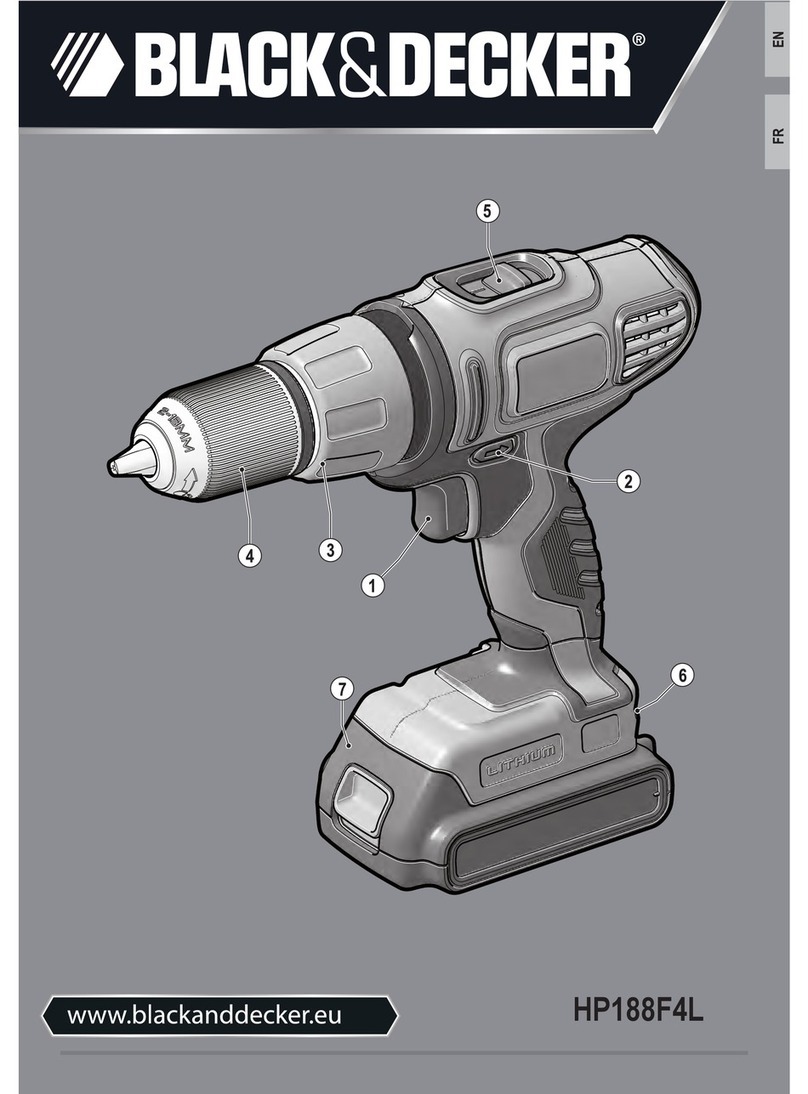

Bollhoff RIVNUT B 4090 User manual

R I V N U T ®B4090

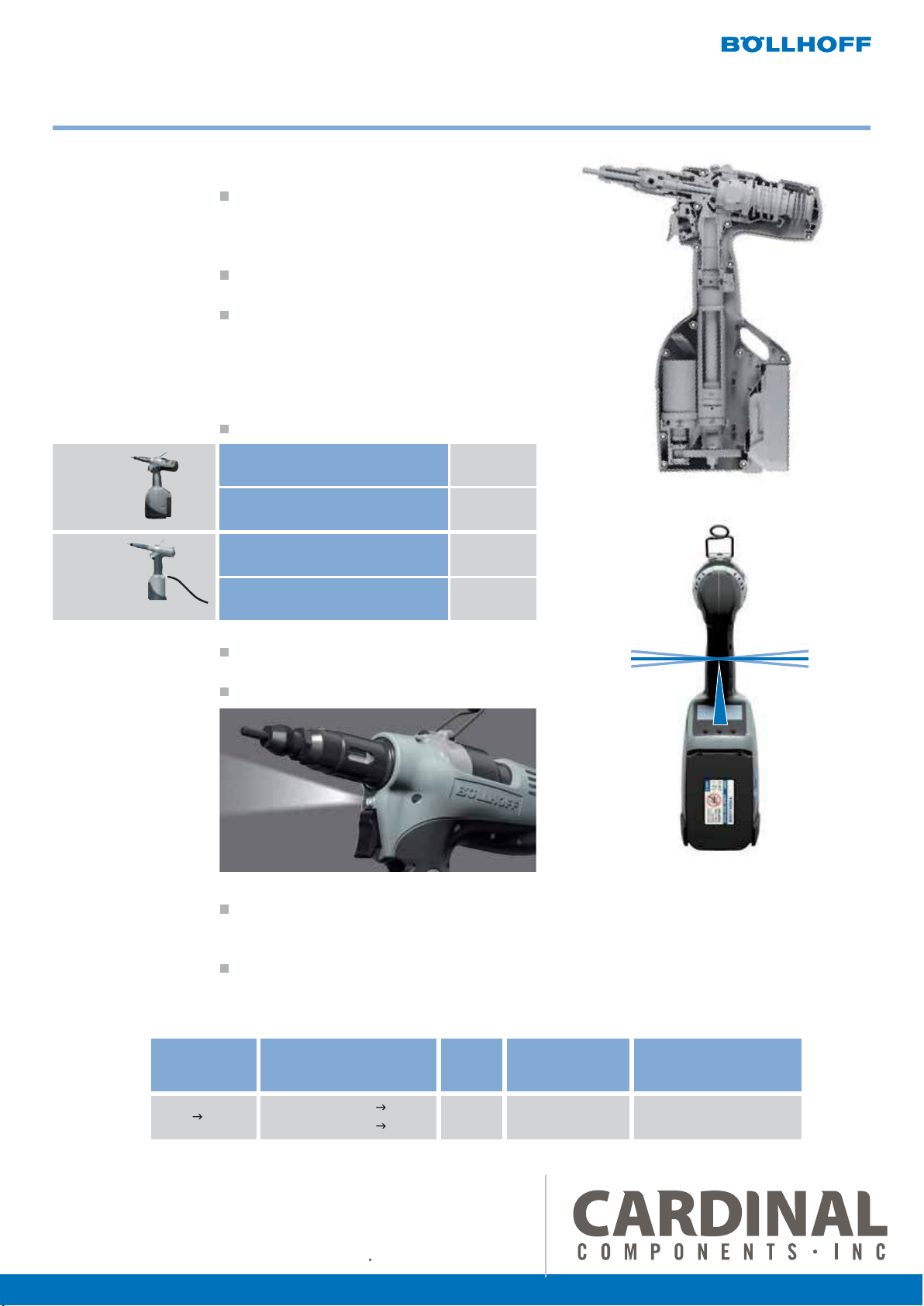

The RIVNUT®Battery tool

B4090 05/16 ENG

Visa, Mastercard, Discover & AMEX Accepted Fax: 262.252.5033

ISO 9001 CERTIFIED

800.236.3200 - sales@rivet-nut.com

Call Cardinal Components to Order or for a Quote

2

2

Advantages :

