Bodytastic SpinTastic II PRO User manual

V1.02017/04/08

Troubleshooting

【Belt loose, adjust the belt】

Adjustment steps:

1. Use a hex wrench to loosen the chain cover screws。

2. Remove the outer chain cover

3. Loosen the flange nuts on both sides 4. Turn the screws clockwise to move the flywheel

forward. Each time turn 1/4 circle tighten until

the belt will not slip.

5、Re-lock the flange nut on both sides, and put back the outer chain cover

Troubleshooting

【Crank and pedal loose】

Pedal adjustment steps:

Use M15 open wrench to lock the pedal. (At right side pedal, lock clockwise direction to tighten. At

left side pedal, lock counterclockwise direction to tighten.

Crank adjustment step:

1. Use the torque wrench to adjust the torque wrench to 650kgf-cm

2. The right crank is locked in a clockwise direction and the left crank is locked in a

counterclockwise direction

【Bike is Wobbling or Uneven While Riding】

Steps:

1. Check the foot levelers on the bottom of the stabilizers

2. Adjust the levelers and the bike until it is square on the floor

【Metal scraping sound from brake】

Steps:

1. Use a Phillips screwdriver to remove the left and right sweat cover and remove the front cover

with a hexagonal wrench.

2. Check whether the brake assembly magnet is in touch with the aluminum ring, resulting in friction

sound

3. Use the adjustment tool to insert to the brake fixing plate (as red circle) from the bottom. Visual

check the magnet brake assembly at the front to adjust brake fixing plate

4. After adjusting the brake fixing plate, test with riding to see if the brake magnet assembly is off

from the aluminum ring.

5. Ensure the problem is solved, then fastening back the sweat cover and front cover with screws.

【Emergency Brake not functioning properly】

Steps:

1. Use a Phillips screwdriver to remove the left and right sweat cover and remove the front cover

with a hexagonal wrench.

2. Use a Phillips screwdriver to remove brake assembly connecting plate screws

3. Use a Phillips screwdriver to remove sensor screw.(If your bike is equipped with electronic)

4. Use a hexagon wrench and open wrench to release screw and nut of brake assembly.

5. Remove screw of brake assembly and remove the brake assembly set

6. Replace a new brake assembly set and follow the removal steps and reassemble them back

7. Test if the brake assembly set emergency brake functioning properly

8. Fastening back the sweat cover and front cover with screws.

【Belt split, need to replace the new belt】

Steps:

1. Use a Phillips screwdriver to remove the left and right sweat cover and remove the front cover

with a hexagonal wrench.1.

2. Use a hex wrench to loosen the chain cover screws

3. Remove chain cover

4 Use the sleeve screwdriver to remove the adjustment screw

5. Use the M15 open wrench to loosen the flange nuts on both sides to allow the flywheel to retreat

6. Remove the belt from pulley

7.Use the M15 open wrench to completely remove the flange nuts and remove the adjust blocks on

both sides

8.Use the hex wrench to release the top plate screw and inner chain cover screw, remove the top

plate and the inner chain cover

9. Remove flywheel and place it flat. Replace with a new belt on flywheel.

10. Place the flywheel back to the flywheel bracket on the frame. Hang the new belt on the pulley,

the other hand rotate the flywheel counterclockwise direction to put the belt, so that the belt

completely hung on the pulley (belt to be completely inside of the pulley)

(Belt need to be inside of idle arm) (Belt need to be inside of pulley)

11.Assembly back the inner chain cover and top plate by using hexagon wrench

12. Use M15 opening wrench to lock both sides of the flange nut and adjustment block (do not

tighten yet)

13.Fasten the adjusting screw and adjusting belt tension (Belt tension 110Hz)

14. Adjust the belt tension value, lock the flywheel flange nut on both sides. (Tighten torque at

450kgf-cm)

