BOMAQ MP Series User manual

Operator's Manual Rev. BXXMP.01 January 2020

1/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

IMPORTANT

Read, understand and obey these safety rules and operating

instructions before operating the machine. Only trained and

qualified personnel shall be authorized to operate the machine.

This manual shall be kept with the machine at all times.

Due to continuous development on the quality of the product,

changes may apply to this manual. Please, ask the manufacturer

to have the latest updates.

For any further information, please contact Bomaq.

CONTACT

BOMAQ INDUSTRIES, S.L.U.

POLÍGO O I DUSTRIAL LA ESTRELLA

C/ALDEBARÁ 47 - P.C. 30500

MOLI A DE SEGURA - MURCIA

SPAI

Telephone +34 968 676 221

Email inf[email protected]

© Copyri ht 2020 BOMAQ INDUSTRIES S.L.U.

All ri hts reserved

CONTENTS

Introduction ............................................................ Page 3

Machine identification ............................................ Page 3

Labels used in the machine ..................................... Page 4

Safety precautions .................................................. Page 4

Description of the main components ..................... Page 12

Controls and instruments ........................................ Page 14

Inspections .............................................................. Page 17

Operating instructions ............................................ Page 20

Transporting the machine ....................................... Page 25

Maintenance ........................................................... Page 28

Faults and troubleshooting ..................................... Page 33

Specifications .......................................................... Page 34

2/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

INTRODUCTION

Thank you for the acquisition of your new Bomaq B30 MP, we

really hope this unit will cover all your expectations, and will

help you to carry out all the jobs you may need in your lifting

activity.

Throughout this Operator's Manual, you will discover all the

aspects related with the operation of this unit. In case you don't

find the information you need, you can contact us, and we will

immediately send you the required information.

Please, take your time to read and understand this Manual

before operating the unit, to be able to do it in a safe way.

All the measures and weights expressed in this manual are in

the metric system. If needed, ask for a different system to our

after-sales department.

MACHINE IDENTIFICATION

All our units are identified by a code, located on the plate on the

left side of the driver, inside the cabin.

This code is composed of several sections, which indicate model,

version and production counter.

In this case for example, we have B30-B-26-0714:

B30 is the model

B is the version of machine

26 is the counter for production

0714 is month/year of assembly init: July 2014

If you need support or parts allocation, you must write down

this code, and include it in any inquiry, so we are sure you are

taking the appropriate support or parts for your unit.

On the other hand, there is a plate indicating the model, weight

and mast type & height, to identify the machine model and

lifting capacity. In this plate you'll find also information about

maximum weight capacities.

The forklift has another serial number stamped on the mast. It is

located in the front profiles, and it is also important when asking

for parts of the mast (rollers, chains, ...).

3/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

LABELS USED IN THE MACHINE

Here we have a list of the symbols used, and their meaning:

LABEL MEANING LOCATION

Risk of hand

injury Mast

Fasten seat belt Dashboard

Use diesel only Diesel tank

In case of

overturn don't get

out of the Cabin

Dashboard

Be careful with

rotating arts Engine cooler

SAFETY PRECAUTIONS

GENERAL OBSERVATIONS

This forklift has been designed in accordance with the provisions

of section 1.1.2 “Principles of safety integration” of point 1

“Essential health and safety requirements” of annex I of

Directive 2006/42/EC on the approximation of the laws of

Member states relating to machinery.

Most accidents involving forklifts and their maintenance or

repair are the result of not complying with the most basic safety

precautions.

It is therefore necessary to always be aware of potential risks

that could arise as a result of operating the forklifts, paying

constant attention to the effects that each action performed

could have.

Being aware of potentially dangerous situations could

prevent an accident.

CONDITIONS TO BE MET BY OPERATORS

The person that usually operates the forklift must meet the

following conditions:

Medical:

Before operating the forklift and during operation, the operator

must not consume alcoholic beverages, drugs or any other

substances that could impair his or her psychological and

physical condition and consequently the ability to drive the

forklift.

Physical:

The operator must have good eyesight, good hearing, good

coordination and the ability to safely perform the functions

needed to operate the forklift as specified in this manual.

Mental:

The ability to understand and apply established safety

standards, rules and precautions; the operator must be alert and

use good judgment for his or her own safety and that of others

and the operator must make every effort to do the work

correctly and responsibly.

4/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

Trainin :

The operator must have carefully read and studied this manual,

the attached charts and diagrams and the warning and hazard

stickers; he or she must be specialized and competent in all

aspects regarding operation and use of the forklift. In many

countries training and licensing must conform and local

authority requirements.

RESIDUAL RISKS

Although BOMAQ I DUSTRIES S.L.U. has made every possible

effort to ensure this forklift's safety by way of its design and

manufacture, it considers that residual risks may occur as a

result of the operator's actions during operation.

Some examples are given below:

-Risks due to working or driving too fast for the loading

conditions or the area of operation.

-Risks due to using incorrect methods for checking or replacing a

hydraulic valve (residual pressure not discharged – uncontrolled

movements).

-Risks due to using incorrect methods for disassembling parts,

such as cylinders without having secured moving parts correctly

(risk of the moving part accidentally falling).

-Risks due to the forklift accidentally overturning without the

operator using the seat belt.

NOISE EMISSIONS AND VIBRATIONS

All BOMAQ forklifts have a guaranteed sound power level

according to Directive 2000/14/EC of the European Parliament

and of the Council on the approximation of the laws of the

Member States relating to the noise emission in the

environment by equipment for use outdoors.

