20

09740-01.2021-DGbFITr

D

GB

F

I

TR

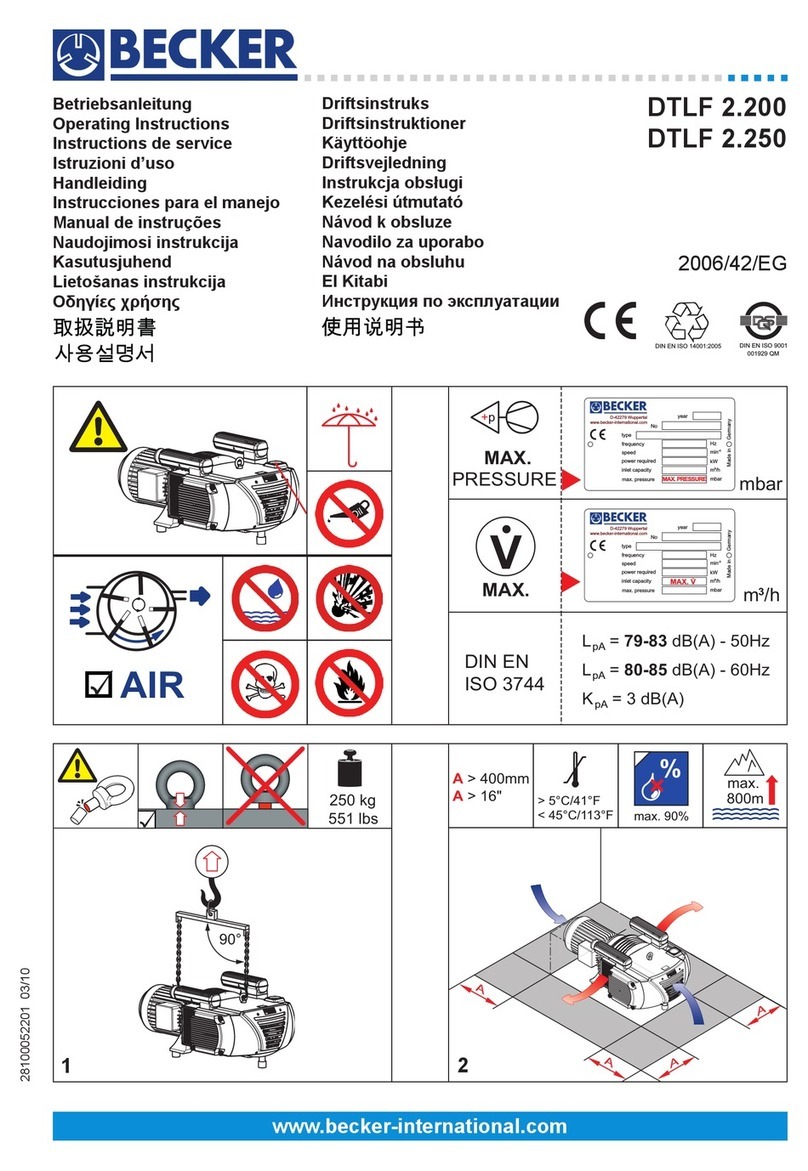

9|Dimensions and connections

Dimensions in ()=KDesign

=Centreofgravity

Shaft end

Dimensions in mm

Dimensions in mm

Fig. 14

Fig. 15

30

99

30°

4x M10 LK 130

115

ca.135

ca.150

155

78,578,5

H

B1

B

3xM10

beidseitig

125

60

73

ca.263

155

110 h8

58

SV

DV

A2

F,G

BX

4x 11

ca.215

ca.270 (280)

M8x22

25

21,69

24,7

6x M5 49

1:4

A4x6,5 DIN 6888

1,5

38 -0,05

34,3

36,3

60

55,1

A1A

View X

155

7878

50

30

99 ±1

30°

130

135

125

X

A1

A

6xM5

A4x6,5 DIN6888

1:4

36,3

34,3

25

60

38-0,05

55,1

110 h8

±0.1

%

F

E

D

C

A

F

E

D

C

41

A

B

5

6

7

8

1

2

34

5

6

78

Zeichn.-Nr. / Drawing-no. :

B

3

Kunde / Customer:

232250

über / above

Freigabe / Approved

zyxwu

Der Lieferant muss sicherstellen, dass die Ware

in einwandfreiem Zustand angeliefert wird

(Korrosionsschutz, Verpackung für sicheren

DIN ISO 2768-mK-E

Allgemeintoleranzen / General tolerances

Drawing-No.

bis / up to

Dok-ID:

ts

-

08511. -

M. Schaich

packaging for safe transportation).

model or design.

in proper conditions (corrosion prevention, Ersatz für / replacement for:

The supplier has to ensure the delivery of parts

Transport).

prohibited. Offenders will be held liable for the Dimension Passung / Clearance 2

Baumustergeprüft / Type examination:

-

K.-Auftrag / C.-Task:

Projektleiter / Project leader:

120

400

±0.5

0.5

6

-

GEA Bock GmbH - Benzstraße 7 -72636 Frickenhausen - Germany - www.bock.de

-

-

-

-

Bearb. / EditedDatum / Date

payment of damages. All rights reserved in the event Änd.-Nr. / Mod-No.

Werkstoff (Zeile 2+3 alternativ) /

Unbemaßte Radien / Undimensioned radii: Base part, Raw part:

-

Geprüft / Appr.

Name

-

Datum / Date

Material (Line 2+3 alternative):

Ausgangsteil, Rohteil /

Workpiece edges

DIN ISO 13715

Erstellt / Drawn 15.05.01

Geprüft / Verified Schaich

1/4

Keuerleber

15.05.01

Werkstückkanten /

Page:

400 Benennung / Description:

±0.8

1000

306

-

±0.3

12030

-

Blatt /

±0.2

of the grant of a patent, utility /

DIN EN ISO 1302

Zust. / Rev.

Gußtoleranzen / General casting tolerances:

Gewicht / Weight: (kg)

Zeichnungs-Nr. /

Indication of surface texture Oberflächenbehandlung, Härte / Treatment of surface, Hardness:

Scale:

C - FK20/145 N

Rz 25

Rz 160 Rz 1,6

Rz 16

Rz 63 Rz 6,3

Rz 12,5

14317

Status:

-

-

Maßstab /

Nein / No

12.03.19

in Bearbeitung (CAD)

12.03.19

.1

02.04.19

02.04.19

02.04.19

02.04.19

02.04.19

E. Bauknecht

E. Bauknecht

E. Bauknecht

E. Bauknecht

E. Bauknecht

E. Bauknecht

E. Bauknecht

0j | FK 20 vereinheitlicht nur noch mit Schauglas

0j | Schraube, Scheibe, Federring am Wellenende entfernt.

0j | Dichtungssatz + Druckschriften zu einem Satz zusammengefasst

0j | Optionale Anbauten (Blatt 4) hinzu

0j | Passcheiben 06986+06987 aufgenommen

0j | Schraubenanzugsdrehmoment ergänzt

0j | Zylinderstift für Zylinderbuchse aus VDGH entfernt und im Endprodukt aufgenommen

10617

10619

10164

10463

10470

10567

10597

M. Schaich

M. Schaich

M. Schaich

M. Schaich

M. Schaich

M. Schaich

K - FK20/145 N

Weitergabe sowie Vervielfältigung dieses Dokuments,

Verwertung und Mitteilung seines Inhalts sind ver-

boten, soweit nicht ausdrücklich gestattet. Zuwider-

handlungen verpflichten zu Schadenersatz. Alle

Rechte für den Fall der Patent-, Gebrauchsmuster-

oder Geschmacksmustereintragung vorbehalten.

The reproduction, distribution and utilization of this

document as well as the communication of its

contents to others without express authorization is

Maß

Oberflächenangaben /

Teile-Nr. /

Part-No.

Fahrzeugverdichter / Vehicle Compressor

1.0851-14317.1 0j

Typ / type Teile-Nr. / part-no. Typ / type Teile-Nr. / part-no. Typ / type Teile-Nr. / part-no.