3 kN to 22 kN (M3-M10 steel)

24 R IVNUT®/ min

Up to 800 cycles with 1 battery

Internal qualification done with 1 000 000 cycles

BÖLLHOFF quality

RIVNUT®nut & stud compatible

Li-Ion technology battery

R I V N U T ®B4090 – Battery tool

S tandard B ÖL LHOFF ergonomic

•S ingle press trigger function to complete

the entire cycle

•Comfortable & ergonomic handling

E lectro-hydraulic technology

•Well balanced

•Power & reliability in a reasonable weight

S oft coverings for comfortable handling

and for tool protection

L C D s c reen

•Load adjustment

•S etting parameters menu

•Battery level information

•Unscrewing button

New quick tooling replacement

•No tool needed

•Uses the existing mandrel & anvil

Visa, Mastercard, Discover & AMEX Accepted Fax: 262.252.5033

ISO 9001 CERTIFIED

800.236.3200 - sales@rivet-nut.com

Call Cardinal Components to Order or for a Quote

B4090

Total weight

2,12 0,07 0,30 2,49 kg

4 090

3

B uilt for intens ive us e

Optimized ergonomic des ign

Electro-hydraulic technology: the choice for ultimate

peformance with the best reliability whilst maintaining

a reasonable weight

Produces 600 to 800 cycles per battery

1 000 000 cycles qualification – BÖLLHOFF quality

Well balanced tool

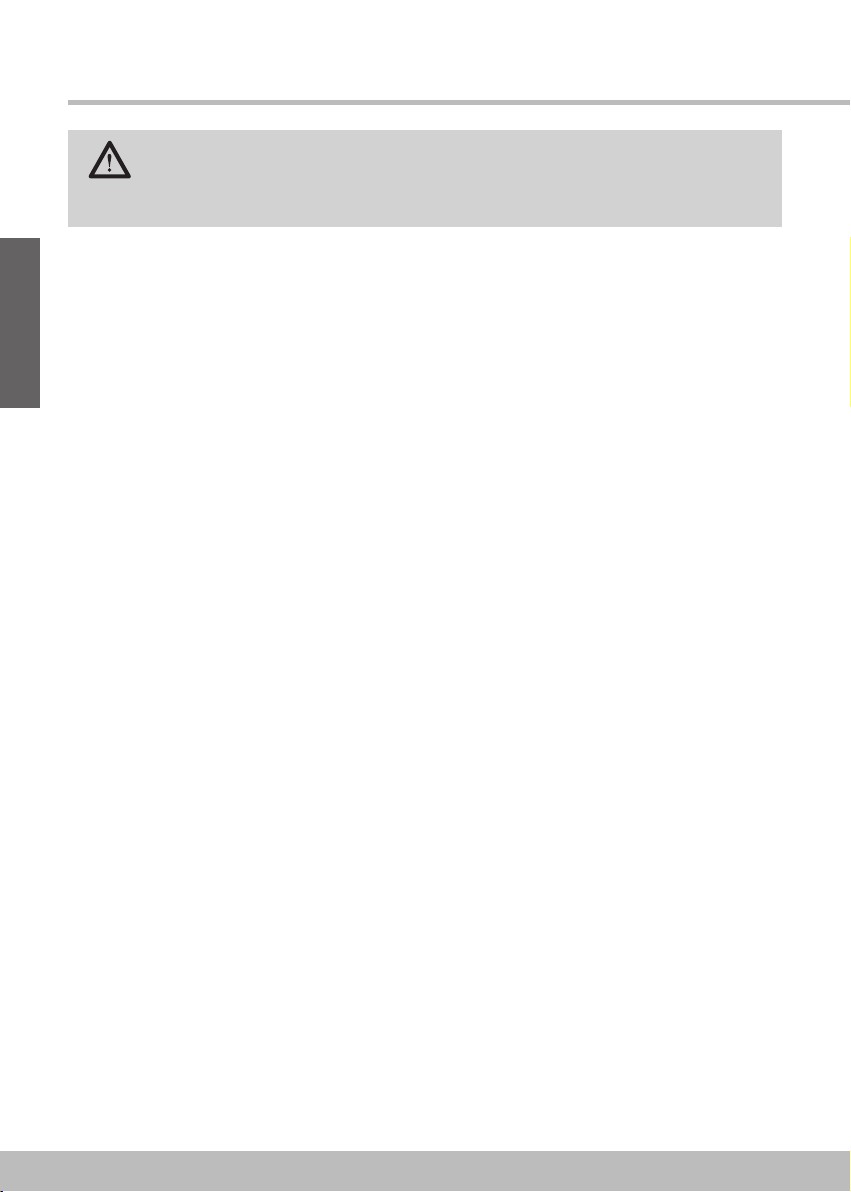

S mart lighting to s ee in dark conditions

Precise force adjustment, easy to do from the

screen (possibility to lock it in the menu)

Full menu to personalize your tool to your wish

R I V N U T ®B4090 – C ordless battery tool for R IVNUT®nut & studs

Tool Tooling B attery

+ +

+ +

Total weight

2,20 0,07 0,33 2,60 kg

Tool Tooling Pneumatic

+ +

+ +

S etting force

range

kN

R IVNUT®capacity

S etting

stroke

max

C adency

R IVNUT®/min

Weight

(Tool + Tooling + B attery)

kg

3 22* S teel: M3 M10*

S tainless s teel: M3 M8* 7 mm 24 2,49

Main c harac teris tic s

* Above 18 kN (M10 steel & M8 S tainless steel) please use fork adaptator & specific tooling

Well balanc ed

Pneumatic

Comparable weight to the 4090 when fitted with hose

Visa, Mastercard, Discover & AMEX Accepted Fax: 262.252.5033

ISO 9001 CERTIFIED

800.236.3200 - sales@rivet-nut.com

Call Cardinal Components to Order or for a Quote

English

4

SAFETY RECOMME DATIO S 5-7

1 - OPERATI G PRI CIPLE A D TECH ICAL FEATURES OF THE DEVICE 8-10

Pooling methods

Pressure setting method: force controlled setting (installation)

Setting force value

Technical features

Device dimensions

Contents of the case

2 - PREPARATIO S FOR USE 11-15

Assembling the tooling

Connection to the battery

Switching on the device

Adjustment of the setting force

Options and accessories

3 - USE 16-19

Procedure for use

Unscrew button

Programming menu

Maintenance submenu

Programming menu

4 - MAI TE A CE 20-22

Daily/weekly maintenance

Occasional maintenance

Oil level check

5 - SPARE PARTS LIST

Spare parts

23-24

25

26

27

6 - TROUBLESHOOTI G

7 - WAR I G LIST

8 - WARRA TY

Table of contents

Call Cardinal Components to Order or for a Quote

5

English

We recommend you to read this User manual carefully before preparing, using or carrying out

device maintenance. Observe the safety rules in force in your Country in order to reduce the risk

of fire, electric shock and personal injury.

