Bodyworx L7900LP User manual

Other Bodyworx Home Gym manuals

Bodyworx

Bodyworx L8000HG User manual

Bodyworx

Bodyworx L700015 User manual

Bodyworx

Bodyworx KR6000PRO User manual

Bodyworx

Bodyworx LBX300G User manual

Bodyworx

Bodyworx 370 HG User manual

Bodyworx

Bodyworx L7750 User manual

Bodyworx

Bodyworx L7800LP User manual

Bodyworx

Bodyworx KRX500 User manual

Bodyworx

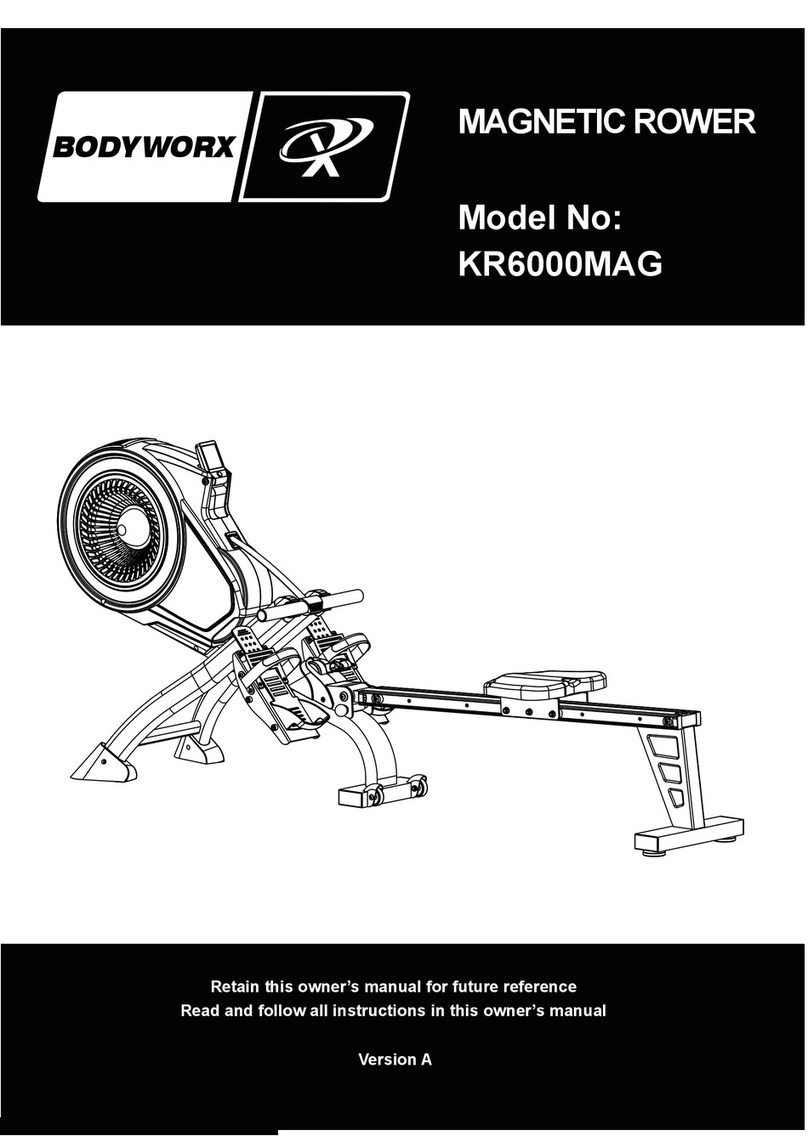

Bodyworx KR6000MAG User manual