In accordance with the provisions of E 12053 and E -ISO 4871,

the emission sound pressure level at the operator's position, for

a complete operational cycle, is below 80 dB.

Noise measurements have been taken under the

following operating conditions: idling, lifting and

movement.

The vibration level to which the operator's body is exposed has

been measured using representative and technically comparable

forklifts as indicated in E 14253:2004, Royal Decree 1311/2005

and Royal Decree 1311/2005 Technical Guidelines in order to

minimize risks for the operator.

These measurements have been taken by an authorized control

body with the forklift in motion and values not exceeding 0.74

have been obtained.

Any arbitrary modification to the forklift causes the sound

power values to vary.

DESCRIPTION AND SAFETY DEVICES

All BOMAQ forklifts have all of the means necessary to

guarantee their safe use.

In designing these forklifts, all possible risks have been taken

into account. As such, covers and guards have been fitted to

protect the operator from any hazards that may be encountered

during operation of the forklift, such as becoming trapped in the

engines and moving parts of the transmission, electrical system,

etc.

If the safety covers and guards are removed (which is only

authori ed during maintenance), they should be refitted

as soon as the repair is completed.

The forklift has an emergency stop button located next to the

hydraulic controls and the corresponding risk indicator

diagrams.

Emer ency stop: the emergency stop is located on the right-

hand side of the operator, next to the hydraulic control joysticks.

It automatically brings the engine to a halt in the event of an

emergency or problem. On those vehicles fitted with a negative

brake, this will come on when the emergency stop button is

pushed.

It is important to remember to release the emergency

stop button after trying to start the engine again,

otherwise you can run out the battery.

5/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

Safety cabin: this robust element protects the driver in the

event of the load falling off of the forks or the forklift

overturning. Type-approved driving cab in compliance with

standards ISO 3449 and E 13510 (ROPS and FOPS).

Fork carria e: this is a rigid element located on the front of the

mast which moves along with the load platform. It increases the

support surface of the loads, preventing them from falling on

top of the operator.

Bonnet: protects the engine from any unauthorized handling.

Chassis: the forklift is totally protected to prevent any contact

with the electrical circuits, tyres, etc.

Acoustic warnin alarm: when the forklift is moving in reverse,

an audible signal is activated.

Seat belt: located on the seat and worn by the operator.

Wearing the seat belt is compulsory to prevent serious

injury in the event of an accident.

Key: locking device that prevents any unauthorized persons

from using the vehicle.

Si nalin beacon: light indicating that the forklift is running. It is

located on top of the rear of the cabin.

SAFETY RECOMMENDATIONS

The driver of any motorized industrial forklift must be at least 18

years of age and be expressly assigned by the company. They

will also have to be trained and licensed as required by local

authorities.

Make sure that new operators are trained, monitored and

assisted by expert staff who are qualified to operate

forklifts.

Anyone who fails to meet these requirements should not be

allowed to drive a forklift truck, of any type.

The driver must be aware that, in addition to those

accidents that he or she may suffer, the equipment that

they are operating can cause injury to other people if all

of the safety rules are not carefully followed.

It is not the forklift truck in itself that is dangerous but rather the

6/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

way in which it is used. On using this type of equipment, hazards

similar to those present when driving other vehicles may occur:

bumps, impacts, turning over, trapped limbs, etc.

Some safety considerations that must be followed are listed

below:

-Never exceed the forklift's load capacity. Failure to follow this

rule may cause the vehicle to overturn, risking injury to both the

driver and to his or her colleagues. See load diagrams on the

forklift for this purpose.

-Do not, under any circumstances, increase the wei ht of the

counterwei ht by addin additional loads, especially by having

people climb onto the vehicle. If the load capacity of the forklift

is never exceeded, resorting to such tricks will never be

necessary.

-Do not use two forklifts simultaneously to move heavy or very

large loads as this is a dangerous operation that requires very

special precautions. This should only be attempted in

exceptional circumstances and under the supervision of the

head maintenance technician.

-To lift a load safely, fully insert the forks underneath the load,

lift the load slightly and immediately tilt the mast backwards.

-Before drivin , check that the load is balanced and secure on

its support. Whenever the forklift is laden, keep the forks

lowered and with the load tilted back towards the driver. This

will ensure greater stability.

-Before undertaking any maneuver, check that there is nobody

in the immediate vicinity of the forklift, especially when

reversing.

-When raising or lowering the forks, the driver must make sure

his or her hands or feet, or those of any colleague, cannot

become trapped.

-Do not point the forks towards people workin close to walls

or boxes.

-Nobody should stand or walk under the raised forks, even

when the vehicle is unladen.

-Never leave the forklift with a raised load.

7/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

RULES ON DRIVING THE FORKLIFT

-Do not allow yourself to become distracted from the task of

driving.

-Look in the direction in which the vehicle is moving,

maintaining good visibility at all times.

-Drive at a reasonable speed, according to the load.

-Avoid accelerating, changing direction or stopping suddenly.

-Take all turns at a low speed, using the horn to warn anyone

nearby.

-Indicate each maneuver that is to be carried out with sufficient

advance warning.

-Use the horn when approaching bridges, crossroads,

pedestrians, animals, etc.

If the si e of the load prevents good forward visibility, the

driver should proceed in reverse.

-Drive slowly over any wet, slippery or uneven terrain.

-Brake progressively, not sharply.

-Respect the signs and driving rules established by the company.

-Only follow the set routes.

-The forklift truck must not be used to carry passengers. The

driver will be held responsible for any consequences resulting

from failing to obey this rule.