Always wear safety goggles when using electrically-operated tools. eep the instructions in a safe place.

The Technical Service is at your disposal for advice or, if necessary, to give you an appropriate training.

General safety rules

Safety within the work area

eep the work area clean and well lit. Cluttered benches and dark areas may cause accidents.

Do not use electrically-operated tools in an explosive atmosphere as, for example, in the presence of

flammable liquids, gases, dusts. Electrically-operated tools produce sparks which may ignite

dusts or gases.

When using an electrically-operated tool, keep all persons present, children and visitors at a distance.

Electrical safety

Battery charger

• Warning: to reduce the risk of injuries, only authorized batteries should be recharged. Other types

of batteries may explode, causing personal injury and damage

• Before using the battery charger, read all the warnings and instructions indicated on the battery,

battery charger and battery-powered products.

• Do not expose the battery to rain, snow or damp environments.

• In order to reduce the risk of damage to the cable and the plug, disconnect the battery charger

unplugging the plug. Never pull the cable.

• The use of non recommended accessories or accessories that are not sold by the manufacturer

can cause fires, electric shock and personal injury.

• Make sure the battery charger cable is in a position where it cannot be stepped on, exposed to

damage or stress, or stumbled over.

• Make proper use of the power supply cable. Do not carry the battery charger holding it by the

cable. eep the cable away from heat sources, oil, water, cutting edges or moving parts.

Replace damaged cables immediately.

• Do not use the battery charger if it is damaged: have it repaired by a qualified assistance centre

• To reduce the risk of electric shocks, unplug the battery charger from the power outlet before carrying

out any maintenance intervention or cleaning. Switching the controls off does not reduce this risk.

• Do not disassemble the battery charger or the batteries: contact a qualified Assistance centre.

Incorrect reassembly can cause electric shocks or fire hazards.

Read all the warnings and instructions.

Failure to comply with the warnings and instructions can cause electric shocks,

fire and/or serious injuries.

Keep all the warnings and instructions for future reference.

Safety recommendations

Call Cardinal Components to Order or for a Quote

English

6

Batteries

• Do not charge the batteries when room temperature is lower than 0°C (32°F) or greater than

40°C (104°F)

• Do not use a step-down transformer, a power-supply unit or a DC supply plug

• Do not short-circuit the batteries: do not touch the terminals with any conductive material.

Avoid keeping the batteries in contact with metal objects such as nails, coins, clips, etc.

• Do not expose batteries to water or rain. A short-circuit of the batteries can cause a strong current

flow, overheating, burns and faults.

• Do not keep the device and the batteries in places where room temperature is equal to or greater

than 50°C (122°F)

• Do not burn the batteries even if they are seriously damaged or completely worn out: they may

explode and cause a fire

• Be careful not to drop, shake or hit the batteries

• Remove the batteries from their boxes or cases before recharging them. eep the batteries in

a well-ventilated area during the charging process

• Do not dispose of batteries with household waste, in fire or water: collect, recycle or dispose of

the batteries in order to protect the environment. Contact an authorized Service Centre to obtain

information on the centers where damaged or unusable batteries can be disposed of.

Personal safety

• Always pay attention to the operation you are performing and use common sense while handling

an electrically-operated tool. Do not use electrically-operated tools if you are tired or under the

influence of drugs, alcohol or medicines. When using electrically-operated tools, even a momentary

lapse of concentration can cause serious personal injuries.

• Wear suitable clothing. Do not wear loose clothes or jewels. Long hair must be tied back.

eep hair, clothes and gloves away from moving parts. Loose clothes, jewels or long hair may get

caught in moving parts.

• Do not lean. eep a correct posture and correct balance at all times. A correct posture and good

balance give you a better control of the tool in unexpected situations.

• Use safety devices. Always wear safety goggles. Always use dust masks, safety anti-slip shoes,

helmets or earmuffs to provide for safe work conditions.

Tool use and maintenance

• Use clamps or other fixing systems to fasten the piece to be processed to a stable platform. A

piece that is held by hand or with the body reduces stability and may lead to a loss of control.

• Do not force the tools. Use a tool suitable for the operation to be performed. The appropriate tool,

used in nominal conditions, allows you to work in the safest way.

• Store unused tools out of the reach of children and unauthorized persons.

• Check that no moving part is unaligned, removed or damaged, and that no other condition may

affect tool operation. In case of damage, check the tool before use. Many accidents are caused by

poor maintenance.

• Use only the accessories recommended by the manufacturer for that specific model.

• This product has been designed exclusively for the tightening of threaded inserts and stud bolts in

pre-holed supports for professional use. Any other use is forbidden. Any alteration, repair and

modification made without the consent of the manufacturer is forbidden.

Call Cardinal Components to Order or for a Quote

7

English

Safety recommendations

• Use only original spare parts: failure to comply with this rule will render the warranty null and void.

• Access inside the tool is reserved to qualified personnel. Do not disconnect any cable before

disconnecting the battery. Pay attention to the voltage remaining in capacitors, which may last for

many hours. Pay attention to possible hot parts.

• In case of faults, do not try to repair the tool if you do not possess the necessary knowledge.

In case of malfunction, entrust the device to a repairer authorized by the manufacturer.

• The tool must be operated and used by personnel trained and authorized by the manufacturer.

Repair, maintenance, assistance

• Tool maintenance must be carried out only by qualified personnel. Maintenance or repair carried

out by non qualified personnel may cause injuries.

• Use only original spare parts when performing tool maintenance. The use of non authorized

components or the failure to comply with the maintenance instructions involves the risk of electric

shock or injury.

• Have the electrically-operated tool repaired only by qualified technicians and use only original spare

parts. This ensures the constant safety of the electrically-operated tool.

Additional general safety rules

• The device has been designed to be used with the material recommended and supplied by the

manufacturer.

• The customer must train operators on the use and precautions for use concerning this device.

• The customer is the only person responsible for possible modifications to the device, of maintenance

which does not comply with the instructions contained in this manual or performed using other

materials.

• The device must undergo regular maintenance, following the recommendations made in this

regard by a person who has received appropriate training, in particular with regard to disassembly

and repair.

• When the device is moved, be careful not to place your hand on the trigger to avoid operating the

device unintentionally.

• If the rivet is placed on the rod by hand, your fingers must be on the rivet stem and must not touch

the ends of the rivet to avoid being crushed. It is recommended to place the rivet into the piece to

be processed and to fit the device rod afterwards, thus eliminating any risk of injury to the fingers.

• The use of gloves is recommended.

• Do not operate the device while pointing it at a person and make sure that no objects get caught

in the device mechanism.