Bodyworx

Bodyworx L7200 User manual

Popular Home Gym manuals by other brands

SportsArt Fitness

SportsArt Fitness S911 Assisted Chin owner's manual

Body Solid

Body Solid PowerLine PFID-130X owner's manual

NordicTrack

NordicTrack Ns Ski 250 manual

Keys Fitness

Keys Fitness Power System KF-2060 owner's manual

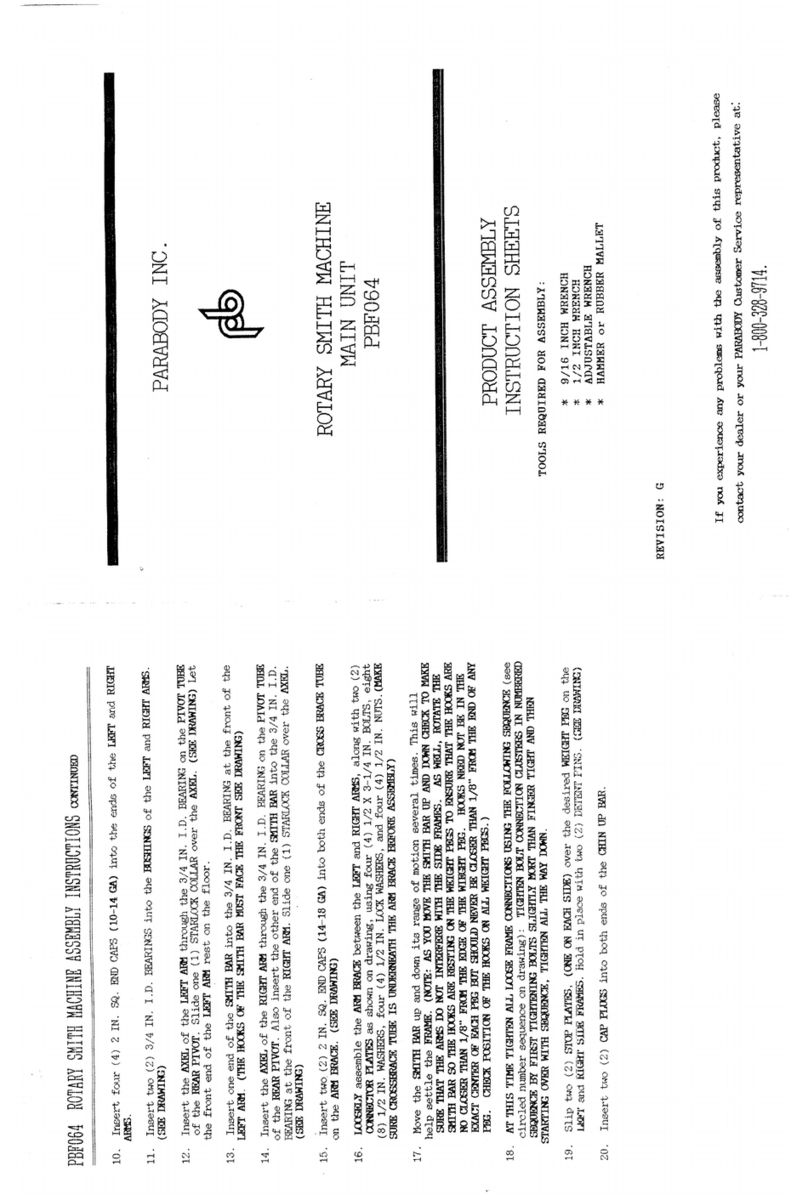

ParaBody

ParaBody PBF064 Assembly instructions

Stamina

Stamina X EXTREME TRAINING Series owner's manual

