Boge airtelligence provis 3 User manual

Operating instructions

Master

compressor control

airtelligence provis 3

BOGE compressor control airtelligence provis 3 Page I

Operating instructions

for the master

compressor control

airtelligence provis 3

Software version V01.00.00.00

BOGE KOMPRESSOREN

Postfach 10 07 13

33507 Bielefeld

Otto-Boge-Straße 1-7

33739 Bielefeld

Fon: +49 5206 601-0

Fax: +49 5206 601-200

Mail: [email protected]

Net: www.boge.com

Issue : 05 / 2020

No. 596.1551.01

Nominal price : € 5,00

BOGE compressor control airtelligence provis 3 Page III

Index

Index

Part 1:

General 1.1 Who are these operating instructions intended for?.................. 1

1.2 Contents of these operating instructions .................................... 1

1.3 Additional important documents .................................................. 2

1.4 Orientation aid for reading these instructions............................. 2

Symbols and typographic features ................................................... 3

Design of warning signs.................................................................... 4

Part 2:

Safety 2.1 Basic information on safety........................................................... 5

Prior to commissioning and operation .............................................. 5

Intended use..................................................................................... 5

Reasonably foreseeable misuse....................................................... 5

Modifications to the product.............................................................. 5

2.2 Special safety notes....................................................................... 5

Transport .......................................................................................... 5

Switch cabinet................................................................................... 6

Touch panel...................................................................................... 6

Network............................................................................................. 6

Change of settings............................................................................ 7

Data backup...................................................................................... 7

2.3 Owner and personnel..................................................................... 7

Personnel requirements.................................................................... 7

Obligations of the operator ............................................................... 8

Obligations of the personnel............................................................. 8

Part 3:

Assembly and connecti-

on

3.1 Installation of the control............................................................... 9

Assembling the switch cabinet.......................................................... 9

Check assembly ............................................................................. 10

3.2 Connecting the control ................................................................ 11

Establishing the electrical connection............................................. 11

Connect the cables for communication in the control cabinet ........ 13

Using external interfaces................................................................ 15

Part 4:

Basic knowledge of con-

trol

4.1 Principle of the master control.................................................... 17

Tasks of the master control in compressed airnets........................ 17

4.2 User levels, rights and functions................................................ 18

Index

Page IV BOGE compressor control airtelligence provis 3

4.3 Operation....................................................................................... 19

Handling by finger or PC mouse..................................................... 19

Operating elements and input functions ......................................... 20

4.4 Symbols......................................................................................... 23

General symbols for components................................................... 23

Special symbols for components - compressor.............................. 23

Special symbols for components - receiver.................................... 24

Special symbols for components - equipment................................ 25

Special symbols for accessory values analog/digital inputs

and outputs..................................................................................... 25

Symbols for basic operating ability ................................................. 26

4.5 Navigation through the views...................................................... 28

Navigation structure........................................................................ 28

Part 5:

Use of the control 5.1 Compressed airnet overview....................................................... 35

5.2 Compressed airnet view .............................................................. 36

Status display: List representation.................................................. 37

Status display: DIN representation ................................................. 37

Status display: 2D representation................................................... 38

Status display: 3D representation................................................... 38

Change arrangement of components in DIN and

2D representation ........................................................................... 39

Calendar display............................................................................. 41

Event display .................................................................................. 50

Progress display ............................................................................. 51

Settings for the compressed airnet................................................. 55

5.3 Component detail view................................................................. 56

Component detail view - compressor ............................................. 57

Component detail view - receiver ................................................... 58

Component detail view- equipment ................................................ 59

5.4 General system settings .............................................................. 61

User administration......................................................................... 62

System settings .............................................................................. 64

Compressed airnet configuration.................................................... 66

Part 6:

Troubleshooting 6.1 Events / message types ............................................................... 69

Process events / messages............................................................ 69

Part 7:

Service, dismantling,

disposal

7.1 Service........................................................................................... 73

Cleaning the display ....................................................................... 73

Software updates............................................................................ 73

7.2 Dismantling / Disassembly .......................................................... 73

7.3 Disposal......................................................................................... 74

BOGE compressor control airtelligence provis 3 Page V

Index

Part 8:

Annex 8.1 Technical data............................................................................... 75

8.2 Housing dimensions and component overview........................ 76

External dimensions and components............................................ 76

Internal components....................................................................... 77

Status LEDs of the control.............................................................. 78

BOGE compressor control airtelligence provis 3 Page 1

General 1.1 Who are these operating instructions intended for?

Part 1: General 1.1 Who are these operating instructions intended

for?

These operating instructions are aimed at BOGE end customers who want to

control the compressed air production of several compressors, organized in

one or several compressed airnets, by means of the master compressor con-

trol airtelligence provis 3.

