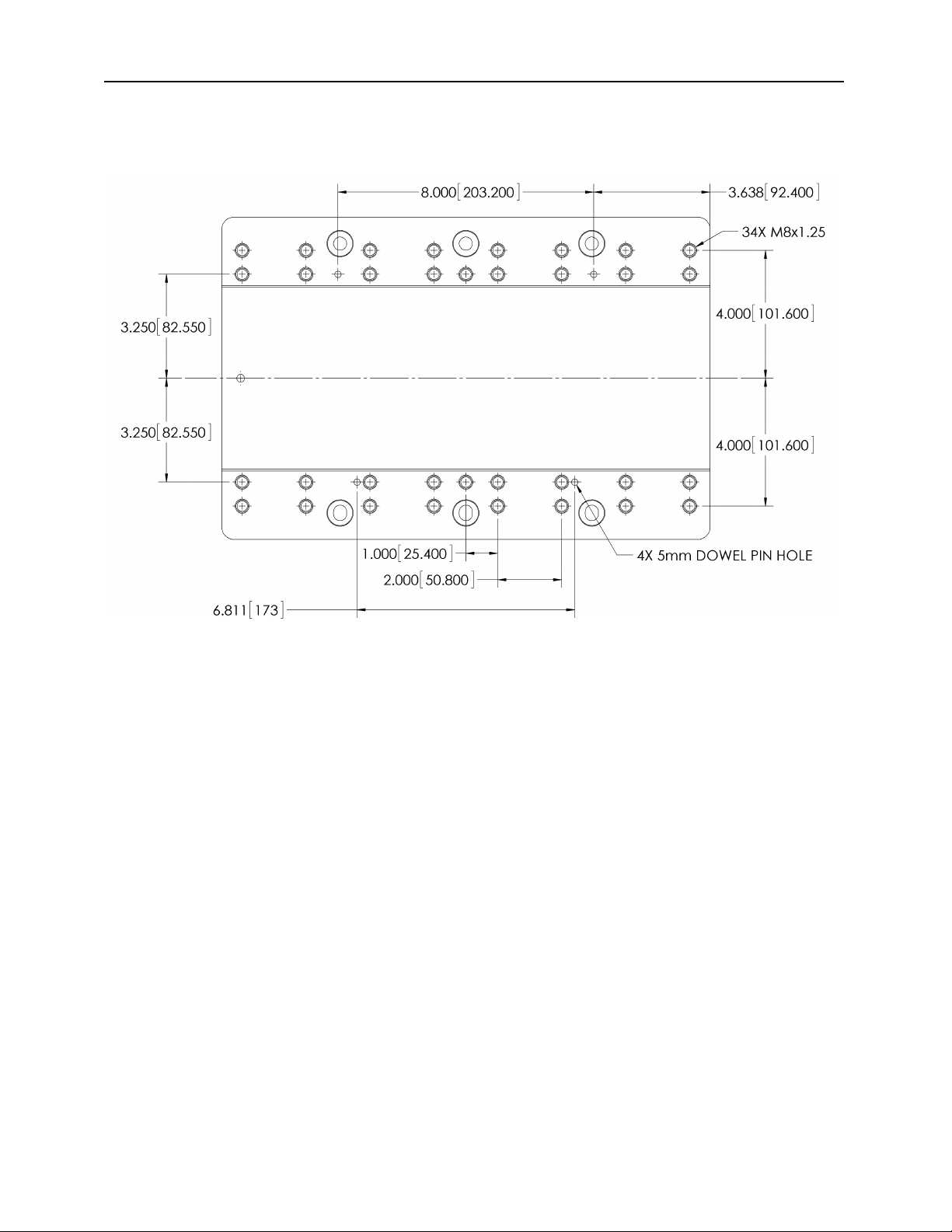

3.1 Mounting Process Equipment

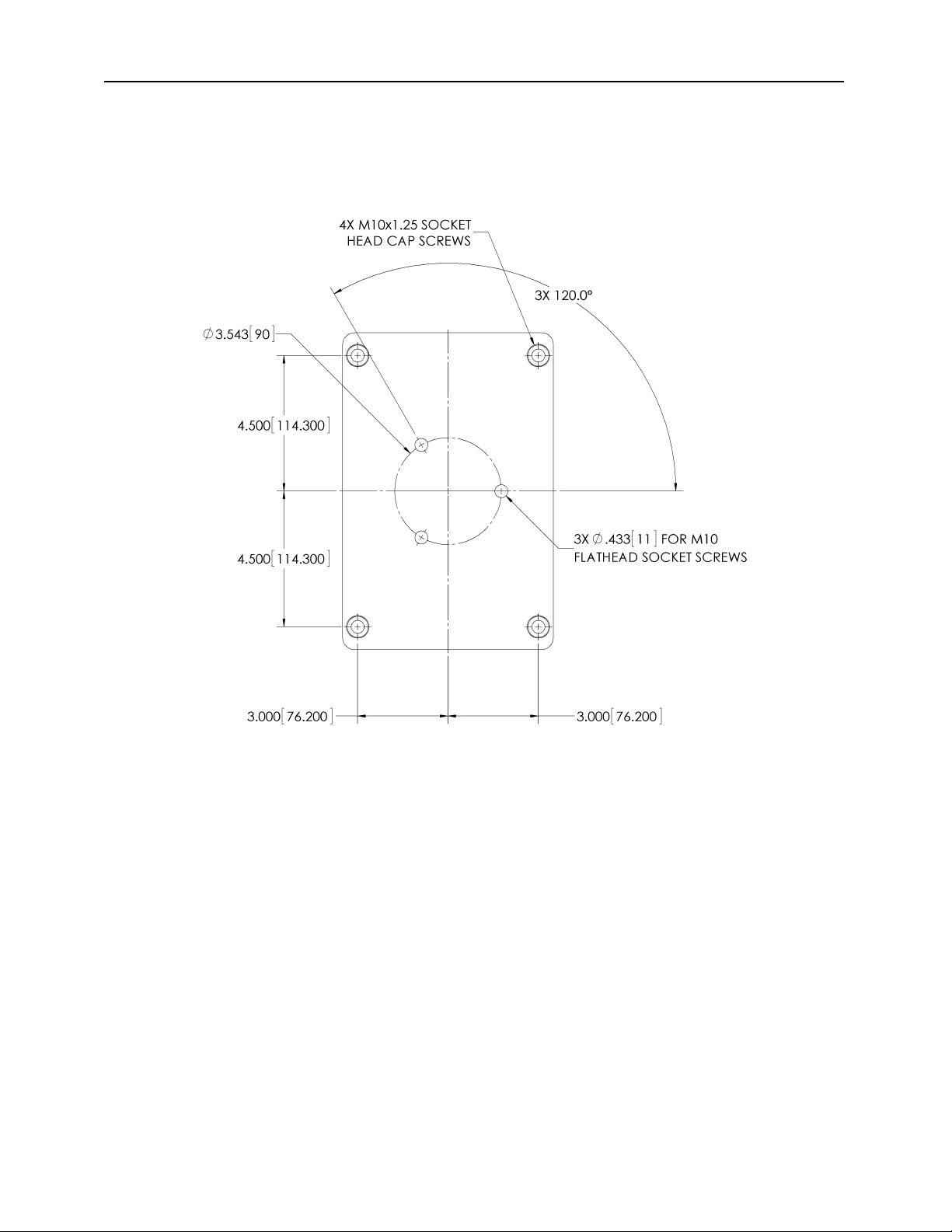

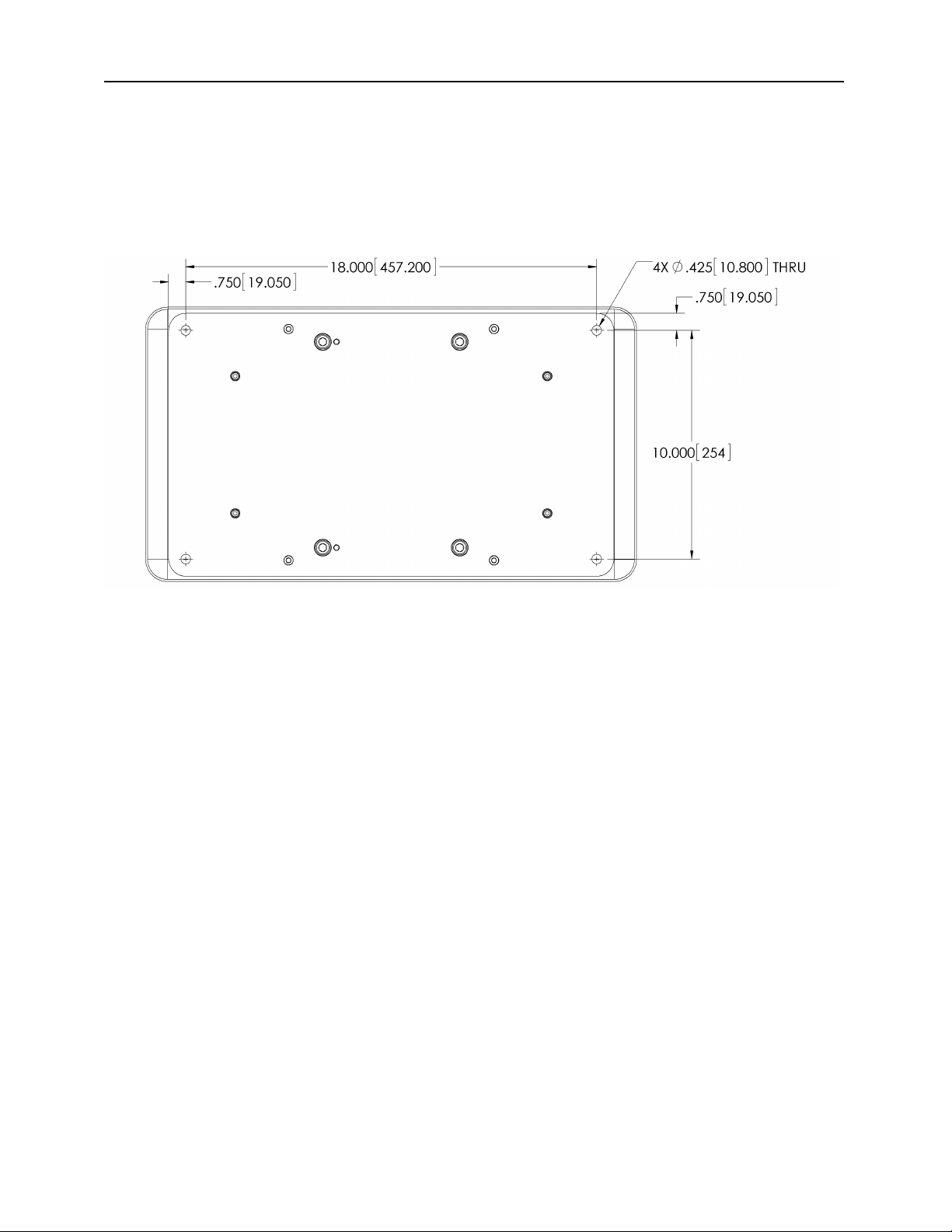

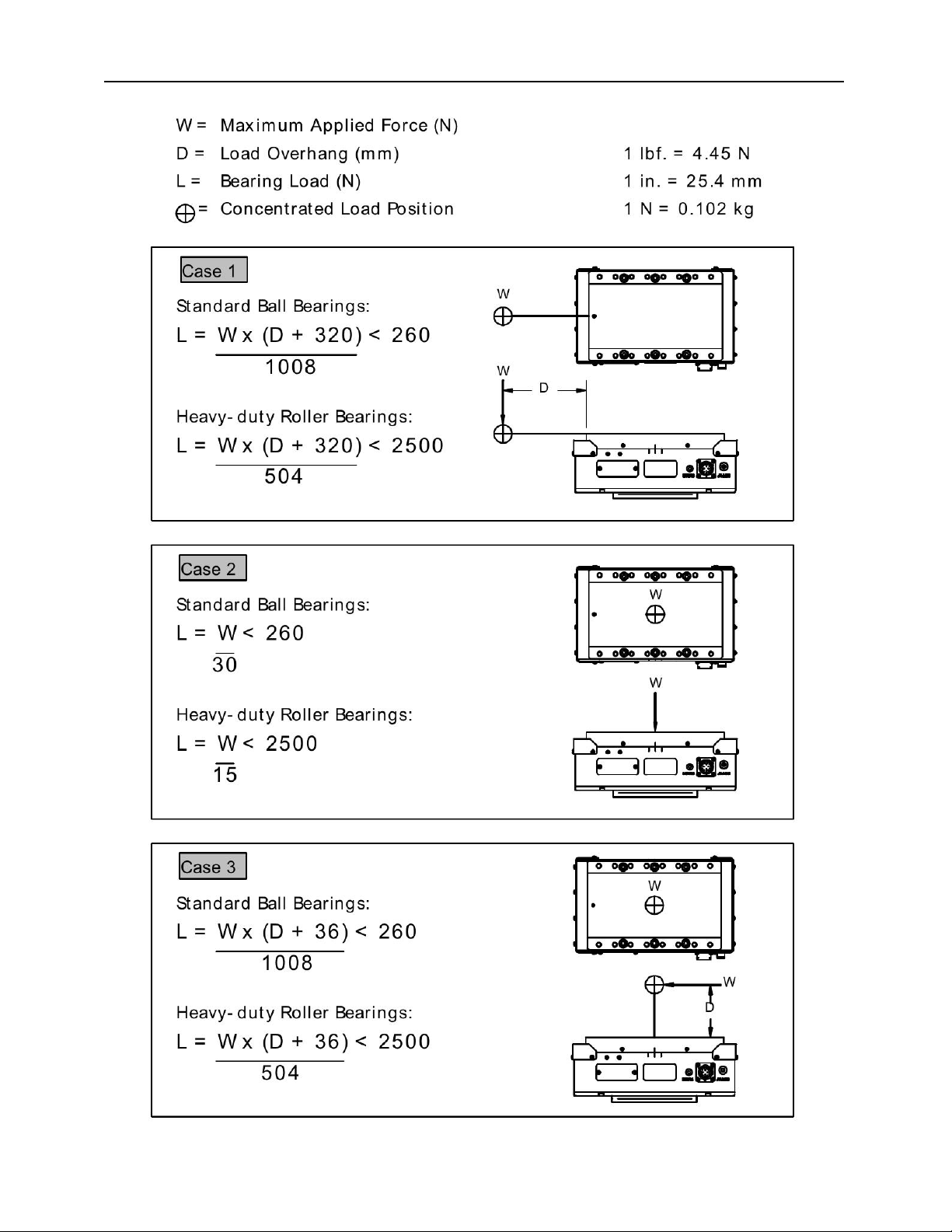

T e AFD92 Adjustable Force Device can accommodate many different types of process

equipment. Pus Corp provides a variety of standard process equipment suc as weld

s avers, ig speed motors, belt sanders, and ot er specialized tooling. Users may

also develop process equipment for t eir own proprietary applications. T e AFD can be

oriented parallel or perpendicular to t e manipulator mounting flange, alt oug it is

important to note t at t e AFD can apply force only in t e direction of Carriage

translation.

W en mounting process equipment to t e Carriage extreme care s ould be taken w ile

designing and installing t e brackets. Correctly designed brackets will increase t e

stiffness of t e Carriage by becoming an external superstructure for t e Carriage. T e

Carriage can gain a tremendous amount of rigidity if t is approac is executed correctly.

Incorrectly designed bracketry will deform t e Carriage causing internal Linear Rail

misalignment. A symptom of Carriage deformation is “slop” or “binding” of t e Carriage.

A deformed or loose Carriage will damage t e Linear Rails and degrade t e consistency

of your process. T e Carriage preload is correctly set at t e factory and s ould not

Copyrig t PushCorp, Inc. 2006. All rig ts reserved