BOCK UL-HGX44e User manual

Reciprocating Compressor

BOCK UL-HGX44e/UL-HGX56e

Assembly instructions

96547-10.2021-Us

(Translation of the original instructions)

UL-HGX44e/475 ML 9

UL-HGX44e/475 S 12

UL-HGX44e/565 ML 12

UL-HGX44e/565 S 15

UL-HGX44e/665 ML 14

UL-HGX44e/665 S 20

UL-HGX44e/770 ML 15

UL-HGX44e/770 S 22

colour the world

of tomorrow

BOCK®

UL-HGX56e/850 ML 18

UL-HGX56e/850 S 25

UL-HGX56e/995 ML 23

UL-HGX56e/995 S 30

UL-HGX56e/1155 ML 28

UL-HGX56e/1155 S 35

Bock GmbH, Benzstr. 7, 72636 Frickenhausen, Germany

Phone: +49 7022 9454-0, Fax: +49 7022 9454-137

www.bock.de, [email protected]

2

D

US

F

E

96547-10.2021-Us

Foreword

Bock GmbH

Benzstr. 7

72636 Frickenhausen

Germany

Phone +49 7022 9454-0

Fax +49 7022 9454-137

www.bock.de

Manufacturer and contact

Risk of accidents.

Refrigerating compressors are pressurized machines and as such call for heightened caution

and care in handling.

Improper assembly and use of the compressor can result in serious or fatal injury!

- To avoid serious injury or death, observe all safety instructions contained in these instructions

before assembly and before using the compressor! This will avoid misunderstandings and

prevent serious or fatal injury and damage!

- Never use the product improperly but only as recommended by this manual!

- Observe all product safety labels!

- Refer to local building codes for installation requirements!

Unauthorized changes and modications to the product not covered by this manual are prohibited and

will void the warranty!

This instruction manual is a mandatory part of the product. It must be available to the personnel who

operate and maintain this product. It must be passed onto the end customer along with the unit in

which the compressor is installed.

This document is subject to the copyright of BOCK GmbH, Germany. The information provided in this

manual is subject to change and improvements without notice.

Contents Page

1 Safety ............................................................................................................................... 4

1.1 Identication of safety instructions .................................................................................... 4

1.2 General safety instructions ................................................................................................ 4

1.3 Intended use ...................................................................................................................... 5

1.4 Qualications required of personnel................................................................................... 5

2 Product description......................................................................................................... 6

2.1 Short description ............................................................................................................... 6

2.2 Name plate (example) ........................................................................................................ 7

2.3 Type key (example) ............................................................................................................ 7

3 Areas of application ........................................................................................................ 8

3.1 Refrigerants....................................................................................................................... 8

3.2 Oil charge .......................................................................................................................... 8

3.3 Limits of application........................................................................................................... 9

D

US

F

E

3

96547-10.2021-Us

Contents Page

4 Compressor assembly................................................................................................... 10

4.1 Storage and transport ...................................................................................................... 10

4.2 Setting up ........................................................................................................................ 10

4.3 Pipe connections.............................................................................................................. 11

4.4 Pipes................................................................................................................................ 11

4.5 Laying suction and pressure lines.................................................................................... 11

4.6 Operating the shut-off valves........................................................................................... 12

4.7 Operating mode of the lockable service connections ....................................................... 13

4.8 Suction pipe lter and lter drier...................................................................................... 13

5 Electrical connection .................................................................................................... 14

5.1 General safety.................................................................................................................. 14

5.2 Information for contactor and motor contactor selection.................................................. 14

5.3 Standard motor design for direct or part winding start..................................................... 14

5.4 Basic circuit diagramm for part winding start with standard motor.................................. 16

5.5 Special motor: design for direct or star-delta start........................................................... 18

5.6 Basic circuit diagramm for star-delta start with special motor......................................... 20

5.7 Electronic trigger unit INT69 G.........................................................................................22

5.8 Connection of the trigger unit INT69 G............................................................................. 22

5.9 Function test of the trigger unit INT69 G .......................................................................... 23

5.10 Oil sump heater (accessories) .......................................................................................... 23

6 Commissioning .............................................................................................................. 24

6.1 Preparations for start-up.................................................................................................. 24

