BOCK BOCK HG12P User manual

BOCK HG

12

P (HC/LG)

BOCK®

2

D

GB

F

E

I

Ru

09652-06.2021-DGbFEIRu

About these instructions

Read these instructions before assembly and before using the compressor. This will avoid misunder-

standings and prevent damage. Improper assembly and use of the compressor can result in serious

or fatal injury.

Observe the safety instructions contained in these instructions.

These instructions must be passed onto the end customer along with the unit in which the compres-

sor is installed.

Bock GmbH

72636 Frickenhausen

Bock GmbH

Benzstraße 7

72636 Frickenhausen

Germany

Phone +49 7022 9454-0

Fax +49 7022 9454-137

www.bock.de

Manufacturer

Contact

Contents Page

1 Safety 4

1.1 Identicationofsafetyinstructions

1.2 Qualicationsrequiredofpersonnel

1.3 General safety instructions

1.4 Intended use

2 Safetyinstructionsforuseofammablerefrigerants 6

2.1 Safety instructions

2.2 Qualicationsrequiredofpersonnel

3 Product description 7

3.1 Short description

3.2 Name plate

3.3 Type key

3.4 Type key HC compressors

3.5 Type key LG compressors

D

GB

F

E

I

Ru

3

09652-06.2021-DGbFEIRu

Contents Page

4 Areasofapplication 10

4.1 Refrigerants

4.2 Oil charge

4.3 Limits of application

5AreasofapplicationonHCandLGcompressors 11

5.1 Refrigerants

5.2 Oil charge

5.3 Limits of application

6Compressorassembly 12

6.1 Storage and transport

6.2 Setting up

6.3 Pipe connections

6.4 Pipes

6.5 Laying suction and pressure lines

6.6 Suctionpipelterandlterdrier

6.7 Operating the shut-off valves

6.8 Operating mode of the lockable service connections

7 Electricalconnection 15

7.1 Information for contactor and motor contactor selection

7.2 Connection of the driving motor

7.3 Circuit diagram for direct start 230 V Δ/ 400 V Y

7.4 Electronic trigger unit INT69 G

7.5 Connection of the electronic trigger unit INT69 G

7.6 Functional test of the electronic trigger unit INT69 G

7.7 Electronic trigger unit INT69 G on HC and LG compressors

7.8 Oil sump heater on HC and LG compressors

8 Commissioning 21

8.1 Preparations for start-up

8.2 Pressure strength test

8.3 Leak test

8.4 Evacuation

8.5 Refrigerant charge

8.6 Start-up

8.7 Avoiding slugging

8.8 Connection of oil level regulator

9 Maintenance 23

9.1 Preparation

9.2 Work to be carried out

9.3 Spare parts recommendation/accessories

9.4 Lubricants / oil

9.5 Decommissioning

9.6 Additionalinformationwhenusingammablerefrigerants

10 Technicaldata 25

11 Dimensionsandconnections 26

12 Declarationofincorporation 27

13 Service 28

4

D

GB

F

E

I

Ru

09652-06.2021-DGbFEIRu

1|Safety

1.2 Qualicationsrequiredofpersonnel

DANGER Indicatesadangeroussituationwhich,ifnotavoided,

willcauseimmediatefatalorseriousinjury.

WARNING Indicatesadangeroussituationwhich,ifnotavoided,

maycausefatalorseriousinjury.

CAUTION Indicatesadangeroussituationwhich,ifnotavoided,

maycausefairlysevereorminorinjury.

ATTENTION Indicatesasituationwhich,ifnotavoided,

maycausepropertydamage.

INFO Importantinformationortipsonsimplifyingwork.

WARNING Inadequatelyqualiedpersonnelposesthe riskof accidents,the

consequencebeingseriousorfatalinjury.Workoncompressors

isthereforereservedforpersonnelwhichisqualiedtoworkon

pressurizedrefrigerantsystems:

• For example, a refrigeration technician, refrigeration mechatronic

engineer. As well as professions with comparable training, which

enables personnel to assemble, install, maintain and repair

refrigeration and air-conditioning systems. Personnel must be capable

of assessing the work to be carried out and recognising any potential

dangers.

1.1 Identicationofsafetyinstructions:

D

GB

F

E

I

Ru

5

09652-06.2021-DGbFEIRu

1|Safety

1.4 Intended use

1.3 Generalsafetyinstructions

WARNING Riskofaccidents.

Refrigeratingcompressorsarepressurisedmachines andassuch

callforheightenedcautionandcareinhandling.

The maximum permissible overpressure must not be exceeded,

evenfortestingpurposes.

Riskofburns!

- Dependingontheoperatingconditions,surfacetemperaturesof

over60°Conthedischargesideorbelow0°Conthesuction

sidecanbereached.

-Avoidcontactwithrefrigerantnecessarily.

Contactwithrefrigerantcancausesevereburnsandskin

damage.

WARNING The compressor may not be used in potentially explosive

environments!

These assembly instructions describe the standard version of the compressor named in the title

manufactured by Bock. Bock refrigerating compressors are intended for installation in a machine

(within the EU according to the EU Directives 2006/42/EC Machinery Directive and 2014/68/EU Pres-

sureEquipmentDirective).