Apart from reading these operating instructions, the following prerequisites

and previous technical knowledge on the part of the user are essential for the

correct operation of the control:

– comprehensive technical knowledge of the connected compressors

– knowledge of the operating instructions of these compressors

– classification as qualified or appropriately trained personnel with technical

background knowledge in compressed air technology (see also

„Personnel requirements“, page 7)

1.2 Contents of these operating instructions

The operating instructions exclusively deal with installation, functioning, oper-

ation and setting of the airtelligence provis 3.

The following contents and descriptions of activities do not form part of these

operating instructions:

– all safety-relevant information as to the individual compressors, they form

part of the compressor operating instructions.

– anyinformationas to controls whicharedirectlyinstalled on theindividually

connected compressors (slave controls).

– any work, e.g. repairs on the control or installation of updates.

– any work on compressors and equipment (e.g. installation, commissioning

or service).

– description of the complete set-up/installation of compressed airnets or

individual compressors within the master control (specially trained BOGE

service personnel only).

Any of the above mentioned work may only be carried out by authorized and

qualified personnel, qualified electricians or BOGE service personnel.

BOGE recommends to have control(s), compressors and equipment set up

and commissioned by BOGE service personnel. Make sure that any servicing

or repair work on the control is also performed by BOGE service personnel.

If you have any questions as to the product, please contact the Technical

Support by calling:

Phone: +49 5206 601-140

If you require service personnel, please contact BOGE Service by calling:

Phone: +49 5206 601-100

General 1.3 Additional important documents

Page 2 BOGE compressor control airtelligence provis 3

1.3 Additional important documents

For any work not described in these operating instructions the following docu-

ments and specifications are required:

– operating instructions of the compressors,

– operating instructions of the connected equipment,

– operating instructions of the subordinate (slave) control(s).

Please observe the specific safety information provided in these documents!

Below you will find directions how to read these instructions and information

as to the design of the warning signs used in these operating instructions.

1.4 Orientation aid for reading these instructions

In order to easily familiarize with the compressor control, the layout of the

operating instructions is intended to give you better orientation and support.

BOGE compressor control airtelligence provis 3 Page 3

General 1.4 Orientation aid for reading these instructions

Symbols and typo-

graphic features The following table provides an overview of all symbols and typographic fea-

tures meant to facilitate the reading:

Tab. 1.1: Overview of the means of design for easier reading of these operat-

ing instructions

Symbol Meaning

Tips and further notes for optimum han-

dling

Particularlyimportanttipsandnoteshelpingto

optimally operate the control are marked with

a frame and the illustrated symbol.

Thesettings describedinthissectioncanonly

be made after login with user name and pass-

word, see also „User levels, rights and func-

tions“, page 18.

– Information 1

– Information 2

– Information 3

Listing

For a clear and understandable presentation

some important information are listed up.

●Action step Instructions I

Instructions with one action step only are in-

dicated with the symbol shown.

1. Action step 1

2. Action step 2

3. Action step 3

Instructions II

Instructions with several action steps are

numbered and must be carried out in the

specified sequence.

Feedback for action step Feedback

The result to be expected after an action step

is indicated with the arrow shown.

(1)

(2)

(3)

Figures and illustrations

For a better understanding, illustrations of the

user interface of the touch panel are possibly

divided by frames into several image areas.

The individual image areas are numbered.

General 1.4 Orientation aid for reading these instructions

Page 4 BOGE compressor control airtelligence provis 3

Design of warning signs The warning signs and notes in these instructions are to indicate dangers that

may occur during execution of specific actions. Apart from this, they point out

how a danger situation can be prevented. Warning signs are designed accord-

ing to a fixed structure, described in the following.

Signal words

The following signal words are used:

General warning sign

The following general warning sign is used in this document:

Warning sign design

Warning signs are a combination of signal words, warning signs and informa-

tion text and structured as follows:

Signal word Meaning

WARNING Warns of dangers that can possibly lead to serious or fatal injuries.

CAUTION Warns of damage to property and loss of data.

NOTE Warns of malfunctions within the operating process/communication.

Warning sign Meaning

Warns of a hazardous area.

SIGNAL WORD

Kind of danger

Source of danger and consequences if the warning is not observed.

How to avoid any danger.

BOGE compressor control airtelligence provis 3 Page 5

Safety 2.1 Basic information on safety

Part 2: Safety 2.1 Basic information on safety

Prior to commissioning

and operation Prior to commissioning and operation of the airtelligence provis 3 control the

following points must be observed:

– These operating instructions must be read completely priorto commission-

ing/operation of the control.

– These operating instructions must always be available at the place of oper-

ation of the control.