6.2 Pressure integrity test...................................................................................................... 24

6.3 Leak test.......................................................................................................................... 24

6.4 Evacuation ....................................................................................................................... 24

6.5 Refrigerant charge........................................................................................................... 25

6.6 Start-up........................................................................................................................... 25

6.7 Avoiding slugging............................................................................................................. 25

7 Maintenance ..................................................................................................................26

7.1 Preparation ...................................................................................................................... 26

7.2 Work to be carried out ..................................................................................................... 26

7.3 Spare parts recommendation/accessories .......................................................................26

7.4 Lubricants / oils ............................................................................................................... 26

7.5 Decommissioning ............................................................................................................ 26

8 Technical data................................................................................................................28

9 Dimensions and connections .......................................................................................30

10 Declaration of incorporation.........................................................................................32

11 UL-CerticateofCompliance........................................................................................33

12 Service ...........................................................................................................................34

4

D

US

F

E

96547-10.2021-Us

1|Safety

Indicates a dangerous situation which, if not avoided, will cause

immediate fatal or serious injury.

Indicates a dangerous situation which, if not avoided, may cause

fatal or serious injury.

Indicates a dangerous situation which, if not avoided, may cause

fairly severe or minor injury.

Indicates a situation which, if not avoided, may cause

property damage.

Important information or tips on simplifying work.

1.2 General safety instructions

Risk of accidents.

Refrigerating compressors are pressurized machines and as such

call for heightened caution and care in handling.

The maximum permissible overpressure must not be exceeded,

even for testing purposes!

Risk of burns!

- Depending on the operating conditions, surface temperatures of

over 60°C (140°F) on the discharge side or below 0°C (32°F) on

the suction side can be reached.

- Contact with refrigerant must be avoided.

Contact with refrigerant can cause severe burns and skin

damage.

1.1 Identicationofsafetyinstructions

D

US

F

E

5

96547-10.2021-Us

1|Safety

1.4 Qualicationsrequiredofpersonnel

Inadequatelyqualiedpersonnelposes theriskofaccidents,the

consequence being serious or fatal injury. Work on compressors

isthereforereservedforpersonnelwhoarequaliedtoworkon

pressurized refrigerant systems:

• For example, a refrigeration technician, refrigeration mechatronic

engineer. As well as professions with comparable training that enables

personnel to assemble, install, maintain and repair refrigeration and

air-conditioning systems. Personnel must be capable of assessing the

work to be carried out and recognizing any potential dangers.

1.3 Intended use

The compressor may not be used in potentially explosive

environments!

• These assembly instructions describe the standard version of the compressor named in the title

manufactured by Bock. Bock refrigerating compressors are intended for installation in a ma-

chine (within the EU according to the EU Directives 2006/42/EC Machinery Directive, 2014/68/

EU Pressure Equipment Directive, outside the EU according to the respective national regulations

and guidelines).

Commissioning is permissible only if the compressor has been installed in accordance with these as-

sembly instructions and the entire system into which it is integrated has been inspected and approved

in accordance with legal regulations.

The compressors are intended for use in refrigeration systems in compliance with the limits of

application.

Only the refrigerant specied in these instructions may be used.

Any other use of the compressor is prohibited!

6

D

US

F

E

96547-10.2021-Us

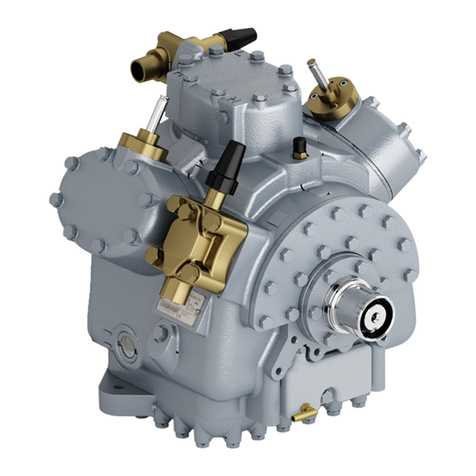

• UL-HGX44e: Semi-hermetic four-cylinder reciprocating compressor with suction-gas cooled drive

motor.