Commissioning is permissible only if the compressor has been installed in accordance with these as-

sembly instructions and the entire system into which it is integrated has been inspected and approved

in accordance with legal regulations.

The compressors are intended for use in refrigeration systems in compliance with the limits of

application.

Onlytherefrigerantspeciedintheseinstructionsmaybeused.

Anyotheruseofthecompressorisprohibited!

6

D

GB

F

E

I

Ru

09652-06.2021-DGbFEIRu

2 |Safety instructions for use of

flammable refrigerants

DANGER • Explosion and fire risk! Hydrocarbons and synthetic HFO

refrigerants are colourless, combustible gases which

occur naturally and which are explosive in a certain blend!

• Hydrocarbons are classied into the safety group A3 (highly-

inammablerefrigerant)accordingtoEN378.

•HFOrefrigerantsareclassiedintothesafetygroupA2L(hardly-

inammablerefrigerant)accordingtoEN378.

Astheyareheavierthanair,theoperatinglocationmustbeabove

groundleveltoallowunrestricteddischargeofthegas.

• By means of a risk and hazard analysis, appropriate technical

measuresaretobeidentifiedinordertoachievesufficientrisk

reduction. If necessary, a classification of the hazardous areas

accordingtoEN60079-10-1shouldbecarriedout.Iftherefriger-

antconcentrationexceedsthevalueof25%ofthelowerflamma-

bilitylimit(LEL),allequipmentinthehazardousareawhichisnot

permittedforoperationinhazardousareasmustbeimmediately

switchedoffwithoutanyvoltage.

•Useonlysuitableequipmentapprovedforflammablerefrigerants.

•Observethenationalregulations.

INFO Semi-hermeticcompressorsaretobeclassifiedas"technically

tight"(seee.g.TRBS2152part2/TRGS722).

2.1 Safety instructions

2.2 Qualicationsrequiredofpersonnel

WARNING Inadequatelyqualiedpersonnelposes theriskofaccidents,the

consequencebeingseriousorfatalinjury.Workonthecompressor

maytherefore onlybe carriedoutby personswho aretrainedin

handlingammablerefrigerants.

D

GB

F

E

I

Ru

7

09652-06.2021-DGbFEIRu

3|Product description

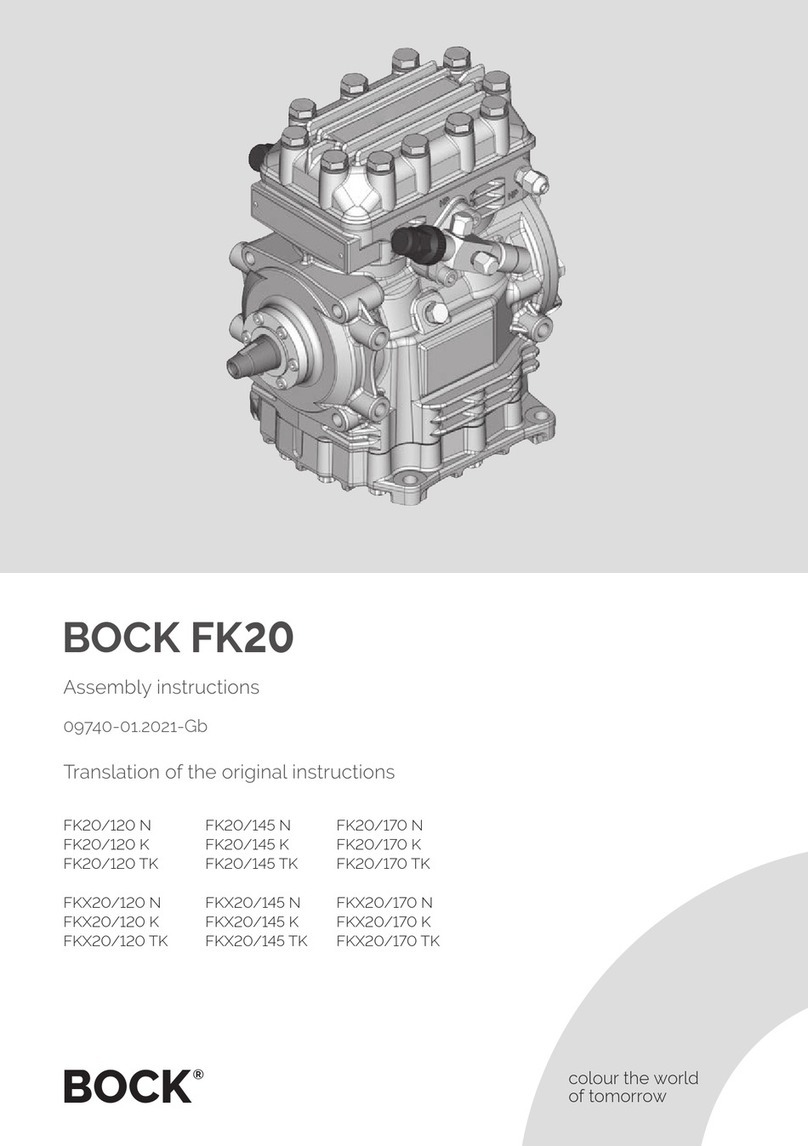

• Semi-hermetic two-cylinder reciprocating compressor with oil pump lubrication.