-Do not drive with the load in the raised position since doing so

would greatly decrease the stability of the vehicle. The load

should always be carried in the lowest possible position.

-With platform forklifts, the vehicle should be driven with the

load in front. The platform operator would then not be crushed

in the event of a fall.

-Whenever driving with the vehicle unladen, the forks should be

kept at around 15 cm from the ground.

-Take special care with loads when passing under bridges or

through doorways.

-If it is necessary to drive on slopes, proceed forwards when

going up and in reverse when going down. Do not turn on a

slope.

-Stacks of material should be placed tidily and safely. If stacking

reels, remember that they can roll around. Pay attention to

where they are left and make sure they are secured using

wedges.

-Do not use the forklift to push other vehicles. If it is necessary

to tow another vehicle, this must be done using a rigid bar at a

very low speed.

8/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

-Make sure that the combined weight of the forklift and the

transported goods does not exceed the maximum load capacity

for the terrain.

-Before driving onto walkways, platforms, gangways, etc., make

sure that they can bear the weight of the vehicle.

-When driving behind another vehicle, maintain a distance equal

to approximately three times the length of the forklift. This will

help prevent accidents in the event that the other vehicle needs

to brake suddenly.

-When passing through narrow passages, the driver must take

care that his or her head, arms and legs do not stick out past the

width of the vehicle.

-When tilting the forks or the back-plate forwards, the stability

of the vehicle is reduced. When it is necessary to put down a

load using these mechanisms, do not lift it any higher than

necessary and, when lowering, do so slowly.

-Tin and sheet metal containers can break and shoot out at

nearby co-workers. Avoid accelerating or braking sharply, as well

as turning at speed.

-If during the course of a job it is necessary to stop, unless said

stop is for a very short period of time, the engine should always

be turned off.

AT THE END OF THE DAY

-At the end of the working day, the forklift should be parked in

the place specifically set aside for this purpose, where it will be

protected from the elements.

-When parking the forklift, the engine should be turned off, the

parking brake applied, the battery disconnected and the key

removed from the ignition.

-The forks should be left in the lowest possible position resting

on the ground.

-The forklift should always be parked on level ground. If for any

exceptional reason it is necessary to leave it parked on a slope,

the wheels must be carefully blocked using wedges and the

parking brake applied.

-The driver must not make any repairs or adjustments to the

forklift. Any anomaly observed during work, no matter how

small, must be duly reported to a senior member of staff.

-The operator must never stand between the mast and the

overhead guard of the forklift. If it is necessary to do so, lock all

controls to prevent any unexpected movement of the mast.

GENERAL SAFETY MEASURES REGARDING THE ENGINE

This section indicates the basic safety precautions that must be

followed. Read and make sure you fully understand the basic

precautions that appear in this section before operating,

lubricating, carrying out maintenance on or repairing this

product.

The operator in charge of engine maintenance must observe the

following safety recommendations:

-Make sure that all warning stickers are clearly legible. Clean or

replace any stickers that cannot easily be read or that have

illustrations that cannot be seen.

-Do not wear any clothing or jewelery that could become

trapped in or wrapped around the controls or any parts of the

engine.

-Make sure that all guards and covers are correctly fitted on the

engine.

-Keep the engine free from foreign materials. Remove any

rubbish, oil, tools and other items from the walkways and from

the steps.

9/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

- ever store maintenance fluids in glass containers. Drain all

liquids into a suitable container.

-Do not disassemble any component or part of the hydraulic

system without having first released the pressure from the

system. Failure to do so could result in injury.

-Do not touch any part of the engine whilst it is running. Allow

the engine to cool before carrying out any maintenance work on

it.

-The electrolyte is an acid and may cause personal injury. Do not

allow the electrolyte to come into contact with skin or eyes.

Always wear protective goggles when servicing the batteries.

Wash your hands after touching the batteries or the connectors.

The use of gloves is recommended.

-Do not smoke whilst filling the fuel tank.

-Do not carry out any welding on pipes or tanks that contain

flammable liquids.

-Do not bend pressurized pipes. Do not hit pressurized pipes. Do

not install pipes that are bent or damaged.

-Do not place any objects near the moving fan blades. The fan

blades will launch or cut any objects that touch them. Wear

protective goggles to prevent possible eye injuries caused by

flying objects.

-Clean up any spilled fuel.

-Any materials that have been splashed with fuel should be set

aside at a safe distance.

-Turn off the engine before starting any cleaning or adjustments

and while adding or checking fuel and lubricants.

-Do not make any kind of adjustment without first learning how

to do so correctly.

-Make sure that the engine is not started in any location where

doing so could lead to a high concentration of toxic emissions.

-Keep other people at a safe distance whilst either the engine or

any auxiliary equipment is running.

-Keep loose clothing and long hair away from moving parts.

-Keep away from moving parts when the engine is running.

Some moving parts are not visible when the engine is

running.

-Do not start the engine if any of the safety guards have been

removed.

-Do not remove the filler cap or any component of the cooling

system whilst the engine is hot and the coolant is under

pressure. Doing so could cause dangerous hot coolant to

overflow.

-Do not allow any sparks or naked flames near the batteries

(especially during the battery recharging process). The gases

given off by the electrolyte are highly flammable. The battery

fluid is harmful to the skin and especially to the eyes.

-There should only be one person at the engine controls.

-Make sure that the engine is only controlled from the control

panel or from the operator's seat.

-If the pressurized fuel comes into contact with anyone's skin,

seek medical attention immediately.