16. Assemble back the chain cover, sweat cover and front cover.

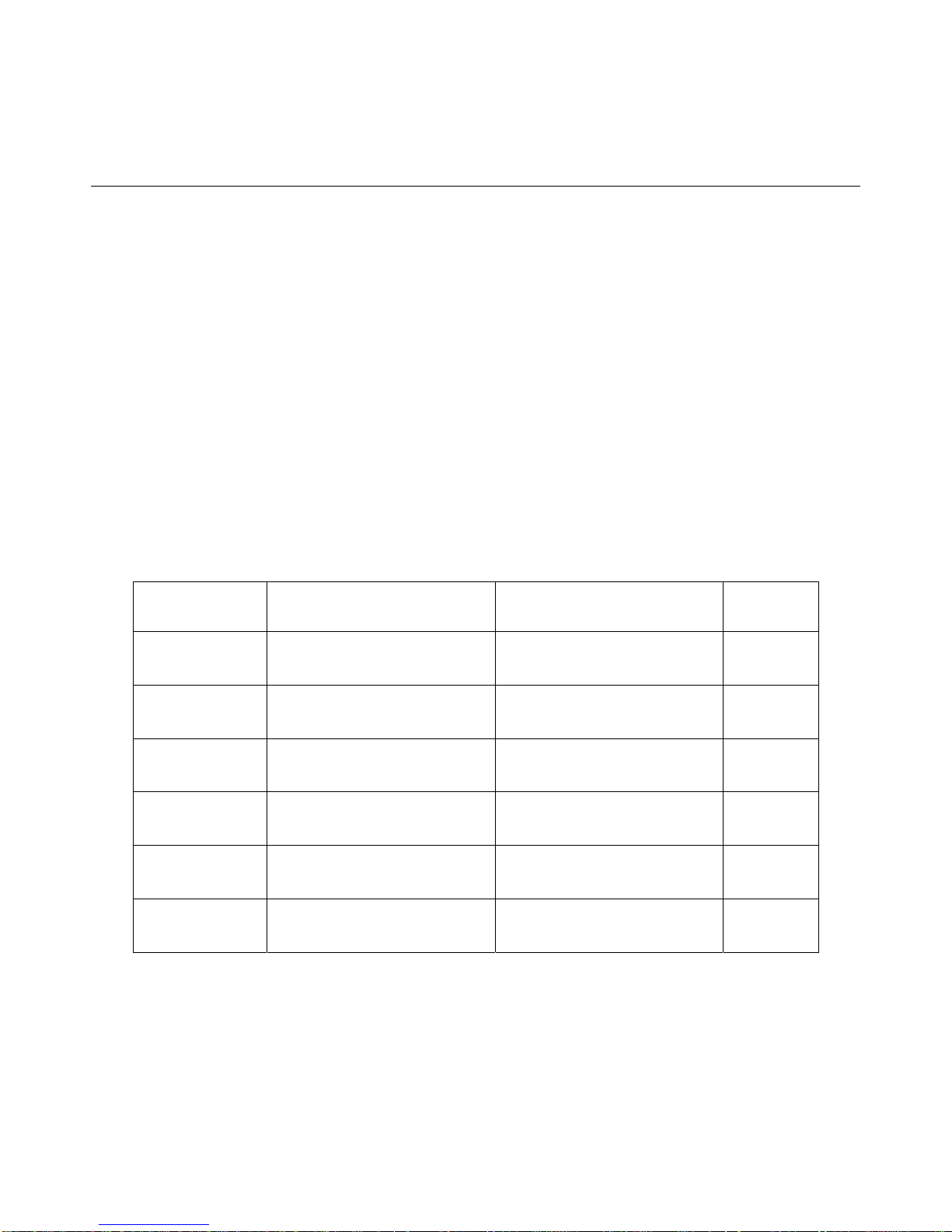

MAINTENANCE

Maintenance Schedule

The safety level given by the design of Series 2 PRO Spin Bikes can be maintained only

when the bike is regularly checked for wear and damage. Fail components should be

replaced immediately. Please read and understand all the maintenance instructions