• Suction gas cooled drive motor.

3.1 Shortdescription

Fig. 2

Dimension and connection values can be found in Chapter 11

Fig. 1

Transport eyelet

Valve plate

Oil pump Name plate

Oil sight glass

Cylinder cover

Discharge

shut-off valve

Drive section

Motor section

Terminal box

Suction

shut-off valve

8

D

GB

F

E

I

Ru

09652-06.2021-DGbFEIRu

3|Product description

3.2 Nameplate(example)

1 Typedesignation 6 Voltage,circuit,frequency

2 Machine number 7 Nominal rotation speed

3 maximum operating current 8 Displacement

4 Startingcurrent(rotorblocked) 9 Voltage,circuit,frequency

5 ND(LP):max.admissibleoperating 10 Nominalrotationspeed

pressure (g)Low pressure side 11 Displacement

HD(HP):

max. admissible operating

12 Oiltypelledatthefactory

pressur

e(g)High pressure side 13 Terminal box protection type

Observethelimitsofapplication Electricalaccessoriescanchange

diagrams! theIPprotectionclass!

50 Hz

}

60 Hz

}

/

HG 21 P 110- 4 SX

3.3 Typekey(example)

¹)HG - HermeticGas-cooled(suctiongas-cooled)forthenormal-/airconditioningapplications

²)X

- Esteroilcharge(HFCrefrigerant,e.g.R134a,R404A/R507,R407C)

³) Additional declaration for Pluscom compressors

4)S - More powerful motor, e.g. for air-conditioning applications

Motor variant 4)

Number of poles

Swept volume

³)

Numbers of cylinders

Size

Oil charge ²)

Series ¹)

Typschild (Beispiel)

1

2

3

4

513

12

7

11

6

10

8

9

1 Typbezeichnung

2 Maschinennummer

3 maximaler Betriebsstrom

4 Anlaufstrom (Rotor blockiert)

5 ND (LP): max. zulässiger Stillstandsdruck

Saugseite

HD (HP): max. zulässiger Betriebsdruck

Hochdruckseite

Einsatzgrenzendiagramme beachten!

50 Hz

60 Hz

6 Spannung, Schaltung, Frequenz

7 Nenndrehzahl

8 Hubvolumen

9 Spannung, Schaltung, Frequenz

10 Nenndrehzahl

11 Hubvolumen

12 Werkseitig eingefüllte Ölsorte

13 Schutzart Klemmenkasten

10,6/6,1A

45A 26A

9,4

11,3

HGX12P/110-4S

AS35830A001

AS35830A001

1

2

3

4

5

6

7

8

9

10

12

13

11

Fig. 3

Bock GmbH, Benzstr. 7

72636 Frickenhausen, Germany

BOCK

BOCK lub E55

D

GB

F

E

I

Ru

9

09652-06.2021-DGbFEIRu

3|Product description

/

/

HG

HG

2

2

1

1

P

P

110-

110

HC

LG

4

S

S

3

X

3.4 Typekey HCcompressor (example)

3.5 Typkey LGcompressor (example)

¹)HG - Hermetic Gas-Cooled (suction gas-cooled)

²) Additional declaration for Pluscom compressors

³)S - More powerful motor

¹)HG - Hermetic Gas-Cooled (suction gas-cooled)

²)X

- Ester oil charge

³) Additional declaration for Pluscom compressors

4)S - More powerful motor, e.g. for air-conditioning applications

ML - Motor for normal cooling and deep freezing

Hydrocarbons

Motor variant ³)

Number of poles

Swept volume

²)

Numbers of cylinders

Size

Series ¹)

HFO refrigerant

Engine performance in hp

Motor variant 4)

Swept volume

³)

Numbers of cylinders

Size

Oil charge ²)

Series ¹)

10

D

GB

F

E

I

Ru

09652-06.2021-DGbFEIRu

4|Areas of application

4.1 Refrigerants

• HFKW/HFC: R134a, R404A/R507, R407C

• (H)FCKW/(H)CFC: R22

4.2 Oilcharge

4.3 Limitsofapplication

INFO Forrefilling,werecommendtheaboveoiltypes.

Alternatives:seechapter 9.4

ATTENTION The oil level must be in the

visiblepartofthesightglass;

damage to the compressor is

possibleifoverfilledorunder-

filled! Fig. 4

max.

min.

0,5 Ltr.

oil level ~

~

ATTENTION Compressoroperationispossiblewithintheoperatinglimits.

ThesecanbefoundinBockcompressorselectiontool(VAP)

undervap.bock.de.Observetheinformationgiventhere.

-Permissibleambienttemperature(-20°C)-(+60°C).

-Max.permissibledischargeendtemperature140°C.

-Max.permissibleswitchingfrequency8x/h.