• The operator must not use the device if a piece is missing or if it is not tightened properly.

• The device must be used in compliance with the current legislation.

Call Cardinal Components to Order or for a Quote

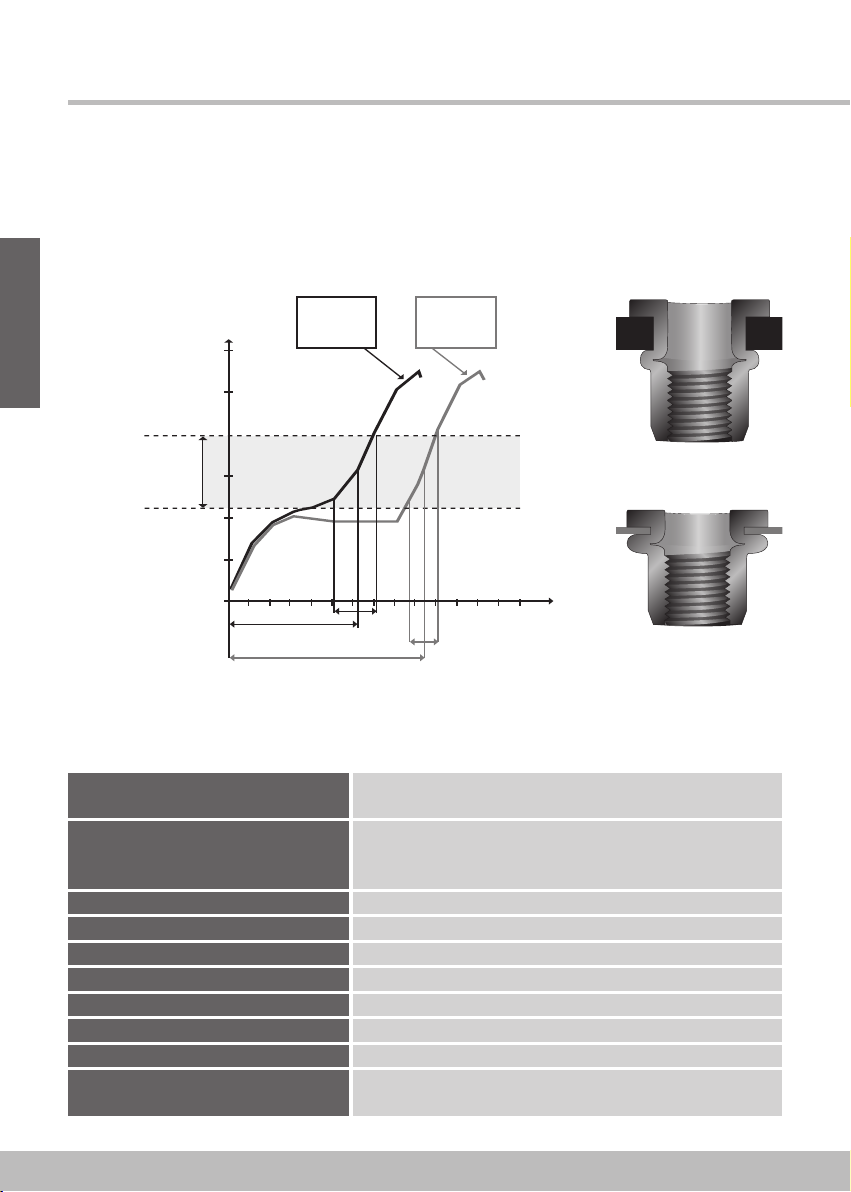

Pressure setting method: force controlled setting

In the stroke setting method, the tool delivers a constant stroke. When

there is a variation in thickness of the workpiece there is a definite risk

that a blind rivet nut may not be set properly, or become damaged

due to the setting mandrel damaging the Rivet Nut® thread. In this

situation there will be premature wear of the mandrel.

This phenomenon is eliminated with the pressure setting method as the

setting force is controlled irrespective of the thickness of the workpiece.

This setting principle is particularly well suited to workpieces with variable thickness (plastic parts,

various layers…) and provides consistent setting quality.

Advantages:

IOptimised setting into panels with thickness variations

IPossibility to set the same Rivet Nut® more than once

IPermits quality control (force indicator…)

IExtended mandrel life

ICan also sett different types of Rivet Nut® with one tool and one single

setup

English

8

1 - Operating principle and technical features of the device

Crimp Spin off

Push pull Insert

Pulling methods

The “pulling method” comprises Push pull, Insert, Pull and Spin off cycles.

F

Call Cardinal Components to Order or for a Quote

9

English

1 - Operating principle and technical features of the device

Setting force (min - max) (kN) 3.00 –> 22.00*

( * > 18kN with appropriate accessory)

Setting capacity

Rivet Nut® M3 to M8*

Rivet Nut® Stud M4 to M8

(*M10 with appropriate accessory set)

Maximum stroke 7.0 mm

Weight of the tool 2.1 kg

Weight of the battery (2,6Ah) 0.3 kg

Battery Li-Ion / 14.4 V / 2.6 Ah

Environmental limitations of use 5°C - 40°C

IP egree of protection Vibration amplitude: 0.672 m/s²

Vibration 20

Noise emission Sound pressure level, LpA : 71.1 dB(A)

Sound power level, LwA : 82.1 dB(A)

Technical features

Setting force value

The recommended setting force is dependent on the combination of information coming from

Rivet Nut® parameters.

Rivet Nut® parameters

Maximum thickness (C1)

Minimum thickness (C2)