– Changes of settings on controls may only be carried out by authorized

qualified personnel, see also „Personnel requirements“, page 7.

– The control is installed in a separate switch cabinet. Work on the control,

for which the switch cabinet must be opened, may only be carried out by

authorized and qualified electricians, see also „Personnel requirements “.

– Prior to first commissioning, check control for visible signs of transport

damage.

– Damage to the control that could impair the safety of machine operation

must be rectified immediately.

Intended use The control serves solely for the correct operation of one or several com-

pressed airnets, consisting of one or several BOGE compressors or compres-

sors of other manufacturers and connected equipment, if applicable. It is

designed for stationary indoor use in manufacturing and industrial areas.

BOGE controls, especially the focus control 2.0, are designed and developed

for use in closed industrial networks (technical network).

Reasonably foreseeable

misuse Non-observance of the application limits (see „8.1 Technical data“, page 75)

is considered unintended use, poses a risk to the operational safety of the con-

trol and can endanger the compressed air supply.

Furthermore, considerable material damage and personal injury may be the

result.

Modifications to the

product Improper or unauthorized operation of the control can endanger the opera-

tional safety and damage connected devices or machines. It is not permitted

to perform any modifications, extensions or conversions to the control, like-

wise no repairs may be carried out. If a component of the control is defective,

contact BOGE service and coordinate any further proceedings.

2.2 Special safety notes

Transport – During transport, removal, relocation or return shipments the switch cabi-

net must be secured against slipping or falling down by means of suitable

measures. Internal transport is only permitted if the switch cabinet is ade-

quately secured against tilting and falling over.

– The instructions for handling the packaged products as well as humidity,

shock, tipping and temperature indicators on the packaging must be

observed.

– The control must be transportedin a horizontal position. The maximum per-

missible deviation from the horizontal is 15°.

Safety 2.2 Special safety notes

Page 6 BOGE compressor control airtelligence provis 3

– Only suitable and approved lifting and transport tools may be used for

unloading and transport.

– Never climb onto control unit or packaging.

– Protect surfaces and frame from damage.

– During transport or intermediate storage, ensure that the surfaces are

weather-protected, dry, clean and protected from external influences.

– The breaking load classes must be observed. Place insensitive parts at the

bottom.

– Observe any information on humidity and temperature range during trans-

port (see „8.1 Technical data“, page 75).

Switch cabinet The control is installed in a separate switch cabinet.

The operating unit of the control, the touch panel, is installed in the front of the

switch cabinet.

– The control may only be operated by means of the touch panel when the

switch cabinet is closed

– Never open switch cabinet during operation.

– If necessary, switch cabinet to be opened by authorized and qualified elec-

tricians only.