-Aminimumrunningtimeof3min.steady-statecondition

(continuousoperation)mustbeachieved.

Foroperationwithsupplementarycooling:

-Useonlyoilswithhighthermalstability.

-Avoidcontinuousoperationnearthethreshold.

Foroperationwithfrequencyconverter:

- The maximum current and power consumption must not be

exceeded.Inthecaseofoperationabovethemainsfrequency,the

applicationlimitcanthereforebelimited.

When operating in the vacuum range, there is a danger of air

enteringonthe suction side.Thiscan cause chemical reactions,

apressureriseinthecondenserandanelevatedcompressed-gas

temperature.Preventtheingressofairatallcosts!

Max.permissibleoperating

pressure(LP/HP)1):19/28bar

1) LP = low pressure HP = high pressure

Thecompressorsarelledatthefactorywiththefollowingoiltype:

- for R404A/R507 BOCK lub E55

- for R22 BOCK lub A46

Compressors with ester oil charge (BOCK lub E55)aremarkedwithanXinthetype

designation (e.g. HGX12P/110-4).

D

GB

F

E

I

Ru

11

09652-06.2021-DGbFEIRu

5 |Areas of application at HC and LG compressors

5.3 Operatinglimits

ATTENTION Compressor operation is possible within the operating limits.

ThesecanbefoundinBockcompressorselectiontool (VAP)under

vap.bock.de. Observe the information given there and the follo-

wingnotes:

-Minimumsuperheating∆tOh=20K(onlyatHCcompressors)

Inordertoguaranteetherequiredminimumsuperheatingof∆tOh

=20K,aninternalheatexchangerIHXmayhavetobeinstalled.

(onlyatHCcompressors)

- Min.pressuregastemperature≥50°C(min.20Kovercondens-

ingtemperature). Suctiongassuperheatingoncompressorent-

ranceshouldbemin.7-10K,mustbeincreasedifnecessary

(onlyatLGcompressors)

-Min.oiltemperature≥ 30°C.

-Operationinthevacuumrangeisnotpermitted.

During operation in the vacuum range, there is a danger of air

entering on the suction side. This can cause chemical reactions,

pressureriseinthecondenserandanexcessivepressuregastem-

peratureaswellasshiftingoftherefrigerantignitionlimitintothe

criticalrange.Avoidabsolutelyanyentryofair!

Usealowpressureswitch!Selectashut-offpointmin.50Pahigher

thantheprevailingsurroundingpressure!

5.1 Refrigerants

• Hydrocarbons: R290,R1270(Recommendationquality2.5(<50ppmH2O))

• HFOrefrigerants: R1234ze,R1234yf,R455A,R454C

5.2Oilcharge

The compressors are factory-charged with the following oil type:

• HCcompressors: BOCK lub G68

• LGcompressors: BOCK lub E55

BOCK lub E85 (from tO>15°C,mustbespecifiedintheorder)

Maximumpermissibleoperating

pressure(LP/HP)1):19/28bar

1) LP = Low pressure HP = High pressure

12

D

GB

F

E

I

Ru

09652-06.2021-DGbFEIRu

6|Compressor assembly

?

6.1 Storageandtransport

Use transport eyelet.

Do not lift manually!

Use lifting gear!

Storageat(-30°C)-(+70°C),maximumpermissiblerelativehumidi-

ty 10 % - 95 %, no condensation

Do not store in a corrosive, dusty, vaporous atmosphere or in a com-

bustible environment.

6.2 Settingup

Setuponanevensurfaceorframewithsufcientload-

bearing capacity.

Single compressor preferably on vibration damper.

Duplex and parallel circuits always rigid.

Provideadequateclearanceformaintenancework.

Ensureadequatecompressorventilation.

Do not use in a corrosive, dusty, damp atmosphere or a

combustible environment.

F

E

D

C

B

A

1

2

3

4

F

E

D

C

4

3

2

1

A

B

Tol.-Ang. DIN ISO 2768-mK

Ra Rz

Maß

Passung

Freigabe

Alternativbezug:

Baumustergeprüft

Teil inaktiv

Lieferantenzeichnung

-

-

K.-Auftrag:

PL:

Zeichnung ungültig

Entwicklungsstand

Teil keine Serie

120

400

±0.5

über 0.5

bis 6

Benzstraße 7 - 72636 Frickenhausen - Germany - www.bock.de

-

-

Unbemaßte Radien:

-

Diese Zeichnung ist unser Eigentum!

Sie darf ohne unsere Genehmigung weder nach-

gebildet, vervielfältigt, oder Dritten Personen zu-

gänglich gemacht werden. Der Nachbau nach

dieser Zeichnung, oder an Hand der nach dieser

Zeichnung hergestellten Gegenstände durch den

Abnehmer oder Dritte ist nicht gestattet.

Wir behalten uns alle Rechte, gemäß DIN ISO 16016

an dieser Zeichnung vor.

Bearb.

Datum

Änderungs-Nr.

Werkstoff:

Ausgangsteil, bzw. Rohteil:

--

Gepr.

Name

Datum

19.04.