FK(X)20/120 N 14315 (14321) FK(X)20/120 K 14316 (14322) * FK(X)20/120 TK 14327 (14330)

FK(X)20/145 N 14317 (14323) * FK(X)20/145 K 14318 (14324) * FK(X)20/145 TK 14328 (14331) *

FK(X)20/170 N 14319 (14325) FK(X)20/170 K 14320 (14326) * FK(X)20/170 TK 14329 (14332)

* Keine Serie / No series

Anschlüsse /

Connections

SV Saugabsperrventil, Rohr (L)* mm - Zoll /

mm - inch 16 - 5/8"

Suction line valve, tube (L)*

DV Druckabsperrventil, Rohr (L)* mm - Zoll /

mm - inch 16 - 5/8"

Discharge line valve, tube (L)*

AAnschluss Saugseite, nicht absperrbar Zoll / inch 7/16“ UNF

Connection suction side, not lockable

A1 Anschluss Saugseite, absperrbar Zoll / inch 7/16“ UNF

Connection suction side, lockable

A2 Anschluss Saugseite, nicht absperrbar Zoll / inch 1/8“ NPTF

Connection suction side, not lockable

BAnschluss Druckseite, nicht absperrbar Zoll / inch 7/16“ UNF

Connection discharge side, not lockable

B1 Anschluss Druckseite, absperrbar Zoll / inch 7/16“ UNF

Connection discharge side, lockable

FÖlablass Zoll / inch G 1/8"

Oil drain

GOpt. Anschlussmöglichkeit Ölsumpfheizung 1) Zoll / inch G 3/8"

Opt. connection oil sump heater 1)

HStopfen Ölfüllung Zoll / inch 1/4“ NPTF

Oil charge plug

KSchauglas Zoll / inch 1 1/8 “ – 18 UNEF

Sight glass

(L)* = Lötanschluss / brazing connection

1) = Nur ab Werk möglich / Only possible ex factory

Massenschwerpunkt

Centre of gravity Änderungen vorbehalten

Subject to change without notice Maße in mm

Dimensions in mm

( ) K Ausführung

( ) K version

beidseitig

both sides

BSV

DV A2

F,G

K

X

4x 11

114,5

+2

215

271 (281) +2

150

H

3x M10x26

B1

B

4x M10x26

15573

60

265 +2

58,1

24,7

21,69

1,5

M8x25

49

155

7878

50

30

99 ±1

30°

130

135

125

X

A1

A

6xM5

A4x6,5 DIN6888

1:4

36,3

34,3

25

60

38-0,05

55,1

110 h8

±0.1

%

F

E

D

C

A

F

E

D

C

41

A

B

5

6

7

8

1

2

34

5

6

78

Zeichn.-Nr. / Drawing-no. :

B

3

Kunde / Customer:

232250

über / above

Freigabe / Approved

zyxwu

Der Lieferant muss sicherstellen, dass die Ware

in einwandfreiem Zustand angeliefert wird

(Korrosionsschutz, Verpackung für sicheren

DIN ISO 2768-mK-E

Allgemeintoleranzen / General tolerances

Drawing-No.

bis / up to

Dok-ID:

ts

-

08511. -

M. Schaich

packaging for safe transportation).

model or design.

in proper conditions (corrosion prevention, Ersatz für / replacement for:

The supplier has to ensure the delivery of parts

Transport).

prohibited. Offenders will be held liable for the Dimension Passung / Clearance 2

Baumustergeprüft / Type examination:

-

K.-Auftrag / C.-Task:

Projektleiter / Project leader:

120

400

±0.5

0.5

6

-

GEA Bock GmbH - Benzstraße 7 - 72636 Frickenhausen - Germany - www.bock.de

-

-

-

-

Bearb. / EditedDatum / Date

payment of damages. All rights reserved in the event Änd.-Nr. / Mod-No.

Werkstoff (Zeile 2+3 alternativ) /

Unbemaßte Radien / Undimensioned radii: Base part, Raw part:

-

Geprüft / Appr.

Name

-

Datum / Date

Material (Line 2+3 alternative):

Ausgangsteil, Rohteil /

Workpiece edges

DIN ISO 13715

Erstellt / Drawn 15.05.01

Geprüft / Verified Schaich

1/4

Keuerleber

15.05.01

Werkstückkanten /

Page:

400 Benennung / Description:

±0.8

1000

306

-

±0.3

12030

-

Blatt /

±0.2

of the grant of a patent, utility /

DIN EN ISO 1302

Zust. / Rev.