• UL-HGX56e: Semi-hermetic six-cylinder reciprocating compressor with suction-gas cooled drive

motor.

• Preferred application range: normal refrigerating and air-conditioning.

• The stream of refrigerant sucked out of the evaporator flows over the motor and cools it

intensively. In this way, the motor can be kept at a relatively low temperature level, particularly

under high loads.

2|Product description

Name plate

Fig. 1

2.1 Short description

Valve plate Cylinder

cover

Dimension and connection values can be found in Chapter 9

Transport eyelet

Discharge

shut-off valve

Oil pump

Suction

shut-off valve

Oil sight glass

Drive section

Motor section

Fig. 2

UL-HGX44e

UL-HGX56e

Terminal box

D

US

F

E

7

96547-10.2021-Us

2| Product description

2.3 Type key (example)

SE 55IP 65

BB12345-A001

107,0 A

YY: 174 AY: 196,

180,0

217,2

380-420 Y/YY

440-480 Y/YY

1 Type designation 6 Voltage, circuit, frequency

2 Machine number 7 Nominal rotation speed

3 maximum operating current 8 Displacement

4 Starting current (rotor blocked) 9 Voltage, circuit, frequency

Y: Part winding 1 10 Nominal rotation speed

YY: Part windings 1 and 2 11 Displacement

5 LP:

Max. admissible operating pressur

e12 Oil type lled at the factory

(g) Low pressure side 13 Terminal box protection type

HP:

Max. admissible operating

Electrical accessories can change

pressur

e (g) High pressure side the IP protection class!

Observe the limits of application

diagrams!

50 Hz

}

60 Hz

}

Fig. 3

Bock GmbH, Benzstr. 7

72636 Frickenhausen, Germany

BOCK

2.2 Name plate (example)

/

HGUL- 4 e 770 S 22X

¹) HG - Hermetic Gas-Cooled (suction gas-cooled)

²) X

- Ester oil charge

3) S - More powerful motor

ML - Motor for normal cooling and deep freezing

Engine performance in HP

Motor variant 3)

Swept volume

e-series

Numbers of cylinders

Size

Oil lling ²)

Series ¹)

Identication UL compressor

4

35,0 A

101 A

BOCK lub E55

: BB12345A001

: UL-HGX44e/770 S 22

thermally protected system

2365 cfh

2838 cfh

Oil: BOCK lub E55

Type

No

LP/HP = 276/406 psig

8

D

US

F

E

96547-10.2021-Us

For refilling, we recommend the above oil types.

Alternatives: see chapter 7.4

3 |Areas of application

3.1 Refrigerants

3.2 Oil charge

The oil level must be in the

visible part of the sight glass;

damage to the compressor is

possible if overfilled or under-

filled!

Max.

Min.

1.9 ltr

67 fl.ozl

Oil level

Fig. 4

~

~

More informations about approved refrigerants on Bock compressor selection tool VAP (vap.bock.de).

HFC + blends R134a, R404A/R507

HFC/HFO blends R448A, R449A, R450A, R513A

The compressors are lled at the factory with the following oil type: BOCK lub E55

D

US

F

E

9

96547-10.2021-Us

3 |Areas of application

Compressor operation is possible within the operating limits. These

can be found in Bock compressor selection tool (VAP)

under vap.bock.de. Observe the information given there.

- Permissible ambient temperature: -20°C...+60°C (-4°F...140°F)

- Max. permissible discharge end temperature 140°C (284°F).

- Max. permissible switching frequency 12x /h.

- A minimum running time of 3 min. steady-state condition

(continuous operation) must be achieved.

For operation with supplementary cooling:

- Use only oils with high thermal stability.

- Avoid continuous operation near the threshold.

- The suction gas superheat temperature may need to be reduced

or set individually when operating near to the threshold.

For operation with frequency converter:

- The maximum current and power consumption must not be

exceeded. In the case of operation above the mains frequency,

the application limit can therefore be limited.

When operating in the vacuum range, there is a danger of air

entering on the suction side. This can cause chemical reactions,

a pressure rise in the condenser and an elevated compressed-gas

temperature. Prevent the ingress of air at all costs!