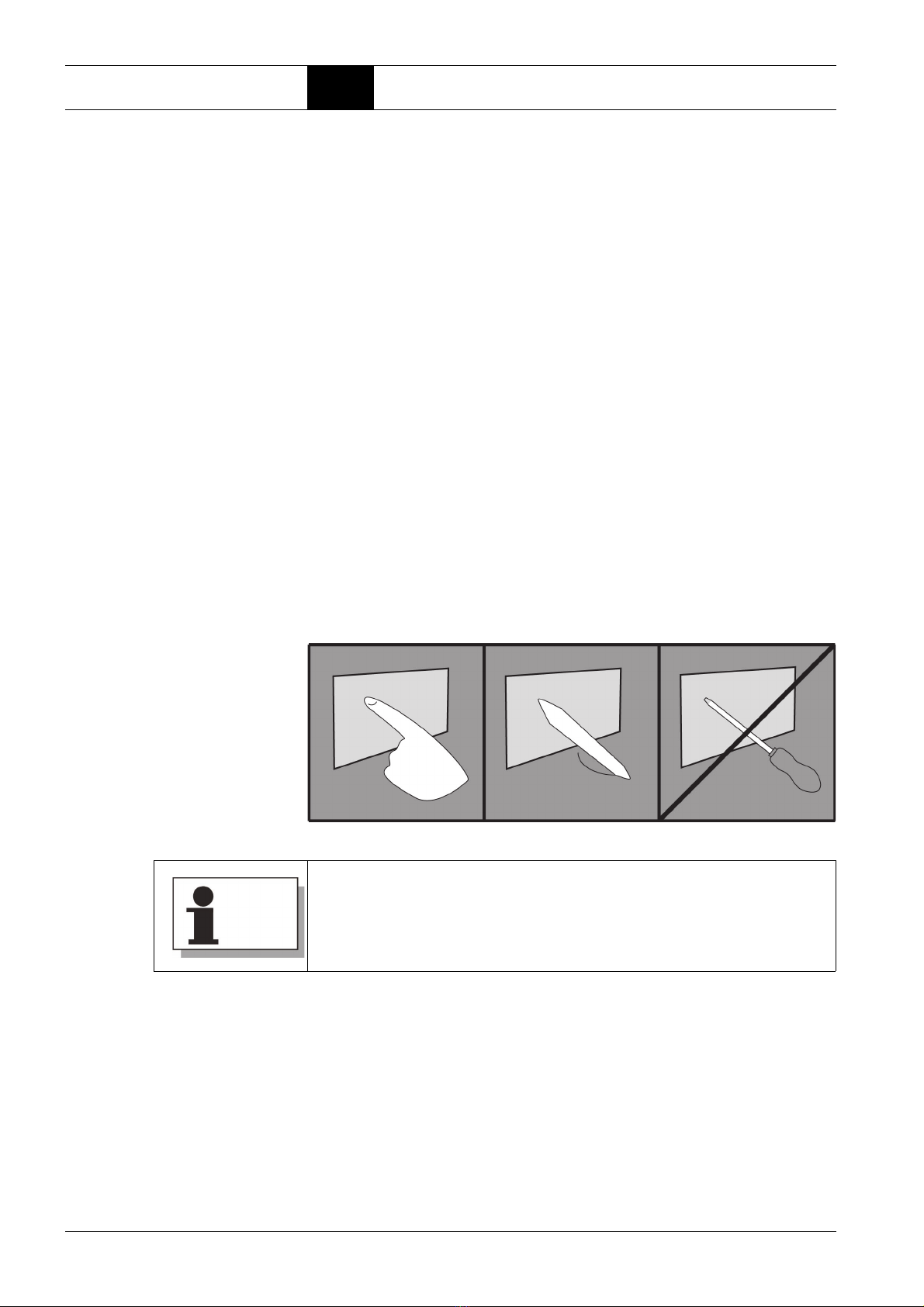

Touch panel – No pointed or sharp-edged objects may be used when operating the touch

panel. They can damage the surface of the touch panel. Only operate the

touch panel with your fingers or a suitable input pen with a plastic tip.

Fig. 2.1: Operate touch panel properly

Network The control and configuration protocols do not provide authentication mecha-

nisms. Furthermore, large amounts of network traffic can lead to an impair-

ment of the controlcommunication. BOGEthereforestronglyrecommendsthe

use of the controls exclusively in closed networks (technical network).

The network configuration, e.g. the IP address assignment, must be carried

out in coordination with the responsible IT department, which is also respon-

sible for the network in which the control is to be operated. Incorrect settings

(such as repeatedly assigned IP addresses,incorrectgateways,etc.)canalso

lead to interference with other network participants.

Notes on cleaning the display on page 73.

BOGE compressor control airtelligence provis 3 Page 7

Safety 2.3 Owner and personnel

In addition, the specified minimum qualities of the network cables (CAT 6)

must be observed.

Change of settings The control regulates the individual compressed airnets by means of settings

or parameters that can be defined individually. These adjustable values can

therefore be used to change the control behavior of the compressors so that

each net produces compressed air on demand. However, incorrect settings

may also cause faults in the operating process or destruction of components.

– The change of settings / parameters may only be carried out by authorized

specialist personnel with sound knowledge of compressed air technology.

– In cases of doubt please contact BOGE service prior to changing any set-

tings.

Data backup The control is equipped with a Solid State Drive (SSD). All changes made to

adjustable values are automatically stored in this internal memory after being

entered.

To ensure that an originally existing configuration is not lost after a possible

defect of the SSD memory or a change of the settings, it can be transferred to

an external memory for backup using the "Export configuration file" function

(see „Configuration import and export“, page 65).

2.3 Owner and personnel

Personnel requirements Basically only those persons may carry out activities on the control who per-

form their tasks duly and reliably and meet the following requirements:

Trained personnel

Trained personnel are persons who have been instructed in a verifiable and

detailed manner by the owner about their assigned tasks and any potential

risks in this conjunction.

Qualified personnel

Qualified personnel are persons who, due to their professional training, knowl-

edge and experience as well as their awareness of the relevant regulations,

are in a position to carry out the tasks assigned to them and be able to auton-

omously identify any potential hazards and to prevent personal injury or prop-

erty damage.

Qualified electricians

Qualified electricians are persons who, due to their professional training,

knowledge and experience as well as their awareness of the relevant stan-

dards and regulations, are in a position to properly carry out work on electrical

installations, to autonomously identify any potential hazards and to prevent

personal injury or property damage caused by electric current.

Prior to describing any work that requires special knowledge, it is clearly

indicated in these operating instructionswhat qualifications profile a person

must comply with to perform the described tasks.