-Fuel and oil (especially used oil) can be harmful to some

people's skin. Wear protective gloves or use a special protective

solution for the skin.

Before working on pressuri ed lines (hydraulic oil,

compressed air) and/or disconnecting hydraulic elements,

make sure the line is not pressuri ed and no longer

contains hot fluid.

10/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

-Do not wear clothing that has been stained with lubricant. Do

not put materials that have been stained with oil in your

pockets.

-Dispose of used lubricant in accordance with local

environmental pollution regulations.

-The material used to make some of the engine components

(some of the seals, for example) can be extremely dangerous if

burned. ever allow this burnt material to come into contact

with skin or eyes.

-Make sure that the transmission control lever is in the neutral

position before starting the engine.

-Take extreme care when carrying out emergency repairs in

adverse conditions.

-Do not allow compressed air to come into contact with skin. If

compressed air breaks the surface of your skin, seek immediate

medical attention.

Do not clean the engine whilst it is running. If cold

cleaning fluids are applied to a hot engine, some engine

components can become damaged.

GENERAL SAFETY MEASURES REGARDING THE ELECTRICAL

SYSTEM

-Work on the electrical system should only be carried out by

specialized personnel with suitable work and verification

methods.

-Stop the engine before working on the electrical system.

-All cables and plugs should be marked up before being

disconnected and must be protected against contact with metal

parts by fitting them with protective caps or taping them with

insulation tape, for example.

-Any defects in the electrical installation (broken insulation, for

example) must be repaired immediately.

-The battery's negative (-) cable must always be disconnected

before starting any cleaning operation. It is not enough to simply

turn off the battery's cut-off switch.

-If it is necessary to clean the interior of the cabin with water or

water-soluble detergents, it is important to take special care not

to damage the electronics system. Use only authorized solvents.

Avoid breathing in the fumes from any thinners used.

-After the cleaning operation, make sure all electrical

components are completely dry before reconnecting the battery.

-The electrical conductors must be protected against wear and

should be checked regularly for damage; change as required.

-Unprotected electrical conductors should not be allowed to rest

on pipes containing oil or brake fluid.

PERSONAL PROTECTION

All forklift truck drivers must be provided with the following

personal protective equipment:

Protective helmet, compulsory when the operator's cabin does

not feature an overhead guard. In any case, it is essential that all

drivers have a helmet for use outside the forklift.

Non-slip safety boots, with reinforced toecap.

Safety loves. Although not necessary for driving, they should

be available for use in any possible emergency and for handling

materials.

Work clothes. Forklift truck drivers should not wear any loose

clothing that could get trapped in or around the moving parts of

the vehicle.

Ear protectors. When the noise level exceeds the established

safety margin and in any case when it is above 80 dB (A), the use

of earphones or earplugs will be compulsory.

The forklift is not designed for working with hazardous materials

such as explosives, toxic, flammable or harmful substances, nor

for working in explosive environments or in bad weather. It is

therefore prohibited to use the vehicle in environments

11/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

containing flammable or explosive materials.

The service life of the forklift is estimated at 6 years, after

which time the vehicle should either be decommissioned

or BOMAQ INDUSTRIES, S.A. should be asked to carry out

a complete inspection of it.

BOMAQ INDUSTRIES, S.A. will not be held responsible for

improper use of the forklift, whatever the circumstances.