3.3 Limits of application

Maximum admissible operating pressure (LP/HP)1):

19/28 bar (276/406 psig)

1) LP = Low pressure

HP = High pressure

10

D

US

F

E

96547-10.2021-Us

Sun protection: If the compressor is set up outdoors, it has

to be protected from direct sunlight.

4 |Compressor assembly

Newcompressorsarefactory-lledwithinertgas.Leavethisser-

vice charge in the compressor for as long as possible and prevent

the ingress of air. Check the compressor for transport damage

before starting any work.

ATTENTION Attachments (e.g. pipe holders, additional units, fastening parts,

etc.) directly to the compressor are not permissible!

Setup on an even surface or frame with sufcient load-

bearing capacity.

Single compressor preferably on vibration damper.

Duplex and parallel circuits always rigid.

Provide adequate clearance for maintenance work.

Ensure adequate compressor ventilation.

Do not use in a corrosive, dusty, damp atmosphere or a

combustible environment.

F

E

D

C

B

A

1

2

3

4

F

E

D

C

4

3

2

1

A

B

Tol.-Ang. DIN ISO 2768-mK

Ra Rz

Maß

Passung

Freigabe

Alternativbezug:

Baumustergeprüft

Teil inaktiv

Lieferantenzeichnung

-

-

K.-Auftrag:

PL:

Zeichnung ungültig

Entwicklungsstand

Teil keine Serie

120

400

±0.5

über 0.5

bis 6

Benzstraße 7 - 72636 Frickenhausen - Germany - www.bock.de

-

-

Unbemaßte Radien:

-

Diese Zeichnung ist unser Eigentum!

Sie darf ohne unsere Genehmigung weder nach-

gebildet, vervielfältigt, oder Dritten Personen zu-

gänglich gemacht werden. Der Nachbau nach

dieser Zeichnung, oder an Hand der nach dieser

Zeichnung hergestellten Gegenstände durch den

Abnehmer oder Dritte ist nicht gestattet.

Wir behalten uns alle Rechte, gemäß DIN ISO 16016

an dieser Zeichnung vor.

Bearb.

Datum

Änderungs-Nr.

Werkstoff:

Ausgangsteil, bzw. Rohteil:

--

Gepr.

Name

Datum

19.04.

Werkstückkanten

DIN ISO 13715

Ersatz für:

Ersetzt durch:

Erstellt

2010

Geprüft

-

Kurz

Zone

1/x

Oberflächenbehandlung / Härte:

-

Blatt:

Änderungsbeschreibung

400

Benennung:

±0.8

1000

30

6

-

±0.3

120

30

±0.2

Zeichn.-Nr. Teile-Nr.

Oberflächenangaben ISO 1302

x.xxxx-xxxxx.x

Zust.

Gußtoleranzen:

Gewicht: (kg)

±0.1

Maßstab:

1:1

Wasserwaage

für Indesign

Der Lieferant muß sicherstellen, dass die Ware in

einwandfreiem Zustand angeliefert wird (Korrosions-

schutz, Verpackung für sicheren Transport).

Rz 25

Rz 160

s

25

z

y

x

w

u

t

0,05

Rz 1,6

0,3

0,7

1,6

2

Rz 16

6,3

Rz 63

Rz 6,3

Rz 12,5

F:\user\kurz\3D Sachen\3D Teile\Zeichnungen\Wasserwaage

4.2 Setting up

?

4.1 Storage and transport

Use transport eyelet.

Do not lift manually!

Use lifting gear!

Storage at (-30°C) - (+70°C), (-22 °F) - (158 °F), maximum permis-

sible relative humidity 10% - 95%, no condensation

Do not store in a corrosive, dusty, vaporous atmosphere or in a com-

bustible environment.

D

US

F

E

11

96547-10.2021-Us

4.4 Pipes

Pipes and system components must be clean and dry inside and free of scale, swarf and layers of

rust and phosphate. Only use air-tight parts.

Lay pipes correctly. Suitable vibration compensators must be provided to prevent pipes being

cracked and broken by severe vibrations.

Ensure a proper oil return.

Keep pressure losses to an absolute minimum.

The pipe connections have graduated inside diameters so that pipes with

standart millimetre and inch dimensions can be used.