Setting effort range

= Force to obtain

a good setting

Force

Stroke

Tolerance

Stroke in

maximum thickness

Stroke in

minimum thickness

Tolerance

C1: setting

in maximum

thickness

C2: setting

in minimum

thickness

Minimum

Maximum

C1

C2

Call Cardinal Components to Order or for a Quote

English

10

Tool dimensions

Tool configurations and item number

Connection made

for Europe

Package with 1 battery 236 166 01 000

Connection made

for US

236 168 01 000

Package with 2 batteries 236 167 01 000 B4090-BOF

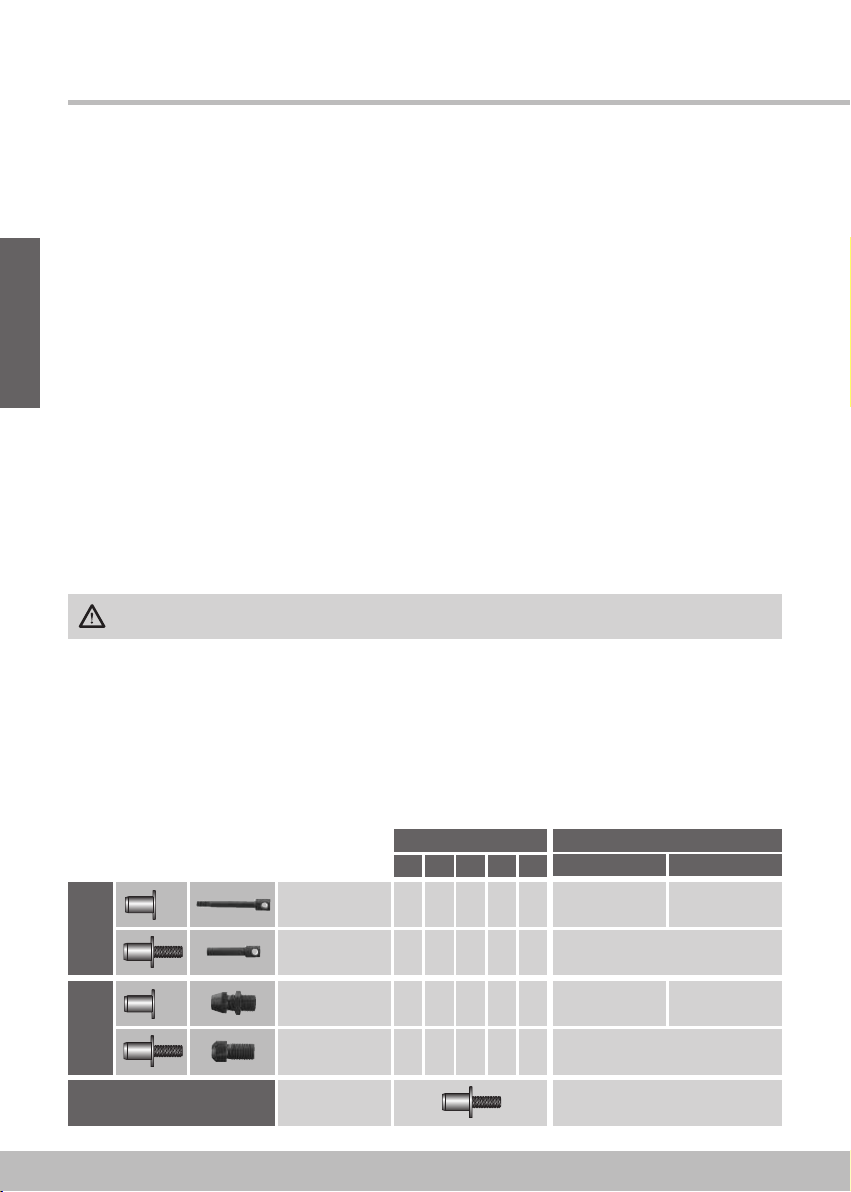

M3 M4 M5 M6 M8 M10

ez standard

ez spécifique

A

L

A

L

Contents of the case:

• 1 device without tooling

• 1 user manual

• 1 tool kit for tooling change

• 1 or 2 battery(ies)

• 1 battery charger

• 1 oil container

320 mm

Ø 28.5 mm

220 mm

L

330 mm

140 mm

A

62 mm

90 mm

Call Cardinal Components to Order or for a Quote

Assembling the device

11

English

2 - Preparation for use

SAFETY: BEFORE CARRYI G OUT A Y I TERVE TIO O THE DEVICE, DISCO ECT

THE BATTERY

03 04 05 06 08

–04 05 06 08

03 04 05 06 08

–04 05 06 08

236 113 XX 020 236 913 08 110

376 113 XX 020

M3 M4

236 913 10 019

–

08 10

–

X

MandrelAnvil

236 113 XX 030

376 113 XX 030

B4090-4076-0303

B4090-4076-0304

Fork and nose for studs &

force >18 kN (M8 & M10)

Fitting with special Rivet Nut® mandrels

You have two assembly options:

• Fitting with special Rivet Nut® mandrels (recommended by BÖLLHOFF for extended

tool life)

• Fitting with standard capscrews

318 k

M5 M6 M8 M8 M10

18 22 k

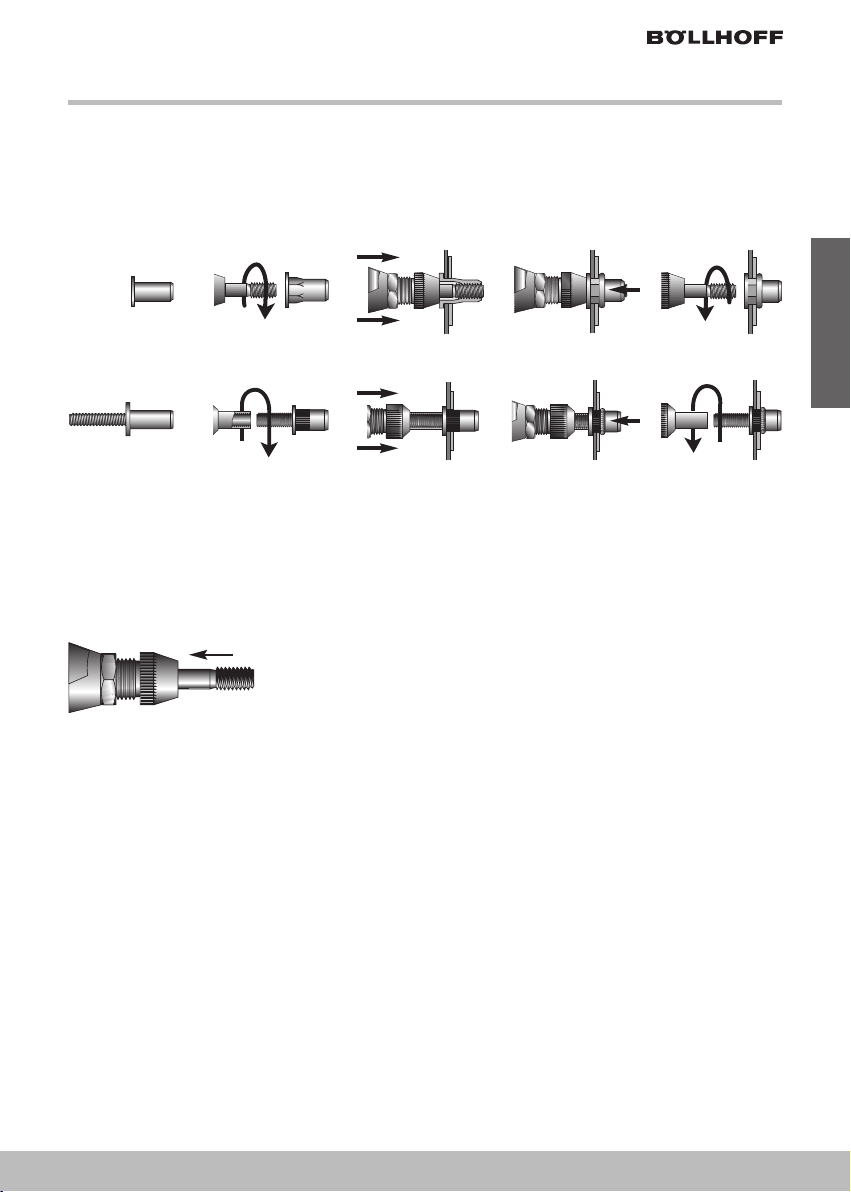

Connection to the battery

The device is delivered with a 14.4 V / 2.6 Ah battery power supply.