First Degree Fitness

First Degree Fitness Titan Rower owner's manual

Body Solid

Body Solid GVKR82 owner's manual

Kettler

Kettler REGATTA 300 Safety Instructions and Information on Use

Vectra Fitness

Vectra Fitness VX-11 owner's manual

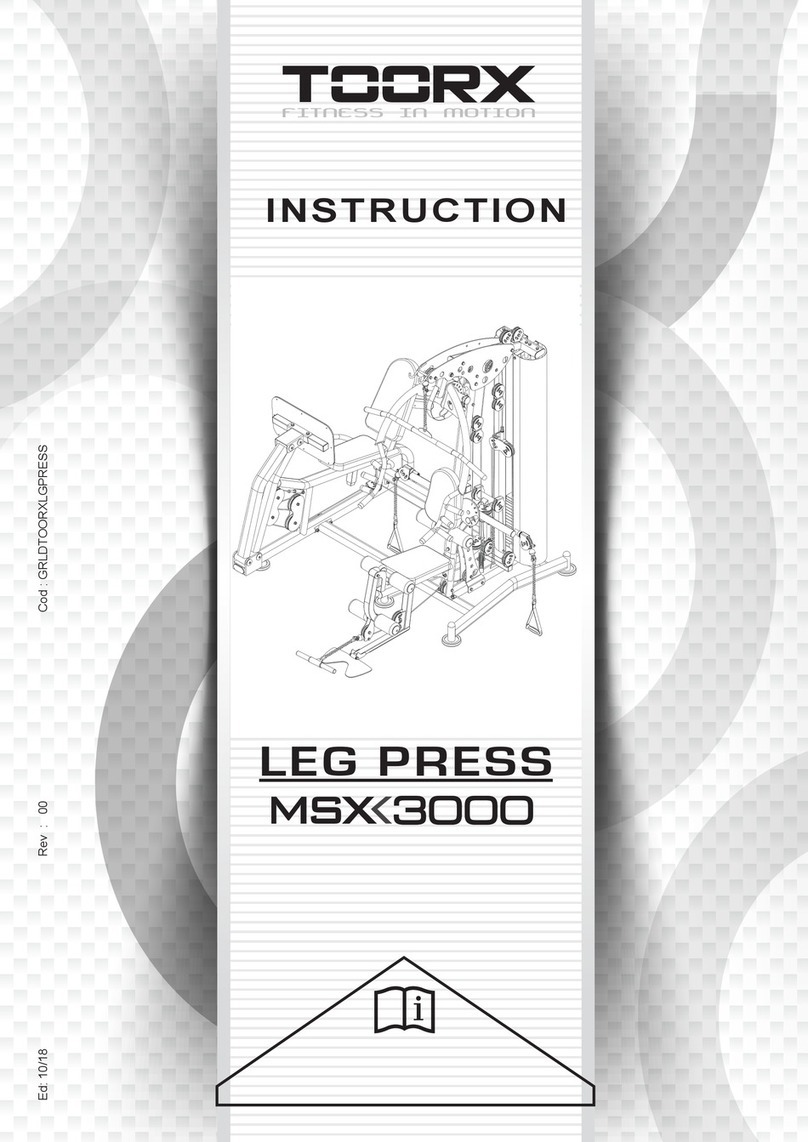

Garlando

Garlando TOORX MSX 3000 instructions

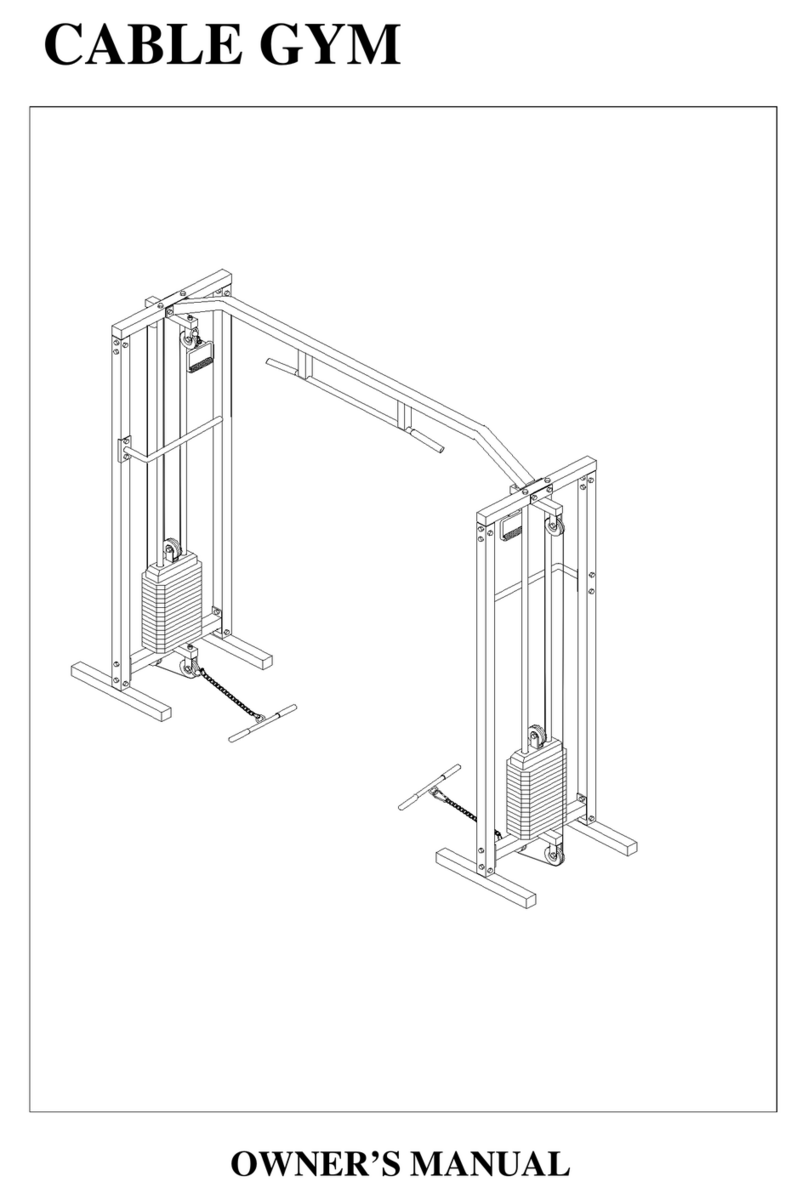

Fitness and Strength

Fitness and Strength CCO1 Cable Cross Over Machine owner's manual