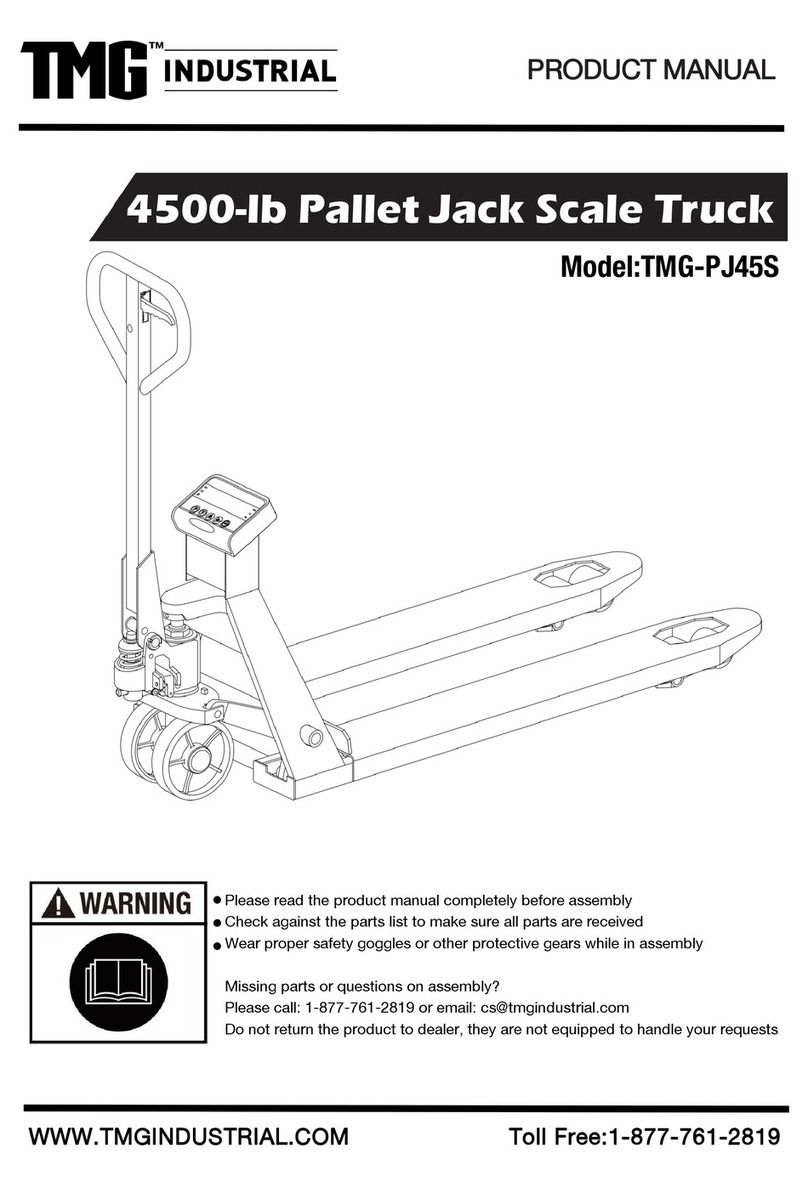

DESCRIPTION OF THE MAIN COMPONENTS

These are the main components the operator has to know about

the forklift:

1. Hydrostatic transmission

This unit consists of parts which drive the machine shifting, and

namely:

- A variable displacement pump connected to the thermal

engine by an elastic joint.

- A motor with variable displacement, with 2 fixed speeds, the

operator can select according to the driving conditions.

- Two rear wheel motors (only in 4WD), which drive power to

the rear wheels.

- A flow divider (only in 4WD), which controls power flow to

each motor in case of driving on a slippery surface.

- A hydraulic oil filter, placed on low pressure line of the pump.

12/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

1

98

7

6

5

4

3

2

Operator's Manual Rev. BXXMP.01 January 2020

- A hydraulic oil filter, placed on the suction of the pump.

- A heat exchanger to cool the circuit down.

2. En ine

The thermal engine is equipped with a heat exchanger which

uses the engine water as cooling medium.

3. Front ri id differential axle

The differential axles transmit the motion to the wheels. The

locking device acting on the front axle enables the machine to

move also on low grip grounds.

The front axle is also equipped with service and parking brake

(negative type). Both with hydraulic actuators.

4. Rear steerin axle

The rear axle is driven (2WD) or powered (4WD), and is also

responsible for the steering of the unit. The steering is hydraulic

actuated.

5. Tyres

The machine is equipped with tyres suitably sized for the

maximum load allowed on the forklift. When worn, they shall be

replaced with new ones having the same dimensions and

loading capacity.

6. Mast hydraulic circuit

It consists of a gear pump connected to the thermal engine

which, through a special valve, dispenses oil to the hydraulic

drive and a distributor for the following functions:

- mast lifting/lowering

- mast tilting

- carriage side shift

- fourth valve service

7. Brackin circuit

It consists of an independent circuit: the pedal directly acts on

the brake pump which dispenses oil to the front axle braking

unit with discs in oil bath. The parking brake, of negative type,

acts on the braking unit of the service brake. This brake is

engaged every time the forklift's engine is stopped or pressing

down the emergency stop button located to the right of the

driving place.

8. Mast

The machine is equipped with an extensible mast (duplex or

triplex), with forks carriage and side-shift integrated. The fourth

valve service is installed to the carriage, with fast connectors.

9. Drivin cab

Type-approved driving cab in compliance with standards ISO

3449 and E 13510 (ROPS and FOPS). The steering column

includes indicators, lights lever and steering wheel with knob.

The dashboard includes indicators for temperature of engine

water and hydraulic oil. The joysticks dashboard includes 2

hydraulic piloted joysticks, to control the 4 functions of the

mast.

OPTIONAL ACCESSORIES

The machine can be fitted with a wide range of optional

accessories: please address to Bomaq sales network.

13/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

CONTROLS AND INSTRUMENTS

The operator's cab has all the controls and indicators necessary

for the good operation of the forklift.

We have 4 groups of controls and/or indicators:

A. Steering column

B. Pedals

C. Joysticks frame

D. Dashboard

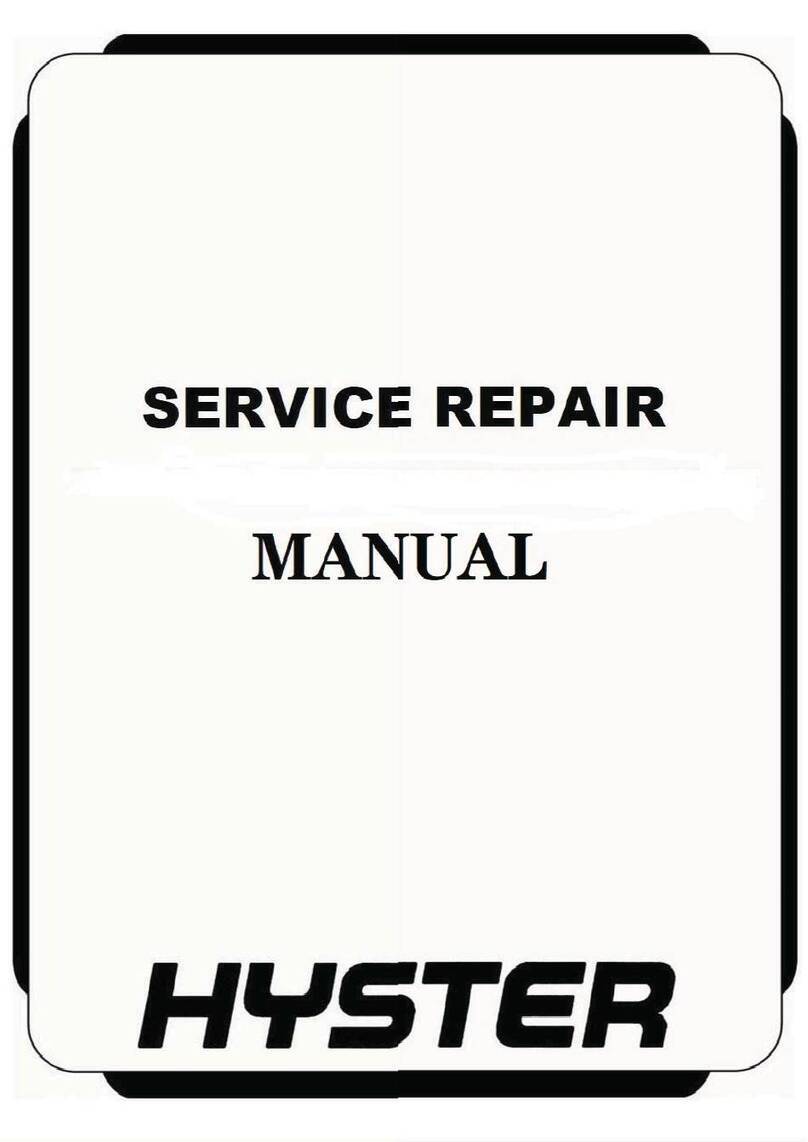

STEERING COLUMN

1. Steerin wheel: with a knob to make it easier. With only 3

turns from left to right.

2. Li hts lever: to control the road lights, indicators and horn.

3. Column buttons: to control parking brake (3.1), emergency

lights (3.2), front windscreen wiper and water jet (3.3), rear

windscreen wiper (3.4), and working light (3.5).

4. Column instrument: a series of indicators are included in this

instrument for the good operation of the forklift:

14/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

2

3

4

1

3.1 3.2 3.3 3.4

3.5

Operator's Manual Rev. BXXMP.01 January 2020

ID FUNCTION COLOR

L1 FORWARD GEAR GREE

L2 LOW FUEL LEVEL AMBER

L3 NEUTRAL GEAR AMBER

L4 HYDRAULIC FILTER CHANGE RED

L5 ENGINE OIL PRESSURE RED

L6 DIRECTION INDICATOR GREE

L7 GLOW PLUG AMBER

L8 STEERING FILTER CHANGE RED

L9 PARKING BRAKE RED

L10 ENGINE AIR FILTER CHANGE RED

L11 BACKWARD GEAR GREE

L12 FAST SPEED GREE

L13 ENGINE WATER HIGH TEMPERATURE RED

L14 HIGH BEAM LIGHTS BLUE

L15 POSITION LIGHTS GREE

L16 BATTERY CHARGE RED

L17 4WD DIFFERENTIAL LOCK AMBER

L18 SEAT & BELT LOCK SYSTEM * AMBER

S1 FUEL LEVEL GAUGE A

S2 BATTERY VOLTAGE LEVEL A

5BATTERY VOLTAGE LEVEL LOW A

6HOURMETER A

(* Seat & belt lock system is optional)

PEDALS

5. Service brake pedal: actuates on the master cylinder, to

activate front axle wet disks brake.

6. Accelerator pedal: to control engine rpm.

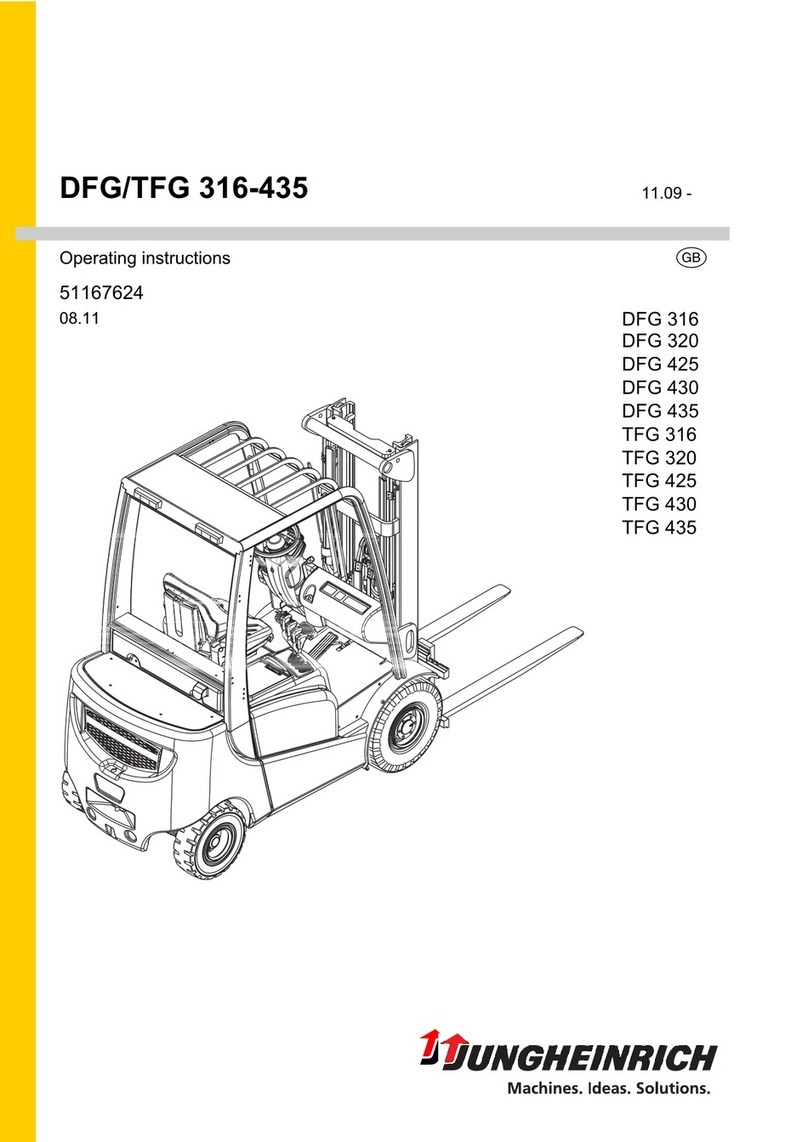

JOYSTICKS FRAME

7. Emer ency stop: it halts the engine by disabling the fuel

injection pump. All the systems stop, and the parking brake

engages.