To connect the battery to the tool:

• Grab the tool

• With your other hand, grab the battery so that the quick-release lever is facing downwards

• Insert the battery into place by sliding it upwards until the quick-release lever on the battery clicks.

It is required to use only the original battery to ensure proper operation of the device.

Charging the battery

• Store the battery charger in a cool and ventilated area.

• Plug the battery charger in the power outlet. SAFETY WAR I G: make sure the power supply

source is compatible with the requirements indicated on the product plate.

• Insert the battery it in the battery charger keeping it parallel. Do not force the battery since it should slide

easily in place. Any possible difficulty may indicate an incorrect alignment.

Call Cardinal Components to Order or for a Quote

12

OK

OK

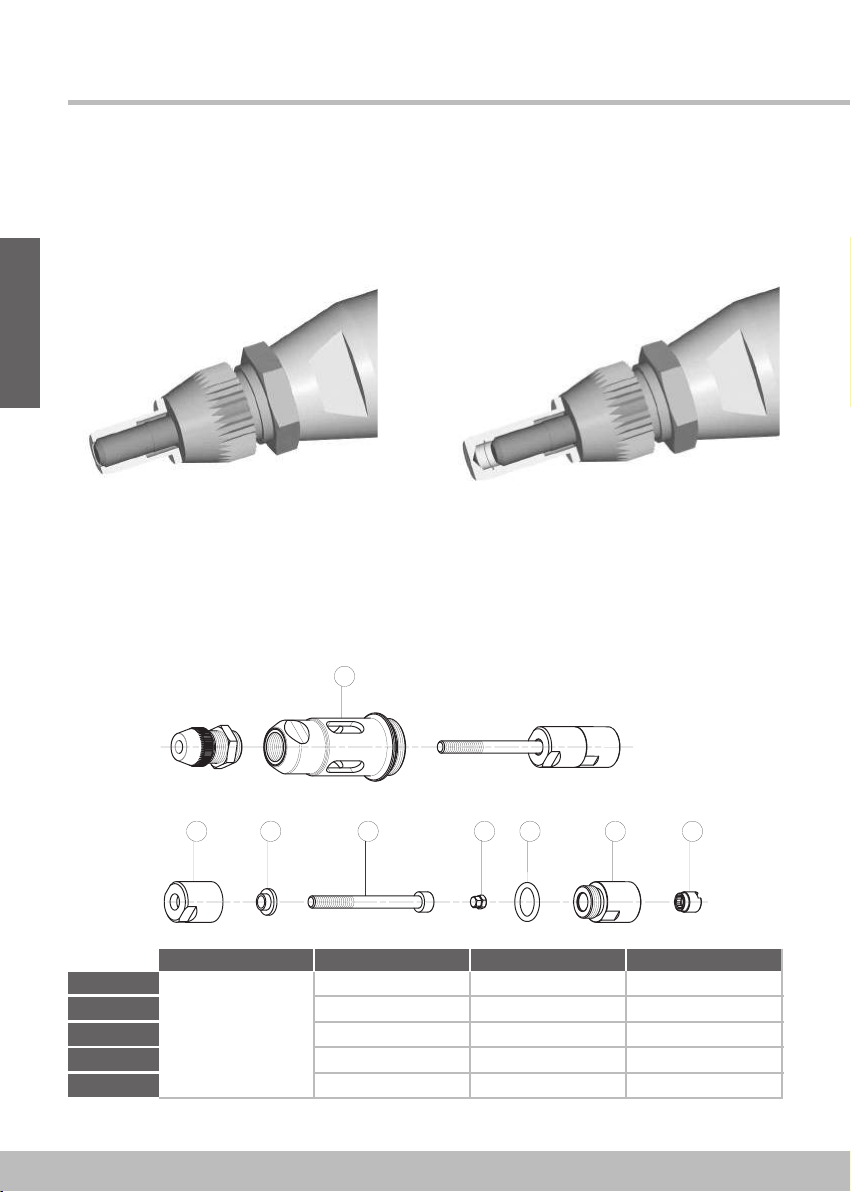

Based on the dimensions of the rivet, check that the following parts are present: mandrel ,

anvil , see diagram above.

• Remove the mandrel

• Refit the new mandrel by taking care to align the back side groove with the screwing driver

(see in figure 4). CAREFULL: grease (Multipurpose grease) has to be applyed between fork

and mandrel .

• Reposition the nose

• Retighten the nose to 15 Nm.

• Screw the new anvil inside the nose and lock it after adjusting the correct position thanks

to the nut.

THE BATTERY HAS TO BE DISCO ECTED WHE REPLACI G THE TOOLI G.

MA DREL (1) MOVES DURI G USE. AVOID CO TACT A D PAY THE UTMOST ATTE TIO .

OK

Mandrel Nose

Fork

Anvil

Figure 4 - Mandrel alignement

A

C D

E

B

Figure 3 - Fork and nose for studs & force >18 kN (M8 & M10)

21,5 mm

Force: 10 Nm

<>

12

ef. 23616600213

Call Cardinal Components to Order or for a Quote

13

English

2 - Preparation for use

Fitting with standard capscrew DI 912:

5 6 7

236 803 03 010 236 803 03040 M3 x 45 12.9

236 803 04040

236 803 05040

236 803 06040

NA

M4 x 55 12.9

M5 x 60 12.9

M6 x 65 12.9

M8 x 65 12.9

236 803 04 010

236 803 05 010

236 803 06 010

236 803 08 010

M3

M4

M5

M6

1+2+3+4

M8

COMMON

ADAPTATOR

8

46 7 52 1 3

Adjusting the position of the anvil in relative to the mandrel

• The position of the anvil depends on the length of the Rivet Nut® before

setting.

• The position of the anvil should be adjusted as shown in figure 5.

• After adjustment, tighten the anvil locknut (2) to 10 Nm.