Safety 2.3 Owner and personnel

Page 8 BOGE compressor control airtelligence provis 3

Personal protective equipment (PPE)

During transport, assembly and maintenance/service work

– protective clothing,

– slip-resistant safety shoes,

– cut and puncture-resistant protective gloves

– protective helmet (for compressor transport and work inside the compres-

sor)

– Safetygoggles(when working onpressurizedcomponents/ on the control

pneumatics)

must be worn.

When operating the control in the compressor room, hearing protection must

also be worn if necessary.

Obligations of the opera-

tor The operator is subject to the statutory obligations for occupational safety and

must be informed about the valid health and safety regulations.

The use of the master control implies that a suitable safety concept has been

developedfor the machines or plants.This includes a hazardand risk analysis

in accordance with the relevant guidelines and standards (e.g. EMC and Low

Voltage Directive) and a test report for the validity of the safety functions.

Furthermore:

– The operator must authorize qualified electricians for any work on the con-

trol cabinet.

– The owner must only provide the key for opening the control cabinet to

qualified electricians who have been authorized by him to perform work on

the control cabinet.

– The owner must authorize specialist staff performing changes to settings/

parameters of the control.

Obligations of the per-

sonnel The personnel is subject to the statutory obligations for occupational safety

and must be informed about the valid health and safety regulations.

Furthermore:

– The personnel must have completely read the operating instructions prior

to commissioning/operation of the control.

– Personnelmust havereadthe operatinginstructions for compressors, their

integrated controls and the equipment in full prior to commissioning/oper-

ating these components.

– The staff must have been authorized based on these instructions for any

work that they may perform depending on their qualification.

BOGE compressor control airtelligence provis 3 Page 9

Assembly and connection 3.1 Installation of the control

Part 3: Assembly and

connection 3.1 Installation of the control

The airtelligence provis 3 is installed in a separate switch cabinet. The oper-

ating unit of the control, the touch panel (1), is located in the front of the switch

cabinet (2).

Fig. 3.1: Switch cabinet with touch panel

After delivery, the switch cabinet must be set up and installed at a suitable

location before the necessary components can be connected and the control

can be put into operation.

Assembling the switch

cabinet Safety instructions prior to assembly

– Ensure that the installation site is free from dirt and moisture.

– Physically separate the switch cabinet from frequency converters and

high-voltage appliances.

– Avoid functional failures that can be caused by heat generation and inter-

ference with adjacent components, by meeting the requirements of EN

61439:

– Ensure that the temperature limits at the place of operation are

observed (see „8.1 Technical data“, page 75).

– Do not place the switch cabinet directly next to heat sources.

– The components are designed for cooling by convection: therefore

avoid heat accumulation and ensure that no openings are covered

(e.g. by surface-mounted cables).

– During assembly, ensure that the bottom side of the control cabinet hous-

ing points downwards (see also „Housing dimensions and component

overview“, page 76). The specified ambient conditions, especially the

ambient temperatures, apply to this alignment only.

(1)

(2)

Assembly and connection 3.1 Installation of the control

Page 10 BOGE compressor control airtelligence provis 3

To assemble the switch cabinet:

1. Mark boreholes on the wall.

2. Drill holes at the marked positions.

3. Insert suitable dowels into the drill holes.

4. Fasten the switch cabinet with suitable screws and washers if necessary.

5. Protect all bores and bare machining points from corrosion.

The switch cabinet is assembled.

Check assembly 1. Check to ensure that the switch cabinet is firmly tightened.

2. Check switch cabinet and components for damages.

3. Ensure that the required assembly clearances have been maintained.

WARNING

Risk of injury due to improper assembly!

The switch cabinet can fall down if not mounted properly. Injuries and dam-

age to property can be the result.

Assembly work may only be carried out by trained personnel.

Carry out assembly with at least two persons.

Follow the instructions in section „ Intended use“, page 5.

Use the fixing material included in the scope of delivery.

Always wear PPE during assembly work.

CAUTION

Risk of property damage due to improper assembly!

If the switch cabinet is exposed to vibrations at its installation location, the

product may be damaged.

Do not install the switch cabinet on vibrating or oscillating supports,

machines and equipment parts.

Ensure that there is sufficient freedom of movement for installation, opera-

tion and service work on the switch cabinet.

BOGE recommends that a circumferential distance of 1 meter to surround-

ing components is maintained.

BOGE compressor control airtelligence provis 3 Page 11

Assembly and connection 3.2 Connecting the control

3.2 Connecting the control

Once the installation of the switch cabinet has been completed, the power sup-

plymust be establishedintheswitchcabinet.Thelinesfor communicationwith

the components to be acquired by the control must also be connected.