8. Left joystick: lifting/lowering and tilting functions for mast

control. Besides, we have F R rocker switch for transmission

shifting, and push buttons for "4WD lock" and "Fast Speed".

Both push buttons are to be used momentarily.

9. Ri ht joystick: side-shift and 4th valve functions for mast

control.

10. Start switch with key: to start/stop the engine. Also for

connecting the pre-heaters.

11. Fast speed switch: if you want to be in fast speed

continuously, you can use this switch instead the push button of

the left joystick.

15/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

5

12

7

9

10

11

8

6

Operator's Manual Rev. BXXMP.01 January 2020

12. Forward/reverse switch: this is only used when the switch

on the joystick (8) fails, so the oeprator can still drive the

machine until the joystick switch is replaced.

DASHBOARD

13. Temperature indicators: for engine water and hydraulics

temperature.

14. Speakers: for the radio CD option.

15. Seat presence detector: it disconnects the transmission if

the operator is not seated.

As an option, the machine can be equipped with a seat belt

detector too, in which case, the operator must seat first, and

then put the seat belt, other wise the machine won't driver

forward or reverse, and there will be a yellow flashing light on

the dashboard, indicating a problem has occured with the seat.

Unless the operator follows the sequence of seating and putting

the belt, the system will keep locked.

16. Fuse box: you'll find all the fuses and relays of the electrical

system here. For detail see section Maintenance.

16/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

13

14

15

16

Operator's Manual Rev. BXXMP.01 January 2020

INSPECTIONS

Pre-operation Inspection Fundamentals

It is the responsibility of the operator to perform a pre-

operation inspection and routine maintenance.

The pre-operation inspection is a visual inspection performed by

the operator prior to each work shift. The inspection is designed

to discover if anything is apparently wrong with a machine

before the operator performs the function tests.

The pre-operation inspection also serves to determine if routine

maintenance procedures are required. Only routine

maintenance items specified in this manual may be performed

by the operator.

Refer to the list on the next page and check each of the items.

If damage or any unauthorized variation from factory delivered

condition is discovered, the machine must be tagged and

removed from service.

Repairs to the machine may only be made by a qualified service

technician, according to the manufacturer's specifications. After

repairs are completed, the operator must perform a pre-

operation inspection again before going on to the function tests.

Scheduled maintenance inspections shall be performed by

qualified service technicians, according to the manufacturer's

specifications.

PRE-OPERATION INSPECTION

- Make sure the operator’s manuals are intact, legible and

placed inside the machine document holder.

- Make sure all decals are present and legible. See Labels used in

the machine chapter.

- Check for engine oil leaks and proper oil level. Top up if

necessary.

- Check for axle oil leaks and proper oil level. Top up if necessary.

- Check for hydraulic oil leaks and proper oil level. Top up if

necessary.

- Check for engine coolant leaks and proper coolant level. Add

coolant if necessary.

- Check for battery fluid leaks and proper fluid level. Add

distilled water if necessary.

Check the following components or zones for damage, missing

or wrongly fitted parts or unauthorized modifications:

- Electrical components, wiring and electrical cables

- Hydraulic hoses, fittings, cylinders and main valves

- Fuel and hydraulic oil tanks

- Drive pump and motor and transmission axles

- Steering system

- Braking system

- Mast rollers and side-shift pads

- Clean glasses, lights and rear view mirrors

- Engine and relevant components

- Limit switches and horn

- Lights

- Machine ignition control

- uts, bolts and other fasteners

Check the entyre machine for:

- Cracks on welds or structural components

- Dents or damage to the machine

Make sure that all structural and other critical

components are present and the relevant fasteners and

pins are fitted and properly tightened.

After inspection, check that all the compartment covers

are in place and latched.

17/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

WARNING

If even one single item is damaged or defective, do not

start work. Stop the machine and repair the fault.

Checkin the tyres

- Check the correct inflation of the tyres, and the correct

tightening of all the nuts.

- Make sure that the tyre plies are not cut or worn.

WARNING

A tyre burst may result in serious injury; never use the

machine if tyres are worn, wrongly inflated or damaged.

CAUTION

If the machine shall be used in a marine or equivalent

environment, protect it against salt deposits with an

adequate treatment against saltiness to prevent rust

formation.

FUNCTION TESTS

CAUTION

The function tests are designed to discover any

malfunctions before the machine is put into service. The

operator must follow the step-by-step instructions to test

all machine functions.

A malfunctioning machine must never be used. If malfunctions

are discovered, the machine must be tagged and removed from

service. Repairs to the machine may only be made by a qualified

service technician, according to the manufacturer's

specifications.

After repairs are completed, the operator must perform a pre-

operation inspection and function tests again before putting the

machine into service.

TESTS

1. Select a test area that is firm, level and free of obstruction. Be

sure there is no load on the forks or attachment.