Gußtoleranzen / General casting tolerances:

Gewicht / Weight: (kg)

Zeichnungs-Nr. /

Indication of surface texture Oberflächenbehandlung, Härte / Treatment of surface, Hardness:

Scale:

C - FK20/145 N

Rz 25

Rz 160 Rz 1,6

Rz 16

Rz 63 Rz 6,3

Rz 12,5

14317

Status:

-

-

Maßstab /

Nein / No

12.03.19

in Bearbeitung (CAD)

12.03.19

.1

02.04.19

02.04.19

02.04.19

02.04.19

02.04.19

E. Bauknecht

E. Bauknecht

E. Bauknecht

E. Bauknecht

E. Bauknecht

E. Bauknecht

E. Bauknecht

0j | FK 20 vereinheitlicht nur noch mit Schauglas

0j | Schraube, Scheibe, Federring am Wellenende entfernt.

0j | Dichtungssatz + Druckschriften zu einem Satz zusammengefasst

0j | Optionale Anbauten (Blatt 4) hinzu

0j | Passcheiben 06986+06987 aufgenommen

0j | Schraubenanzugsdrehmoment ergänzt

0j | Zylinderstift für Zylinderbuchse aus VDGH entfernt und im Endprodukt aufgenommen

10617

10619

10164

10463

10470

10567

10597

M. Schaich

M. Schaich

M. Schaich

M. Schaich

M. Schaich

M. Schaich

K - FK20/145 N

Weitergabe sowie Vervielfältigung dieses Dokuments,

Verwertung und Mitteilung seines Inhalts sind ver-

boten, soweit nicht ausdrücklich gestattet. Zuwider-

handlungen verpflichten zu Schadenersatz. Alle

Rechte für den Fall der Patent-, Gebrauchsmuster-

oder Geschmacksmustereintragung vorbehalten.

The reproduction, distribution and utilization of this

document as well as the communication of its

contents to others without express authorization is

Maß

Oberflächenangaben /

Teile-Nr. /

Part-No.

Fahrzeugverdichter / Vehicle Compressor

1.0851-14317.1 0j

Typ / type Teile-Nr. / part-no. Typ / type Teile-Nr. / part-no. Typ / type Teile-Nr. / part-no.

FK(X)20/120 N 14315 (14321) FK(X)20/120 K 14316 (14322) * FK(X)20/120 TK 14327 (14330)

FK(X)20/145 N 14317 (14323) * FK(X)20/145 K 14318 (14324) * FK(X)20/145 TK 14328 (14331) *

FK(X)20/170 N 14319 (14325) FK(X)20/170 K 14320 (14326) * FK(X)20/170 TK 14329 (14332)

* Keine Serie / No series

Anschlüsse /

Connections

SV Saugabsperrventil, Rohr (L)* mm - Zoll /

mm - inch 16 - 5/8"

Suction line valve, tube (L)*

DV Druckabsperrventil, Rohr (L)* mm - Zoll /

mm - inch 16 - 5/8"

Discharge line valve, tube (L)*

AAnschluss Saugseite, nicht absperrbar Zoll / inch 7/16“ UNF

Connection suction side, not lockable

A1 Anschluss Saugseite, absperrbar Zoll / inch 7/16“ UNF

Connection suction side, lockable

A2 Anschluss Saugseite, nicht absperrbar Zoll / inch 1/8“ NPTF

Connection suction side, not lockable

BAnschluss Druckseite, nicht absperrbar Zoll / inch 7/16“ UNF

Connection discharge side, not lockable

B1 Anschluss Druckseite, absperrbar Zoll / inch 7/16“ UNF

Connection discharge side, lockable

FÖlablass Zoll / inch G 1/8"

Oil drain

GOpt. Anschlussmöglichkeit Ölsumpfheizung 1) Zoll / inch G 3/8"

Opt. connection oil sump heater 1)

HStopfen Ölfüllung Zoll / inch 1/4“ NPTF

Oil charge plug

KSchauglas Zoll / inch 1 1/8 “ – 18 UNEF

Sight glass

(L)* = Lötanschluss / brazing connection

1) = Nur ab Werk möglich / Only possible ex factory

Massenschwerpunkt

Centre of gravity Änderungen vorbehalten

Subject to change without notice Maße in mm

Dimensions in mm

( ) K Ausführung

( ) K version

beidseitig

both sides

BSV

DV A2

F,G

K

X

4x 11

114,5

+2

215

271 (281) +2

150

H

3x M10x26

B1

B

4x M10x26

15573

60

265 +2

58,1