Werkstückkanten

DIN ISO 13715

Ersatz für:

Ersetzt durch:

Erstellt

2010

Geprüft

-

Kurz

Zone

1/x

Oberflächenbehandlung / Härte:

-

Blatt:

Änderungsbeschreibung

400

Benennung:

±0.8

1000

30

6

-

±0.3

120

30

±0.2

Zeichn.-Nr. Teile-Nr.

Oberflächenangaben ISO 1302

x.xxxx-xxxxx.x

Zust.

Gußtoleranzen:

Gewicht: (kg)

±0.1

Maßstab:

1:1

Wasserwaage

für Indesign

Der Lieferant muß sicherstellen, dass die Ware in

einwandfreiem Zustand angeliefert wird (Korrosions-

schutz, Verpackung für sicheren Transport).

Rz 25

Rz 160

s

25

z

y

x

w

u

t

0,05

Rz 1,6

0,3

0,7

1,6

2

Rz 16

6,3

Rz 63

Rz 6,3

Rz 12,5

F:\user\kurz\3D Sachen\3D Teile\Zeichnungen\Wasserwaage

6.3 Pipeconnections

INFO Newcompressorsarefactory-lledwithinertgas.Leavethisser-

vicechargeinthecompressorforaslongaspossible and prevent

the ingress of air. Check the compressor for transport damage

beforestartinganywork.

ATTENTION Attachments(e.g.pipeholders,additionalunits,fasteningparts,

etc.)directlytothecompressorarenotpermissible!

ATTENTION Damagepossible.

Donotsolderaslongasthecompressorisunderpressure.

Superheatingcandamagethevalve. Removethepipesupports

thereforefromthevalveforsolderingandaccordinglycoolthe

valvebodyduringandaftersoldering.

Onlysolderusinginertgastoinhibitoxidationproducts(scale).

Sunprotection:Ifthecompressorissetupoutdoors,ithas

to be protected from direct sunlight.

D

GB

F

E

I

Ru

13

09652-06.2021-DGbFEIRu

6|Compressor assembly

6.4 Pipes

Pipes and system components must be clean and dry inside and free of scale, swarf and layers of

rust and phosphate. Only use air-tight parts.

Lay pipes correctly. Suitable vibration compensators must be provided to prevent pipes being

cracked and broken by severe vibrations.

Ensure a proper oil return.

Keep pressure losses to an absolute minimum.

Rigid

fixedpoint

Asshortas

possible

The pipe connections have graduated inside diameters so that pipes with

standart millimetre and inch dimensions can be used.

The connection diameters of the shut-off valves are rated for maximum

compressor output. Theactualrequiredpipecrosssectionmustbe

matchedtotheoutput.Thesameappliesfornon-returnvalves.

Fig.5:graduated

internal diameter

6.5 Layingsuctionandpressurelines

Aruleofthumb: Alwayslaytherstpipesectionstartingfromtheshut-offvalvedownwards and

paralleltothedriveshaft.

ATTENTION Improperlyinstalledpipescancausecracksandtears,theresult

beingalossofrefrigerant.

INFO Proper layout of the suction and discharge lines directly after

the compressor is integral to the system’s smooth running and

vibrationbehaviour.

Fig. 6

For systems with long pipes and higher degree of contamination, a lter on the suction-side is

recommended.Thelterhastobebereneweddependingonthedegreeofcontamination(reduced

pressureloss).

Moisture in the refrigeration circuit can lead to crystal and hydrate formation. For this reason, we

recommendusingalterdrierandasightglasswithamoistureindicator.

6.6Suctionpipelterandlterdrier

14

D

GB

F

E

I

Ru

09652-06.2021-DGbFEIRu

6|Compressor assembly

Before opening or closing the shut-off valve, release the valve spindle seal by approx. 1/4of a turn

counter-clockwise.

After activating the shut-off valve, re-tighten the adjustable valve spindle seal clockwise.

Fig. 7 Fig. 8

6.7 Operatingtheshut-offvalves

Valvespindleseal

Release

Tighten

Pipe connection

Pipe connection

6.8 Operatingmodeofthelockableserviceconnections

Fig. 9

Openingtheshut-offvalve:

Spindle:turntotheleft(counter-clockwise)asfarasitwillgo.

—> Shut-off valve completely opened / service connection closed.

Fig. 10

Openingtheserviceconnection

Spindle:Turn1/2- 1 turn to the right clockwise.

—> Service connection opened / shut-off valve opened.

Service connec-

tion closed

Connection

blocked

Spindle

Service connec-

tion opened

Spindle Connection

open

Compressor

Compressor

Afteractivatingthespindle,generallytthespindleprotectioncapagainandtightenwith14-16Nm.

This serves as a second sealing feature during operation.

D

GB

F

E

I

Ru

15

09652-06.2021-DGbFEIRu

7|Electrical connection

7.1 Informationforcontactorandmotorcontactorselection

Allprotectiondevicesandswitchingormonitoringunitsmustbettedinaccordancewiththelocal

safetyregulationsandestablishedspecications(e.g.VDE)aswellaswiththemanufacturer’sinfor-

mation. Motor protection switches are required! Motor contactors, feed lines, fuses and motor

protection switches must be rated on the basis of the maximum working current (see name plate).