The connection diameters of the shut-off valves are rated for maximum

compressor output. The actual required pipe cross section must be

matched to the output. The same applies for non-return valves.

Fig. 5: graduated

internal diameter

4.3 Pipe connections

4 |Compressor assembly

4.5 Laying suction and pressure lines

Improperly installed pipes can cause cracks and tears, the result

being a loss of refrigerant.

Proper layout of the suction and discharge lines directly after

the compressor is integral to the system’s smooth running and

vibration behavior.

Damage possible.

Do not solder as long as the compressor is under pressure.

Superheating can damage the valve. Remove the pipe supports

therefore from the valve for soldering and accordingly cool the

valve body during and after soldering.

Only solder using inert gas to inhibit oxidation products (scale).

12

D

US

F

E

96547-10.2021-Us

Fig. 6

As short as

possible

Rigid

fixed point

4 |Compressor assembly

A rule of thumb: Always lay the rst pipe section starting from the shut-off valve downwards and

parallel to the drive shaft.

a) For HG44e a intermediate ange (height 27 mm) is optional available,

Art-Nr. 81194.

With this intermediate ange it is possible to lay the pressure line directly from

the valve to the left or right.

4.6 Operating the shut-off valves

Before opening or closing the shut-off valve, release the valve spindle seal by approx. ¼ of a turn

counter-clockwise.

After activating the shut-off valve, re-tighten the adjustable valve spindle seal clockwise.

Fig. 7 Fig. 8

Valve spindle seal

Release Tighten

a)

D

US

F

E

13

96547-10.2021-Us

4 |Compressor assembly

Pipe connection

Pipe connection

4.7 Operating mode of the lockable service connections

Fig. 9

Opening the shut-off valve:

Spindle: turn to the left (counter-clockwise) as far as it will go.

—> Shut-off valve completely opened / service connection closed.

The connection which cannot be shut off is intended for safety devices.

Fig. 10

Opening the service connection

Spindle: Turn ½ - 1 turn to the right clockwise.

—> Service connection opened / shut-off valve opened.

The connection which cannot be shut off is intended for safety devices.

Service connection

closed

Connection

blocked

Spindle

Connection cannot

be shut off

Connection cannot

be shut off

Service connection

opened

Spindle Connection

open

Compressor

Compressor

After activating the spindle, generally t the spindle protection cap again and tighten with 14-16 Nm.

This serves as a second sealing feature during operation.

For systems with long pipes and higher degree of contamination, a lter on the suction-side is

recommended. The lter has to be be renewed depending on the degree of contamination (reduced

pressure loss).

Moisture in the refrigeration circuit can lead to crystal and hydrate formation. For this reason, we

recommend using a lter drier and a sight glass with a moisture indicator.

4.8Suctionpipelterandlterdrier

14

D

US

F

E

96547-10.2021-Us

Designation on the name plate

Y/YY

Compressors with this marking are suitable for direct or partial winding start. The motor winding is

subdivided into two parts: Part winding 1 = 50% and part winding 2 = 50%. This winding division

reduces the start-up current needed for a part winding start to approx. 50% of that for a direct start.

A mechanical unloaded start with bypass solenoid valve is

not required.

5 |Electrical connection

5.2 Information for contactor and motor contactor selection

All protection equipment, switching and monitoring devices must comply with the local safety regula-

tions and established specications (e.g. VDE) and regulations as well as the manufacturer’s speci-

cations. Motor protection switches are required! Motor contactors, feed lines, fuses and motor

protection switches must be rated according to the maximum operating current (see name plate).

For motor protection, use a current-independent, time-delayed overload protection device for monitor-

ing all three phases. Adjust the overload protection device so that it must be actuated within 2 hours

at 1.2 times the maximum working current.

5.1 General safety

5.3 Standard motor, design for direct or part winding start

Connect the compressor motor in accordance with the circuit diagram

(see inside of terminal box).

Use suitable cable entry point of the correct protection type (see

name plate) for routing cables into the terminal box. Insert the strain

relieves and prevent chafe marks on the cables.

Compare the voltage and frequency values with the data for the

mains power supply.

Only connect the motor if these values are the same.

Risk of electric shock! High voltage!

Only carry out work when the electrical system is disconnected

from the power supply!