2. Enter the operator's compartment and sit on the seat.

3. Fasten the seat belt.

4. Adjust the rear view mirrors.

5. Be sure the parking brake is on and the transmission control is

in neutral.

6. Start the engine. See Starting the Engine in the Operatin

Instructions section.

Test the Control Joysticks

7. Using the lifting/tilting control lever, momentarily raise and

lower the forks, tilt the mast backward and forward.

Result: All functions should operate smoothly.

8. Using the side-shift/4th control lever, momentarily move the

carriage left and right, and check 4th service (if installed)

Result: All functions should operate smoothly.

Test the Steerin

9. Check the steering operation by turning the steering wheel

approximately half turn in each direction.

Result: the rear wheels should turn in the same direction as the

steering wheel, smoothly.

Test the Transmission and Brakes

10. Be sure the mast is fully lowered and tilted back.

11. Step on the service brake pedal.

12. Move the transmission control in the lifting joystick to

forward. Slowly let up on the service brake pedal, and press

gently the accelerator pedal, until the machine begins to move.

Then release the accelerator pedal and push the brake pedal.

Put the transmission control to again.

Result: The machine should move forward, then come to an

abrupt stop.

13. Move the transmission control in the lifting joystick to

backward. Slowly let up on the service brake pedal, and press

gently the accelerator pedal, until the machine begins to move.

Then release the accelerator pedal and push the brake pedal.

Put the transmission control to again.

Result: The machine should move forward, then come to an

abrupt stop. The back-up alarm should sound when the

transmission control lever is in reverse.

14. Move the transmission control lever to neutral.

18/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

15. Push the top of the parking brake switch.

Result: The red parking brake indicator light should come on,

indicating the parking brake is on.

16. Move the transmission control lever forward, then in

reverse.

Result: The parking brake is still on, but the machine can be

moved. When back to , the parking brake is engaged. This is

useful to work on slopes.

CAUTION

If you leave the parking brake switch on, to work on

slopes, you must be careful as this brake is abrupt, and

can cause accidents, specially if the operator forgets

about it, and puts N when driving at high speed!

Always look to the instrument panel and check the

parking brake light before driving.

17. Push the bottom of the parking brake switch. The parking

brake is off when the indicator light is off.

Test the Road Li hts

18. Verify that all lights are functional.

WORKPLACE INSPECTION

WARNING

The workplace inspection helps the operator determine if

the workplace is suitable for safe machine operation. It

should be performed by the operator prior to moving the

machine to the workplace.

It is the operator's responsibility to read and remember the

workplace hazards, then watch for and avoid them while

moving, setting up and operating the machine.

Be aware of and avoid the following hazardous situations:

- Drop-offs or holes

- Bumps, floor obstructions or debris

- Sloped surfaces

- Unstable or slippery surfaces

- Overhead obstructions and high voltage conductors

- Hazardous locations

- Inadequate surface support to withstand all load forces

imposed by the machine

- Wind and weather conditions

- The presence of unauthorized personnel other possible unsafe

conditions

19/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

Operator's Manual Rev. BXXMP.01 January 2020

OPERATING INSTRUCTIONS

ENTERING THE MACHINE

You can enter the machine the left hand side. There are 3

handles installed on the frame of the cab, so the operator can

grab them when entering or exiting the machine.

For entering from the left side:

- Grab one handle with your left hand.

- Put your left foot on the entering step (the one with the

aluminum plate).

- Go up and enter the right leg over the seat, taking care with

your head no to crash against the overhead frame.

Use only the ri ht side in case of emer ency, or if it's not

possible to access the left side, as it's more difficult to

access it due to the joysticks dashboard

All the B30 MP are equipped with semi cabin (front, top and rear

windows). In case of emergency, you can break front or rear

windows to exit from the cab. The glasses are laminated to

prevent injuries in case of break.

ADJUSTING THE SEAT

A correct adjustment of the seat ensures the operator a safe and

comfortable driving. The forklift seat is fitted with devices which

allow for the adjustment of the springing, the height and the

distance from the controls.

- Seat distance from the controls

The seat is equipped with an adjusting device to slide the same

seat forward or back with respect to the steering column.

To adjust the seat, pull the lower front right lever up, and push

the seat to the desired direction. Then release the lever and

make sure that the seat locks in position.

- Springing adjustment

Pull out and rotate the lower front knob by 180°. Then pull the

lever up and down to adjust the springing degree required. After

that put it back.

- Back angle adjustment

Pull the lower right lever up, and push the seat back to the

desired direction. Then release the lever and make sure that the

seat locks in position.

- Arm rests height adjustment

You can adjust the height of the arm rests with the knob below

them, until you find a relaxed position of the right arm over the

joysticks.

DANGER

The seat is for one person only

Don’t adjust the seat when the machine is moving

FASTENING THE SEAT BELTS

Sit correctly in the driving seat, then:

- The safety belts are equipped with reel re-tractor. To fasten the

belt, pull tab 1 and push it into buckle 2.

- To release the belt, push button 3 and remove the tab from the

buckle.

- Make sure that the buckle is correctly located at the hip point

and not on the stomach.

- Operate the end adjusters to reach the length you wish and

make sure the buckle is always in the middle.

STEERING COLUMN ANGLE ADJUSTMENT

The steering column can be adjusted in angle, pushing the tab in

the below, and then moving it grabbing from the steering wheel.

20/34 BOMAQ I DUSTRIES SLU MODEL BXX MP

This manual suits for next models

1

Table of contents