OPE Rivet Nut®SEALED Rivet Nut®

Flush rod on the end of the Rivet Nut®Thread root single-turn rod

Figure 5 - Adjustment of the anvil position

Call Cardinal Components to Order or for a Quote

14

English

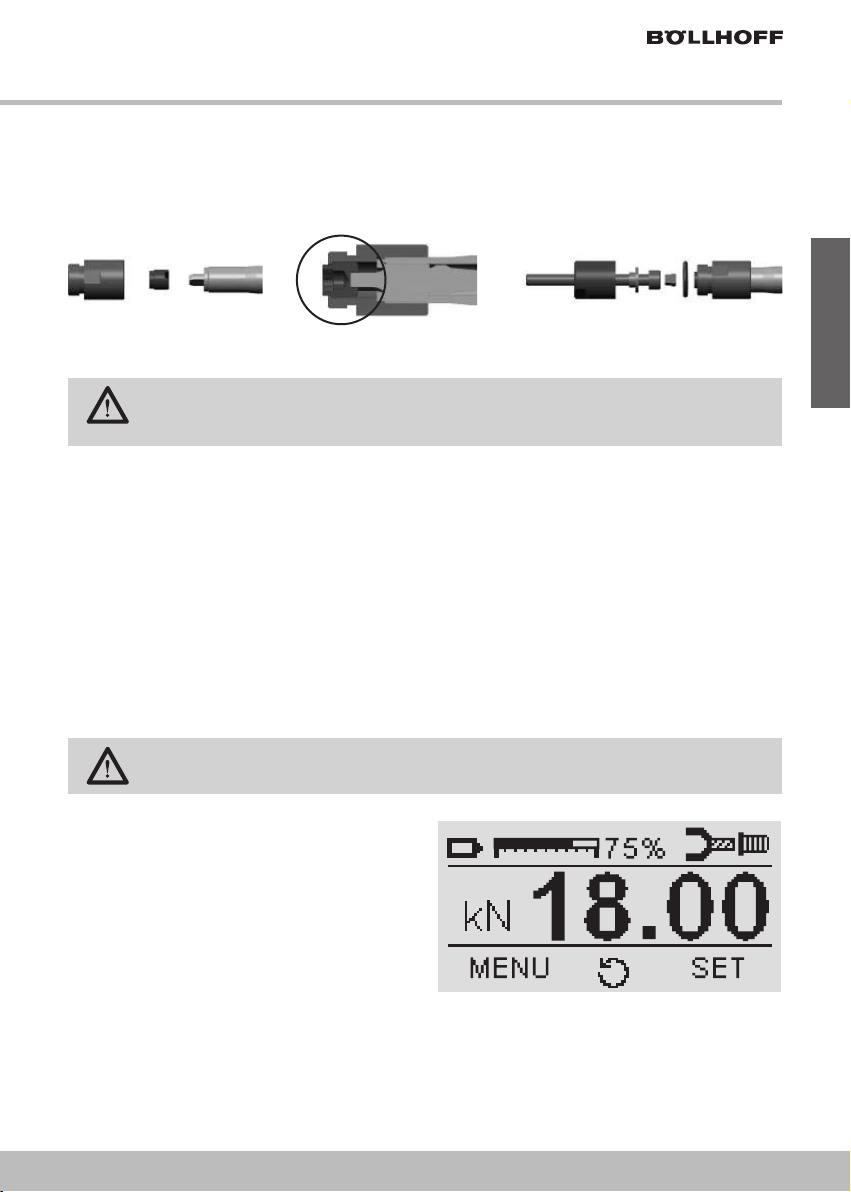

Switching on the device

After inserting the battery, activate and release the trigger once, which is located on the front part

of the handle.

In this condition, the tool is able to operate immediately, i.e. approached to a rivet, it will carry out the

screwing on the nose. After this operation, the tool is ready to pull the rivet and the selected pull.

• Connect the battery

• Switch on the device

• To adjust the setting force value, press the

RIGHT button (SET) at any time and keep it

pressed for 2 seconds. The digits indicating

the setting value start to blink.

• Press the LEFT (-) and RIGHT (+) keys,

decreasing or increasing the value in 100N

steps, until the desired value is reached.

• Press the CENTER (O ) confirmation button

or wait 5 seconds without pressing any button.

Please note that when changing the force, the battery life also varies depending on the required pull:

a pull with less force will need less current, so the battery life will be longer and vice versa.

Adjustment of the setting force

For allowing the use of the commercial screw kit, this is required:

• To take off the fork which is installed on the standard tool

• Install the pieces pos 1 and 3.

Adjust the anvil (refer to page 20 for instruction).

THE BATTERY HAS TO BE DISCO ECTED WHE REPLACI G THE TOOLI G.

MA DREL (1) MOVES DURI G USE. AVOID CO TACT A D PAY THE UTMOST

ATTE TIO

AT THE TIME OF DELIVERY, THE DEVICE IS SET TO THE MI IMUM FORCE. THE

DEVICE EEDS TO BE SET FOR THE FIRST USE.

12 3

Call Cardinal Components to Order or for a Quote

15

English

2 - Preparation for use

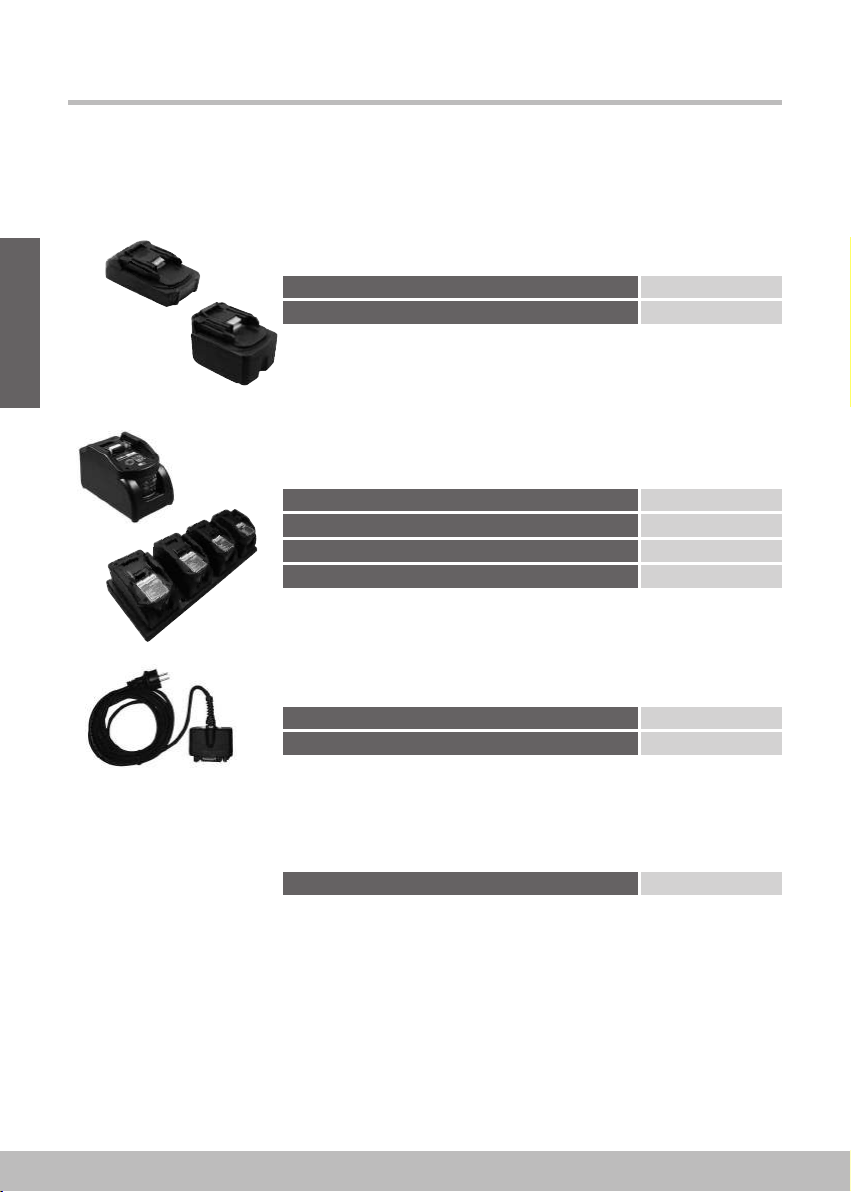

Options and accessories

The shart below lists the different accessories and options which are available for this tool.