When attaching accessories with an electrical cable, a minimum

bending radius of 3 x the cable diameter must be maintained for

laying the cable.

D

US

F

E

15

96547-10.2021-Us

5 |Electrical connection

400 V

Direktstart YY Teilwicklungsstart Y/YY

1V1 1W11U1

2W12V12U1

L3L2L1 L3L2L1

L3L2L1

1V1 1W11U1

2W12V12U1

Direct start YY Part winding start Y/YY

The motor is wired for direct start (YY) at the factory. For part winding start Y / YY, the bridges must

be removed and the motor feed line connected according to the circuit diagram:

Failure to do this results in opposed rotary elds and results in

damage to the motor. After the motor starts up via partial winding

1, partial winding 2 must be switched on after a maximum delay

of one second. Failure to comply can adversely affect the service

life of the motor.

16

D

US

F

E

96547-10.2021-Us

5.4 Basic circuit diagram for part winding start with standard motor

Οnderung

2

0

Datum Name

Datum

Bearb.

Gepr.

Norm

1

20.02.2009

bauknecht

26.11.2020

Urspr.

2

Ers. f.

3

Ers. d.

4

PW INT69 HG44/66

567

BOCK COMPRESSORS

8

=

+

9

Bl.

6.d Bl.

5.a

2.a

Anschlußkasten Verdichter

BT1

INT69

DELTA- P II

QA1

L1 L2 L3 N PE

FC1.1

I> I>

I>

QA2

1U1

1V1

1W1

PE

EC1

M

Y/YY

2U1

2V1

2W1

FC1.2

I> I>

I>

QA3

FC1.1

FC1.2

FC2

SF1

BP2

P>

QA2

BP3

P

QA2

KF1

KF1

QA2

L1.1

L2.1

L3.1

L1.2

N

PE

QA3

BT4

BT2

Θ

1112 14

L N B1 B2

12

11

10

9

8

7

6

5

4

3

2

1

Θ

vio bn bu gr

Θ

EB1

pk og

21

20

BT3

Θ

Fig. 11

50% 50%

Compressor terminal box

BP2 High pressure safety monitor

BP3 Safety chain (high/low pressure monitoring)

BT1 Cold conductor (PTC sensor) motor winding

BT2 Thermal protection thermostat (PTC sensor)

BT3 Oil temperature sensor

BT4 Release switch (thermostat)

DELTA-P II Oil differential pressure sensor DELTA-P II (accessorie)

EB1 Oil sump heater

EC1 Compressor motor

D

US

F

E

17

96547-10.2021-Us

Οnderung

2

0

Datum Name

Datum

Bearb.

Gepr.

Norm

1

20.02.2009

bauknecht

26.11.2020

Urspr.

2

Ers. f.

3

Ers. d.

4

PW INT69 HG44/66

567

BOCK COMPRESSORS

8

=

+

9

Bl.

6.d Bl.

5.a

2.a

Anschlußkasten Verdichter

BT1

INT69

DELTA- P II

QA1

L1 L2 L3 N PE

FC1.1

I> I>

I>

QA2

1U1

1V1

1W1

PE

EC1

M

Y/YY

2U1

2V1

2W1

FC1.2

I> I>

I>

QA3

FC1.1

FC1.2

FC2

SF1

BP2

P>

QA2

BP3

P

QA2

KF1

KF1

QA2

L1.1

L2.1

L3.1

L1.2

N

PE

QA3

BT4

BT2

Θ

1112 14

L N B1 B2

12

11

10

9

8

7

6

5

4

3

2

1

Θ

vio bn bu gr

Θ

EB1

pk og

21

20

BT3

Θ

FC1.1/1.2 Motor protection switch

FC2 Control power circuit fuse

INT69 G Electronic trigger unit INT69 G

KF1 Delay relay for contactor switchover

QA1 Main switch

QA2 Mains contactor (part winding 1)

QA3 Mains contactor (part winding 2)

SF1 Control voltage switch

18

D

US

F

E

96547-10.2021-Us

5 |Electrical connection

5.5 Special motor: design for direct or star-delta start

A mechanical unloaded start with bypass solenoid valve is required for the star-delta start.