Safety instructions prior to establishing the connections

– All work on and in the switch cabinet, including establishing of the connec-

tions and subsequent commissioning, may only be carried out by author-

ized electricians.

– When connecting to the power supply, observe the valid national and inter-

national regulations (e.g. VDE regulations, DIN-EN standards) and the

local safety regulations.

– The electrical equipment of the installation must be designed in accord-

ance with the Low Voltage Directive and the EMC Directive.

Establishing the electri-

cal connection To establish the electrical connection:

1. Ensure that the customer has installed the back-up fuse recommended in

the Technical Data on page 75.

2. Open switch cabinet.

3. Checkthatall componentsare securely seated on the top-hat rails and that

the retaining clips of the components are firmly engaged.

4. Check whether all installed conductive connections are firmly tightened.

5. If necessary, tighten loose connections with a torque screwdriver. Observe

the following torques:

Tab. 3.1: Torques of switch cabinet components

For proper connection and commissioning of the control you need the sup-

plied wiring diagram. The circuit diagram must be kept in a safe place for

later use.

WARNING

Risk of injury from live parts!

When establishing the electrical connection, there is a risk of life-threatening

electric shock when the power supply is connected.

The electrical connection may only be established in a de-energized

state.

Work may only be carried out by authorized qualified electricians.

BMK Designation/Type Torque

-14K1 Panel-PC - airtelligence provis 3 0.89 Nm

-20K1 Industrial Ethernet Switch - FL Switch SFNB 8TX 0,5 Nm ... 0,6 Nm

Assembly and connection 3.2 Connecting the control

Page 12 BOGE compressor control airtelligence provis 3

6. Insert the cable into the switch cabinet through the threaded cable gland.

CAUTION Riskof propertydamages.Insufficientcross-sectionofthecable

wires can lead to malfunctions and overheating of the cable.

Use wires with a minimum cross section of 1.5 mm².

7. Strip the cable and the cable cores according to the required length.

8. Strip wire ends.

9. Fit the individual wires with suitable wire ferrules.

The wires are ready for connection to the terminal strip

-12X0.

Necessary specifications of the cable wires for connection to terminal

strip -12X0:

Tab. 3.2: Specifications of conducting wires for power supply

In order to connect thewires correctly, the numbers on the terminals of the ter-

minal block must be observed so that the external conductor, neutral conduc-

tor and protective earth can be assigned to the correct connections of the

-12X0 terminal block.

Tab. 3.3: Assignment of terminal block to cable wire

To connect a cable wire to the terminal strip -12X0:

10.Press and hold the orange push button with a special screwdriver for elec-

trical installation.

11.Insert the cable wire into the round opening of the push-in terminal block.

12.Release the push button to fix the wire in the terminal compartment.

The cable wire is connected.

13.Perform the procedure with all 3 wires of the cable according to the assign-

ment in table 4.3.

14.Check all cable wires for tight fitting.

The electrical connection is established.