For motor protection use a current-dependent and time-delayed overload protection device for moni-

toring all three phases. Set the overload protection device so that it must be actuated within 2 hours,

if there is 1.2 times the max. working current.

7.2 Connectionofthedrivingmotor

The compressor is designed with a motor for star-delta circuits.

Designation on the name plate

∆/Y

Star-deltastart-upisonlypossibleon230Vvoltagesupply.Example:

INFO Connect the compressor motor in accordance with the circuit diagram

(seeinsideofterminalbox).

Use suitable cable entry point of the correct protection type (see

nameplate)forroutingcablesintotheterminalbox.Insertthestrain

reliefs and prevent chafe marks on the cables.

Comparethevoltageandfrequencyvalueswiththedataforthe

mains power supply.

Onlyconnectthemotorifthesevaluesarethesame.

DANGER Riskofelectricshock!Highvoltage!

Onlycarryoutworkwhentheelectricalsystemisdisconnected

fromthepowersupply!

INFO Theconnectionexamplesshownrefertothestandardversion.In

thecaseofspecialvoltages,theinstructionsafxedtotheterminal

boxapply.

ATTENTION Whenattachingaccessorieswithanelectrical cable,a minimum

bendingradiusof3xthecablediametermustbemaintainedfor

layingthecable.

230V∆

Direct start Star-deltastart

400VY

Directstartonly

Elektrischer Anschluss

Electrical connection

Raccordement électrique ∆/ Y

96027-11.06-DGbF

∆

Niedere Spannung

Low voltage

Bas voltage

Y

Hohe Spannung

High voltage

Haut voltage

L3

L1 L2

L3

L1 L2

Elektrischer Anschluss

Electrical connection

Raccordement électrique ∆/ Y

96027-11.06-DGbF

∆

Niedere Spannung

Low voltage

Bas voltage

Y

Hohe Spannung

High voltage

Haut voltage

L3

L1 L2

L3

L1 L2

L1 L2 L3

L1 L2 L3

16

D

GB

F

E

I

Ru

09652-06.2021-DGbFEIRu

BT1 Coldconductor(PTCsensor)motorwinding

BT2 Thermalprotectionthermostat(PTCsensor)

FC1 Load circuit safety switches

FC2 Control power circuit fuse

BP1 High pressure safety monitor

BP2 Safety chain (high/low pressure monitoring)

BT3 Release switch (thermostat)

7.3 Circuitdiagrammfordirectstart230V∆/400VY

Fig. 11

Anschlußkasten Verdichter

BT1

INT69G

QA1

L1 L2 L3 N PE PE

FC1.1

FC2

SF1

BP1

P>

QA2

BP2

P

QA2

L1.1

L2.1

L3.1

L1.2

N

PE

BT3

1112 14

L N B1 B2

12

11

10

9

8

7

6

5

4

3

2

1

BT2

Θ

BT2

Θ

FC1.1

I> I>

I>

1

2

QA2

3

4

5

6

-EC1 3~

M

Θ

EB1

Compressor terminal box

D

GB

F

E

I

Ru

17

09652-06.2021-DGbFEIRu

Anschlußkasten Verdichter

BT1

INT69G

QA1

L1 L2 L3 N PE PE

FC1.1

FC2

SF1

BP1

P>

QA2

BP2

P

QA2

L1.1

L2.1

L3.1

L1.2

N

PE

BT3

1112 14

L N B1 B2

12

11

10

9

8

7

6

5

4

3

2

1

BT2

Θ

BT2

Θ

FC1.1

I> I>

I>

1

2

QA2

3

4

5

6

-EC1 3~

M

Θ

EB1

QA1 Main switch

SF1 Control voltage switch

EC1 Compressor motor

QA2 Compressor contactor

INT69 G Electronic trigger unit INT69 G

EB1 Oil sump heater

DANGER Explosionrisk!

ElectronictriggerINT69 GatHC and LG compressorshas to be

installedoutsideanydangerarea!

Seealsochapter7.7.

18

D

GB

F

E

I

Ru

09652-06.2021-DGbFEIRu

7.4 ElectronictriggerunitINT69G

7.5 ConnectionofthetriggerunitINT69G

The compressor motor is tted with cold conductor temperature sensors (PTC) connected to the

electronic trigger unit INT69 G in the terminal box. In case of excess temperature in the motor

winding, the INT69 G deactivates the motor contactor. Once cooled, it can be restarted only if the

electroniclockoftheoutputrelay(terminalsB1+B2)isreleasedbyinterruptingthesupplyvoltage.

The hot gas side of the compressor can also be protected against overtemperature using thermal

protectionthermostats(accessory).

Theunittripswhenanoverloadorinadmissibleoperatingconditionsoccur.Findandremedy

thecause.

INFO Therelayswitchingoutputisexecutedas a oating changeover

contact.Thiselectricalcircuitoperatesaccordingtothequiescent

currentprinciple,i.e.the relaydropsintoa the idle position and

deactivatesthemotorcontactorevenincaseofasensorbreakor

open circuit.