Designation on the name plate

∆/ Y

D

US

F

E

19

96547-10.2021-Us

5 |Electrical connection

Star-delta start-up is only possible for 230 V power supply. Example:

230 V ∆

Direct start Star-delta start

400 V Y

Direct start only

5.4 Sondermotor: Ausführung für Direkt- oder Stern-Dreieck-Anlauf

Für den Stern-Dreieck-Anlauf ist eine mechanische Anlaufentlastung mit Bypass-Magnetventil

(Zubehör) erforderlich.

Bezeichnung auf dem Typschild Aufkleber auf Klemmenkasten

∆/ Y

Stern-Dreieck-Anlauf ist nur im Spannungsbereich ∆(230 V) möglich. Beispiel:

230 V ∆

Direktstart Stern-Dreieck-Start

L3L1

V1 W1

U1

V2

U2

W2

L1 L2 L3

L2

V1 W1

U1

V2

U2

W2

L3L2L1

400 V Y

nur Direktstart

V1 W1U1

V2U2W2

L1 L2 L3

5.4 Sondermotor: Ausführung für Direkt- oder Stern-Dreieck-Anlauf

Für den Stern-Dreieck-Anlauf ist eine mechanische Anlaufentlastung mit Bypass-Magnetventil

(Zubehör) erforderlich.

Bezeichnung auf dem Typschild Aufkleber auf Klemmenkasten

∆/ Y

Stern-Dreieck-Anlauf ist nur im Spannungsbereich ∆(230 V) möglich. Beispiel:

230 V ∆

Direktstart Stern-Dreieck-Start

L3L1

V1 W1

U1

V2

U2

W2

L1 L2 L3

L2

V1 W1

U1

V2

U2

W2

L3L2L1

400 V Y

nur Direktstart

V1 W1U1

V2U2W2

L1 L2 L3

5.4 Sondermotor: Ausführung für Direkt- oder Stern-Dreieck-Anlauf

Für den Stern-Dreieck-Anlauf ist eine mechanische Anlaufentlastung mit Bypass-Magnetventil

(Zubehör) erforderlich.

Bezeichnung auf dem Typschild Aufkleber auf Klemmenkasten

∆/ Y

Stern-Dreieck-Anlauf ist nur im Spannungsbereich ∆(230 V) möglich. Beispiel:

230 V ∆

Direktstart Stern-Dreieck-Start

L3L1

V1 W1

U1

V2

U2

W2

L1 L2 L3

L2

V1 W1

U1

V2

U2

W2

L3L2L1

400 V Y

nur Direktstart

V1 W1U1

V2U2W2

L1 L2 L3

20

D

US

F

E

96547-10.2021-Us

Οnderung

4

0

Datum Name

Datum

Bearb.

Gepr.

Norm

1

20.02.2009

bauknecht

03.11.2020

Urspr.

2

Ers. f.

3

Ers. d.

4

D/S INT69 HG44/66 neu

567

BOCK COMPRESSORS

8

=

+

9

Bl.

6.d Bl.

6.b

6.a

Anschlußkasten Verdichter

BT1

INT69G

DELTA- P II

QA1

L1 L2 L3 N PE

U1

V1

W1

PE

U2

V2

W2

FC1.1

FC1.2

FC2

SF1

BP2

P>

BP3

P

QA2

L1.1

L2.1

L3.1

L1.2

N

PE

BT4

BT2

Θ

1112 14

L N B1 B2

12

11

10

9

8

7

6

5

4

3

2

1

Θ

vio bn bu gr pk og

Θ

EB1

FC1.1

I> I>

I>

1

2

QA2

FC1.2

I> I>

I>

3

4

5

6

1

2

QA4

Y

3

4

5

6

1

2

QA3

D

3

4

5

6

EC1

M

3˜

QA2

QA2

QA4 KF1

QA4

QA3

KF1

QA3

QA4 KF1

20

21

BT3

Θ

Fig. 12

5.6 Basic circuit diagram for star-delta start with special motor

Compressor terminal box

BP2 High pressure safety monitor

BP3 Safety chain (high/low pressure monitoring)

BT1 Cold conductor (PTC sensor) motor winding

BT2 Thermal protection thermostat (PTC sensor)