BMK fixed conductor flexible conductor Stripping length

without ferrule with ferrule

-12X0 0.14 mm² ... 4 mm² 0.14 mm² ... 2.5 mm² without plastic sleeve

0.14 mm² ... 2.5 mm²

with plastic sleeve

0.14 mm² ... 2.5 mm²

8 mm ... 10 mm

Number on terminal

block Designation Explanation

1 L1 Connection for external conductor

2 N Connection for neutral conductor

3 PE Connection for protective earth conductor

Table of contents

Other Boge Control Unit manuals

Popular Control Unit manuals by other brands

VXI Technology

VXI Technology VM1548C user manual

Burkert

Burkert 6650 operating instructions

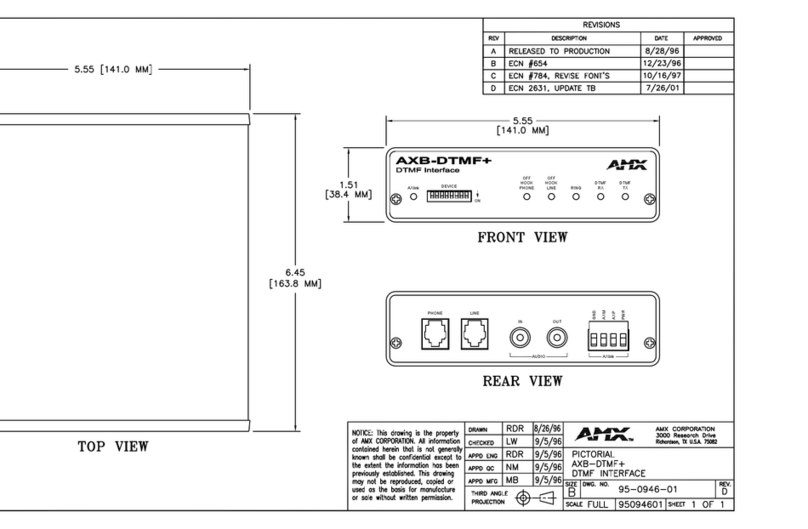

AMX

AMX AXB-DTMF Plus Specifications