thoroughly before starting maintenance

Daily maintenance

The life of your bike will be determined by how consistently you make the daily

maintenance. Clean, Dry at end of each use to remove mositure- Swear, water…

Note : Never use abrasive cleaning liquids or prtroleum-based

solvents to wipe down the bike

Par Recommended Action Cleaner Lubricant

Frame Wipe down to remove

mositure- Swear, water… Soap & water, diluted non-

abrasive cleaning liquids N/A

Flywheel Wipe down to remove

mositure- Swear, water… Soap & water, diluted non-

abrasive cleaning liquids N/A

Stabilizer Wipe down to remove

mositure- Swear, water… Soap & water, diluted non-

abrasive cleaning liquids N/A

Chain Guard Wipe down to remove

mositure- Swear, water… Soap & water, diluted non-

abrasive cleaning liquids N/A

Handlebar Post Raise up to the highest

setting to allow to dry Soap & water, diluted non-

abrasive cleaning liquids N/A

Seat Post Raise up to the highest

setting to allow to dry Soap & water, diluted non-

abrasive cleaning liquids N/A

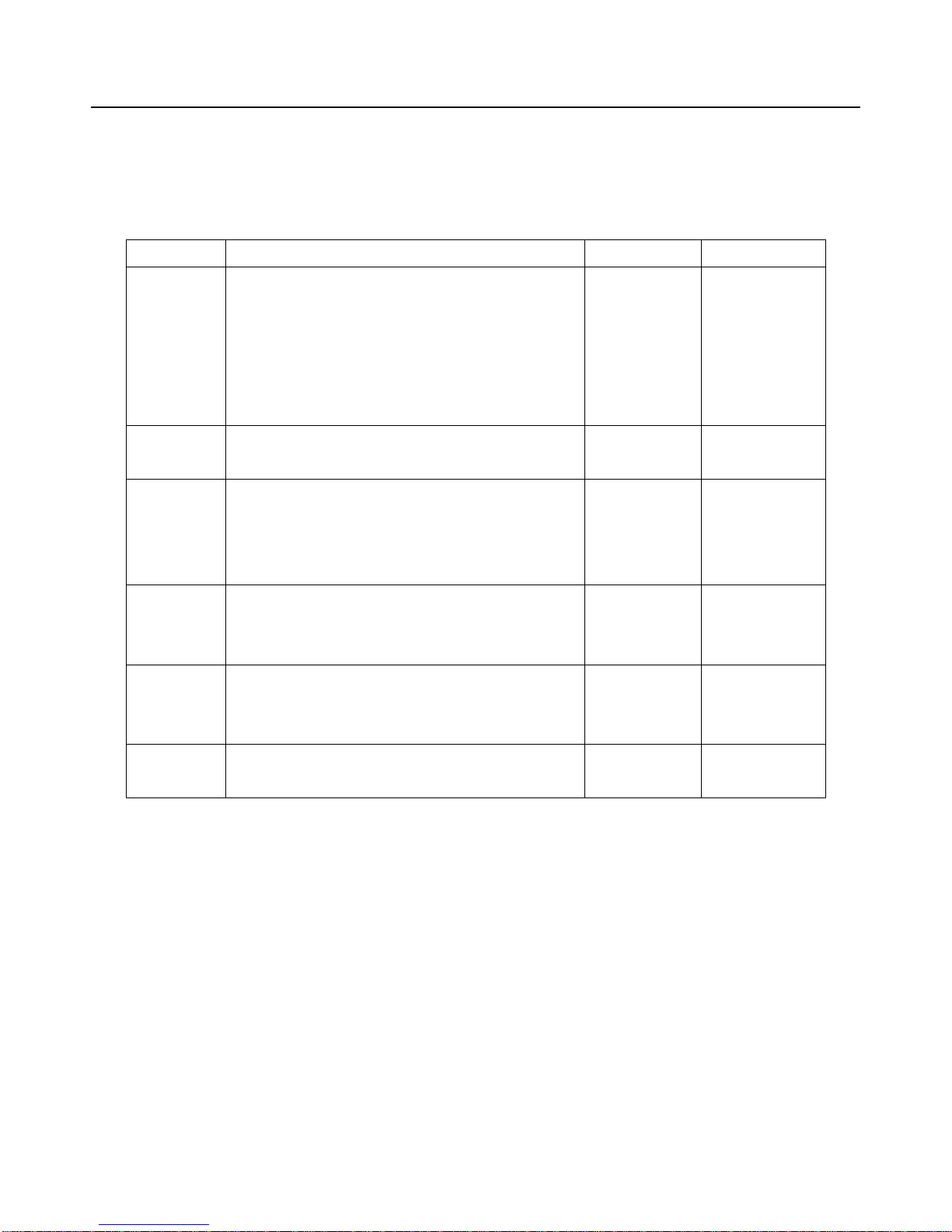

MAINTENANCE

Horizontal Slider Wipe down to remove

mositure- Swear, water… Soap & water, diluted non-

abrasive cleaning liquids N/A

Pedal

Check and ensure that the

pedals are tight in the crank.

A

ll screws on pedal are tight.

Toe clip cage and strap are

not damaged and frayed

N/A

N/A

Brake Knob

Release the brake to ZERO

resistance N/A

N/A

Weekly maintenance

This should focus on the overall performance.Try to look for vibration and

possible loose parts during the checking

Part Recommended Action Cleaner Lubricant

Flywheel 1. Apply the light coat of WD-40 on side of

flywheel for corrosion resistance

2. Check the flywheel alignment to the frame WD-40 N/A

Hardware Tighten all the frame hardware (Bolt, nut,

screw) N/A N/A

Pop-Pin Tighten all the Pop-pin N/A N/A

Crank Torque Crank bolts to 650kgf-cm N/A N/A

MAINTENANCE

Monthly mintenance

This should be comprehensive checking of the overall frame, main assembly

components

Part Recommended Action Cleaner Lubricant

Chain 1. Lubricate drive chain with bicycle

lubricant containing PTFE (Teflon®) from

the hope in top of the chain guard.

2. Check the chain tension(See Chain

tension adjustment procedure)

N/A

Lubricant

containing

PTFE (Teflon®)

Leveling

Feet Check it the feet is damaged to affect the

balance of bike N/A

N/A

Pop- pin If post has still too much play after

tightening, it maybe the thread of pop-pin or

itself was wore or damaged. Need to

change the pop-pin

N/A N/A

Brake Pad Inspect for wear. Excessive wear, or too

glazing, separated from the plastic bracket,

indicates replacement is needed.

N/A

N/A

Seat

Inspect for wear. Rip, tear, cannot be tight

(too much movement), indicates

replacement is needed.

N/A N/A

Pedal

Inspect for excessive play, indicates

replacement is needed. N/A

N/A

Table of contents

Popular Fitness Equipment manuals by other brands

G-FITNESS

G-FITNESS AIR ROWER user manual

CAPITAL SPORTS

CAPITAL SPORTS Dominate Edition 10028796 manual

Martin System

Martin System TT4FK user guide

CIRCLE FITNESS

CIRCLE FITNESS E7 owner's manual

G-FITNESS

G-FITNESS TZ-6017 user manual

Accelerated Care Plus

Accelerated Care Plus OMNISTIM FX2 CYCLE/WALK user manual