INFO ConnectthetriggerunitINT69Ginaccordancewiththecircuitdia-

gram.Protectthetriggerunitwithadelayed-actionfuse(FC2)of

max.4A.Inordertoguaranteetheprotectionfunction,installthe

triggerunitastherstelementinthecontrolpowercircuit.

Οnderung

Klebeschilder

0

Datum Name

Datum

Bearb.

Gepr.

Norm

1

04.12.2009

Kelich

22.05.2015

Urspr.

2

Ers. f.

3

Ers. d.

4

Schaltplan

567

BOCK COMPRESSORS

8

=

+

9

Bl.

MP10 INt69 Bl.

MP10 INt69

INT69 G

Motor Protection MP10

Steuerstrom-

kreis

L

N

Steuerstrom-

kreis

L N

1112 14

B1 B2OG OG

+

-

BT1

Θ

X1 L1 L1 N N 43 43 11 12 14

L S M

X2123456

R1 R2

+

-

BT1

Θ

+

-

BT2

Θ

+

-

BT2

Θ

L

N

Terminal box

Fig. 12

ATTENTION

Measure circuit BT1 andBT2

(PTC sensor)mustnot come

into contact with external

voltage.

Thiswoulddestroythetrigger

unitINT69GandPTCsensors.

Control circuit

7| Electrical connection

D

GB

F

E

I

Ru

19

09652-06.2021-DGbFEIRu

Relay position INT69 G

B2 12 14 11

Fig. 13

7.6FunctiontestofthetriggerunitINT69G

Before commissioning, after troubleshooting or making changes to the control power circuit, check

the functionality of the trigger unit. Perform this check using a continuity tester or gauge.

Gaugestate Relayposition

1. Deactivated state 11-12

2. INT69 G switch-on 11-14

3. Remove PTC connector 11-12

4. Insert PTC connector 11-12

5. Reset after mains on 11-14

7| Electrical connection

7.7 ElectronictriggerunitINT69GatHCandLGcompressors

The supplied INT69 G must be connected according to the wiring diagram shown here in a separate

control cabinet, which must be installed outside each danger zone.

BT1 Cold conductor (PTC

sensor)motorwinding

BT2 Heat protection thermo-

stat(PTCsensor)

EB1 Oil sump heater

ATTENTION Installheatprotectionthermostatsandcoldconductormotor

windinginseries!

Fig. 14

Οnderung

0

Datum Name

Datum

Bearb.

Gepr.

Norm

1

04.12.2009

Kelich

08.05.2020

Urspr.

2

Ers. f.

3

Ers. d.

4

HG12

567

BOCK COMPRESSORS

8

=

+

9

Bl.

5Bl.

2

1

Schaltschrank

EB1 BT2

BT1

1 2 3 4 5 6 7 8 09 10 11 12

INT69G

Οnderung

0

Datum Name

Datum

Bearb.

Gepr.

Norm

1

04.12.2009

Kelich

08.05.2020

Urspr.

2

Ers. f.

3

Ers. d.

4

HG12

567

BOCK COMPRESSORS

8

=

+

9

Bl.

5Bl.

2

1

Schaltschrank

EB1 BT2

BT1

1 2 3 4 5 6 7 8 09 10 11 12

INT69G

Switch cabinet

20

D

GB

F

E

I

Ru

09652-06.2021-DGbFEIRu

7 |Electrical connection

7.8OilsumpheateratHCandLGcompressors

As the solubility of hydrocarbons and HFO refrigerants in oil can be very high, especially at high

suction pressures, the compressor must be equipped with an oil sump heater. For this reason, a

pump-down circuit is recommended during standstill to reduce the suction-side standstill pressures.

ATTENTION Theoilsumpheatermustgenerallybeconnectedandoperated!

•InaTT-orTNsystem,aresidualcurrentprotectiondevice(RCD)

mustbeused.

•InanITsystem,aninsulationmonitoringdevicemustbeused.

Nationalstandardsandregulationsmustbeobserved.