GEM

GEM R690 Installation, operating and maintenance instructions

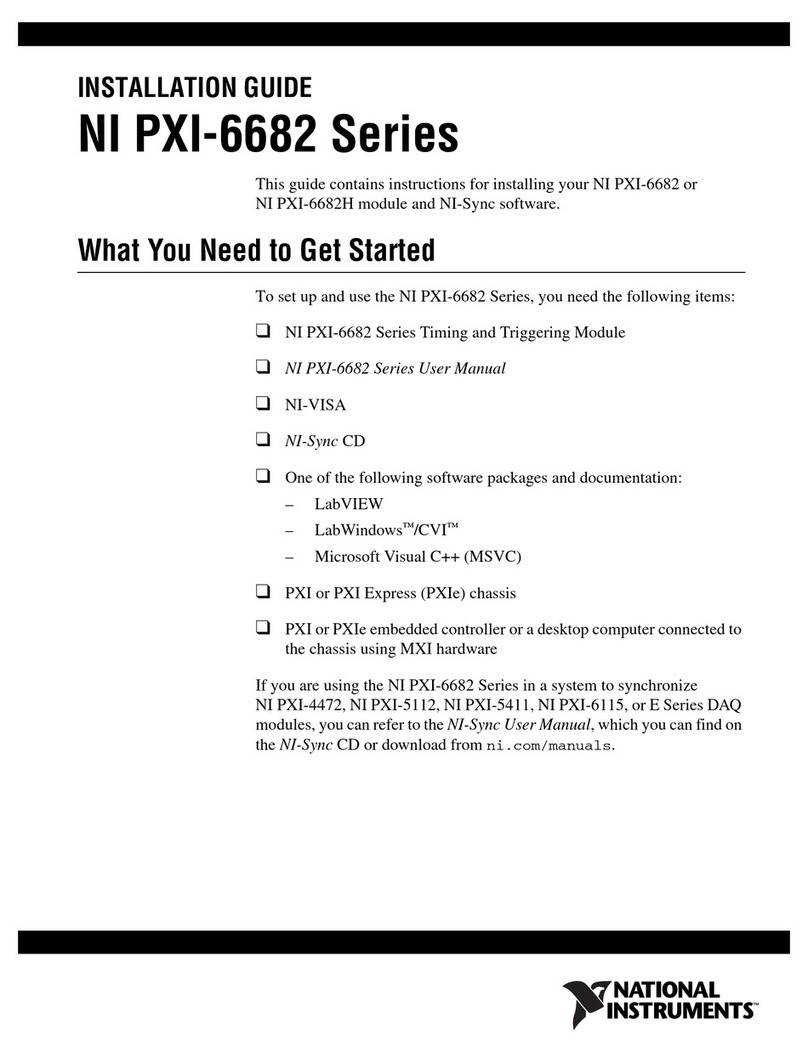

National Instruments

National Instruments NI PXI-6682 installation guide

Arbor Technology

Arbor Technology EmNANO-i2300 user manual

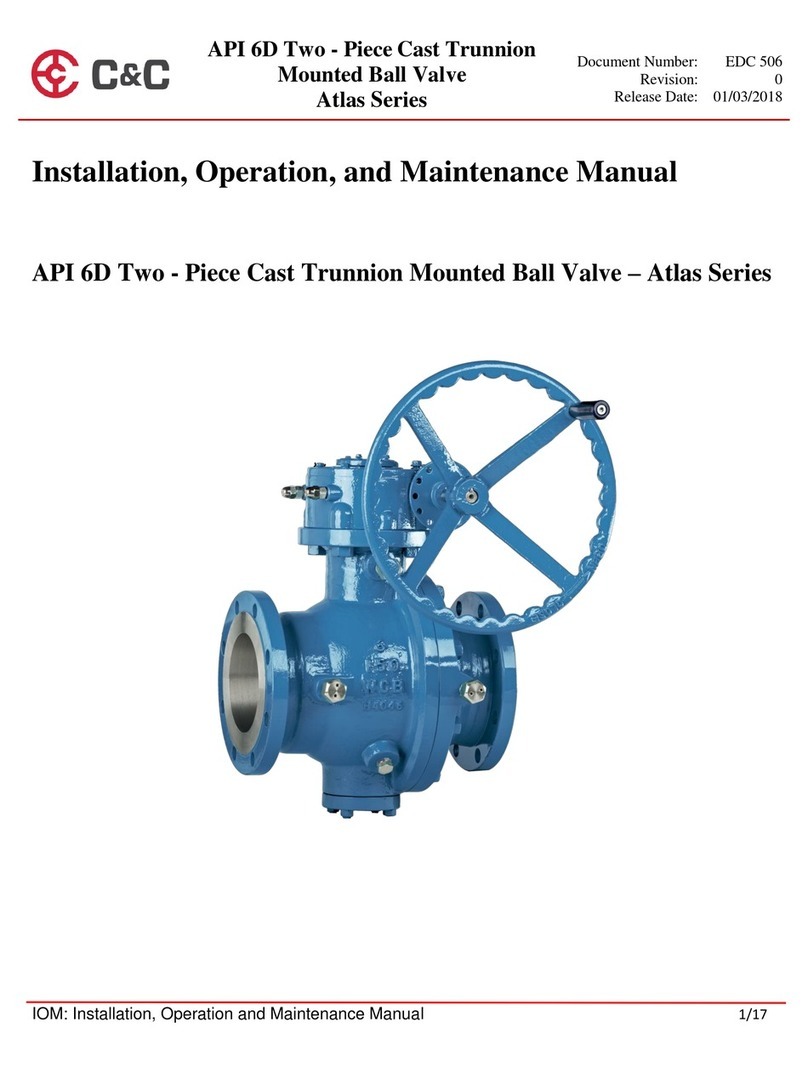

C&C

C&C Atlas Series Installation, operation and maintenance manual

RJG

RJG Lynx IA1-M-V product manual

Digital Equipment

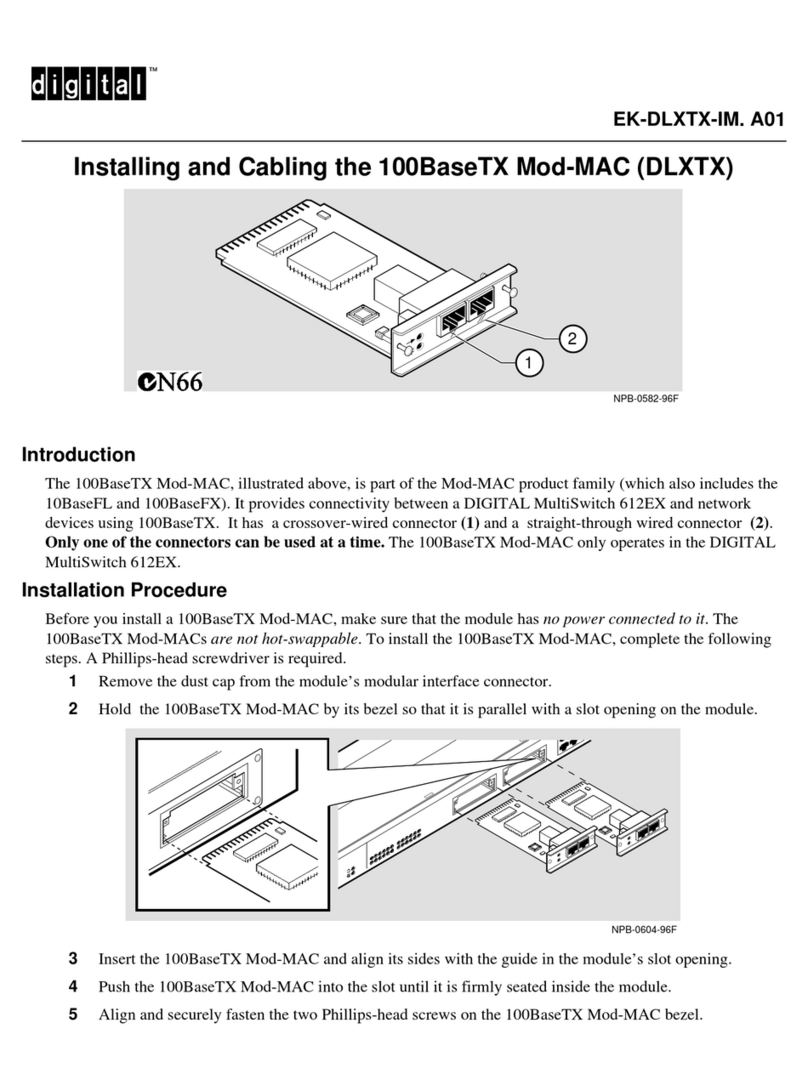

Digital Equipment Mod-MAC Series Installing and Cabling

INSTEON

INSTEON 2634-222 owner's manual

Drivecon

Drivecon XT Series Service manual

Savant

Savant IP Audio 125 with Savant Music 2.0 Quick reference guide