BT3 Oil temperature sensor

BT4 Release switch (thermostat)

DELTA PII Oil differential pressure sensor DELTA-P II (accessorie)

EB1 Oil sump heater

EC1 Compressor motor

This manual suits for next models

15

Table of contents

Other BOCK Compressor manuals

Popular Compressor manuals by other brands

Parkside

Parkside PAK 16 A1 Original instructions

Dürr Technik

Dürr Technik HB-304M Installation and operationg instructions

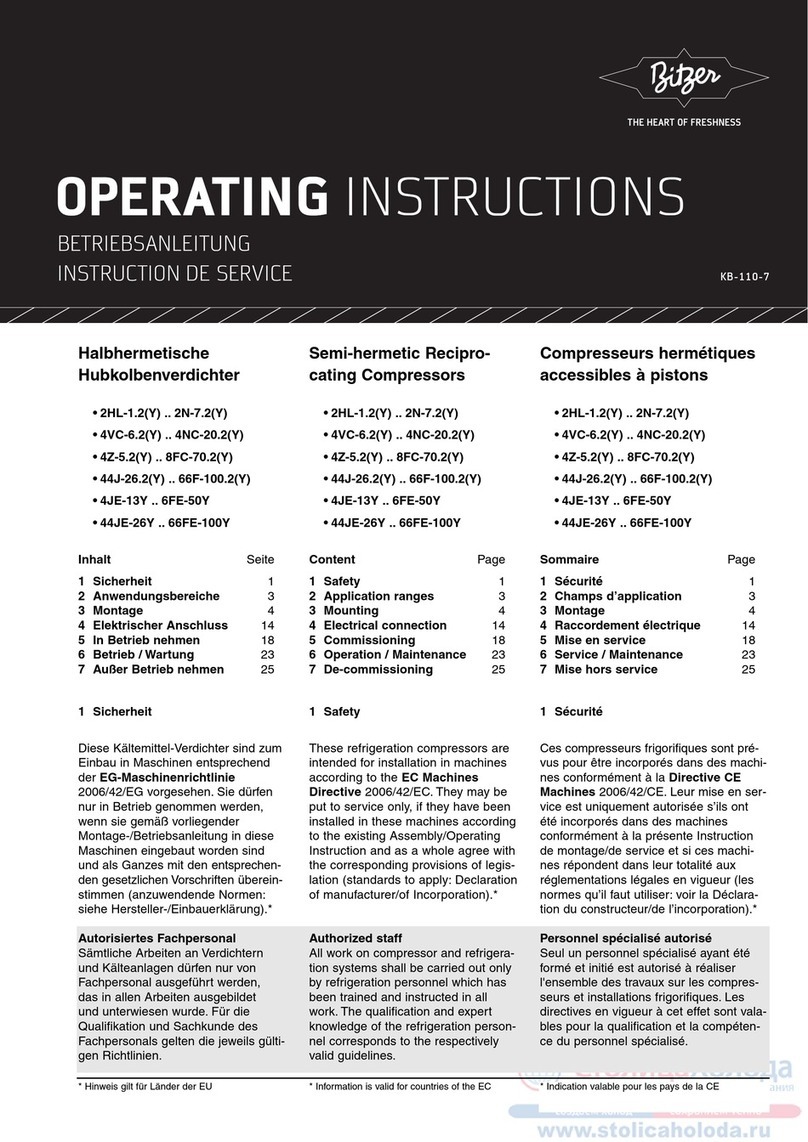

Bitzer

Bitzer 2HL-1.2Y operating instructions

Carrier

Carrier TRANSICOLD 05G Operation and service

EKOM

EKOM DK50 4x4VRT/M user manual

Pittsburgh

Pittsburgh 3980 Assembly and operating instructions

Scheppach

Scheppach HC 6 Original instruction manual

Ingersoll-Rand

Ingersoll-Rand XHP750WCAT Operation & maintenance manual

Quantum Design

Quantum Design HAC 4500 Maintenance Instruction

Parkside

Parkside PKO 270 A1 Operation and safety notes

GreenWorks

GreenWorks 4104107 user manual

Alsafix

Alsafix ALAIR 4/40 User manual and spare parts list