This manual suits for next models

29

Table of contents

Other BOCK Compressor manuals

Popular Compressor manuals by other brands

Sealey

Sealey VS1824 instructions

Campbell Hausfeld

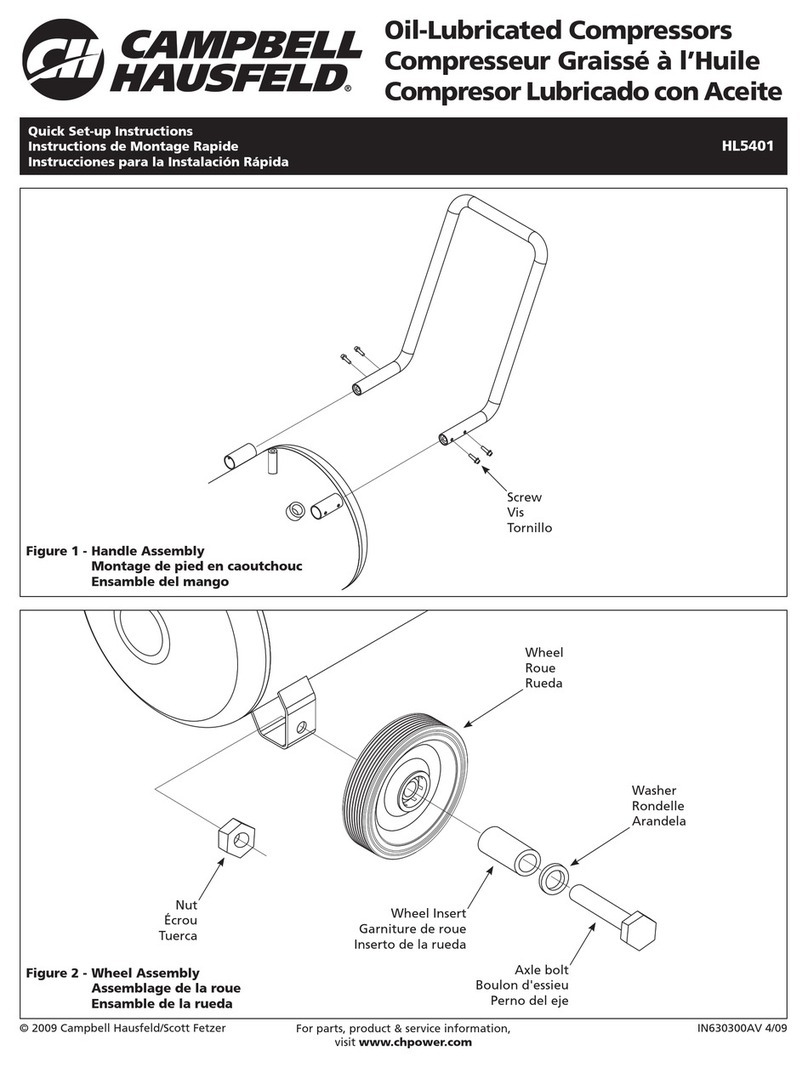

Campbell Hausfeld HL5401 Series Quick setup instructions

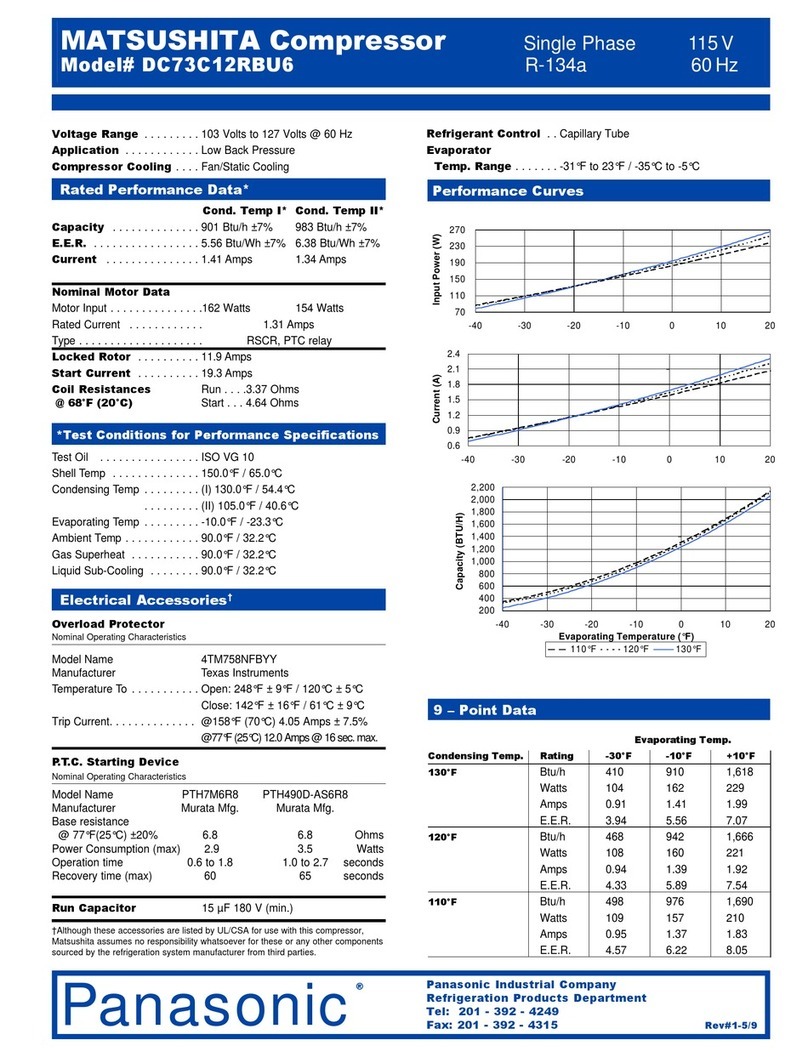

Panasonic

Panasonic Matsushita DC73C12RBU6 Specification sheet

Atlas Copco

Atlas Copco LF 2 Instruction book

Profroid

Profroid SUPERCOLD SCS SCROLL Series operating instructions

Rentokil

Rentokil Vertex Aquatic Solutions QuietAir owner's manual