B4090-4076-0350

B4090-4076-0351

Battery 14,4V 2,6AH

Battery 14,4V 4,0AH

Different capacities of battery

282 590 30353

282 590 30354

Battery loa er Solo EU

Battery loa er Solo US

Battery loa er Multi x4 EU

282 590 30355

Battery loa er Multi X4 US

Different loader

282 590 30356

282 590 30357

Continuous power supply 5m EU

Continuous power supply 5m US

Continuous power supply

236 166 00305

RK B4090 Support

Support for the tool

282 590 30352

Call Cardinal Components to Order or for a Quote

16

English

3 - Use

The device can be used in all positions, carried by hand or suspended.

Procedure for use

• Install the battery

• Switch the device on, by pulsing on the main trigger

• Position the Rivet Nut® on the mandrel. A light pressure starts the motor and causes the

automatic screwing of the Rivet Nut®, then the shutdown (Push-Pull system). Then insert

the Rivet Nut® into the hole.

• Alternatively, insert the Rivet Nut® into the hole, then push the mandrel against it in order

to activate the push-pull.

• Press the trigger and hold it until the mandrel has gone outside from the Rivet Nut® thread.

KEEP THE TRIGGER PRESSED FOR THE E TIRE DURATIO OF THE CYCLE.

IF THE TRIGGER IS RELEASED, THE I SERTIO IS OT CORRECT

Push pull (automatic) Insert Crimp Spin off (automatic)

Unscrew button

• If unscrewing is difficult, use the CENTER (UNSCREW / RESET) button.

To unscrew, hold the button down until the mandrel has fully gone outside from the Rivet

Nut® thread.

Call Cardinal Components to Order or for a Quote

17

English

3 - Use

Press the LEFT (MENU) button for 2 seconds to enter the programming menu. The LEFT button

moves the selection UP, the RIGHT button moves it DOWN, the CENTER button CONFIRMS.

The screen shows the main menu. Selectable options are:

I1. Language

Select the display language. Available options: French, English,

German, Italian, Spanish, Portuguese.

I2. Partial counter

Displays and allows resetting the partial cycle counter. Reset is

done by pushing LEFT and RIGHT buttons at the same time.

I3. Switch OFF time

Select the time after which the tool switches off, if no operation is

performed or no button is pressed (available options: 1, 5 or 10

minutes). In order to switch it on again, press the trigger briefly.

This time affects battery life.

Programming menu

The display screen appears after start up with the definition below:

Battery loa level (%)

Access to the menu pages

Information

of screwing state

Setting force level (in kN)

Access to the setting

force a justment screen

Manual comman for the

unscrewing / Acquitment button in case of fault

Call Cardinal Components to Order or for a Quote

Service sub-menu

Access by selecting option 6 of the main menu. Selectable options are:

18

English

I4. Start condition

Select the status of the tool at start.

Available options: Screwing done – Without condition.

I5. Force setting lock

By pushing on both + and - button at the same time, the setting is

getting lock, which means, that it will not be possible to modify the

setting force “SET” accessibility button, from production page.

Operation is reversible by proceeding the same way

I6. Service

Service sub-menu, see below.

IEXIT

For coming back to the production main page.

IOption 1: Identification

Displays Serial number, Firmware version, Total number of cycles.

These data are important in case you require assistance.

All our battery tool have been tested before delivery. Counter level

might be includes between 1500 cycles and 5000 cycles.

IOption 2: Buttons

Allows checking the functionality of the three display buttons and

the trigger. Differently from the other screens, to exit all three display

buttons shall be pushed at the same time.

Call Cardinal Components to Order or for a Quote

19

English

3 - Use

IOption 3: Sensors

Displays the status of the “Rest” sensor and the pressure sensor.

Rest sensor is the sensor checking the position of the main motor.

“ACT” means that the main motor is in the position ready to perform a

cycle. Pressure sensor: the value read by tis sensor is then translated

in the reading of the setting force. At rest, it might be possible that

residual pressure is present < 10 bars

IOption 4: Push-Pull view

The Push-Pull is calibrated at the factory, this page is giving access

to the sensor status.

IOption 5: Temperature View

Displays the temperature measured by three internal sensors.

For safety reasons, the machine stops working and displays an

error if an overheating occurs.

IOption 6: Battery

Displays the type and charge status of the battery. The tool will

stop, in case one of these temperature reach 75°C as a safety rule.

IOption 7: ext Service

Displays the number of cycles left before the next scheduled service.

A warning will be displayed when approaching and surpassing the

service threshold. The counter is defined for 250 000 cycles, refer

to the shart given on page 27. Reset of this counter can only be

done by Böllhoff staff. Maintenance service frequency is defined for

250 000 cycles.

IOption 8: Force set. Verify

The menu allows to adjust the convenient conditions for measuring

the real setting force applied on the mandrel using a force indicator

measurement devide (282 522 14000/00).

An offset < 400 N between measured value and consign appearing

on the display screen is considered as acceptable.

IOption 9: Restore defaults

This page will allow you to restore the setting as they were at the

initial preparation.)

IEXIT

For coming back to the “Option” main page.

Call Cardinal Components to Order or for a Quote

20

English

4 - Maintenance

Daily maintenance

The display screen appears after start up with the definition below:

Operation Frequency

Check the mandrel thread

Control the battery load level

Everyday

Everyday

Add grease inside the traction fork Each mandrel replacement

eplacement or cleaning of the mandrel

The Rivet Nut® should be screwed freely by hand Between 5,000 and 10,000 cycles

Oil draining and filling up Between 5,000 and 15,000 cycles

eplacement of the anvil

(If the internal diameter is > D + 0.5mm) Between 25,000 and 50,000 cycles

INSPECTION 1

Controling the main fonctions and performances

Every 250,000 cycles

eplacement of the oil and draining

Calibration of setting load

INSPECTION 2

Full maintenance of the setting head (seal parts, spring, …)

eplacement of the traction fork

Every 500,000 cycles

Call Cardinal Components to Order or for a Quote

Table of contents

Other Bollhoff Power Tools manuals